Prefabricating construction process for corrugated steel web prestressed concrete I-shaped beam

A corrugated steel web and construction technology technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of immaturity, difficult to guarantee the quality of the beam body, difficult prefabrication construction, etc., to achieve convenient erection, high practical value, structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

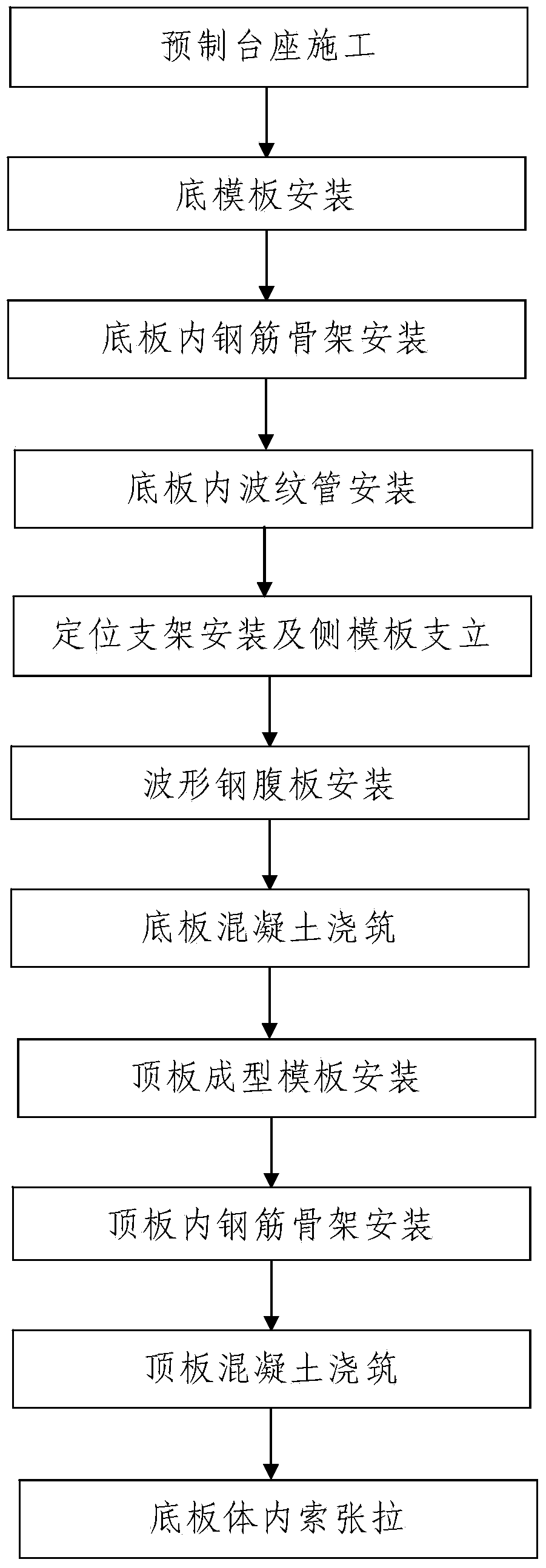

[0064] like figure 1 The shown prefabrication construction process of a corrugated steel web prestressed concrete I-beam includes the following steps:

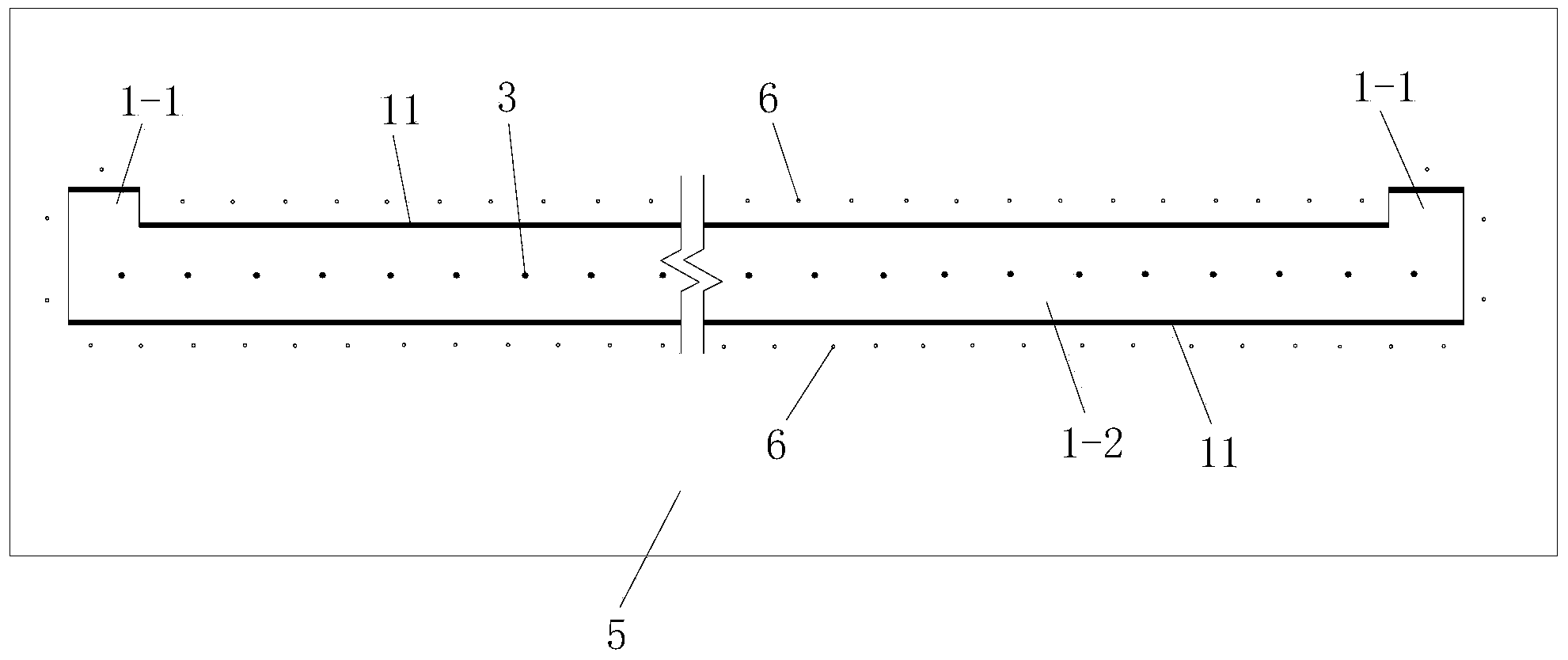

[0065] Step 101, prefabricated pedestal construction: firstly lay a layer of concrete cushion 5 on the prefabricated site, and construct concrete pedestal 1 on the concrete cushion 5 as the prefabricated pedestal of corrugated steel web PC I-beam 7, see details for details Figure 3-1 and Figure 3-2 .

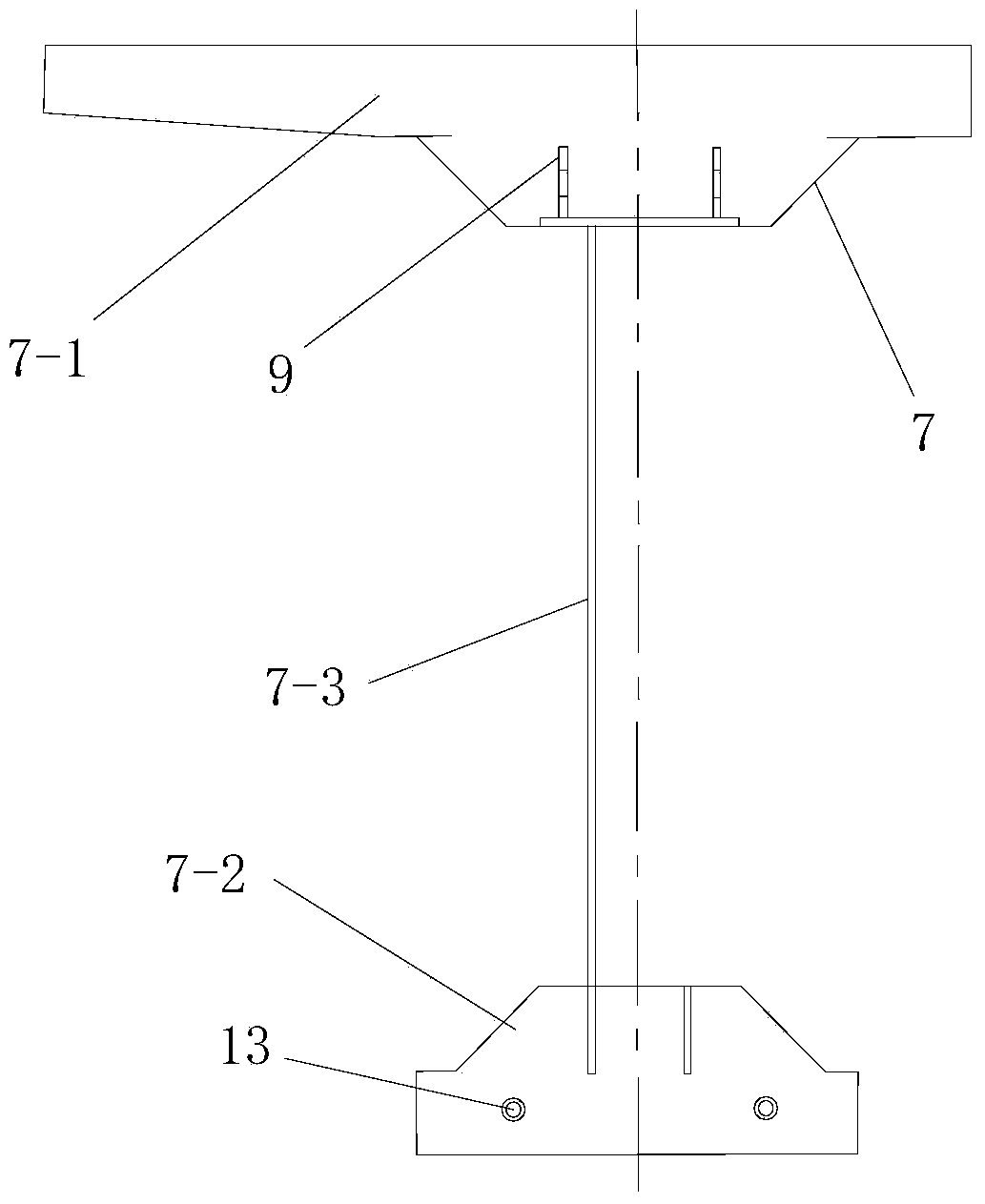

[0066] The length of the concrete pedestal 1 is not less than the longitudinal length of the corrugated steel web PC I-beam 7, and the corrugated steel web PC I-beam 7 consists of a concrete bottom plate 7-1 and a concrete top plate located above the concrete bottom plate 7-1. 7-2 and the corrugated steel web 7-3 connected between the concrete bottom plate 7-1 and the concrete top plate 7-2, see details figure 2 . The width of the concrete pedestal 1 is not less than the width of the concrete bottom plate 7-1, the concret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com