Cloth fixing and line-drawing mechanism

A technology for fixing marking lines and fabrics, which is applied in marking textile materials, textiles and papermaking, etc. It can solve the problems of manual marking, such as difficulty, offset, trouble, etc., and achieve the effect of straight marking, high efficiency and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

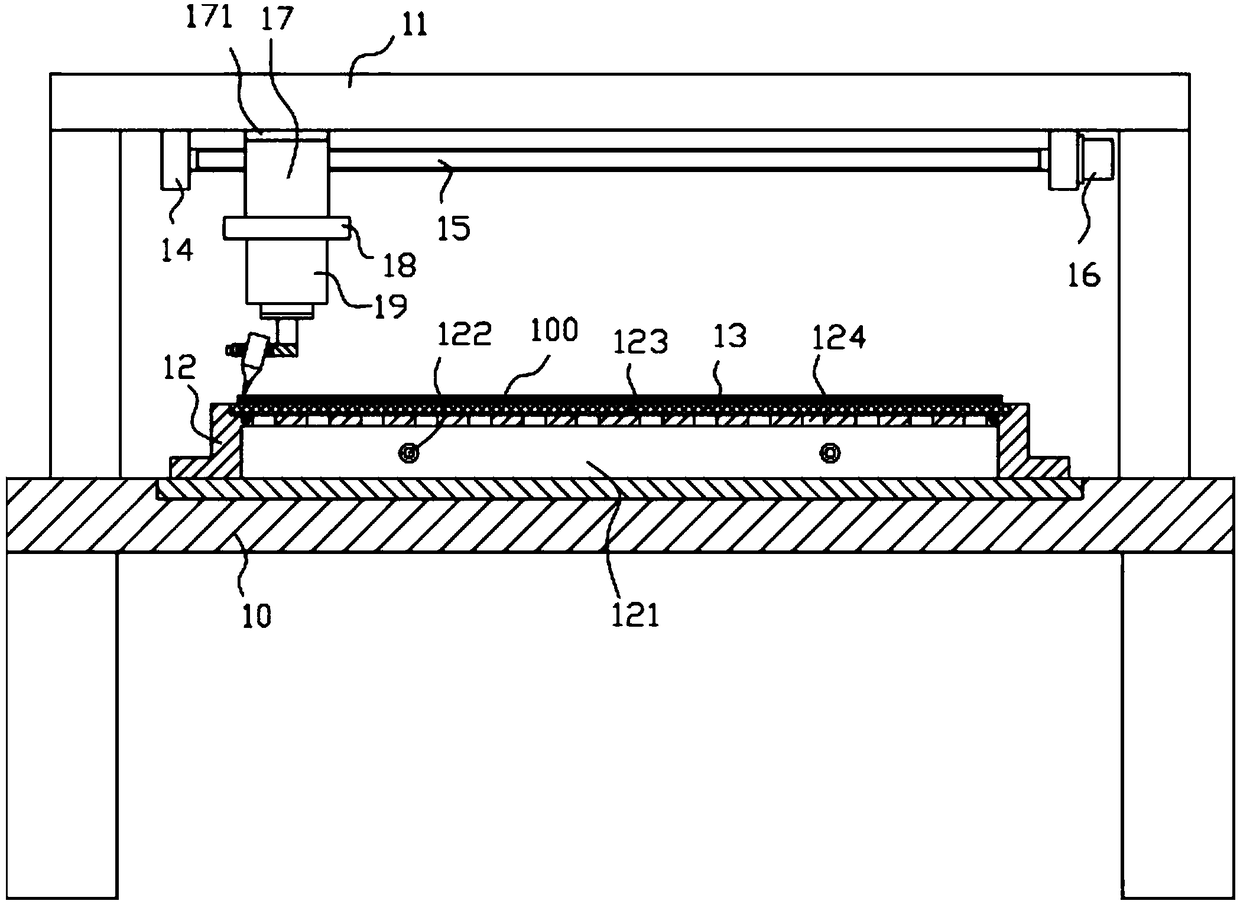

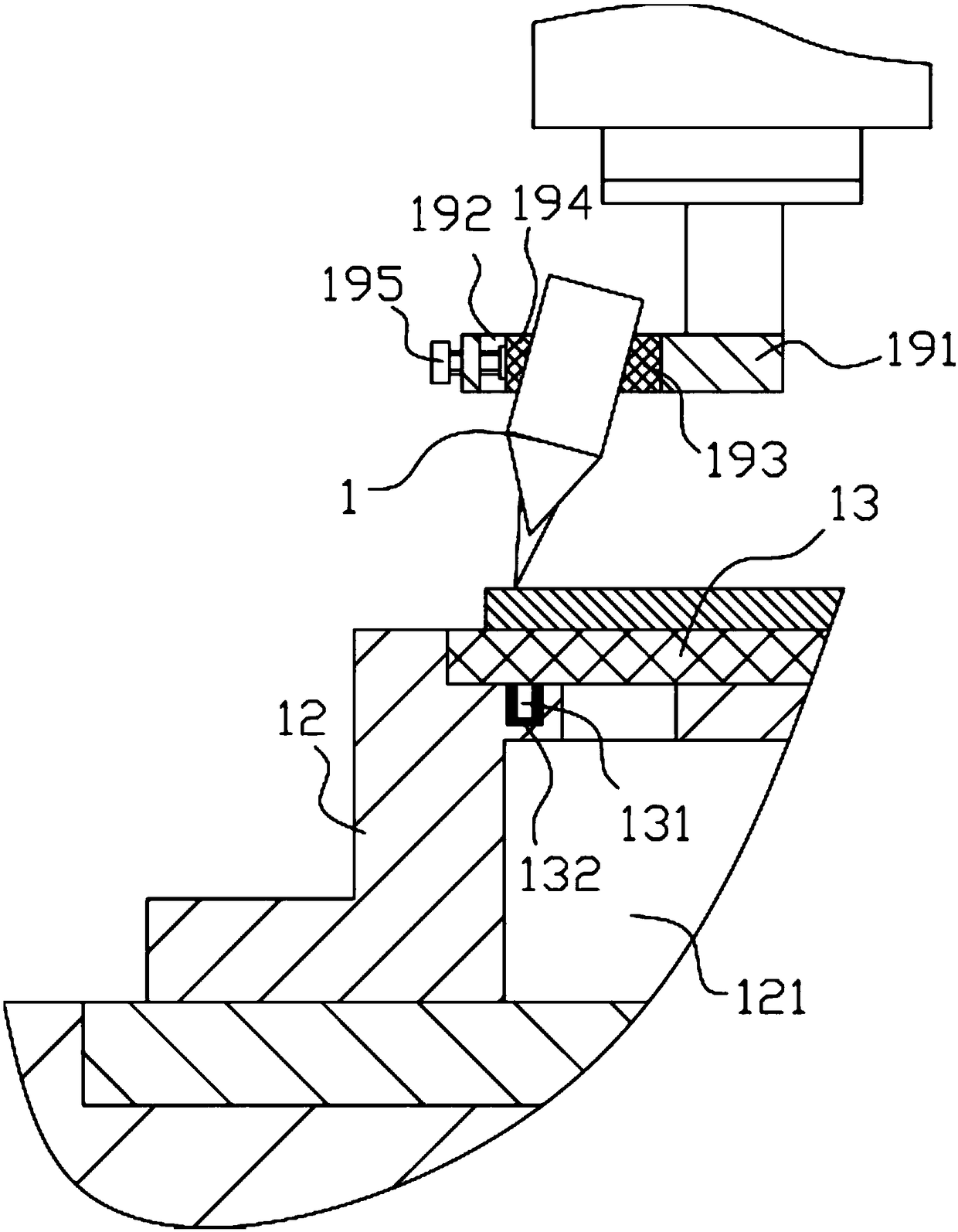

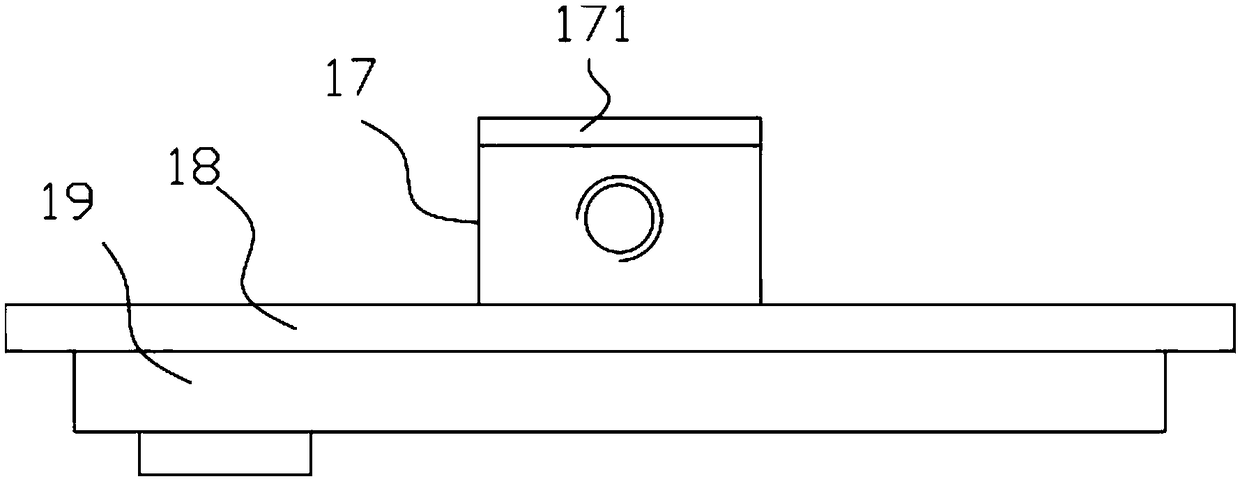

[0017] Example: see Figure 1 to Figure 4 Shown, a kind of cloth fixed scribing mechanism comprises frame 10, and the top surface of the top plate of described frame 10 is fixed with upper supporting frame 11 and placement block 12, and the middle part of the bottom surface of placement block 12 has lower inner cavity 121, The side wall of the lower inner cavity 121 is connected with a suction pipe 122, and the suction pipe 122 communicates with the lower inner cavity 121. The top surface of the placement block 12 is formed with a mounting groove 123, and the perforated plate 13 is inserted into the mounting groove. In 123, the bottom surface of the installation groove 123 is formed with a plurality of suction through holes 124, the suction through holes 124 communicate with the lower inner cavity 121, the perforated plate 13 covers all the suction through holes 124, and the cloth 100 to be processed is placed on the On the top surface of the perforated plate 13;

[0018] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com