Single pile foundation and single pile foundation manufacturing method

A single pile foundation and pile body technology, which is applied in the direction of foundation structure engineering, building structure, construction, etc., can solve the problems of long construction period and difficulty in ensuring the quality of single pile foundation, and achieve the effect of ensuring quality and reducing construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

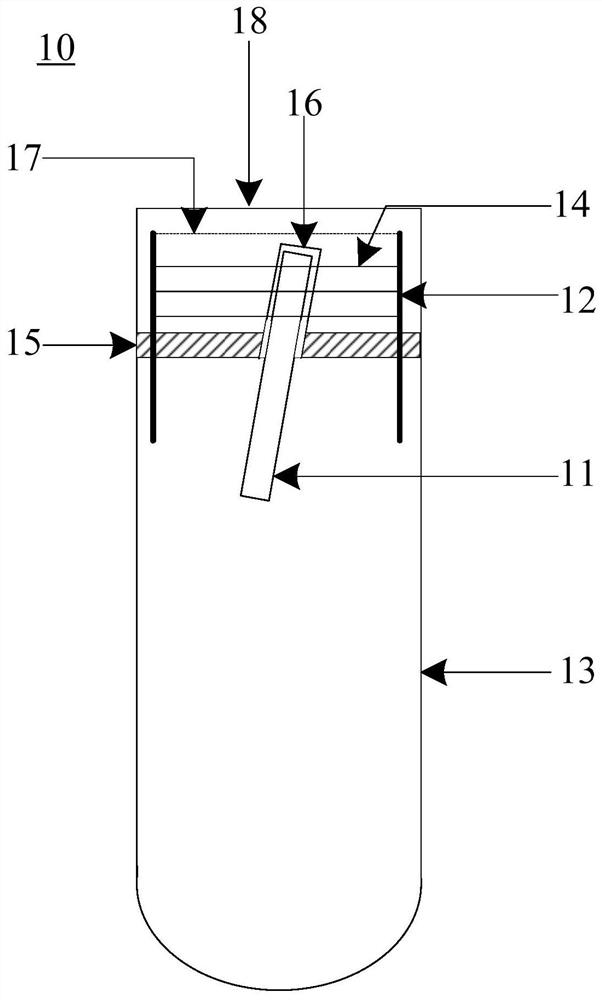

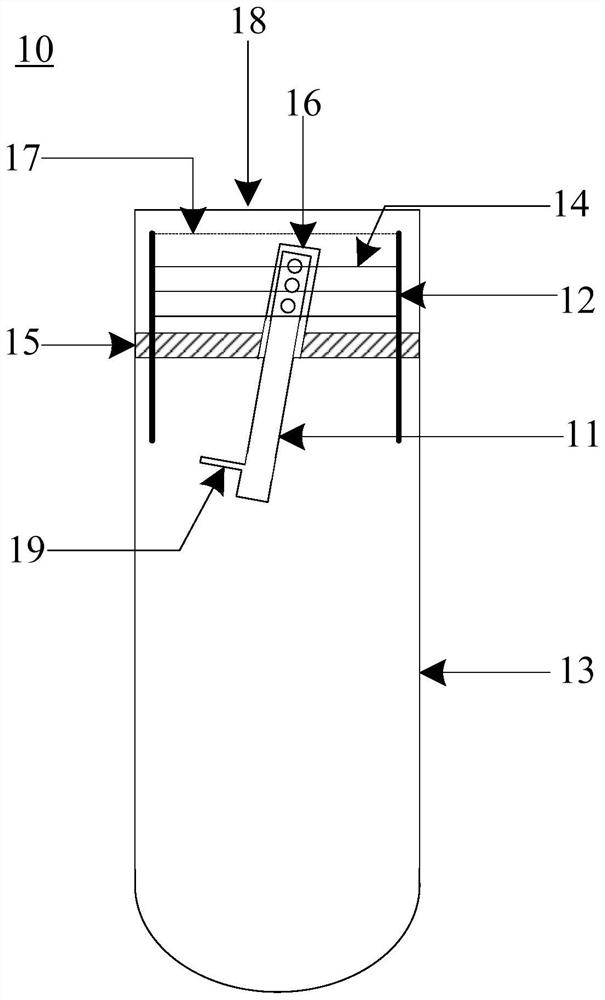

[0045] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

[0046] When transmission lines pass through river networks, swamps, ponds and other areas, the single pile foundation with embedded parts in the columnar pile body is usually used to connect with the tower.

[0047] In the related technology, since the embedded parts expose the end surface of the top of the columnar pile, there is a risk of being damaged during high-strain testing. Therefore, the high-strain testing is performed on the single pile foundation without embedded parts first, and then the high-strain testing will be carried out. A predetermined section of the columnar pile on the top of the detected single pile foundation is chiseled off, and then the embedded parts are set at the predetermined position, and the single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com