Composite building template compound system

A technology of building formwork and composite materials, which is applied in the direction of construction, building structure, formwork/formwork/work frame, etc., can solve the problems of concrete overflowing easily on the surface, waste of materials, etc., and achieve the advantages of easy disassembly, cost reduction and waste reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0114] The present invention will be further described in detail below in conjunction with specific examples, but the structure of the present invention is not limited to the following examples.

[0115] A composite building formwork combination system of the present invention, the combination system includes a staircase formwork 100, a closed inner corner formwork 200, a spliced inner corner formwork 300, and a first L-shaped outer corner formwork 400, a second L-shaped external corner formwork 500, a door opening formwork 600, a window opening formwork 700, a floor edge beam formwork support structure 800, a building formwork diagonal support structure 900 and a A kind of pull device 1000 for building formwork.

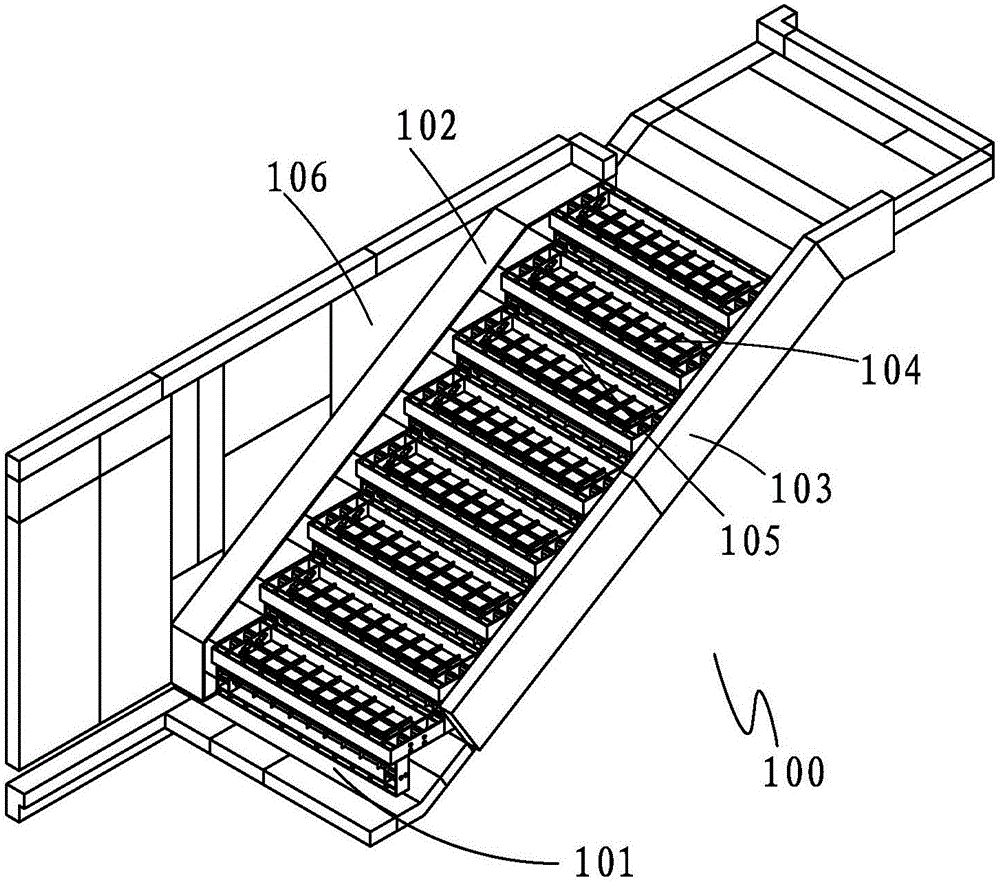

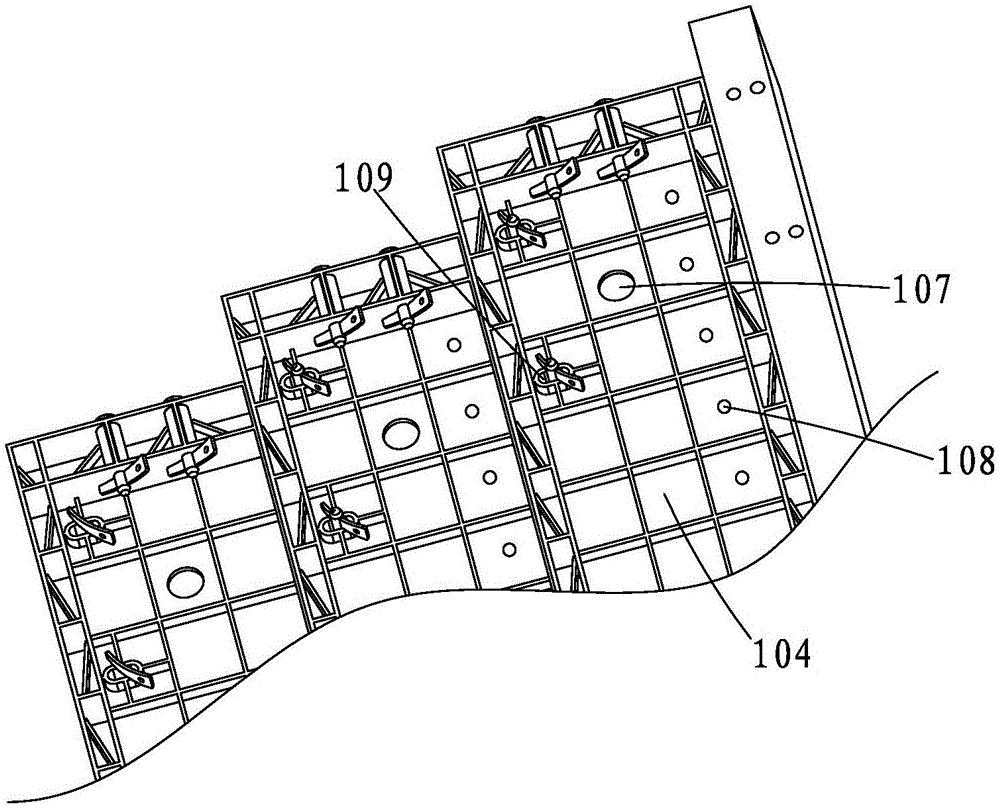

[0116] The specific embodiment of described stair formwork 100 is:

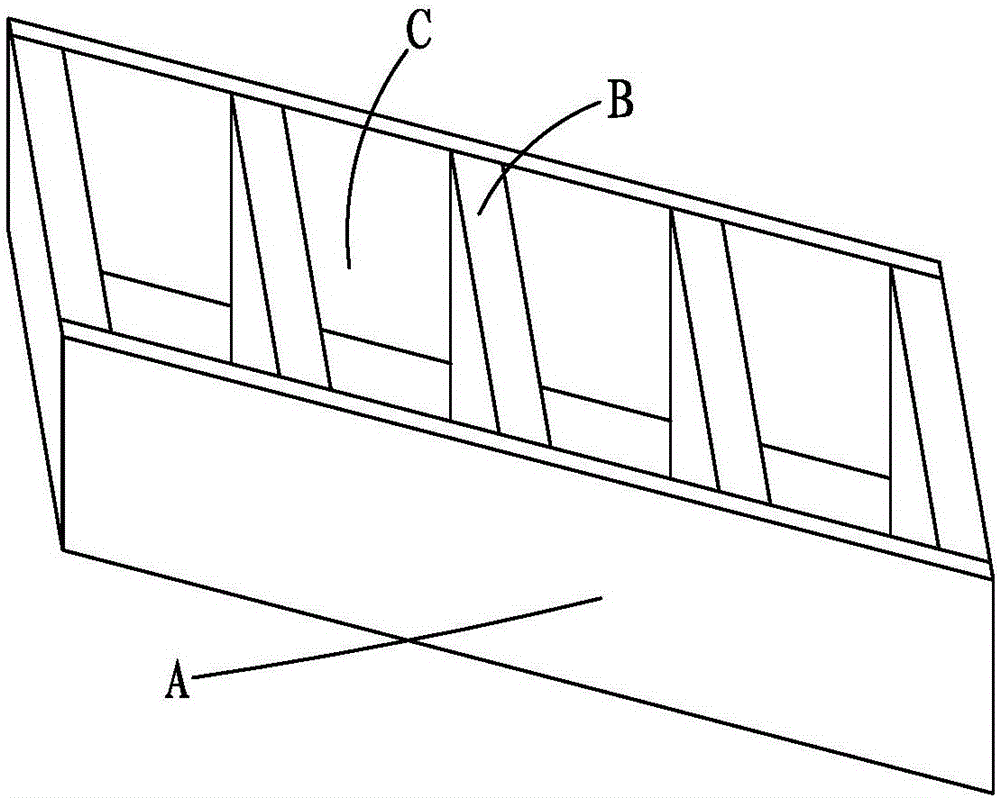

[0117] Such as Figure 2a to Figure 2c As shown, the stair template 100 includes a blocking plate 101, a dog tooth 102, a stair side plate 103, a plurality of stair treads 104 and a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com