Drilling with casing method for gas extraction hole of soft broken coal seam

A coal seam gas and pipe drilling technology, which is applied to drilling equipment and methods, gas discharge, drilling equipment, etc., can solve the problems of difficult deep hole drilling and poor hole forming effect of gas extraction holes, and achieves the goal of construction method Science, improvement of working environment, effect of increasing drilling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

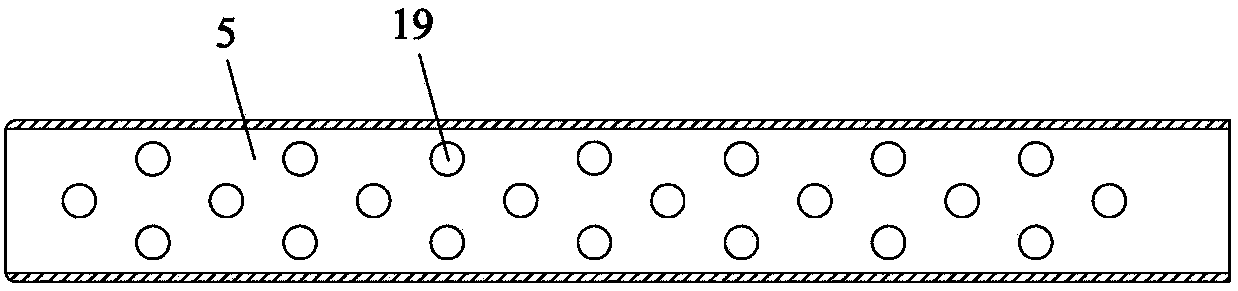

[0015] Depend on Figure 1-8 Given, the present invention utilizes the gas extraction hole and pipe drilling device of the soft broken coal seam to carry out according to the following steps:

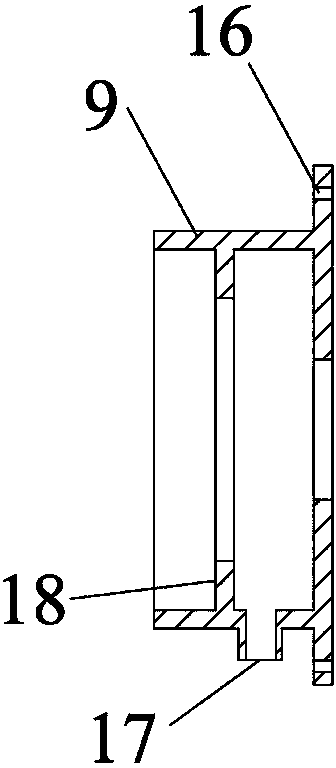

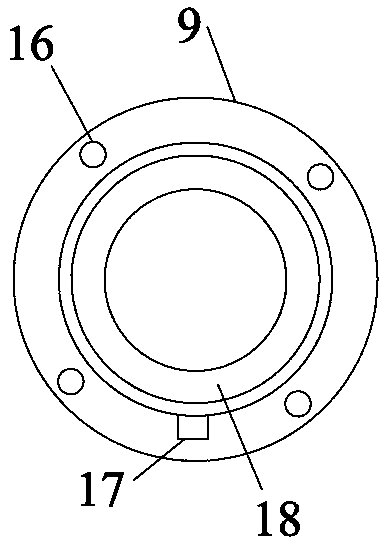

[0016] The first step is to stabilize the drilling rig. The base of the drilling rig support 11 is anchored to the roadway floor with a short anchor rod 14. The guide rail 13 is installed on the support 11. The drilling rig motor 12 and the drilling rig slip 10 are installed on the guide rail 13. The casing propeller 9 Installed on the front end of the slipper 10 of the drilling rig, connected to the power supply of the drilling rig and the hydraulic oil pipe, the slag discharge hole 17 in the casing thruster 9 is connected to the sewage hose to the ditch or the water tank;

[0017] The second step is to install the drilling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com