Cutting device and flexible circuit board machining machine

A cutting device and cutting technology, used in printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as low processing efficiency, and achieve the effects of high processing efficiency, high cutting yield, and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as Figure 16-22 The shown cutting device 5 includes a fixed seat 51, a gravity tension mechanism 52 and a fixed-length cutting mechanism 53; The tightening mechanism 52 and the fixed-length cutting mechanism 53 are installed on the fixed seat 51, and the gravity tensioning mechanism 52 tightens the flexible circuit board that has been glued, as a transition mechanism, to ensure the stable and reliable operation of the fixed-length cutting mechanism 53; The cut-to-length mechanism 53 is used for cutting the flexible circuit board that has been glued.

[0039] Gravity tensioning mechanism 52 comprises transition roller 521, gravity movable roller 522, vertical optical axis 523, photoelectric sensor 524, discharge roller 525 and connecting plate 526; Above; the gravity movable roller 522 is connected on the vertical optical axis 523 through a linear bearing, and the flexible circuit board is located below the gravity movable roller 522; the upper and lower ends of t...

Embodiment 2

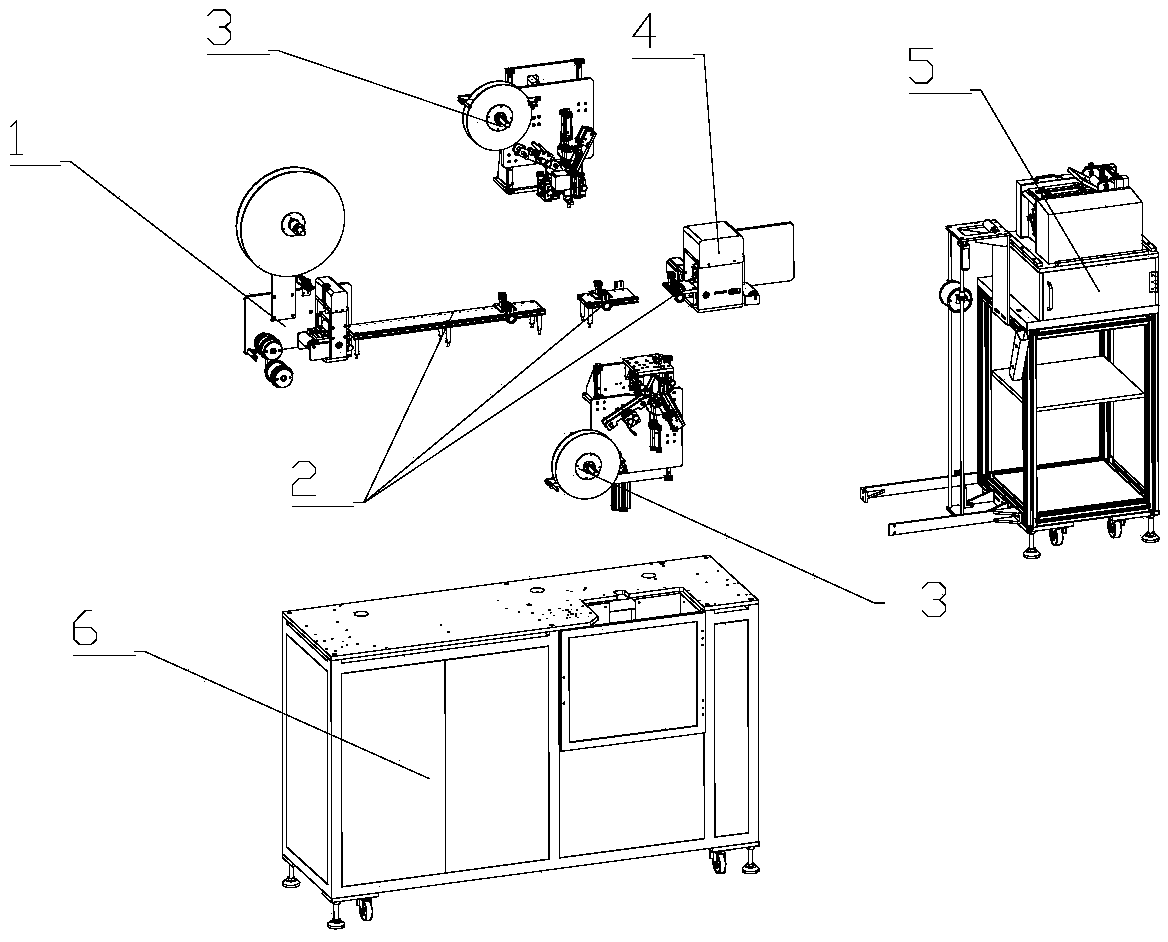

[0052] Such as Figure 1-Figure 22 The shown processing equipment of a flexible circuit board includes a frame 6, a feeding device 1, a material passing platform assembly 2, a gluing device 3, a gluing device 4 and a cutting device 5, a feeding device 1, a material passing platform Component 2, gluing device 3 and gluing device 4 are installed on the frame 6, the feeding device 1 is connected with the material passing platform component 2, the position of gluing device 4 corresponds to the material passing platform component 2, gluing device 3, gluing The device 4 and the cutting device 5 are sequentially connected.

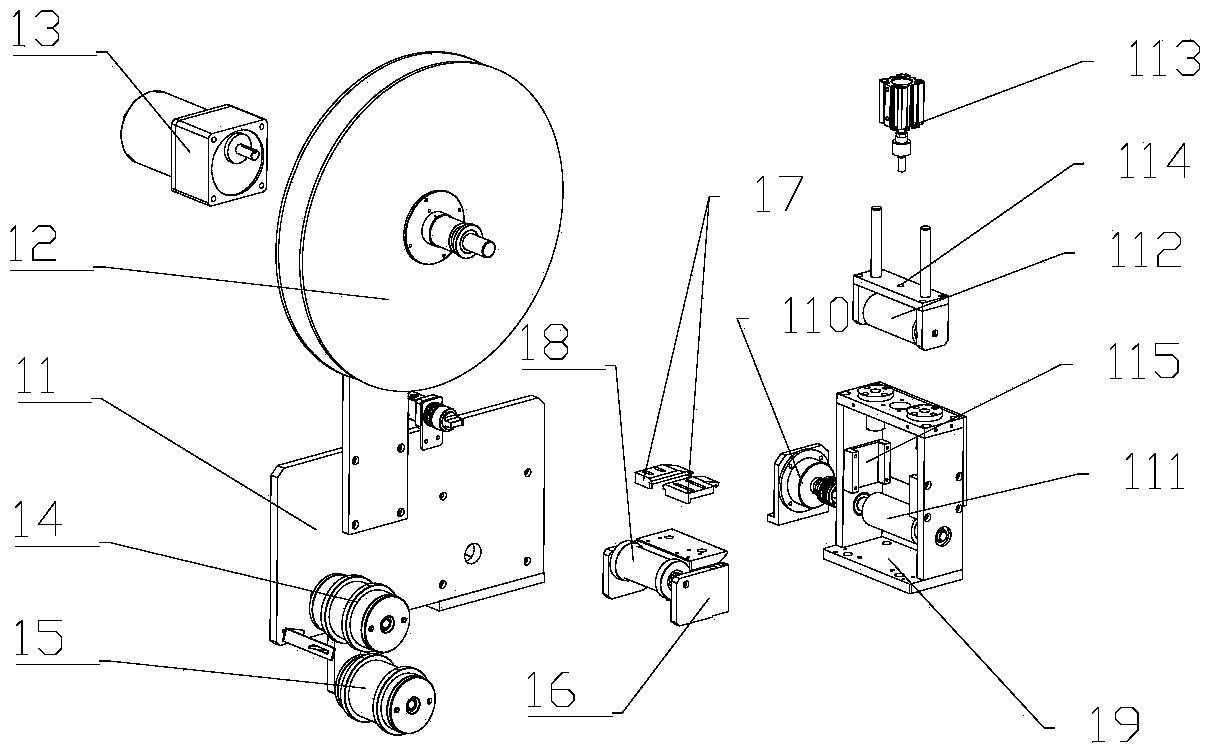

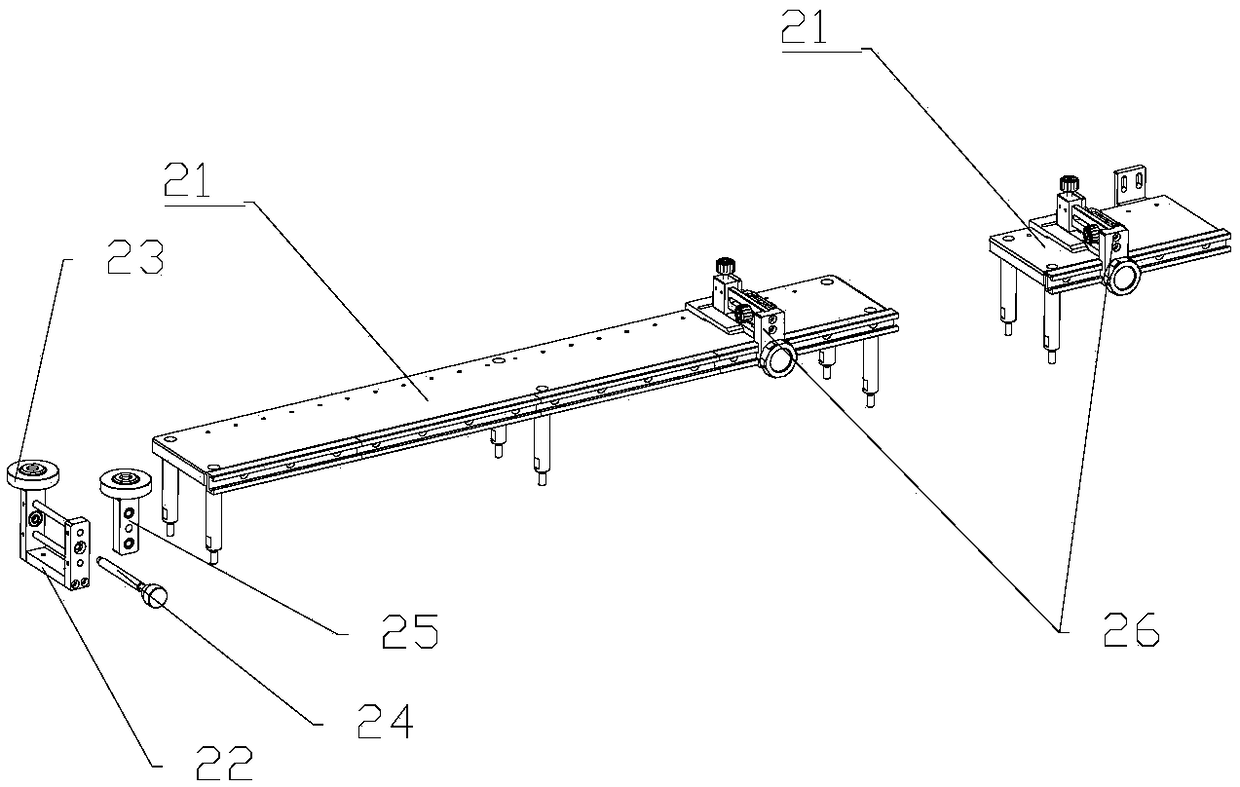

[0053] Feeding device 1 is used to feed the pre-made coiled wire; material passing platform assembly 2 is used to guide the wire into a straight line, and realize gluing at this place; there are two gluing devices 3, upper and lower Arrangement, used to paste the upper and lower adhesive tapes; the glue pressing device 4 is connected with the end of the glue app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com