A2/O-MBR composite processing system and method based on efficient utilization of carbon source

A composite treatment and high-efficiency technology, applied in the fields of water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of affecting the low-carbon nitrogen ratio and high emission standard of urban sewage treatment plants. and energy saving and consumption reduction, underutilized denitrification, underutilized carbon sources, etc., to achieve the effect of significant energy saving and consumption reduction, improving carbon source utilization rate, and improving energy saving and consumption reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

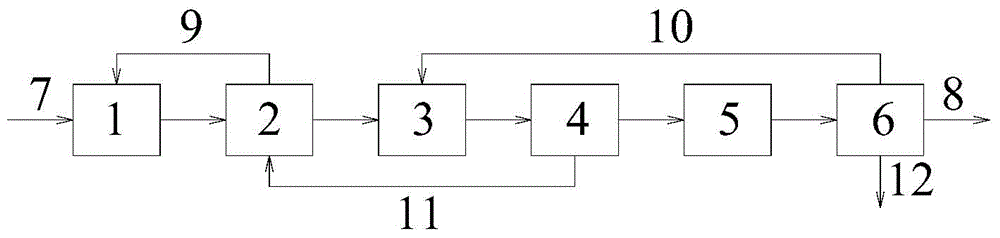

[0029] Embodiment 1: A kind of A based on efficient utilization of carbon source 2 The composite processing method of / O and MBR includes the following steps:

[0030] a, the pretreated sewage 7 enters the anaerobic pool 1 together with the first anoxic pool 2 mixed solution that is backflowed through the first internal reflux system 9, and stays for 1.5 hours under anaerobic stirring conditions. L) under the action of anaerobic phosphorus release reaction; wherein the return flow of the mixed solution of the first anoxic tank is 2 times of the influent flow of sewage 7;

[0031] B, the anaerobic tank 1 mixed solution that step a gained enters the first anoxic tank 2 together through the second internal reflux system 11 refluxed aerobic tank 4 mixed solution, stays 4 hours under anoxic stirring condition, in microorganism ( MLSS is 4.5g / L) to carry out denitrification reaction and denitrification phosphorus removal reaction; wherein the return flow of the mixed liquid in the ...

Embodiment 2

[0037] Embodiment 2: A kind of A based on efficient utilization of carbon source 2 The composite processing method of / O and MBR includes the following steps:

[0038] a, the pretreated sewage 7 enters the anaerobic pool 1 together with the mixed solution of the first anoxic pool 2 backflowed through the first internal reflux system 9, and stays for 1 hour under anaerobic stirring conditions. L) under the action of anaerobic phosphorus release reaction; wherein the return flow of the mixed solution of the first anoxic tank is 1 times of the influent flow of sewage 7;

[0039] B, the anaerobic tank 1 mixed solution that step a gained enters the first anoxic tank 2 together through the second internal reflux system 11 refluxed aerobic tank 4 mixed solution, stays 3 hours under anoxic stirring condition, in microorganism ( MLSS is 6g / L) to carry out denitrification reaction and denitrification phosphorus removal reaction; the return flow of the mixed liquid in the aeration tank ...

Embodiment 3

[0045] Embodiment 3: A kind of A based on efficient utilization of carbon source 2 The composite processing method of / O and MBR includes the following steps:

[0046] a, the pretreated sewage 7 enters the anaerobic pool 1 together with the first anoxic pool 2 mixed solution that is backflowed through the first internal reflux system 9, and stays for 1.5 hours under anaerobic stirring conditions. L) under the action of anaerobic phosphorus release reaction; wherein the return flow of the mixed solution of the first anoxic tank is 2 times of the influent flow of sewage 7;

[0047] B, the anaerobic tank 1 mixed solution that step a gained enters the first anoxic tank 2 together through the second internal reflux system 11 refluxed aerobic tank 4 mixed solution, stays 4 hours under anoxic stirring condition, in microorganism ( MLSS is 4.5g / L) to carry out denitrification reaction and denitrification phosphorus removal reaction; the return flow of the mixed liquid in the aeration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com