Soot blowing system for horizontal flue of boiler

A technology of horizontal flue and soot blowing system, which is applied to the treatment of combustion products, combustion methods, and removal of solid residues, etc., and can solve problems such as lowering the temperature of hot secondary air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

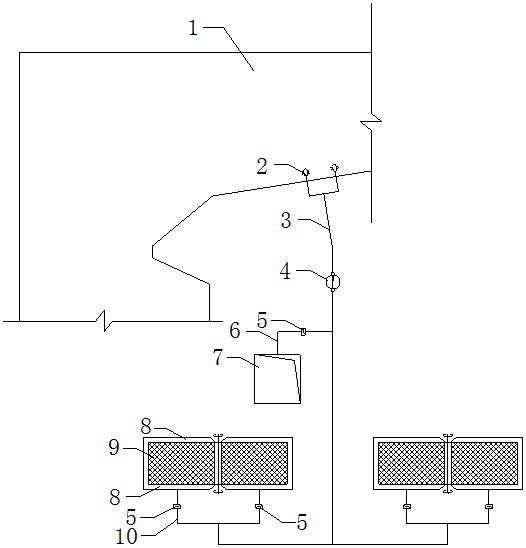

[0028] A 600MW class supercritical coal-fired power generation unit is applied figure 1 The horizontal flue soot blowing system of the boiler shown in the present invention is calculated and demonstrated as follows.

[0029] The boiler unit includes two rotary air preheaters, and the flue gas volume at the outlet of the preheater is designed to be 2626823m 3 / h, the exhaust gas temperature is 119°C, and the volume of flue gas converted to the standard state is 1883313Nm 3 / h, and the mass flow rate of flue gas is about 2505t / h. According to the current sealing technology status of rotary preheater, in the rotary preheater without sealing air system, the air leakage can be controlled to 5%. According to the above conditions, it can be The calculated air leakage volume is 94165 Nm 3 / h; after installing the sealed air system, according to the current relatively advanced sealing technology, the air leakage rate of the preheater can be controlled to 2%, and the air volume enteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com