Ultra-high molecular weight polyethylene alloy tube and preparation method thereof

A technology of ultra-high molecular weight and polyethylene, which is applied in the field of ultra-high molecular weight polyethylene alloy pipes and their preparation, which can solve the problems of reduced mechanical properties of pipes, low molecular weight of paraffin, large power consumption, etc., and achieves reduced melt viscosity and improved processing fluidity Good, high production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

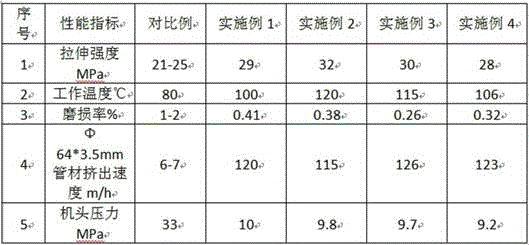

Examples

Embodiment 1

[0037] A kind of ultra-high molecular weight polyethylene alloy pipe, its preparation method comprises the steps:

[0038] (1) 40 parts by weight of ultra-high molecular weight polyethylene with a molecular weight of 8 million, 35 parts by weight of polyethylene p-hydroxybenzoyl terephthalate, 6 parts by weight of maleic anhydride grafted polyethylene, B215 phenolic 1 weight part of antioxidant and 4 weight parts of calcium stearate are mixed evenly;

[0039] (2) Dry the above mixture at 100~120°C for 8 hours;

[0040] (3) Mix the above-mentioned dried raw materials evenly under high-speed stirring;

[0041] (4) Extrude the uniformly mixed material into the pipe through the extruder, where the processing temperature is: feeding section 120-180°C, compression section: 220-280°C, homogenization section 230-300°C, outlet 180-240°C ; Head extrusion pressure 10MPa.

[0042] The extruder is a conical twin-screw extruder.

Embodiment 2

[0044] A kind of ultra-high molecular weight polyethylene alloy pipe, its preparation method comprises the steps:

[0045] (1) 72 parts by weight of ultra-high molecular weight polyethylene with a molecular weight of 8 million, 50 parts by weight of polyethylene p-hydroxybenzoyl terephthalate, 10 parts by weight of maleic anhydride grafted polyethylene, B215 phenolic 2 parts by weight of antioxidant and 5 parts by weight of calcium stearate are mixed uniformly;

[0046] (2) Dry the above mixture at 100~120°C for 8 hours;

[0047] (3) Mix the above-mentioned dried raw materials evenly under high-speed stirring;

[0048] (4) Extrude the uniformly mixed material into the pipe through the extruder, where the processing temperature is: feeding section 120-180°C, compression section: 220-280°C, homogenization section 230-300°C, outlet 180-240°C ; Head extrusion pressure 9.8MPa.

[0049] The extruder is a conical twin-screw extruder.

Embodiment 3

[0051] A kind of ultra-high molecular weight polyethylene alloy pipe, its preparation method comprises the steps:

[0052] (1) 95 parts by weight of ultra-high molecular weight polyethylene with a molecular weight of 8 million, 50 parts by weight of polyethylene p-hydroxybenzoyl terephthalate, 10 parts by weight of maleic anhydride grafted polyethylene, B215 phenolic 2.5 parts by weight of antioxidant and 5 parts by weight of calcium stearate are mixed evenly;

[0053] (2) Dry the above mixture at 100~120°C for 8 hours;

[0054] (3) Mix the above-mentioned dried raw materials evenly under high-speed stirring;

[0055] (4) Extrude the uniformly mixed material into the pipe through the extruder, where the processing temperature is: feeding section 120-180°C, compression section: 220-280°C, homogenization section 230-300°C, outlet 180-240°C ; Head extrusion pressure 9.7MPa.

[0056] The extruder is a conical twin-screw extruder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com