Shock-proof bundled energy clearing slope support

A technology of anti-seismic beams and diagonal braces, applied in the direction of anti-seismic, building components, etc., can solve problems such as reduced operating efficiency, inability to plug and install, and difficulty in controlling precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

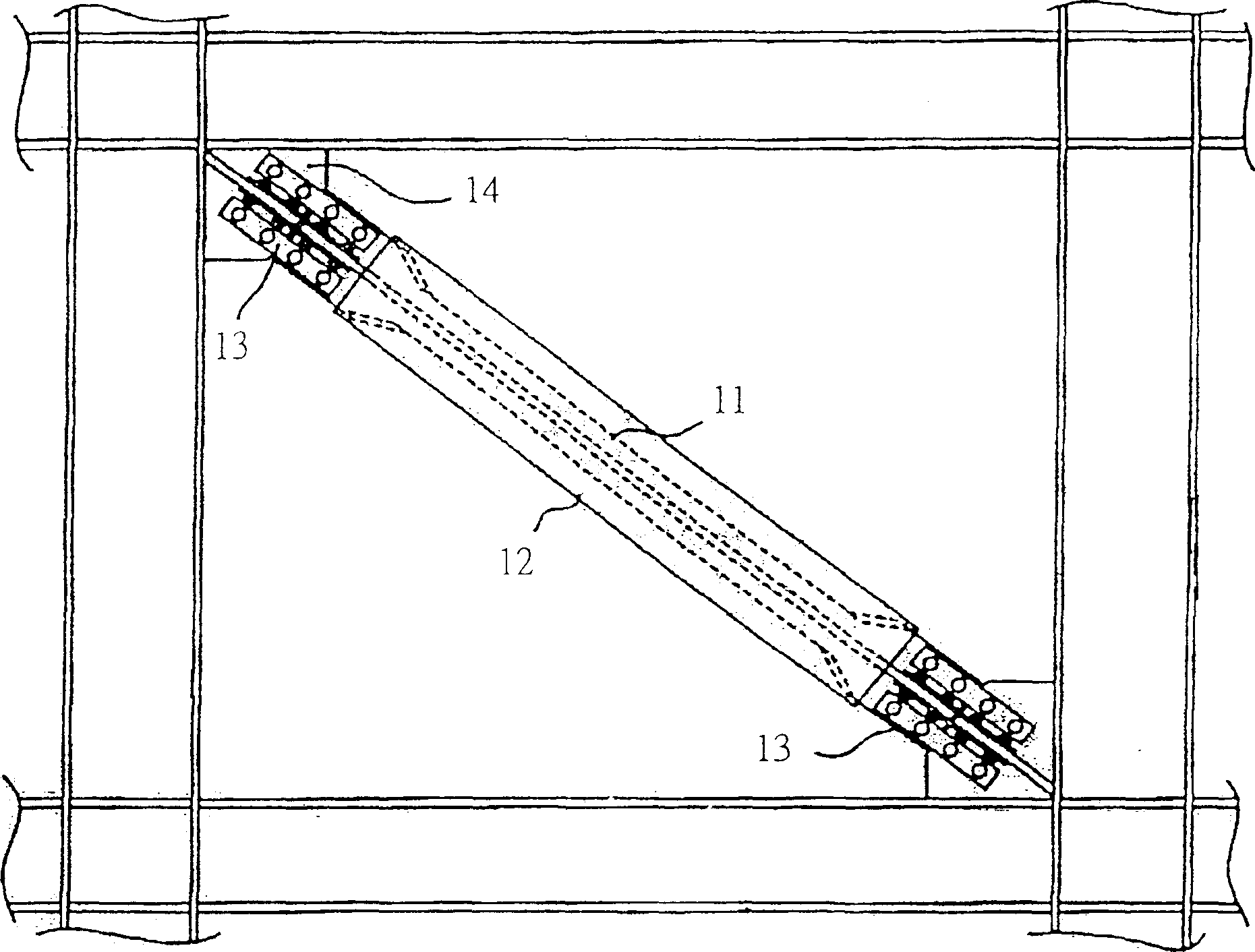

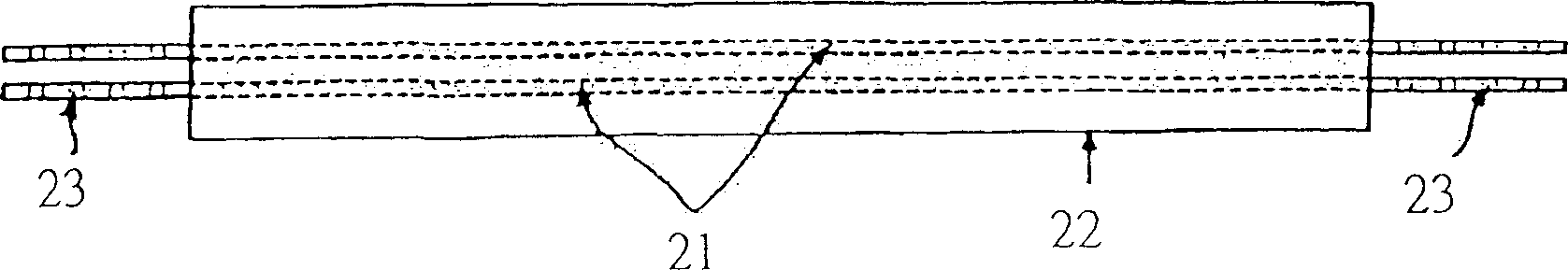

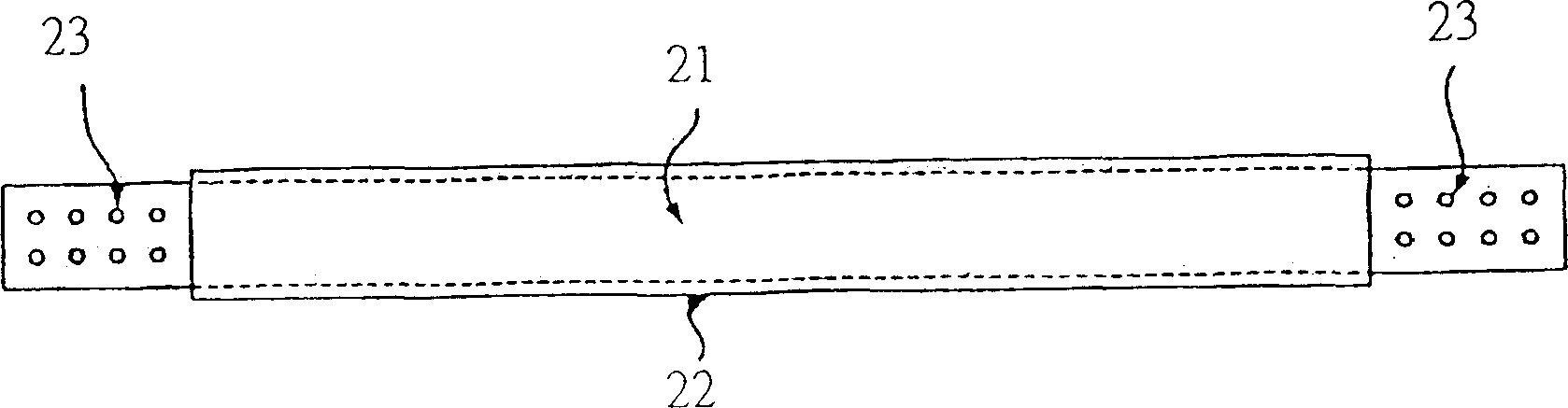

[0063] The invention is illustrated by two combinations, where Figure 5-17 It is an energy-dissipating diagonal bracing made of bundled joints; and Figures 18-38 The energy-dissipating diagonal bracing for the improved splicing bundle is now described in detail in conjunction with the illustrations and examples:

[0064] see Figure 5-9 As shown, the first embodiment of a lap joint combined energy-dissipating brace 3 of the present invention includes a main stress unit 31 and a restraint unit 32, and the main stress unit 31 and the restraint unit 32 are respectively It is a pair of glyph-shaped main force-bearing members 311 and a pair of double-steel steel enclosure members 3211 that are independently formed. The end section of the main force-receiving member 311 is larger than that of the middle section, and is inserted through the enclosure of the binding unit 32 Component 3211, the bolt holes 33 on the overlapping joint surfaces at both ends of the main force-bearing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com