Connecting structure of assembly type underground structure vertical member and construction method thereof

A technology for underground structures and vertical components, which is used in infrastructure engineering, protection devices, building structures, etc., can solve problems such as the need for investigation of waterproof performance, difficult positioning of steel bars, and prolonged construction period, so as to ensure the effectiveness of force transmission and shorten the construction period. Construction period and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

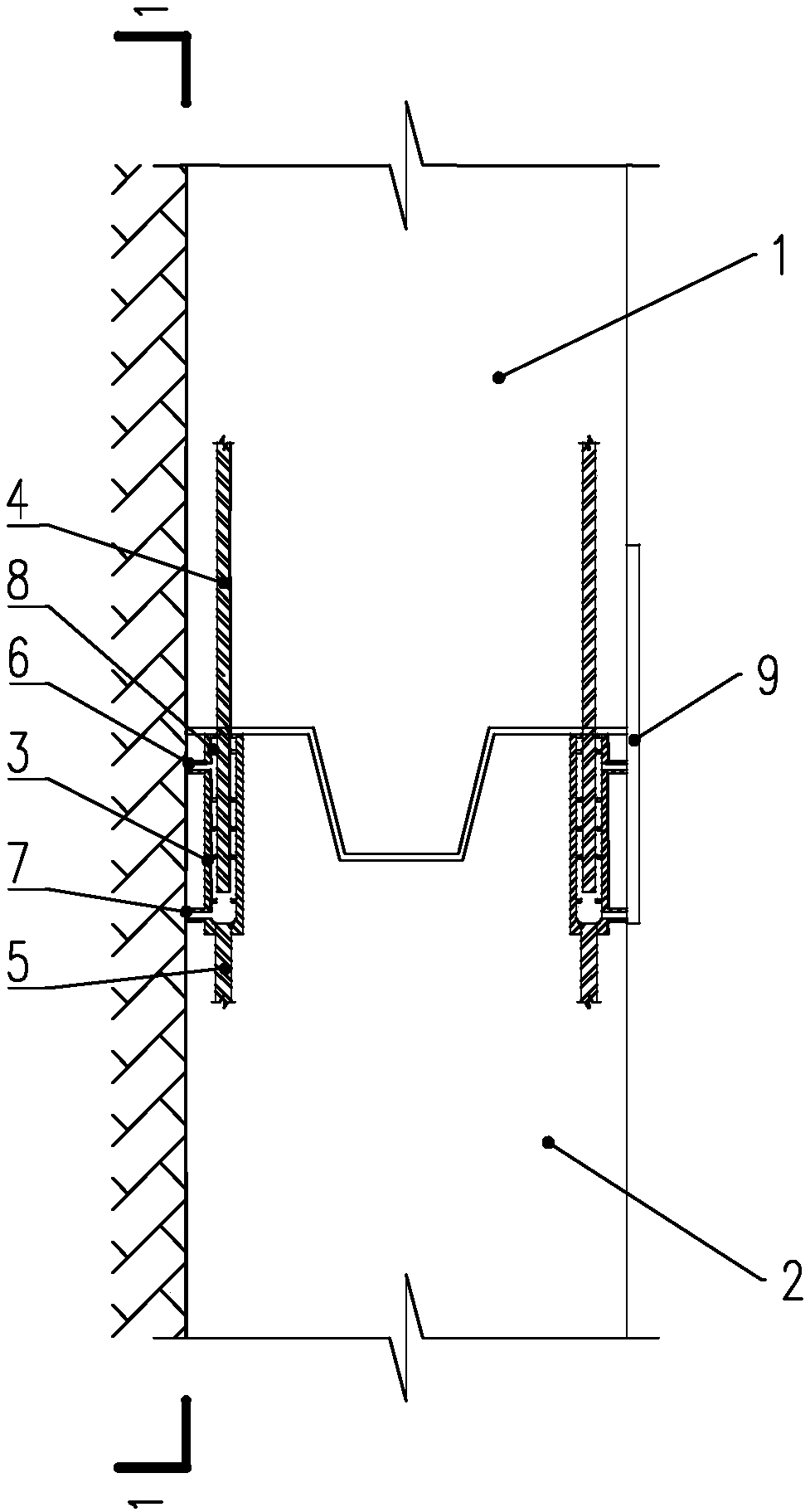

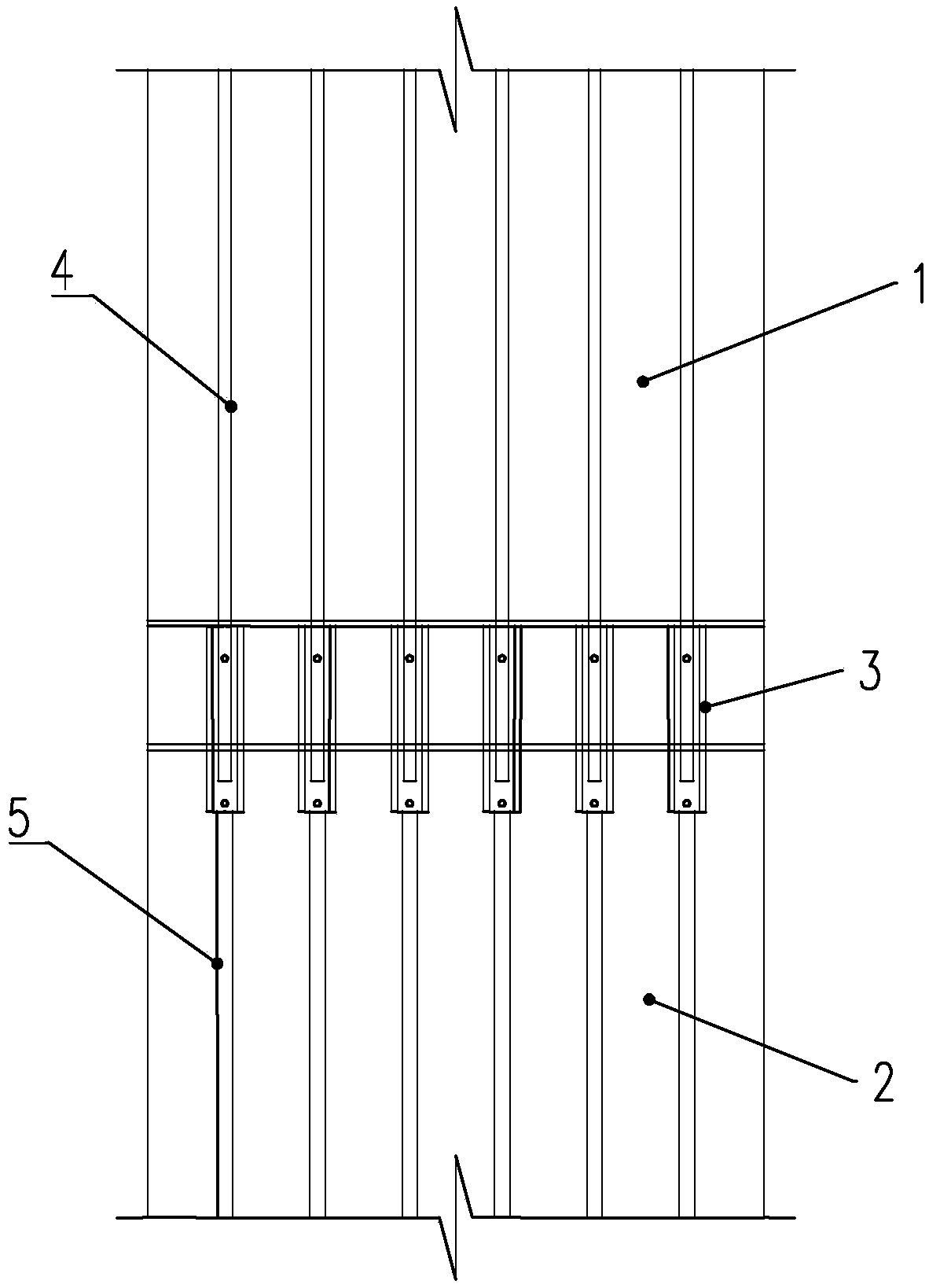

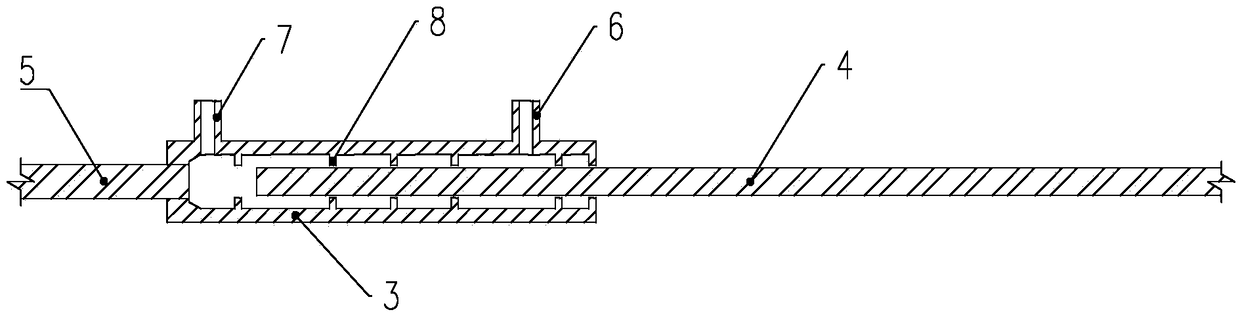

[0027] like figure 1 and figure 2 As shown, the connection structure of the vertical components of a prefabricated underground structure in the present invention includes an upper component 1 and a lower component 2, wherein the joint between the upper component 1 and the lower component 2 is a concave-convex structure, and the upper component 1 It is tenon-jointed with the lower side member 2, and the joint between the upper side member 1 and the lower side member 2 is filled with modified epoxy resin.

[0028] Several evenly distributed sleeves 3 are arranged in the lower member 2 of the present invention near the seam, and the lower steel bars 5 fixedly connected with the sleeves 3 are pre-embedded in the lower member 2 . In the upper side member 1, an upper side steel bar 4 is arranged at a position opposite to each sleeve 3, and one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com