Energy conversion and recovering method of coal gasification supercharging association circulating power generation system

A technology of combined cycle power generation and energy conversion, which is applied in the directions of energy input, charging system, combined combustion mitigation, etc., and can solve problems such as the full utilization of considerable energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

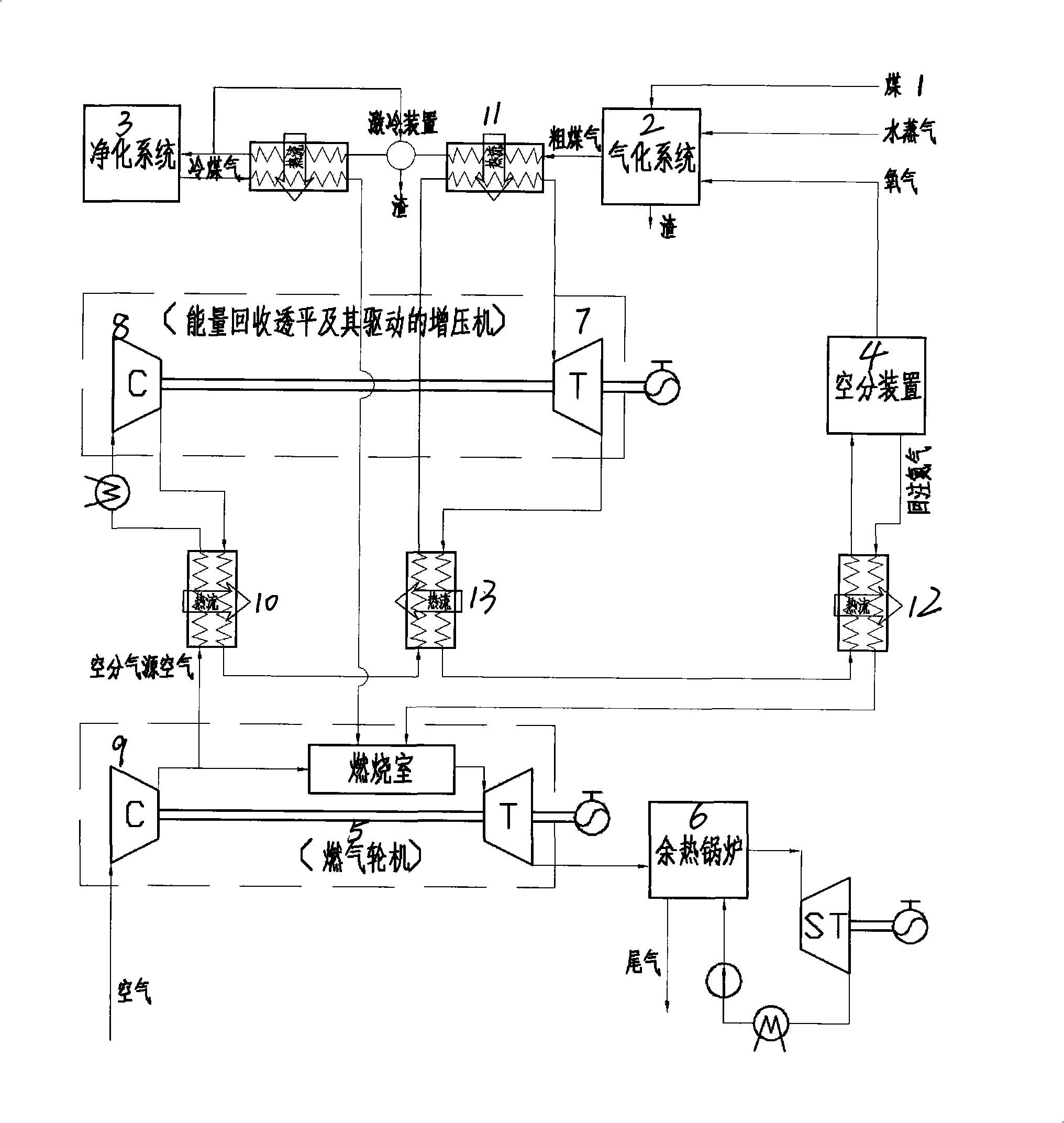

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings: the energy conversion and recovery method of the coal gasification supercharging combined cycle power generation system of the present invention is: it mainly consists of coal gasification and purification process and gas-steam combined cycle power generation The process consists of two parts. The gas is mixed and burned with high-pressure air in the combustion chamber, and the high-temperature and high-pressure gas generated drives the expander to do work, drives the compressor and the generator, and the gas turbine system provides the raw air for the air separation as the working fluid. Pressurize, gradually heat up, and then obtain the heat energy of the high-temperature gas at the outlet of the gasifier device, so that the temperature of the working fluid can reach a high enough level, and generate electricity through the energy recovery turbine, and then heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com