Construction method of concrete packing light pipeline

A construction method and concrete technology, applied in the sewer system, waterway system, water supply device, etc., can solve the problems of delay in construction period, light pipe displacement, etc., and achieve the effect of preventing position movement, simple construction method and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

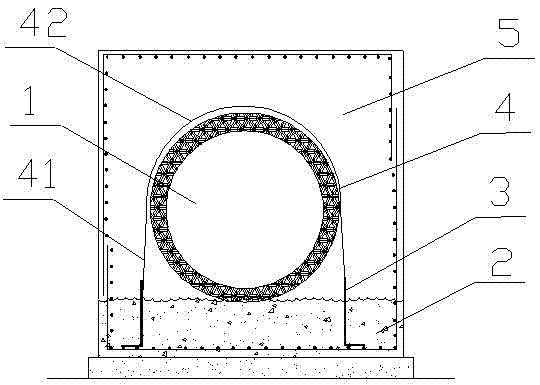

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0023] Such as figure 1 As shown, in the present embodiment, the construction method of concrete-encapsulated lightweight pipelines includes the following steps: 1. When pouring the concrete layer at the bottom of the lightweight pipelines, a certain amount of water is pre-embedded on both sides of the installation position of the lightweight pipelines. The length of the L-shaped steel bar, the upper end of the steel bar is exposed to a certain height on the surface of the concrete layer, such as exposed 100mm-200 mm; the lower end of the L-shaped steel bar is arranged in the concrete layer, or connected to the steel bar of the concrete layer, such as Bind it by welding (spot welding) or small steel wire or tie wire; or simply hook it on the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com