Bridge floor cast-in-place concrete guardrail installation reference frame

A technology of installation datum and concrete, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of no automatic level adjustment function, no lifting mobile structure, inconvenient use, etc., and achieve automatic adjustment mode , accurate position, convenient operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

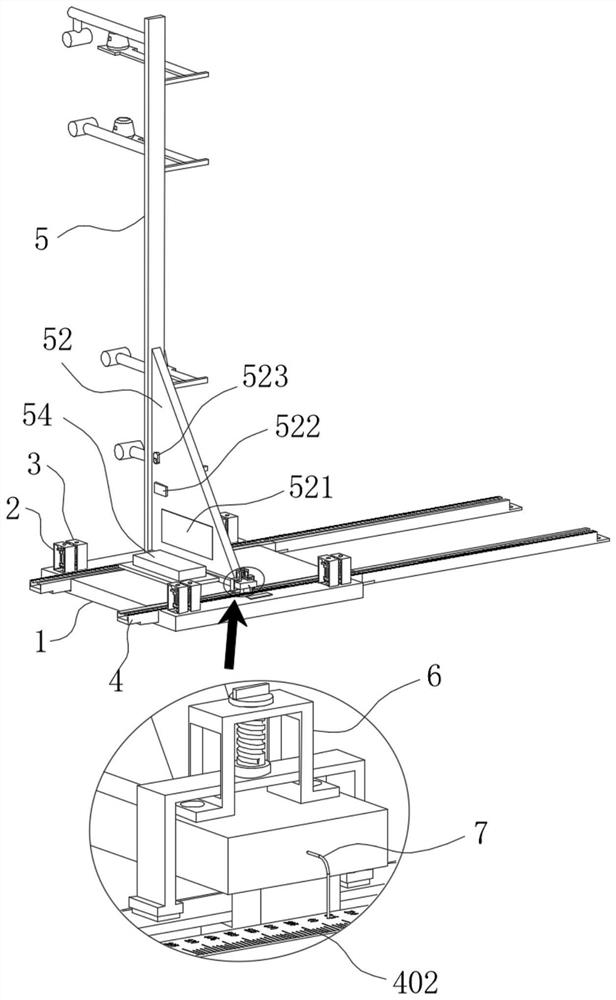

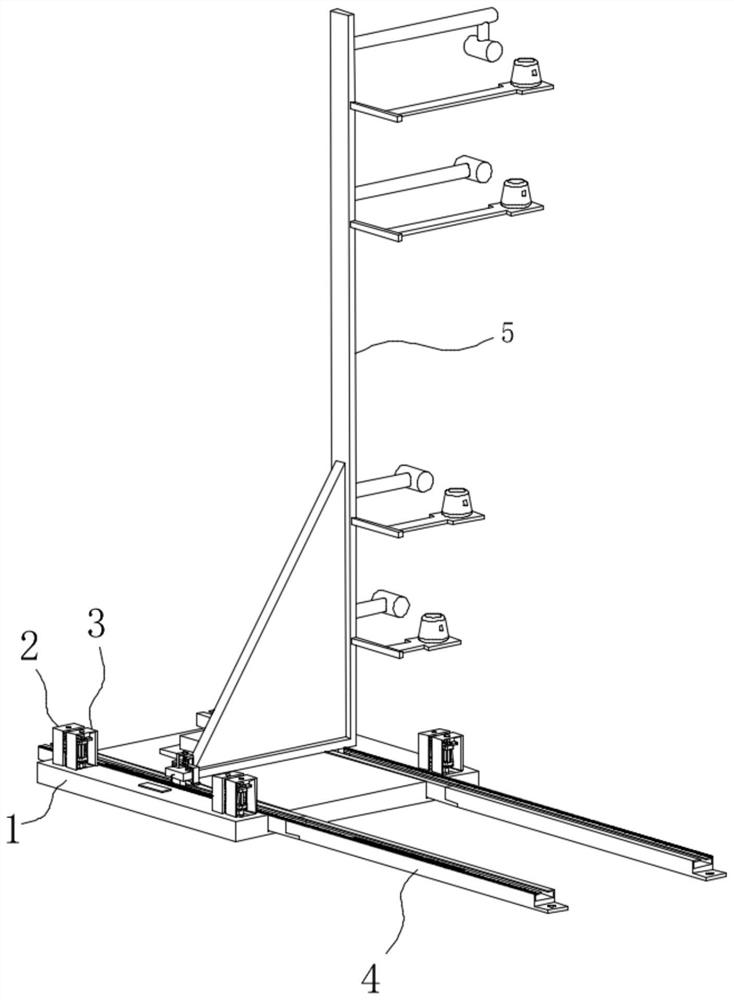

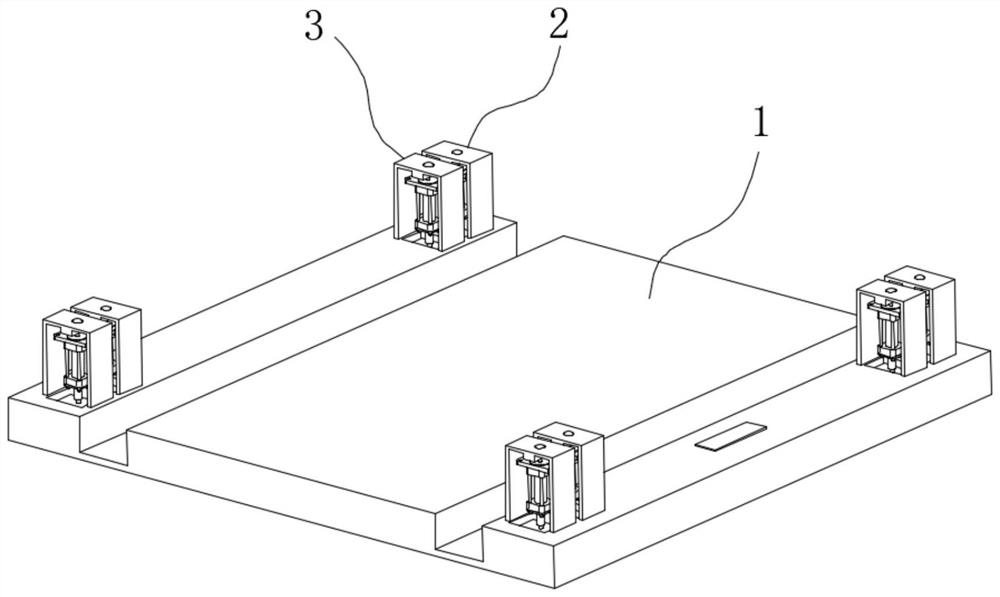

[0045] see Figure 1-4 with Figure 9 As shown, the present invention is a bridge deck cast-in-place concrete guardrail installation reference frame, including a base 1, a lifting type mobile structure 2, a lifting type adjustment structure 3, a slide rail 4, a reference fixing frame 5, a locking structure 6 and an indicator rod 7. A mounting groove 11 is provided on the top surface of the base 1, and a control switch 12 is fixed on one edge of the top surface of the base 1, and two symmetrical mounting holes 101 are provided inside the mounting groove 11;

[0046] The base 1 is detachably connected with a slide rail 4 through screws, the size of the slide rail 4 matches the size of the installation groove 11, one end of the slide rail 4 is the first connector 41, and the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com