Large-aperture assembly-type reinforced concrete culvert member

A reinforced concrete and prefabricated technology, which is applied in the direction of buildings and road floors, etc., can solve the problems of long turnover period of templates and brackets, difficult control of construction quality, and scattered construction points, etc., to achieve easy control of production quality, internal quality and appearance Effects of quality improvement and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

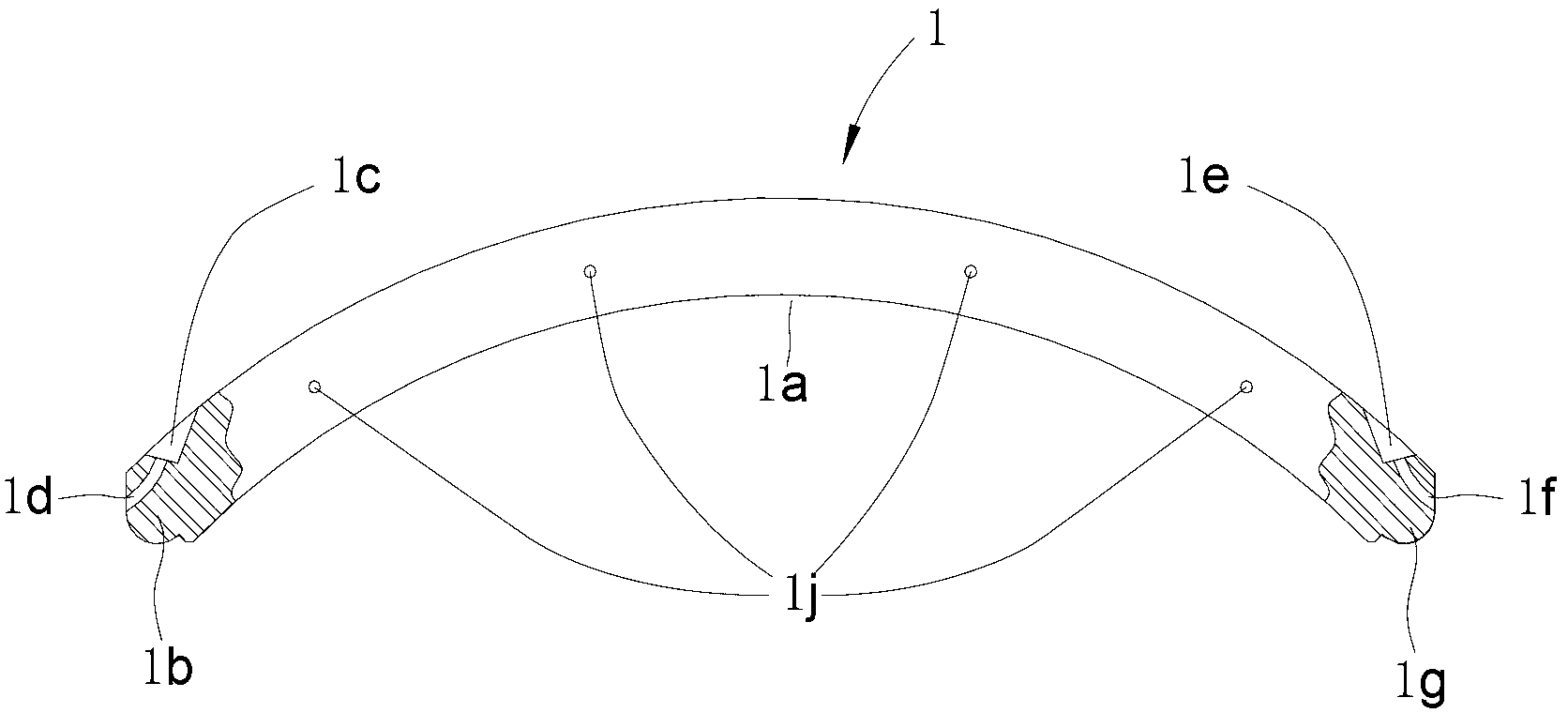

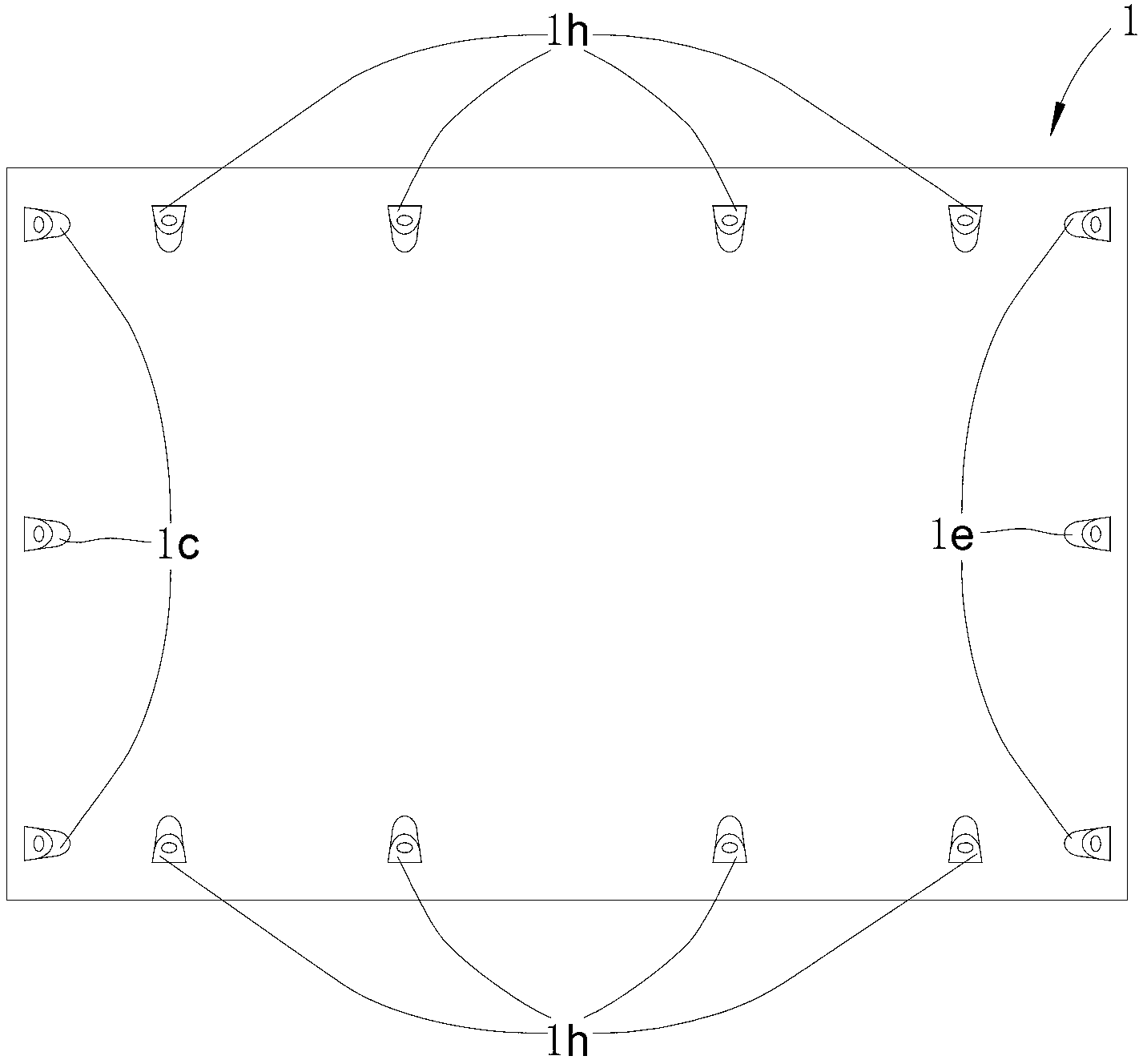

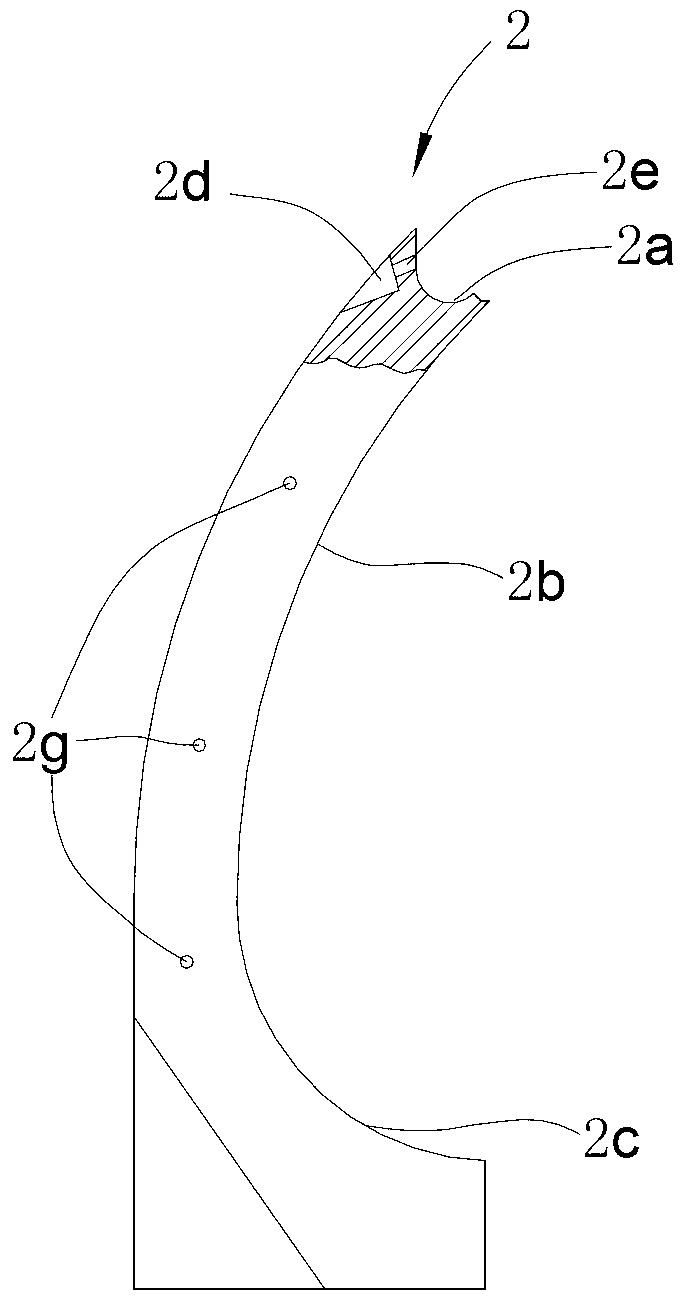

[0018] Such as Figures 1 to 2 shown

[0019] The top plate 1 is arched and protrudes upwards. The inner surface 1a of the top plate is a cylindrical surface. Three two-stage stepped first installation holes are respectively processed. The first installation hole is composed of a first-stage hole 1c and a second-stage hole 1d. The radius of the first-stage hole 1c is greater than the radius of the second-stage hole 1d. The first The opening of the second-stage hole 1d of the installation hole is on the end face of the first assembly boss 1b, the opening of the first-stage hole 1c of the first installation hole is on the outer surface of the top plate 1, and the center line of the first installation hole is an arc line; the right end of the top plate 1 is respectively processed with three two-stage stepped second installation holes, the second installation hole is composed of the third-stage hole 1e and the fourth-stage hole 1f, and the radius of the third-stage hole 1e is lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com