Casting material for rear kilneye of cement rotary kiln rear kiln opening

A cement rotary kiln and castable technology, which is applied in the field of refractory materials, can solve the problems of use mode and product performance in the application field that cannot meet the application requirements of refractory materials, and achieves good resistance to structural spalling, reduced maintenance times, and excellent wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

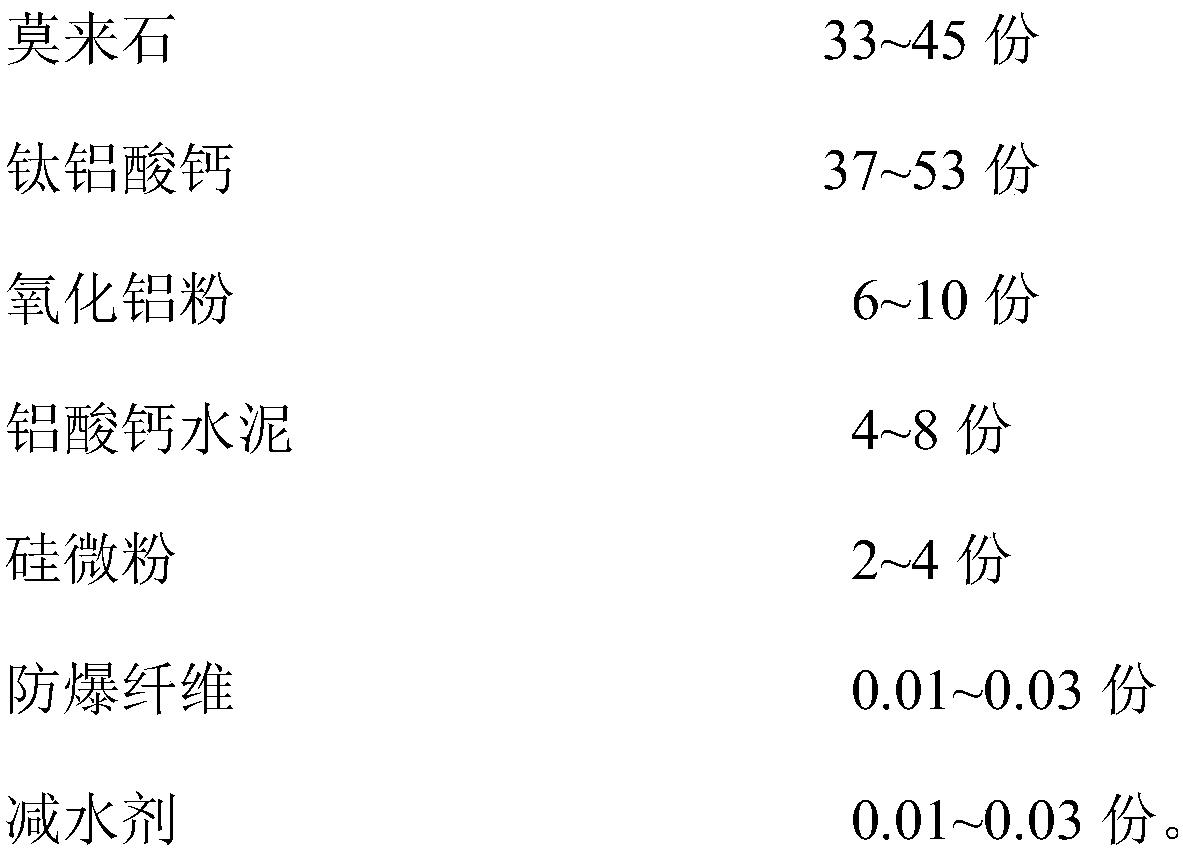

[0020] A casting material for the rear kiln mouth of a cement rotary kiln, comprising the following components and parts by weight:

[0021]

[0022]

[0023] Wherein, the Al in the mullite 2 o 3 The mass percentage content of not less than 68%. Al in the calcium aluminate titanate 2 o 3 The mass percentage of CaO is not less than 70%, the mass percentage of CaO is not less than 10%, and the mass percentage of TiO 2 The mass percentage content of not less than 10%. Al in the calcium aluminate cement 2 o 3 The mass percentage content of not less than 50%. The water reducer is polyphosphate.

Embodiment 2

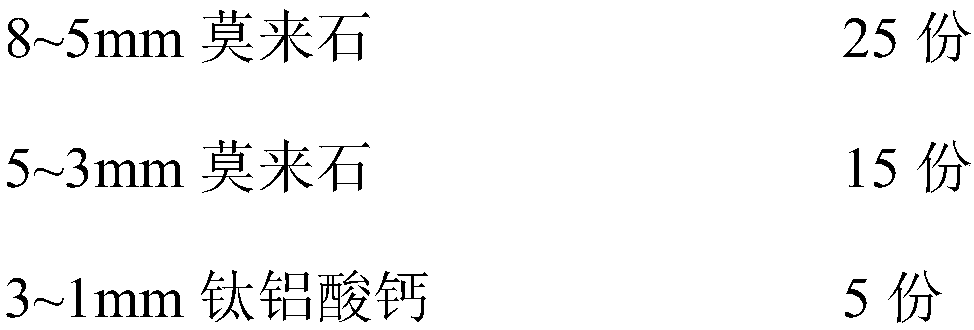

[0025] A casting material for the rear kiln mouth of a cement rotary kiln, comprising the following components and parts by weight:

[0026]

[0027] Wherein, the Al in the mullite 2 o 3 The mass percentage content of not less than 68%. Al in the calcium aluminate titanate 2 o 3 The mass percentage of CaO is not less than 70%, the mass percentage of CaO is not less than 10%, and the mass percentage of TiO 2 The mass percentage content of not less than 10%. Al in the calcium aluminate cement 2 o 3 The mass percentage content of not less than 50%. The water reducer is polyphosphate.

Embodiment 3

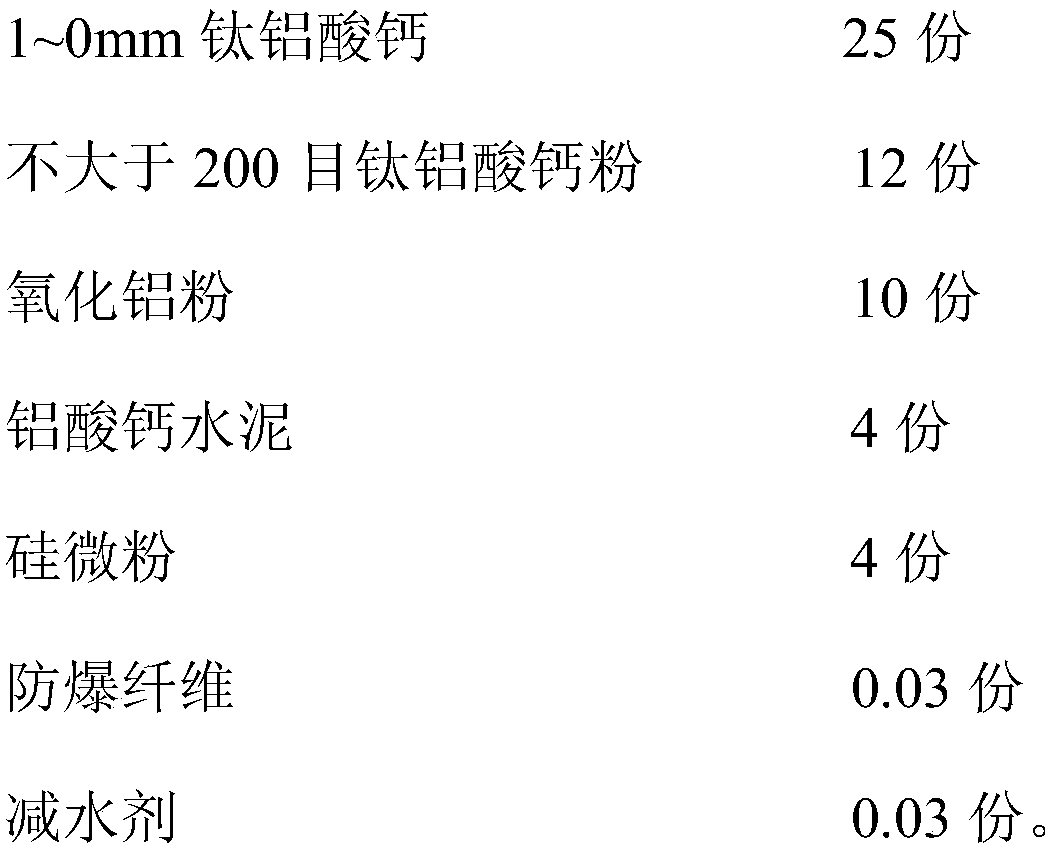

[0029] A casting material for the rear kiln mouth of a cement rotary kiln, comprising the following components and parts by weight:

[0030]

[0031] Wherein, the Al in the mullite 2 o 3 The mass percentage content of not less than 68%. Al in the calcium aluminate titanate 2 o 3 The mass percentage of CaO is not less than 70%, the mass percentage of CaO is not less than 10%, and the mass percentage of TiO 2 The mass percentage content of not less than 10%. Al in the calcium aluminate cement 2 o 3 The mass percentage content of not less than 50%. The water reducer is polyphosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com