Patents

Literature

197results about How to "Meet the force requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

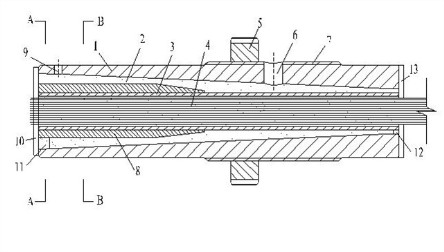

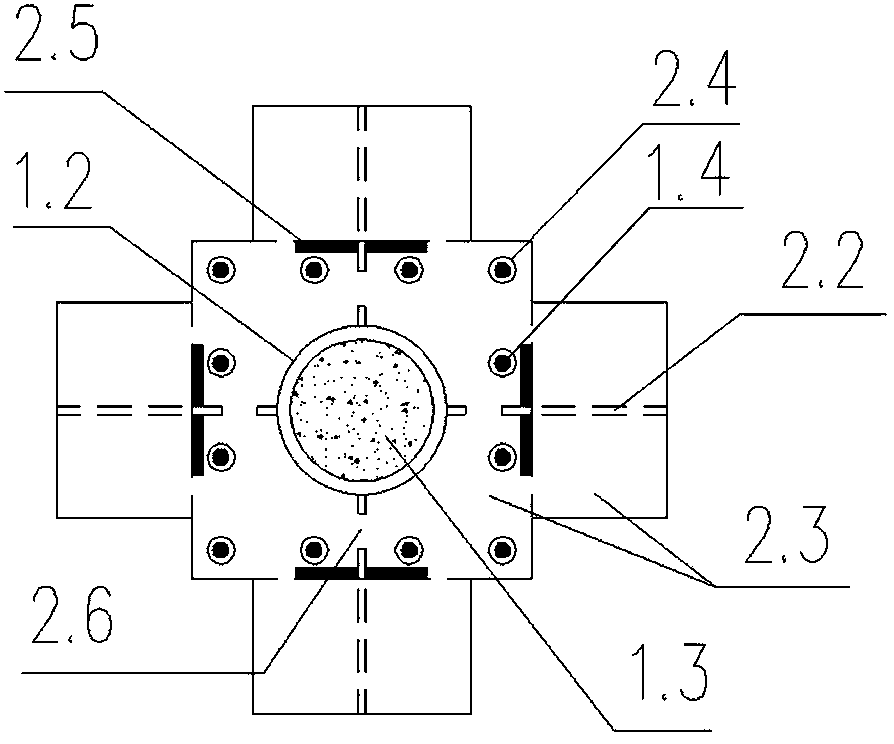

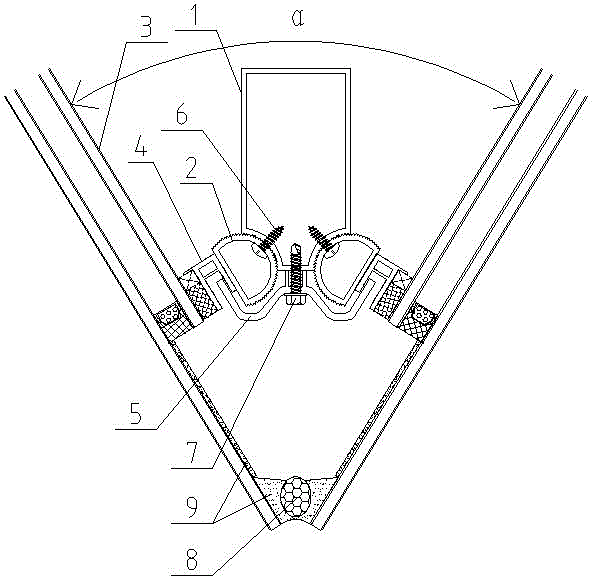

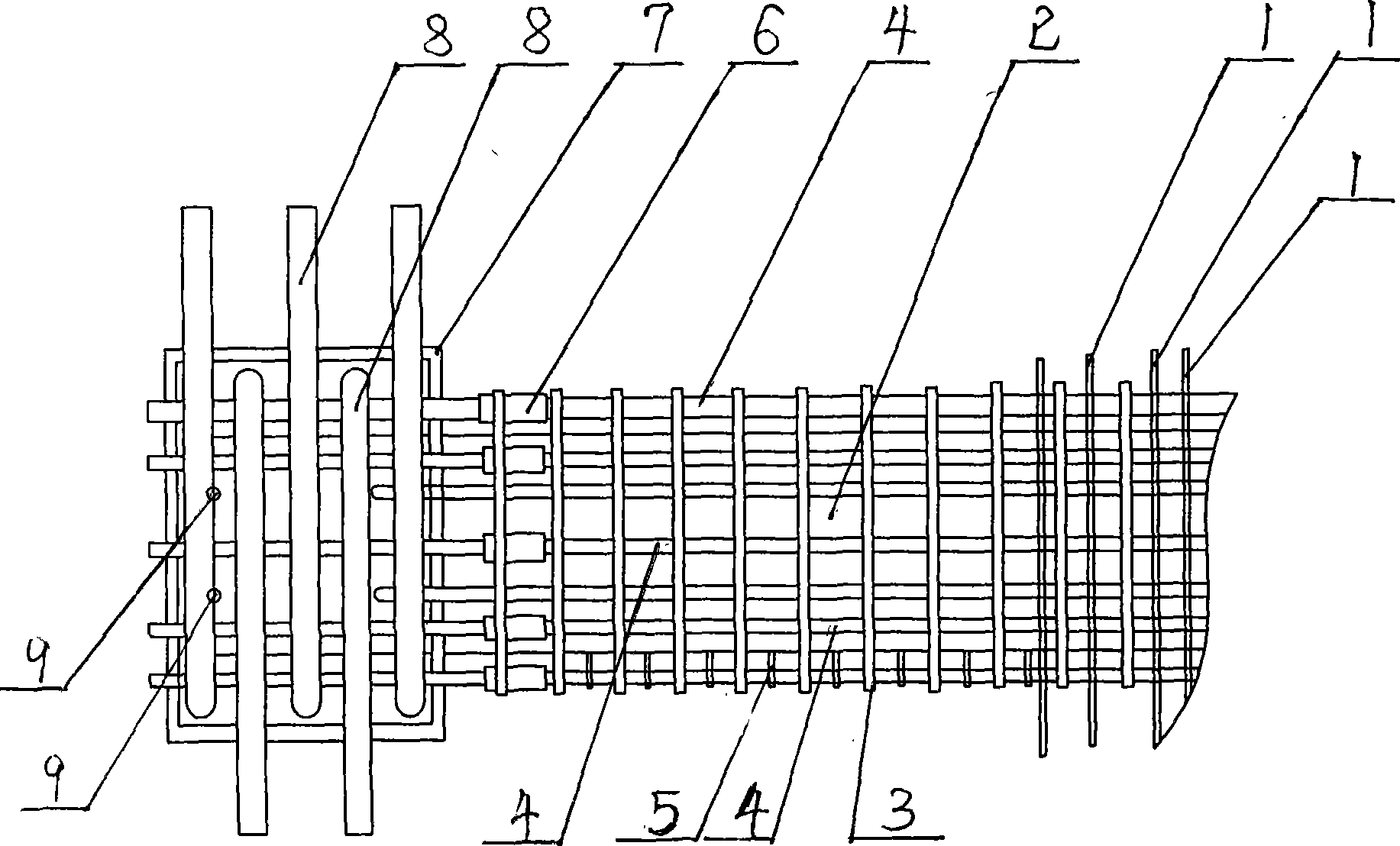

Carbon fiber cable strand inner sleeve conical bonded anchorage device

InactiveCN102002911AImprove adhesionAct as a stiff skeletonBridge structural detailsBuilding reinforcementsFiberCarbon fibers

The invention discloses a carbon fiber cable strand inner sleeve conical bonded anchorage device. In the carbon fiber cable strand inner sleeve conical bonded anchorage device, a reinforced thread reinforcing steel bar is arranged on the outer side of a sleeve; an axial wedge-shaped hollow groove is formed in the sleeve; and a wedge tip of the hollow groove faces the small hole end of an anchor ring conical hole. By the anchorage device of the invention, the condition of non-uniform transverse and longitudinal stress of carbon fiber reinforced plastic (CFRP) cable strands can be improved; the anchorage device can be prestressed; all the CFRP wires can exert limit bearing capacity at the same time; the anchoring efficiency is improved; the anchoring efficiency coefficient can reach 100 percent; and the anchorage device has excellent static performance and dynamic performance and low manufacturing cost, is simple and convenient in assembly and is easy in construction.

Owner:CCCC HIGHWAY CONSULTANTS +1

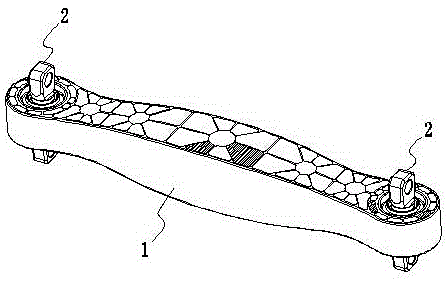

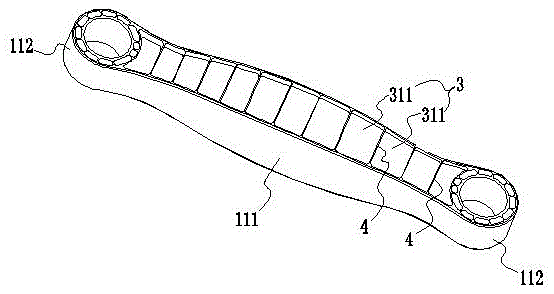

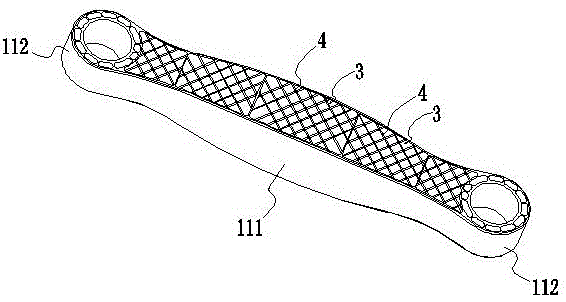

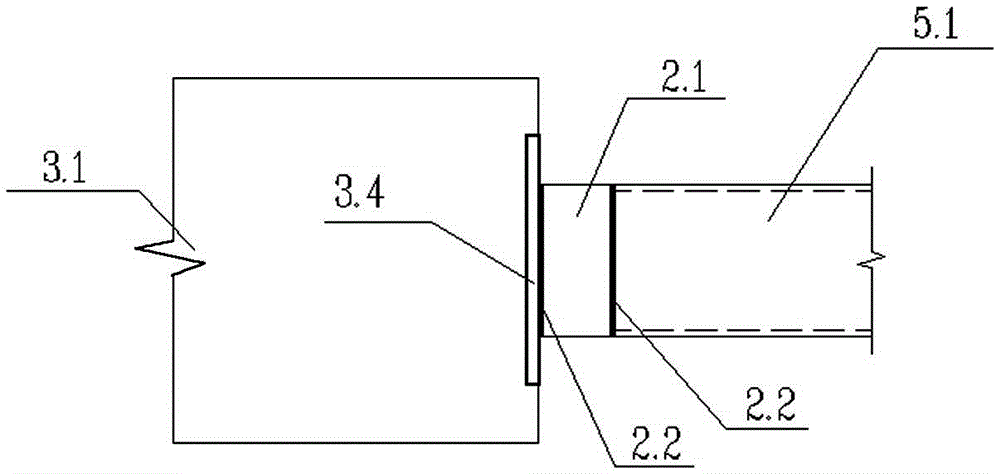

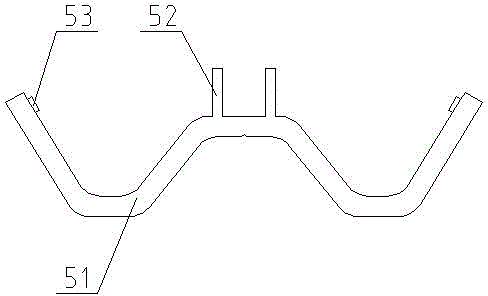

Thrust bar lightening method and lightened thrust bar

ActiveCN106627013AReduce weightMeet different force requirementsPivoted suspension armsThrust bearingEngineering

The invention discloses a thrust bar lightening method and a lightened thrust bar. According to the thrust bar lightening method, a bar body and a mandrel of an elastic spherical hinge are made of a high polymer material and formed at a time through injection molds, the two opposite side faces of the bar body are set to be the side faces with first intermittent grooves, each first intermittent groove comprises multiple first sub grooves sequentially distributed in the length direction of the bar body, multiple protruding ribs are arranged on the bottom face of each first sub groove, and therefore each first sub groove is divided into multiple small grooves through the multiple protruding ribs. On the premise that the use requirements of the thrust bar are met, the weight of the thrust bar can be reduced as much as possible, and the lightening requirement of the thrust bar is met.

Owner:BOGE RUBBER&PLASTICS ZHUZHOU CO LTD

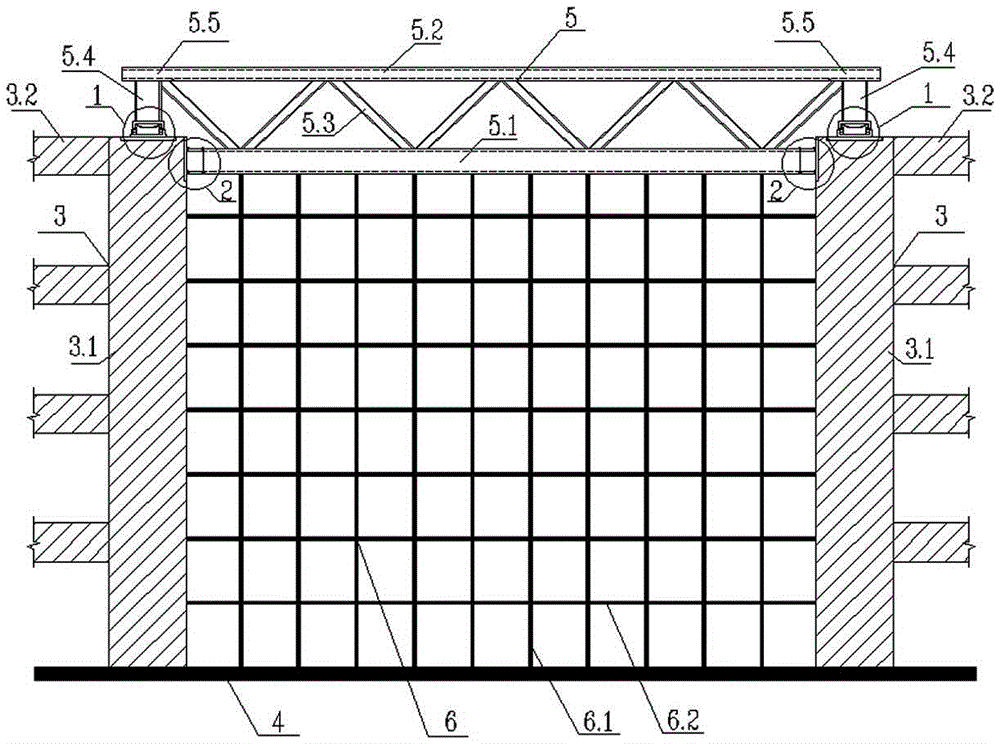

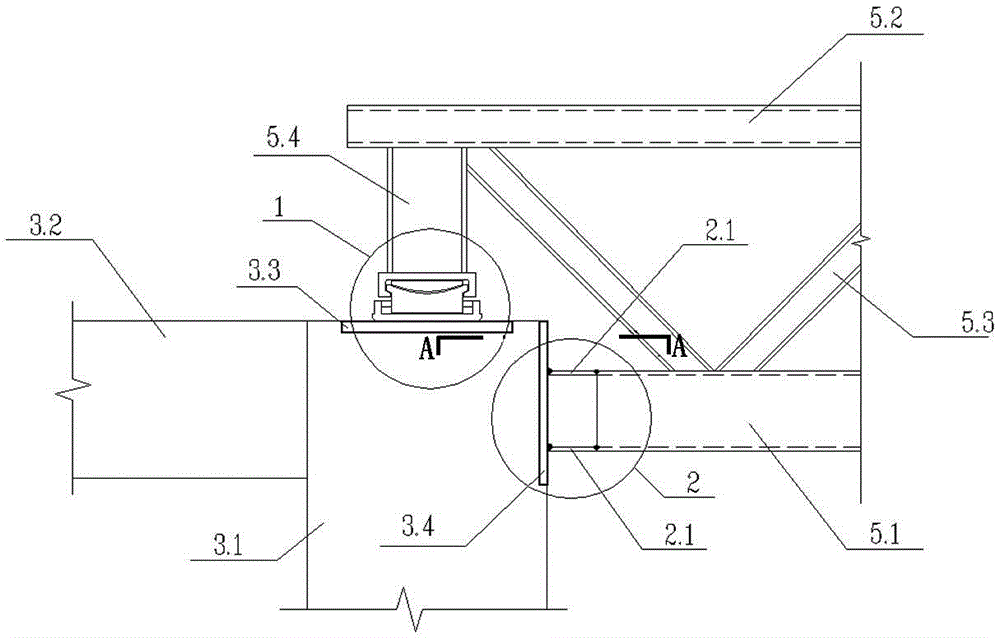

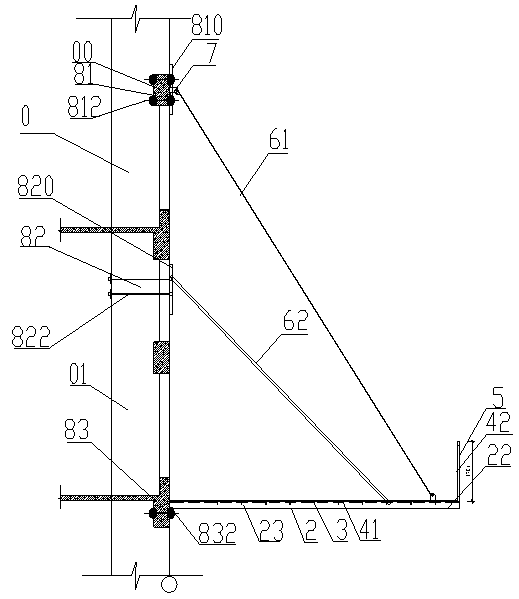

Dragline curtain wall support system with steel truss at top and construction method thereof

ActiveCN105332452ASolve processing problemsImprove structural strengthWallsBuilding material handlingSupporting systemPre stress

The invention provides a dragline curtain wall support system with a steel truss at the top and a construction method thereof. The dragline curtain wall support system comprises main building structures at two sides, a support structure at the lower part, the steel truss at the top and a curtain wall steel cable at the middle, wherein the main building structures provide left and right fixed points of the steel cable, and the steel truss and the support structure at the lower part provide upper and lower fixed points of the curtain wall steel cable; a two-direction fixed mode of horizontal connection and vertical connection is adopted at the two ends of the steel truss and between the main building structures; and the horizontal connection is realized through a horizontal bearing support, and the vertical connection is realized through a vertical bearing support. The dragline curtain wall support system is simple in structure and convenient in construction; by virtue of the two-direction support fixed mode, the structure strength is increased, the node structure is simplified, and the structure safety is greatly increased; The horizontal bearing support is installed after vertical steel cable prestress tension to enable the steel truss to freely rotate under the action of the vertical force, so that the secondary stress of buildings at two sides is reduced; and by transferring force by a horizontal steel plate, the bearing force is large, the stress is reliable, and micro-vertical deformation of the steel truss can also be applicable.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

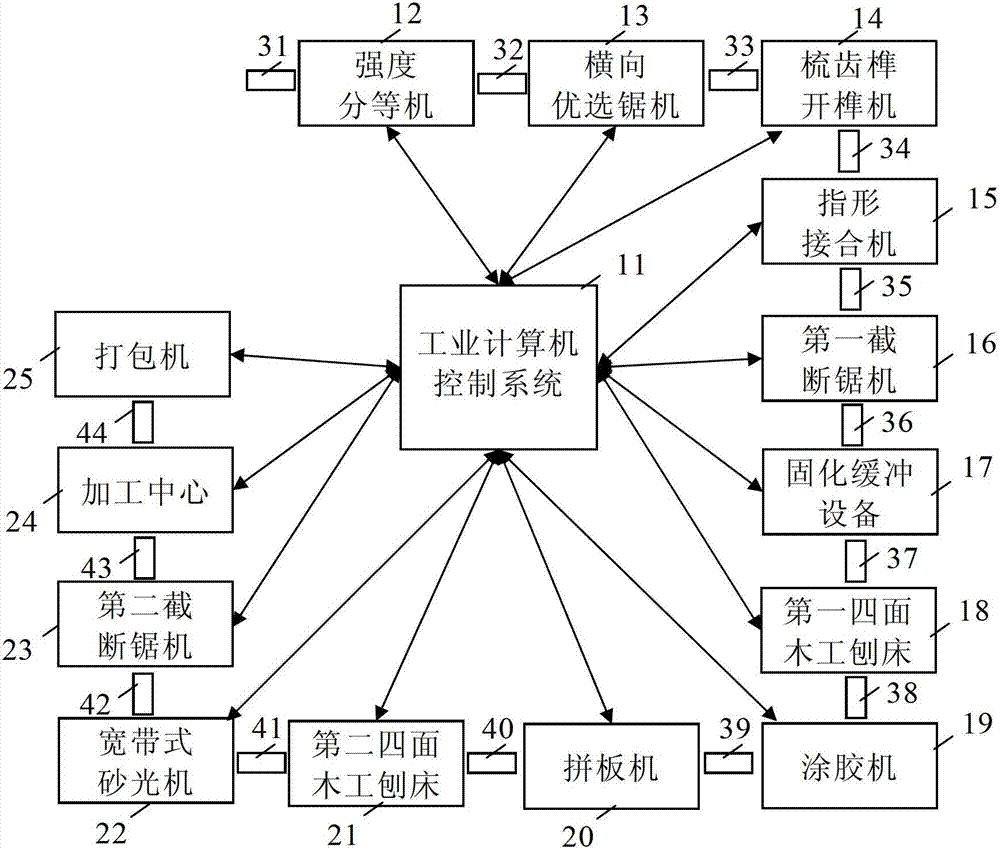

Glulam automatic production system and method thereof

ActiveCN103085132AEasy to operateIncrease productivityLaminationLamination apparatusWood wasteIndustrial PC

The invention discloses a glulam automatic production system and a method thereof. The glulam automatic production system comprises a strength grading machine, a transverse optimizing saw, a comb-tooth-tenon tenoning machine, a finger-type jointing machine, a first cutting saw, solidifying buffering equipment, a first four-side wood planer, a gumming machine, a felt-board machine, a second four-side wood planer, a wide-belt-type sander, a second cutting saw, a machining center, a packer and an industrial computer control system. Due to the glulam automatic production system, the glulam automatic production method is achieved. The glulam automatic production system can achieve automatic quantity production-manufacturing of glulam. The glulam produced can meet requirements of stress in practical use well. The glulam automatic production system is high in automatic level, convenient to operate, high in production efficiency, and capable of reducing wood waste, saving manpower and lowering production cost.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION +1

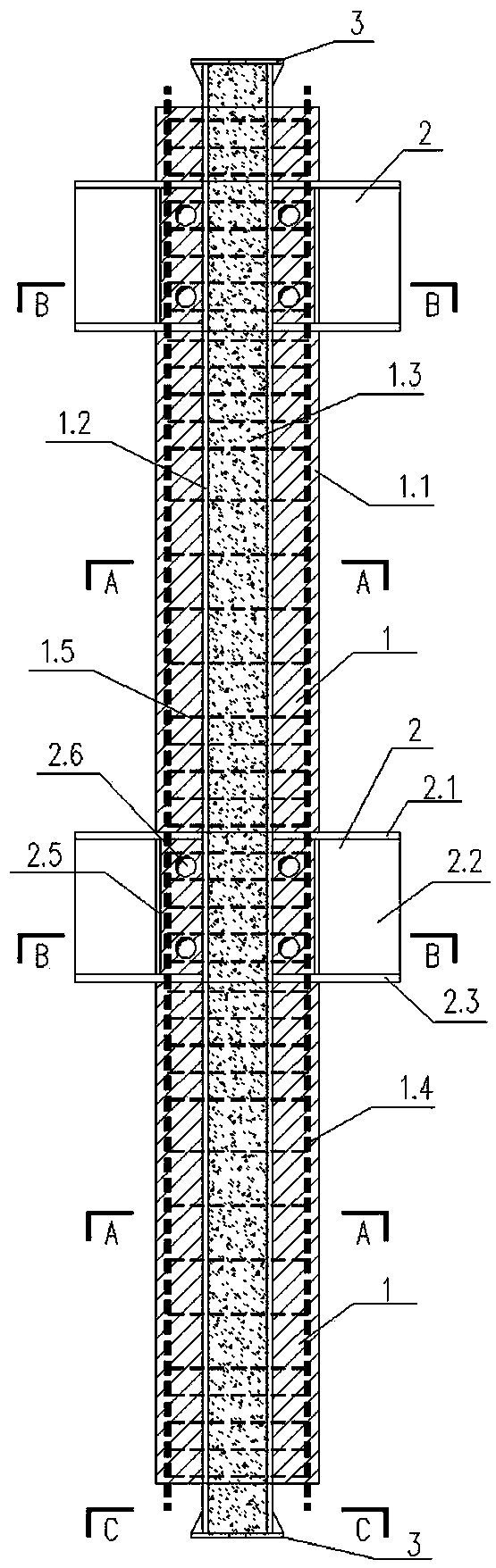

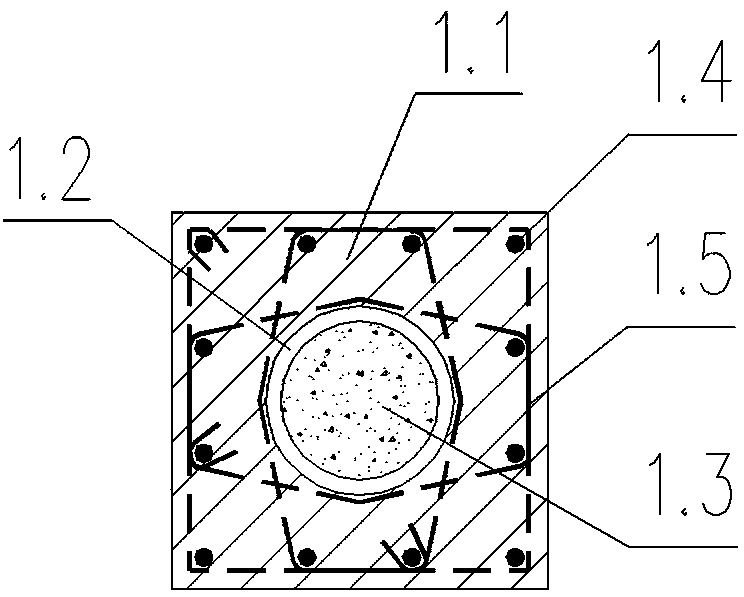

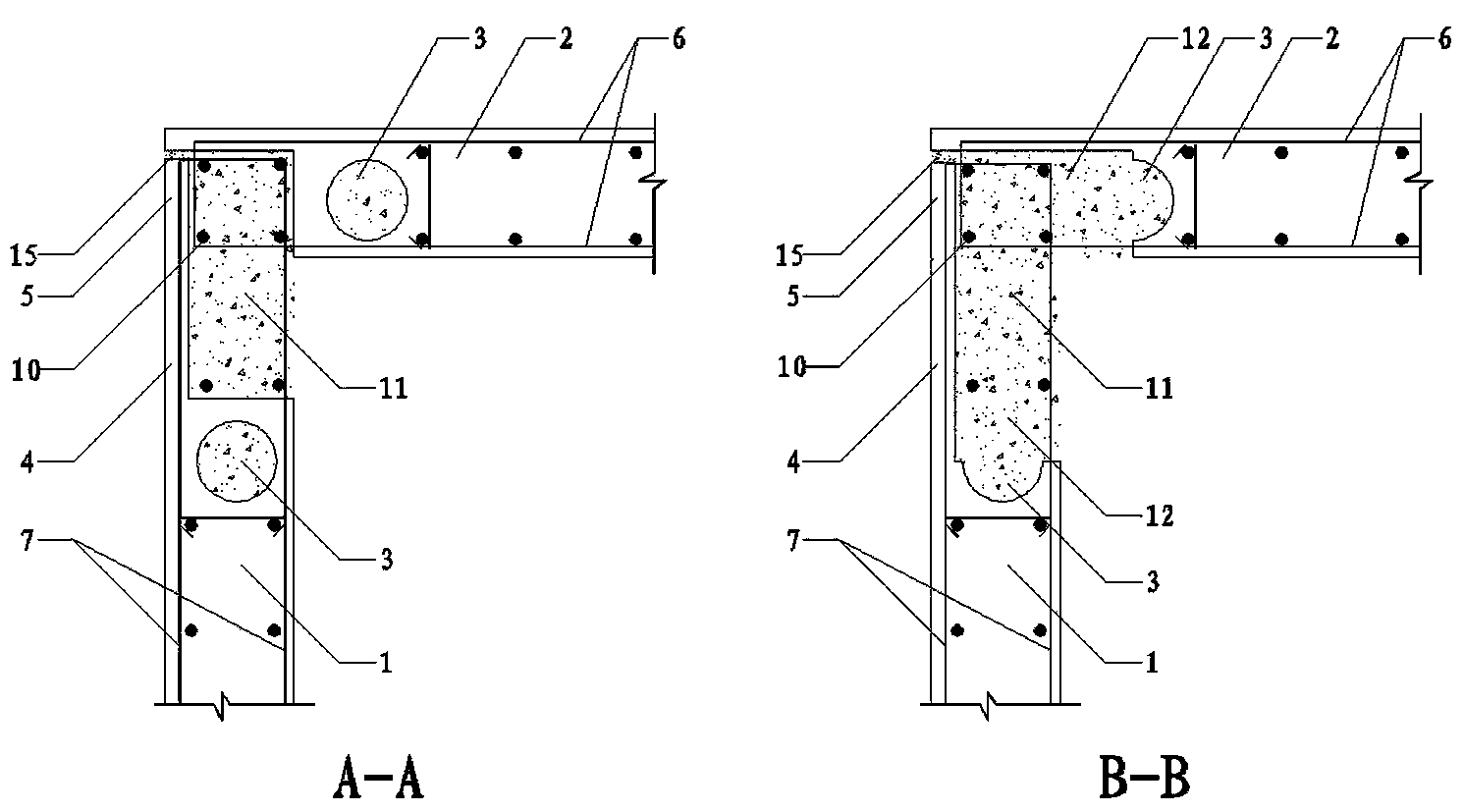

Fabricated frame strip steel bracket long column and construction method thereof

ActiveCN103556781AEasy to processEasy to installStrutsPillarsReinforced concrete columnEarthquake resistance

The invention discloses a fabricated frame strip steel bracket long column and a construction method of the fabricated frame strip steel bracket long column. The column body is a composite column consisting of three parts, namely steel pipe outer reinforced concrete, a steel pipe and steel pipe inner concrete; the steel pipe and the steel pipe inner concrete penetrate through the whole long column; the steel pipe inner concrete is subjected to primary prefabrication to form a steel pipe concrete column; concrete at a steel pipe outer joint or total concrete is poured in advance at the second time; a steel bracket is welded with the steel pipe. The long column has the advantages that 1, a multi-layer frame column is manufactured into a long column, the manufacture is simple, and the installation is convenient; 2, the column body is a composite column, the compression bearing capacity and shear capacity of the column are 2-4 times that of a reinforced concrete column with the same section, and the bearing capacity and anti-seismic property of the frame column are obviously improved; 3, the steel bracket is arranged and can be connected with a steel beam or a cast-in-place reinforcedconcrete beam, and the connection is convenient and reliable; and 4, high-strength concrete in the steel pipe is prefabricated in a factory, and the construction cost of the column is greatly reducedcompared with that of a conventional composite column. Therefore, the long column is suitable for various multi-story and high-rise prefabricated buildings and is wide in market prospects.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

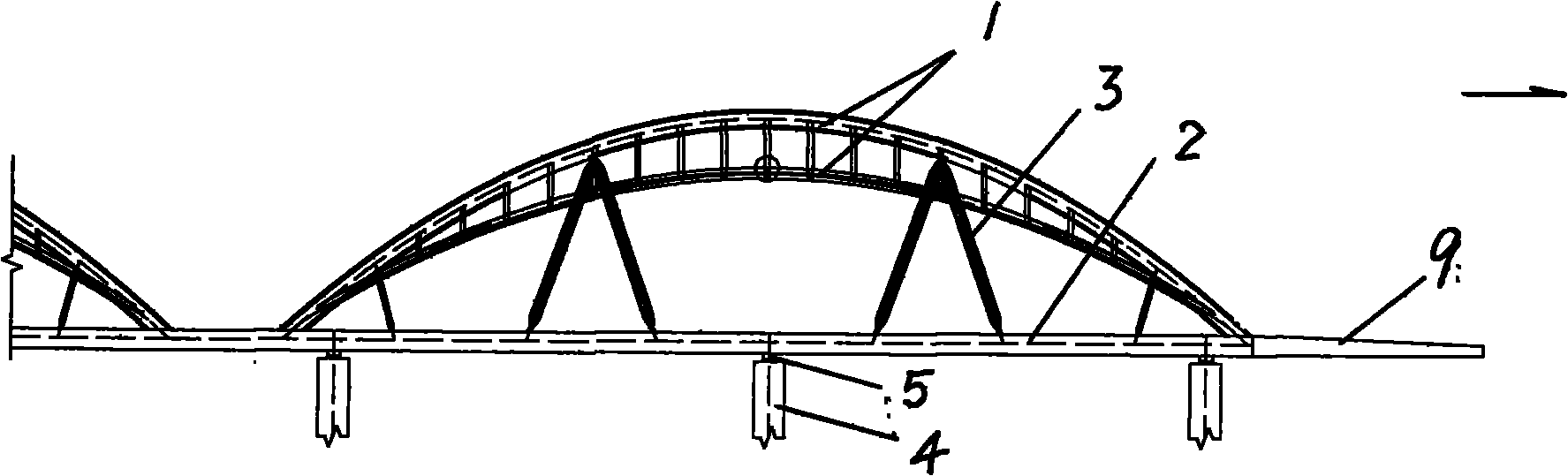

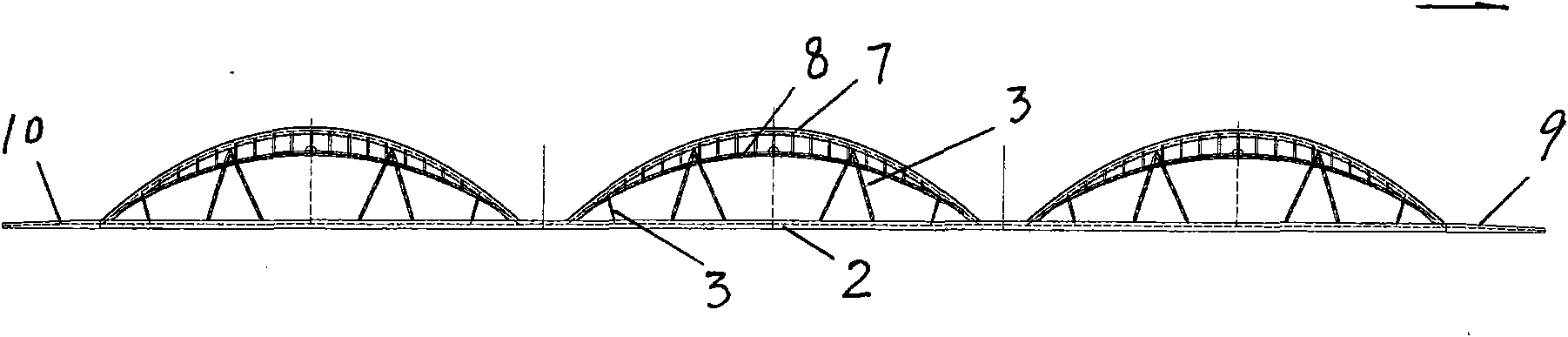

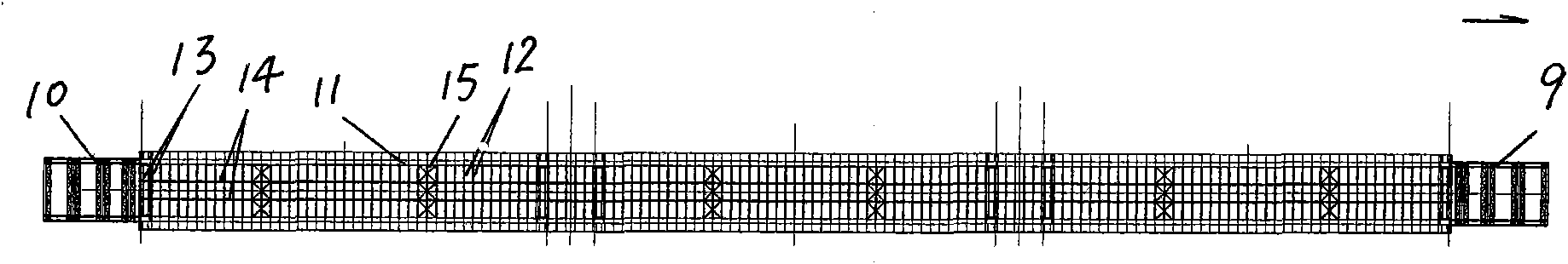

Arch bridge construction method for combined beam-steel arch combined system

ActiveCN102108676AMeet the force requirementsSave the amount of temporary pier foundationBridge erection/assemblyArch-type bridgeBridge deckEngineering

The invention relates to an arch bridge construction method for a combined beam-steel arch combined system. The method is characterized by comprising the following steps: assembling a steel arch, a steel beam and a temporary supporting rod for connecting the steel arch and the steel beam into an arch beam combined system ashore in advance, arranging pushing guide beams at the ends of the arch beam combined system, performing integral pushing by using pushing equipment arranged at the top of each pier, detaching the temporary rods and the pushing guide beams after the pushing is in place, and tensioning hanging rods in batch to perform bridge deck construction. The invention provides the arch bridge construction method completely different from the traditional methods; and the arch bridge construction method has high popularization values on the aspects of applicability, economy, processing quality, construction period and the like, has development significance for later similar engineering, and can be extended to the construction of steel beam-steel arch combined system arch bridges.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Composite bamboo rib combined bolting and shotcrete support for foundation pit supporting and construction method of composite bamboo rib combined bolting and shotcrete support

InactiveCN103362131AReduce construction costsImprove stabilityExcavationsBulkheads/pilesShotcreteSoil stabilization

The invention relates to a composite bamboo rib combined bolting and shotcrete support for foundation pit supporting and a construction method of the composite bamboo rib combined bolting and shotcrete support, and belongs to the technical field of municipal construction. Firstly, deep mixed piles are used for soil stabilization construction, then, excavation is conducted in a layered mode, and a bamboo rib anchoring and shotcreting structure is arranged on a soil body with a certain gradient. The bamboo rib anchoring and shotcreting structure comprises a panel, and further comprises bamboo anchor rods, bamboo ribs, bamboo nails, short steel bars and the like. Holes are transversely drilled in the tail portions of the bamboo anchor rods, and the two phi 10 steel bars which are 20cm long are installed in the holes to form a whole with the panel. The composite bamboo rib combined bolting and shotcrete support for foundation pit supporting and the construction method of the composite bamboo rib combined bolting and shotcrete support have the advantages of being low in construction cost and environmentally friendly, and are suitable for being used in regions where soil layer conditions are poor.

Owner:WUXI DAZHU GEOTECHN TECH +1

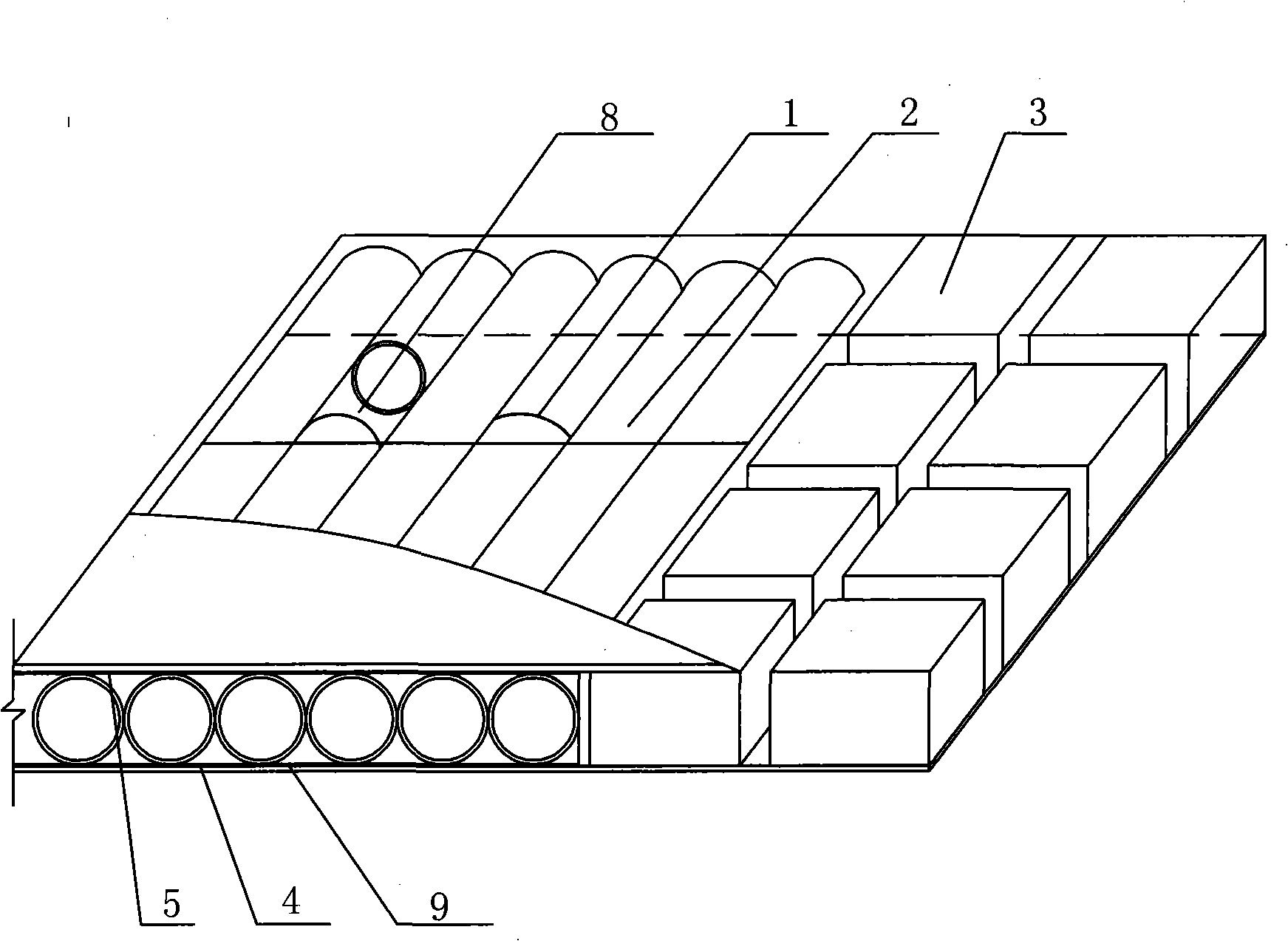

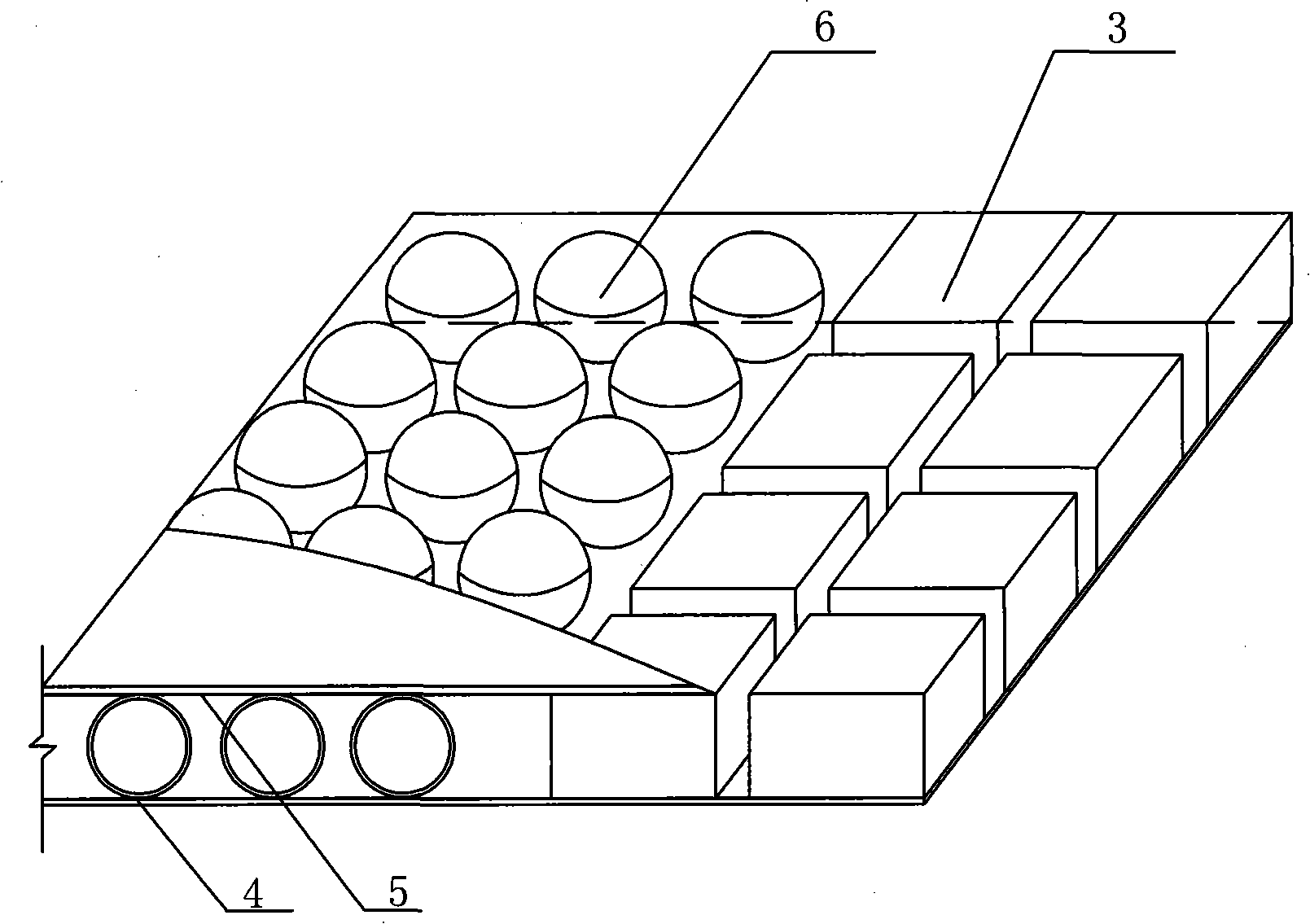

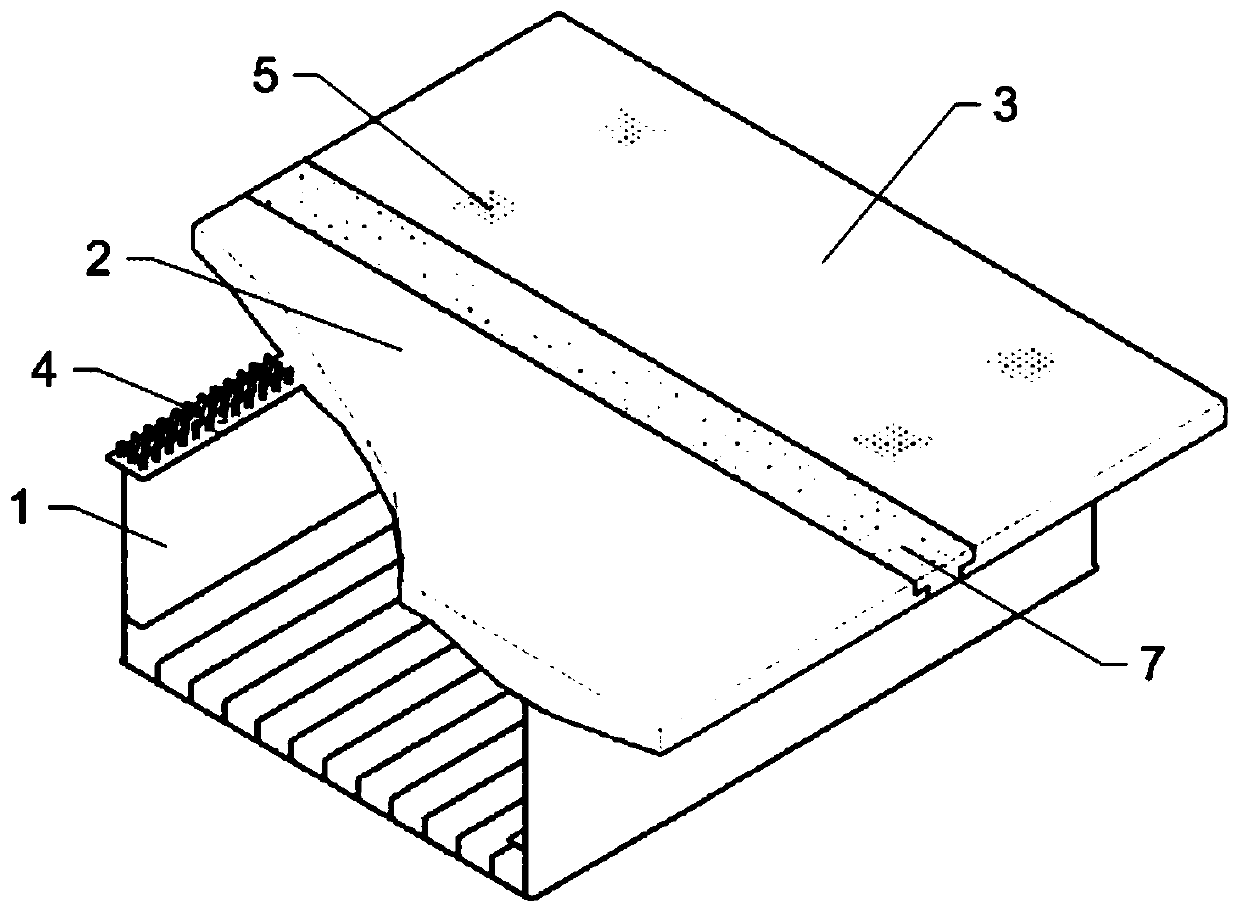

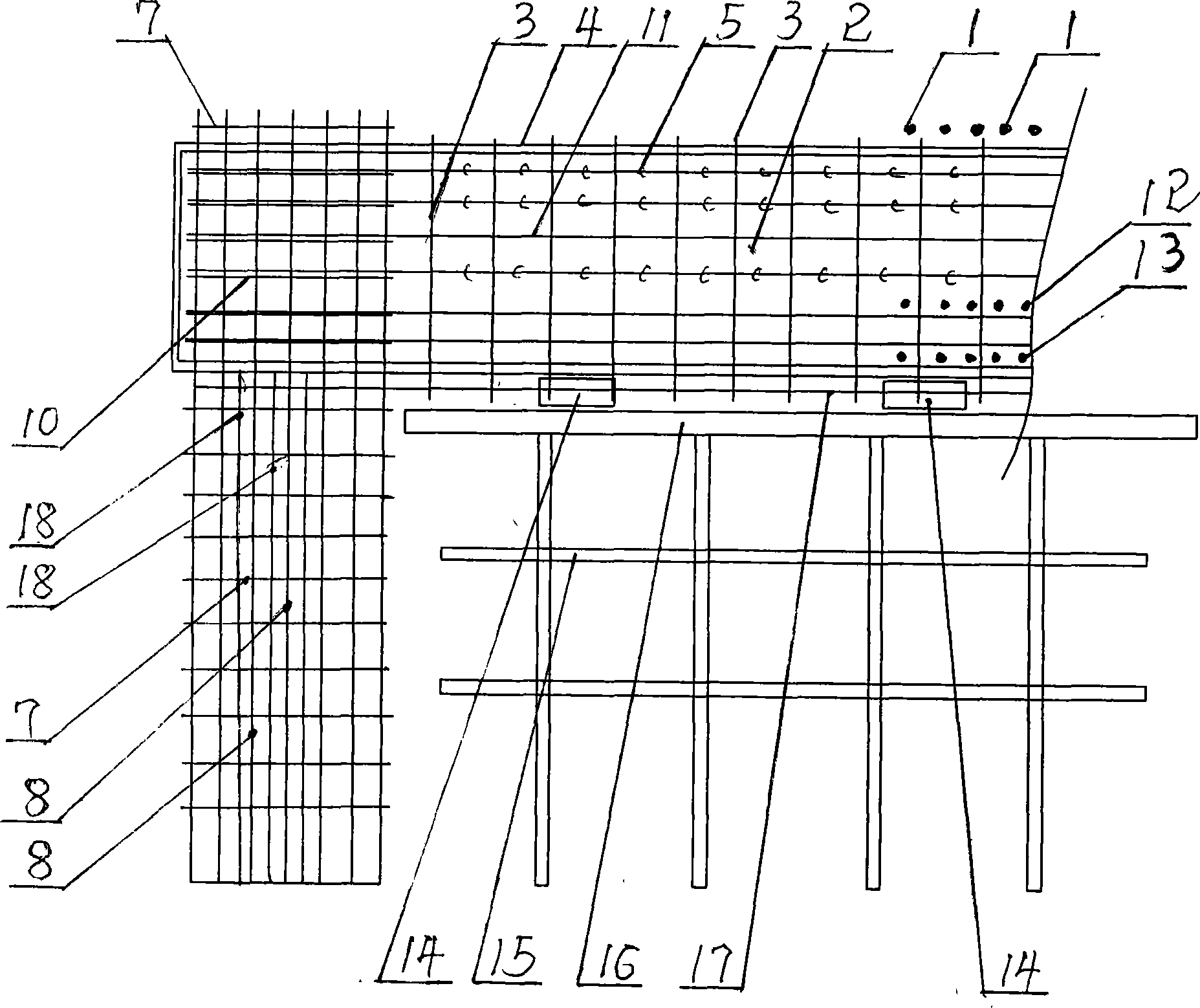

Combined type relief component cast-in-situ hollow building roof and construction method thereof

InactiveCN101324093AFlexible layoutFlexible arrangementFloorsForms/shuttering/falseworksRebarHollow core

The invention belongs to the field of general building construction, in particular to a combination-typed off-loading component cast-in-situ hollow floor and a construction method. The invention adopts a technical proposal that the invention comprises off-loading components which are fixed between an upper layer reinforcement and a lower layer reinforcement by a fixed connecting part; the concrete is filled in the gaps between the off-loading component and the reinforcement in the whole floor and between the off-loading components; the off-loading component comprises at least two cylindrical or box-shaped or spherical off-loading cells; the off-loading components are intermittently or compactly arranged; the off-loading components with different shapes are combined and applied; the type and form of the off-loading components are smartly arranged according to the requirement, thus having the advantages of good porosity, good quality, light self-weight and optimum section.

Owner:王军艇

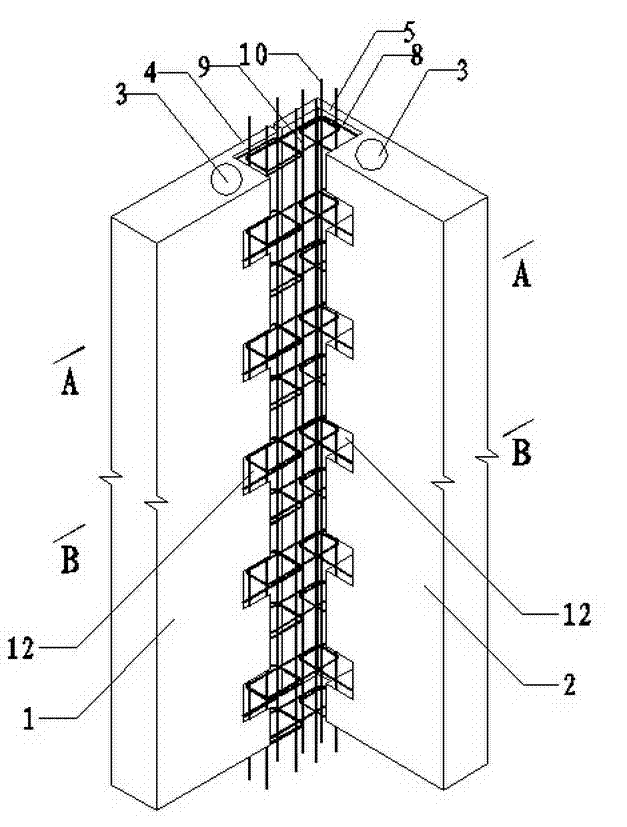

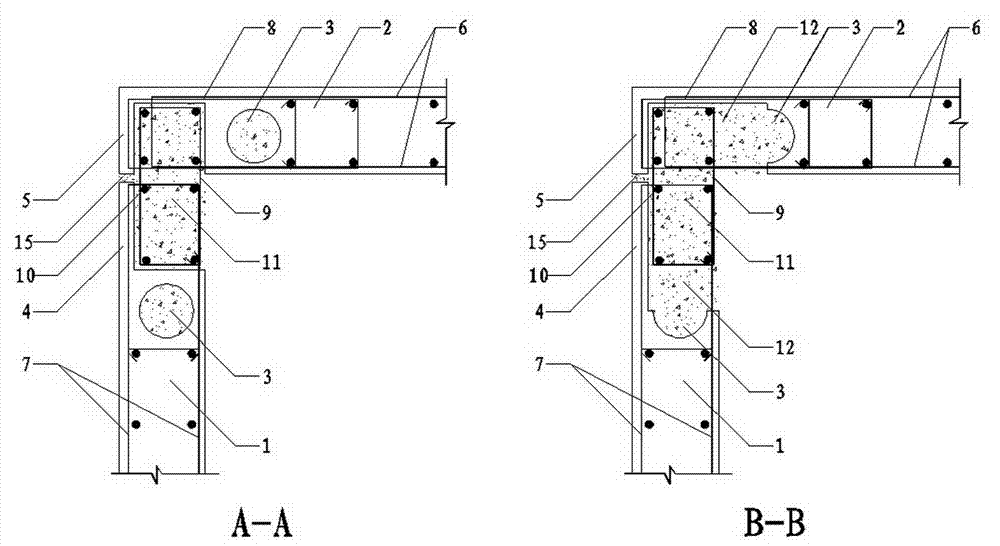

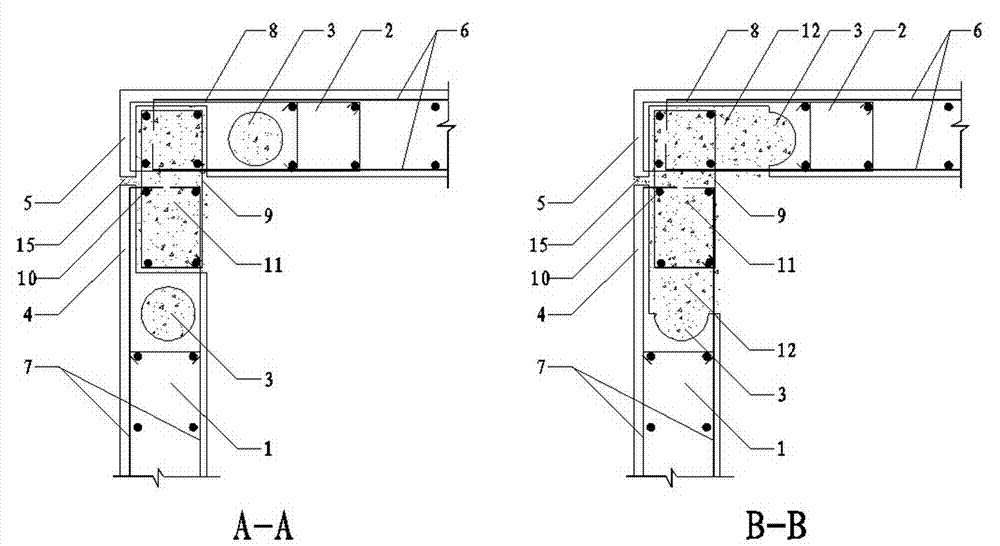

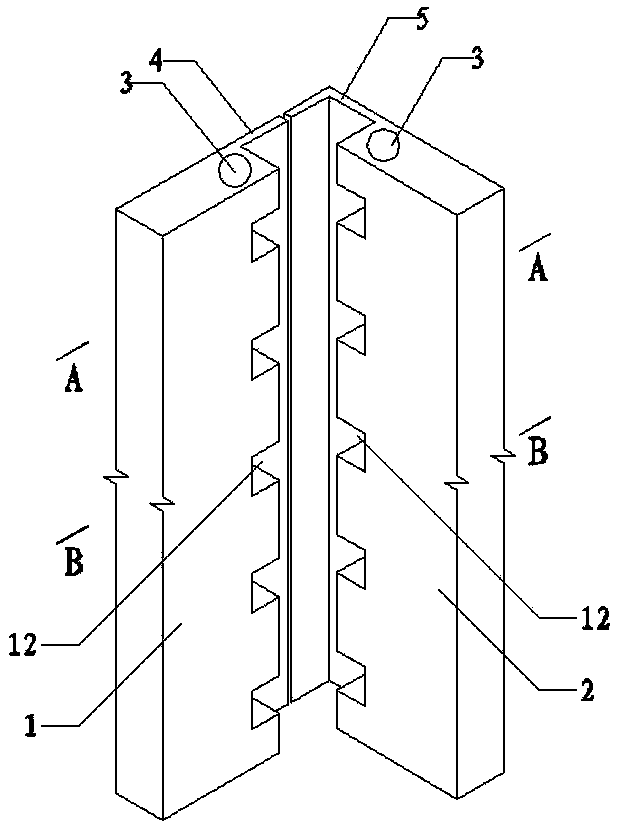

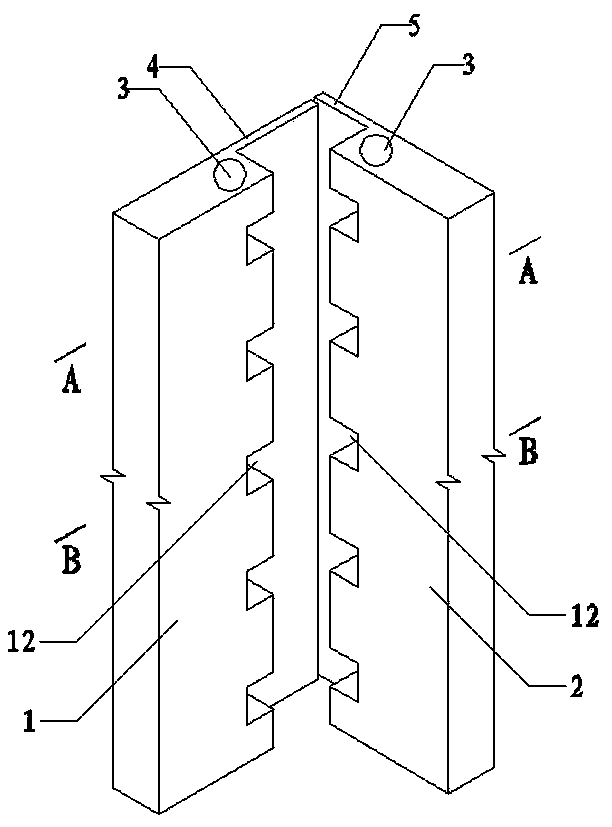

L-shaped precast concrete wall connection

The invention provides an L-shaped precast concrete wall connection, belonging to the technical field of the building structures. The L-shaped precast concrete wall connection comprises a first precast concrete wall and a second precast concrete wall, wherein longitudinal penetrating holes are formed on the precast concrete walls on the connection side in the vicinity of end faces and a plurality of transverse grooves crossing with the longitudinal holes are oppositely formed on the end faces; first and second thin plates extend from the connection-side end faces of the first and second precast concrete walls, respectively; a first horizontal reinforcing steel bar extending to the edge of the first thin plate is arranged in the first precast concrete wall, while a second horizontal reinforcing steel bar and a first embedded column stirrup both extending to the edge of the second thin plate are arranged in the second precast concrete wall; cast-in-place concrete is poured in the space formed by the first and second thin plates, the longitudinal holes and the transverse grooves; and a second embedded column stirrup and a vertical reinforcing steel bar are arranged in the cast-in-place concrete. The L-shaped precast concrete wall connection is capable of improving the integrity of the assembled integrated concrete structure and improving the performance of the building structures.

Owner:初明进

Closed type cantilever scaffold system and construction method

ActiveCN109629810AGuaranteed to be stable and safeInnovative designScaffold accessoriesBuilding support scaffoldsFalseworkHigh intensity

The invention discloses a closed type cantilever scaffold system and a construction method thereof. The closed type cantilever scaffold system comprises a cantilever steel beam through-wall structure,a cantilever steel beam balcony slab placement structure for containing a balcony slab and manufacturing a cantilever balcony, a closed type cantilever scaffold system for building a scaffold, and anoverhead cantilever formwork protective shed for erecting a protective shed, wherein the cantilever steel beam through-wall structure is used for through-wall fixing construction of a structural steel girder; an anchoring device adopting the cantilever steel beam through-wall structure is convenient to install and flexible to disassemble, the turnover utilization rate can be effectively increased, and an integrated high-intensity embedded U-shaped pull ring and an inclined strut steel tube shaping connecting beam piece are adopted, so that the balcony slab is effectively prevented from beingdamage by crushing, an adjustable vertical rod is adopted for compression joint of a fixing rod and a wall column reinforcing type connecting wall rod, the application range of the scaffold is enlarged, the overhead cantilever formwork dual-layer protective shed is adopted, safety risk in external frame erection is reduced, and safety construction is facilitated.

Owner:浙江恒鸿建设有限公司

Fabricated self-insulation single face laminated shearing force wall board and casting method thereof

InactiveCN109866315AImprove performanceNot easy to damageDischarging arrangementWallsFoam concreteThermal insulation

The invention relates to a fabricated self-insulation single face laminated shearing force wall board and a casting method thereof. The casting method includes the steps that a laminated shearing force wall rebar framework and a basalt fiber reinforced polymer (BFRP) rib mesh piece in an outer wythe precast wall board are correspondingly bonded and manufactured, and insulation connecting parts arefixedly bonded on the rebar framework; and the rebar framework is placed on a protective layer cushion block of a casting framework platform, inner wythe wall board concrete is cast, the inner wytheprecast wall board after the inner wythe wall board concrete is cured to design strength is overturned by 180 degrees and moves to the upper part of another casting framework platform, the BFRP rib mesh piece is placed on a protective layer cushion block of another casting framework platform, outer wythe foam concrete is casted, the insulation connecting parts are pressed into the outer wythe concrete before initial set of the outer wythe foam concrete, and formwork stripping is conducted when the strength is reached. According to the fabricated self-insulation single face laminated shearing force wall board and the casting method thereof, a BFRP is treated as a bar material of the built-in mesh piece in the outer wythe wall board and a material of the connecting parts, the good thermal insulation performance of outer wythe foam concrete boards can be guaranteed, and stress requirements of the laminated wall board can also be met.

Owner:WUHAN UNIV OF TECH

Manufacturing method for double-rhombus connection structure

InactiveCN105171199AMeet the styling requirementsMeet the force requirementsStrutsArc welding apparatusSubmerged arc weldingCarbon dioxide

The invention provides a manufacturing method for a double-rhombus connection structure. The method includes the following steps that two flange plates and two webs are spliced into the side faces of a single-rhombus box; strip-shaped reserved carbon dioxide gas arc welding and submerged-arc welding gaps and welding grooves are formed between the flange plates and the webs, and full-penetration welding is performed; a rhombus-shaped inner partition plate connected with the side faces in a T shape is installed at the position, close to the middle, inside the single-rhombus box and provided with a grouting hole and an exhausting hole; a rhombus-shaped sealing plate connected with the side faces in a T shape is installed at the position, close to the end, inside the single-rhombus box; strip-shaped reserved carbon dioxide gas arc welding and submerged-arc welding gaps and welding grooves are formed in the joints of the rhombus-shaped inner partition plate, the flange plates and the webs and the joints of the rhombus-shaped sealing plate, the flange plates and the webs, and full-penetration welding is performed; and two single single-rhombus boxes are connected into the double-rhombus connection structure through connecting plates between double-rhombus columns. The manufacturing method is scientific, reasonable and capable of making manufacturing easy and guaranteeing welding and quality.

Owner:湖北精工钢结构有限公司

Negative bending moment area UHPC treatment steel-concrete composite structure and preparation method thereof

PendingCN110241724AIncrease cracking loadSolve crackingBridge structural detailsBridge materialsBridge deckComposite beams

The invention discloses a negative bending moment area UHPC treatment steel-concrete composite structure and a preparation method thereof. An UHPC bridge deck slab is adopted within a segment length of a steel-concrete composite structure negative bending moment area; and a top flange of an adjacent steel girder is welded (bolted) to a pier top. For a steel-concrete simply supported bridge deck continuous composite structural beam, the negative bending moment area UHPC treatment steel-concrete composite structure has the advantages that the cracking load of the negative bending moment area composite beam can be obviously increased; and due to smaller fracture interval, the development of a concrete crack can be obviously suppressed; and the excellent anti-cracking performance can effectively solve the cracking problem of the negative bending moment area.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

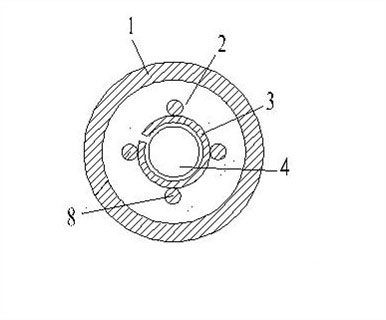

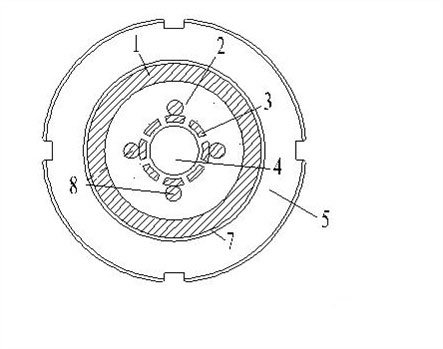

Main bearing for wind power generation

InactiveCN101363472AReduce shockExtended service lifeRolling contact bearingsShaftsUpper limbEngineering

The invention relates to a wind power generation main bearing which belongs to the aerogenerator field, the wind power generation main bearing is characterized by comprising a main bearing upper limb, a main bearing lower limb, an anti-thrust cylindrical roller and a holder; the inner sides of the main bearing inner limb and the main bearing lower limb are provided with two rows of anti-thrust cylindrical rollers; the outer side of the main bearing inner limb is provided with a single row of centripetal cylindrical rollers and the cylindrical rollers are placed on the holder. The bearing of the invention saves a main shaft so that the impact of an original stiff shaft on a gear box and a generator can be reduced greatly and the service life of the gear box and the generator can be prolonged; the transmission of power can be realized well and the main bearing of the invention is easy to be repaired and detached. The main bearing can stand axial force with big load and big radial load, which can be well suitable for the working condition of aerogenerators with no main shaft, thus meeting the stress requirements of the aerogenerator.

Owner:包头市汇全稀土实业(集团)有限公司

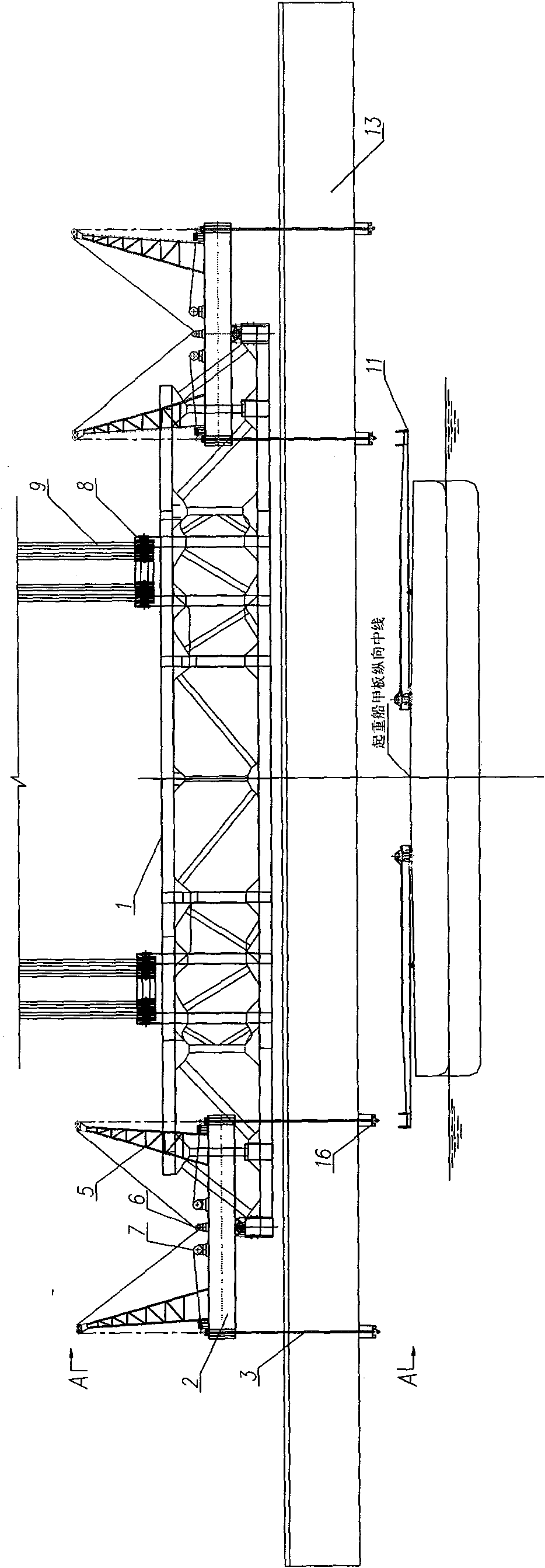

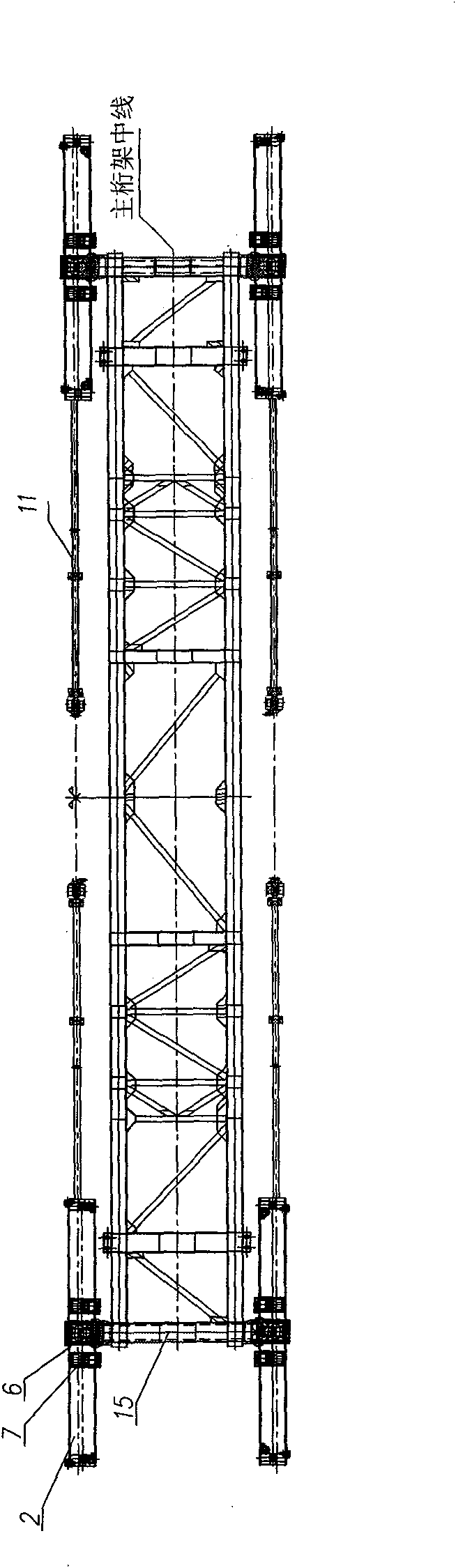

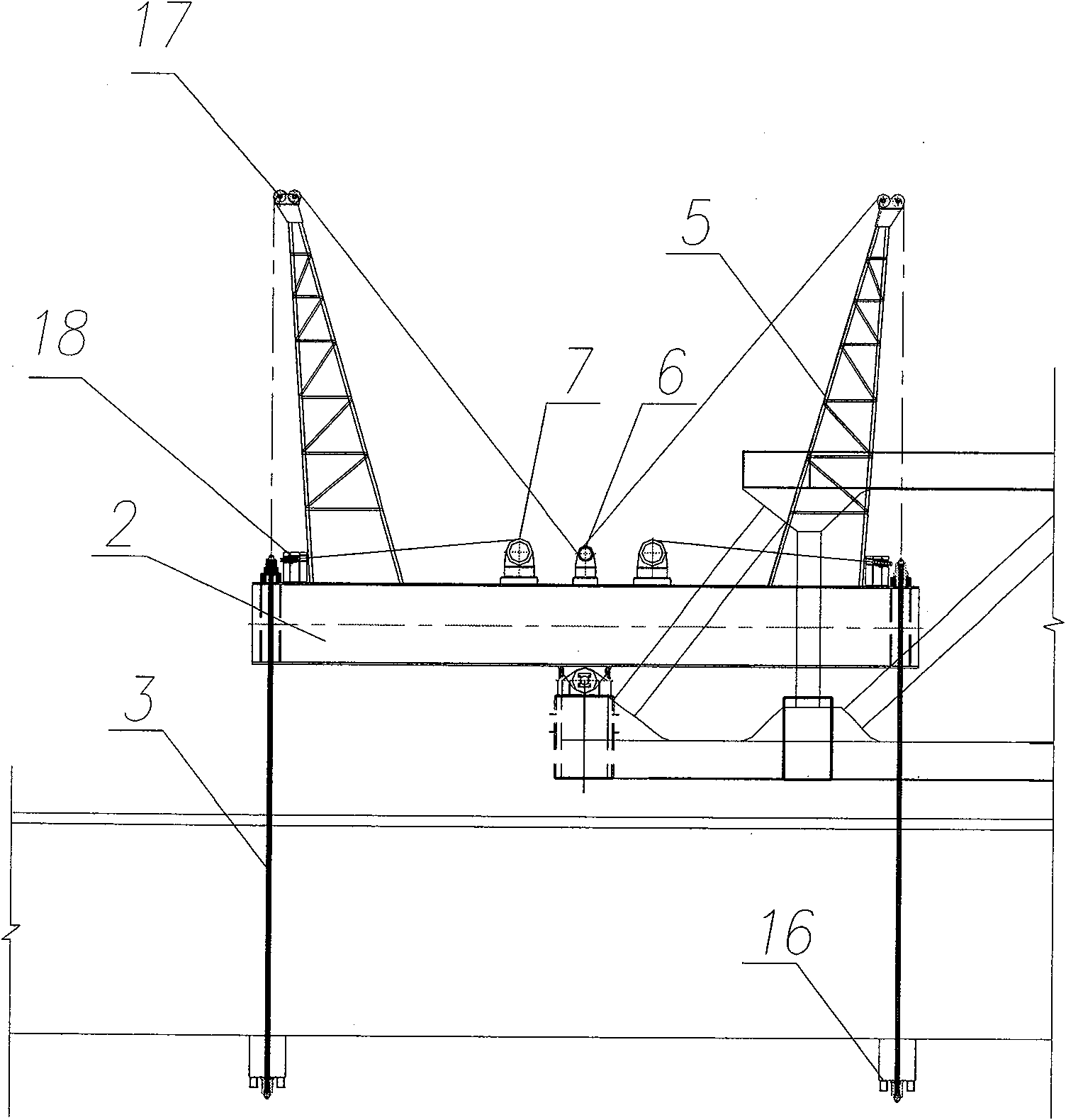

Hanging device of large-scale over-long box girder

ActiveCN101591890AShorten the lengthReduce the overall heightCargo handling apparatusPassenger handling apparatusJoistBox girder

The invention discloses a hanging device of a large-scale over-long box girder, comprising a shoulder pole main truss of a truss structure, wherein the truss structure can be connected with a hoisting device. The shoulder pole main truss is connected with a hanging point distribution beam, and a traction and connection device of the large-scale over-long box girder is arranged on the hanging point distribution beam and is connected with a supporting component joist used for the large-scale over-long box girder. In the invention, the hanging point distribution beam is arranged on the shoulder pole main truss and is utilized to realize the hanging of the large-scale over-long box girder. The hanging device of a large-scale over-long box girder is safe and reliable, is easy and convenient to operate and is suitable for the hanging construction of the large-scale over-long box girder.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

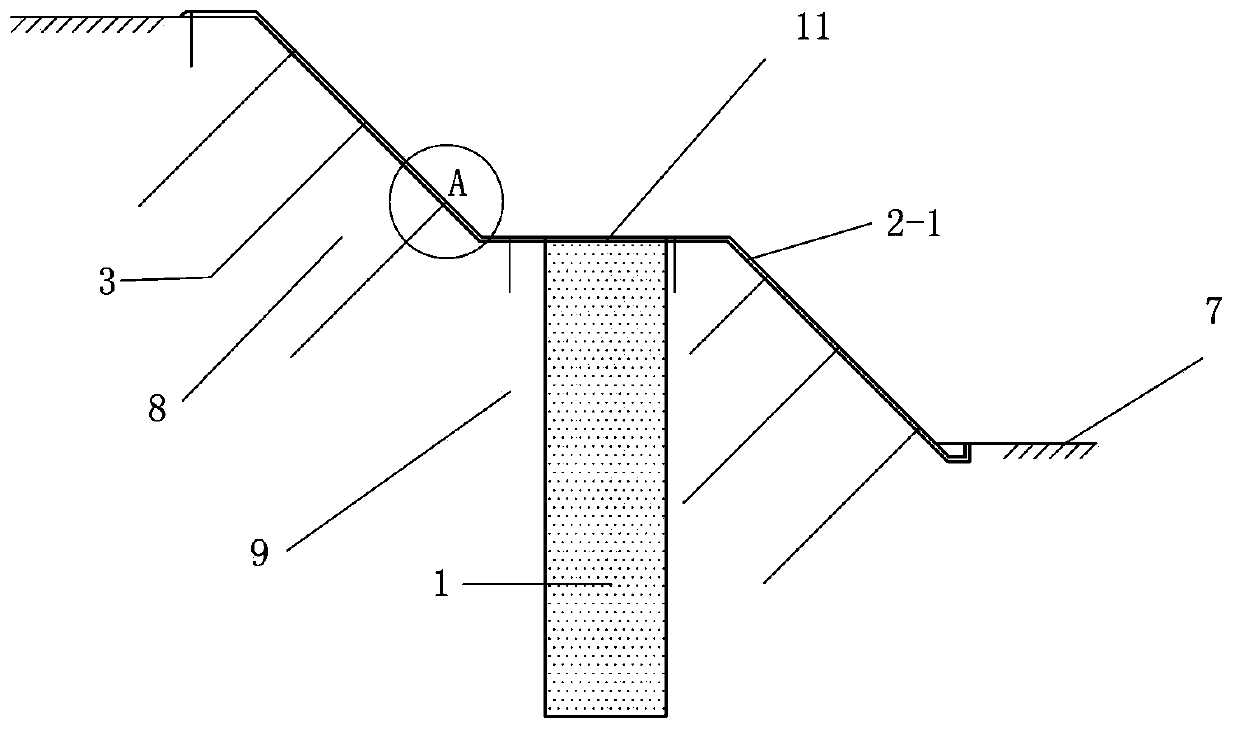

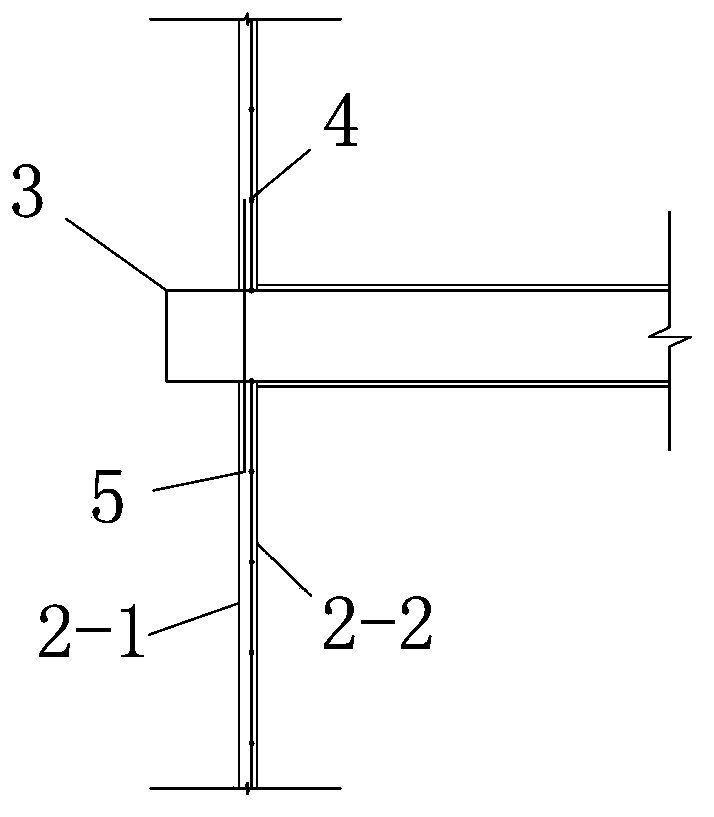

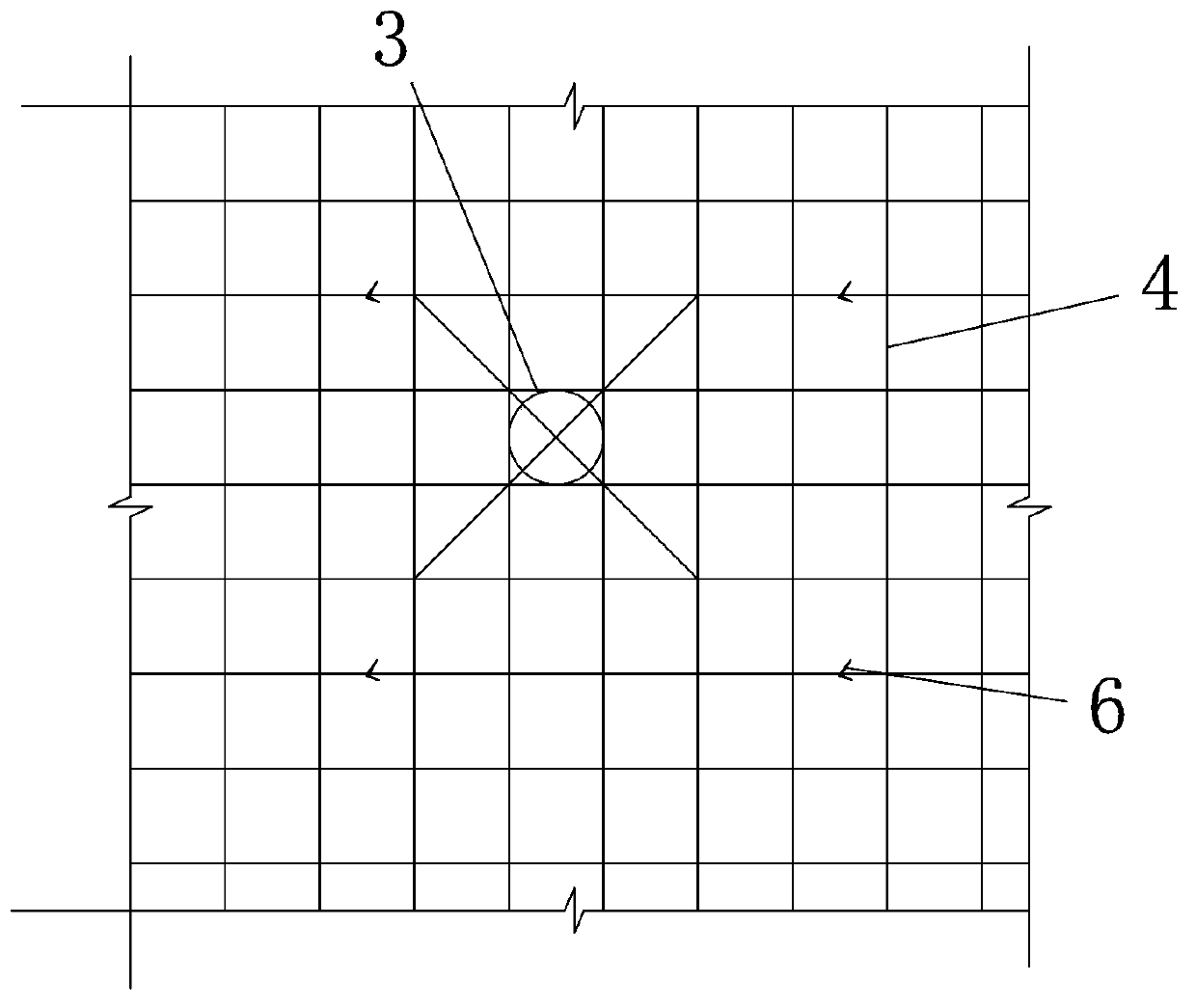

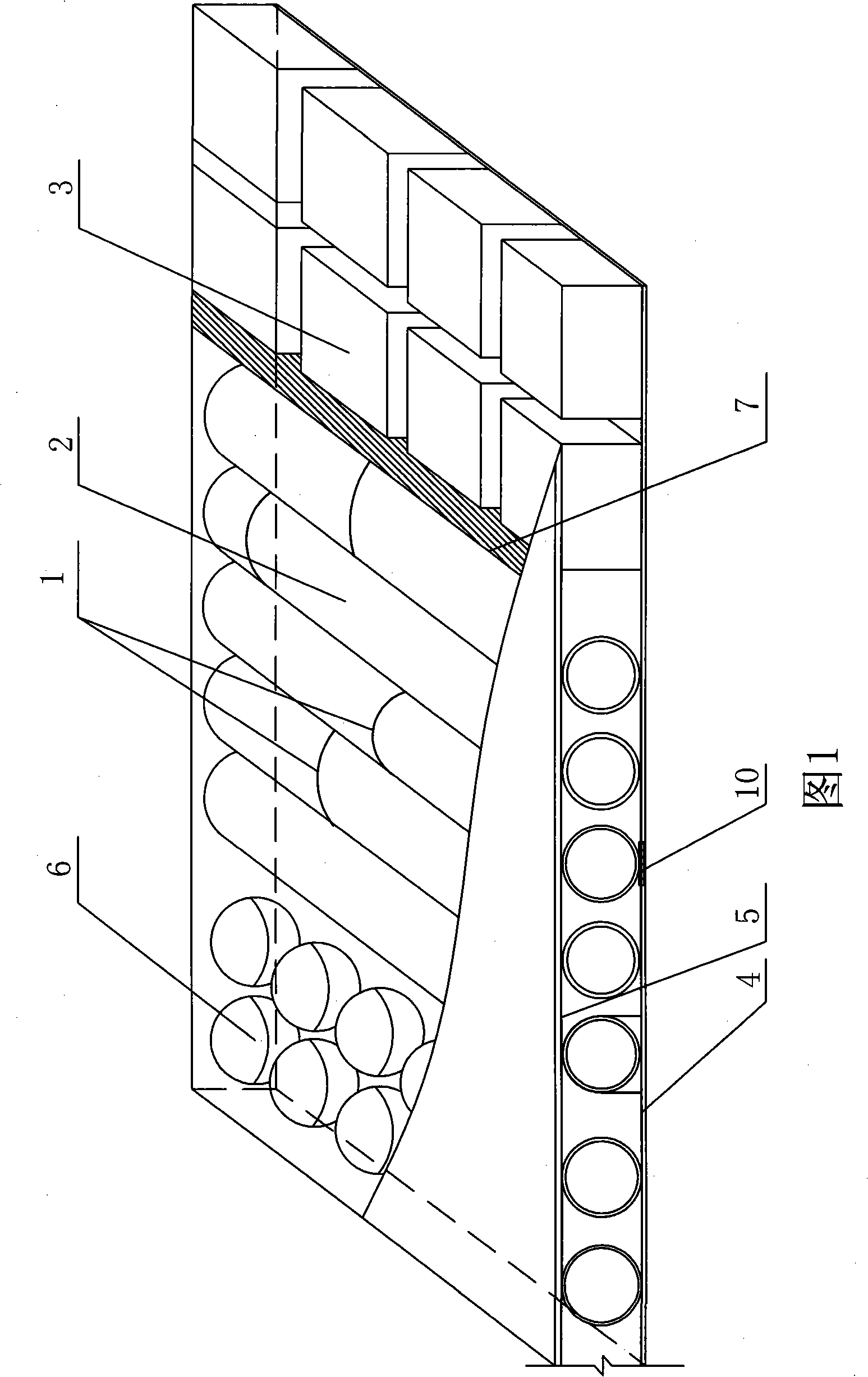

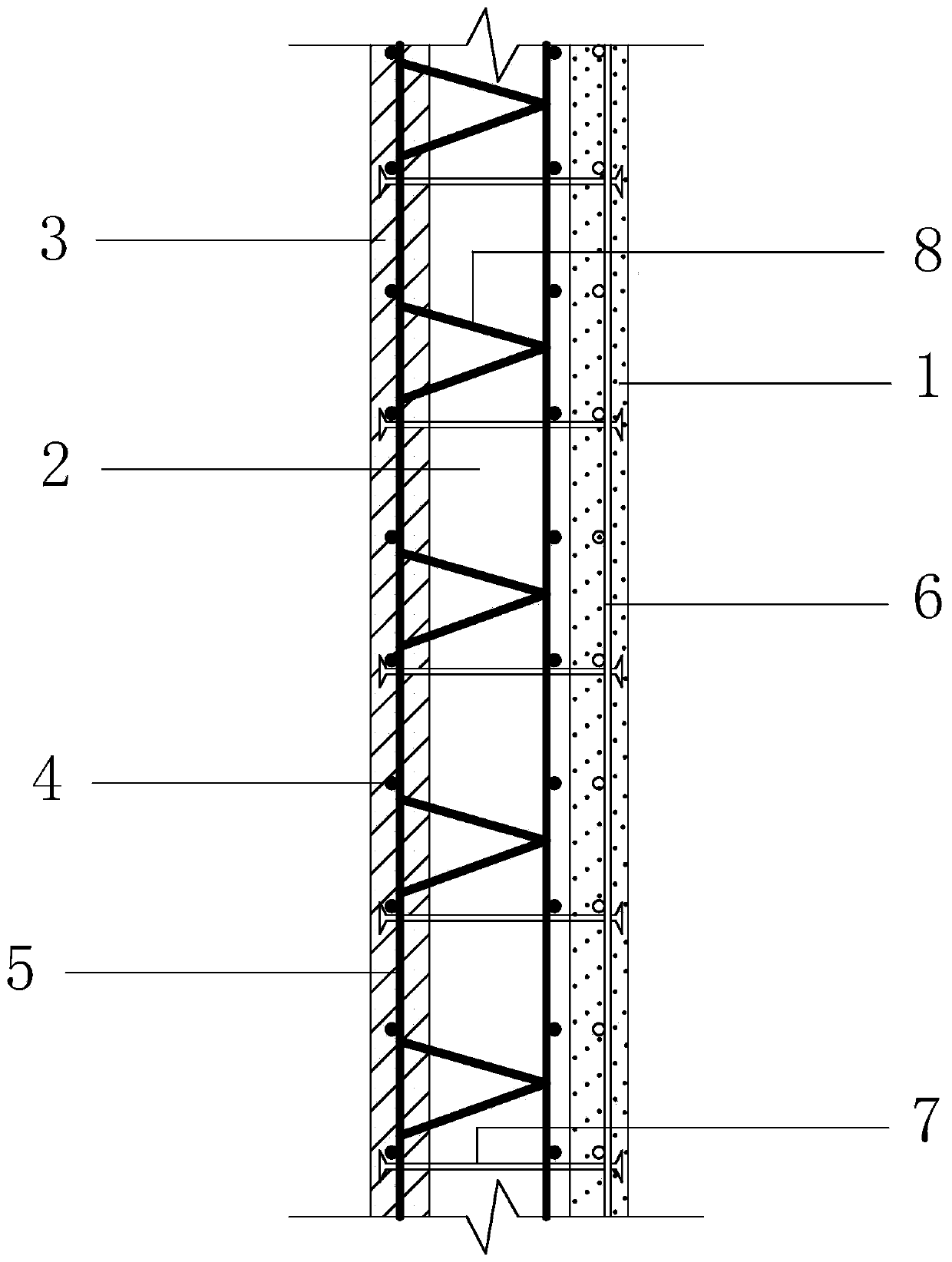

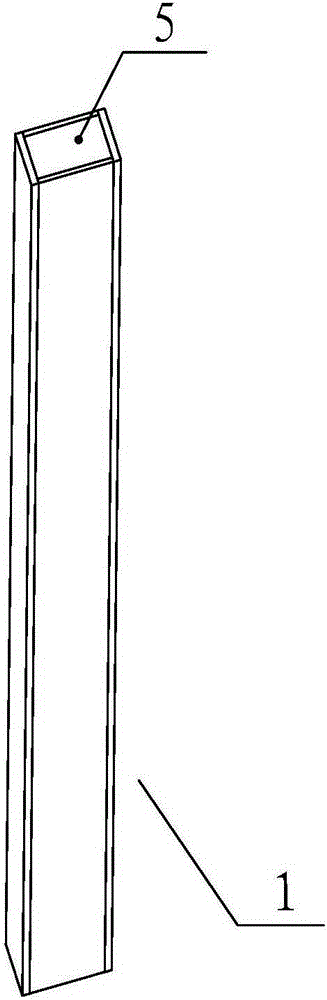

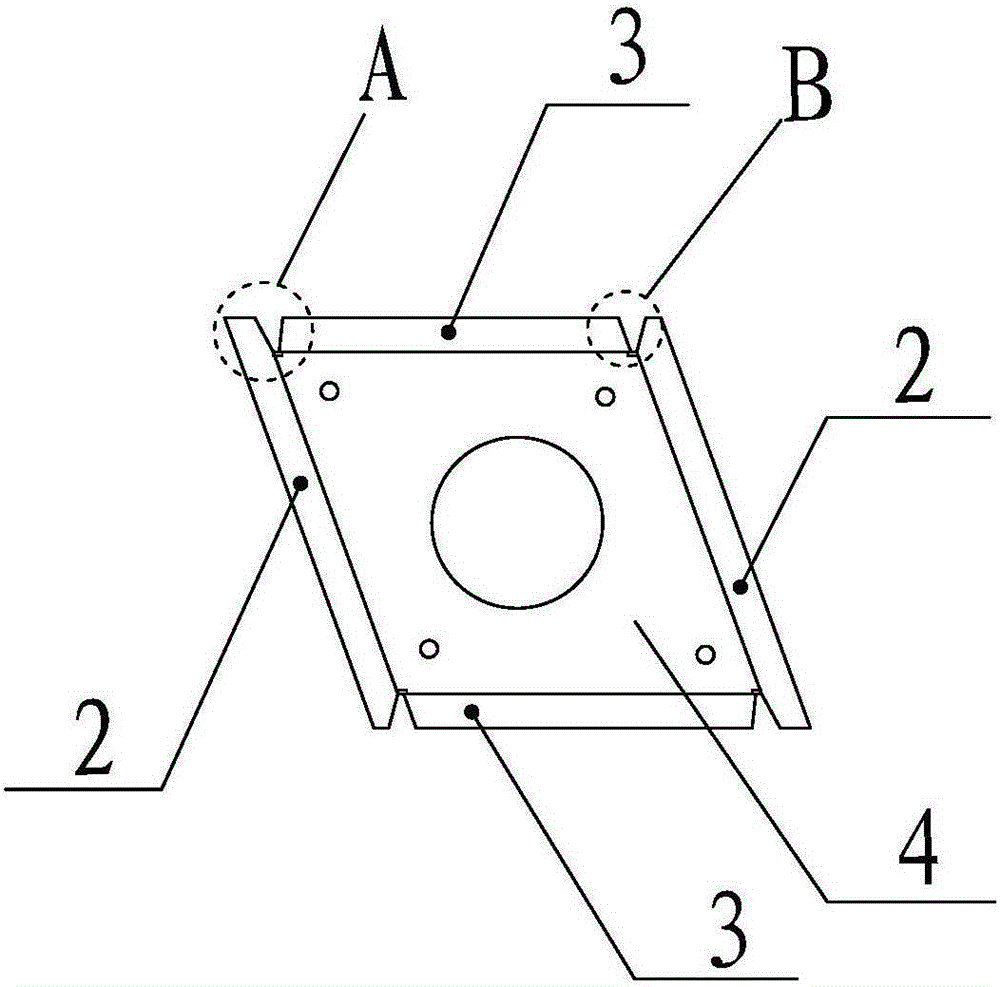

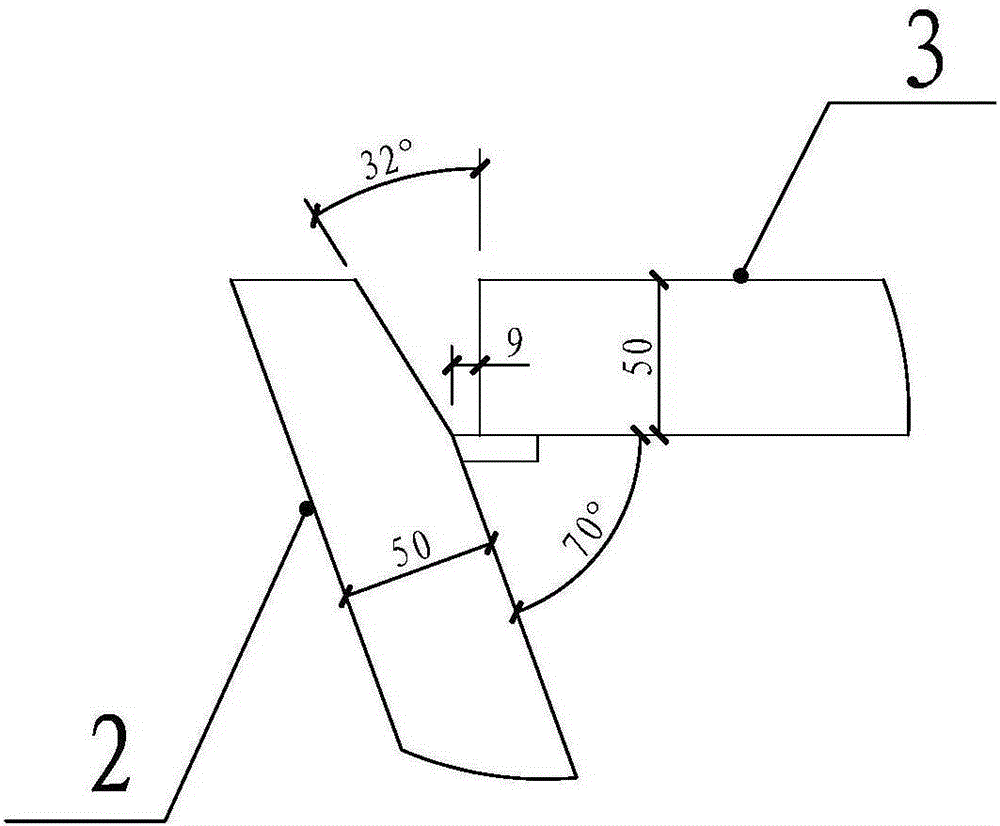

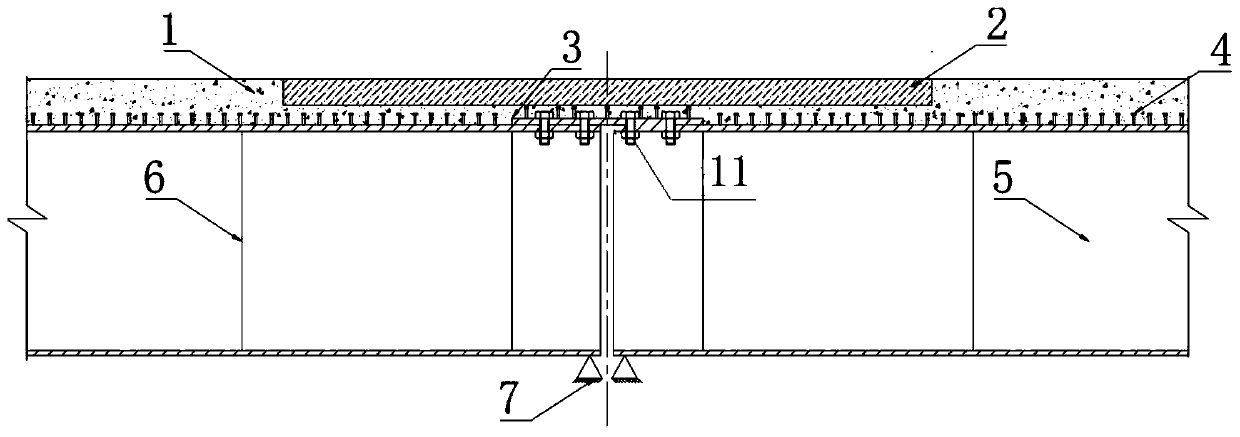

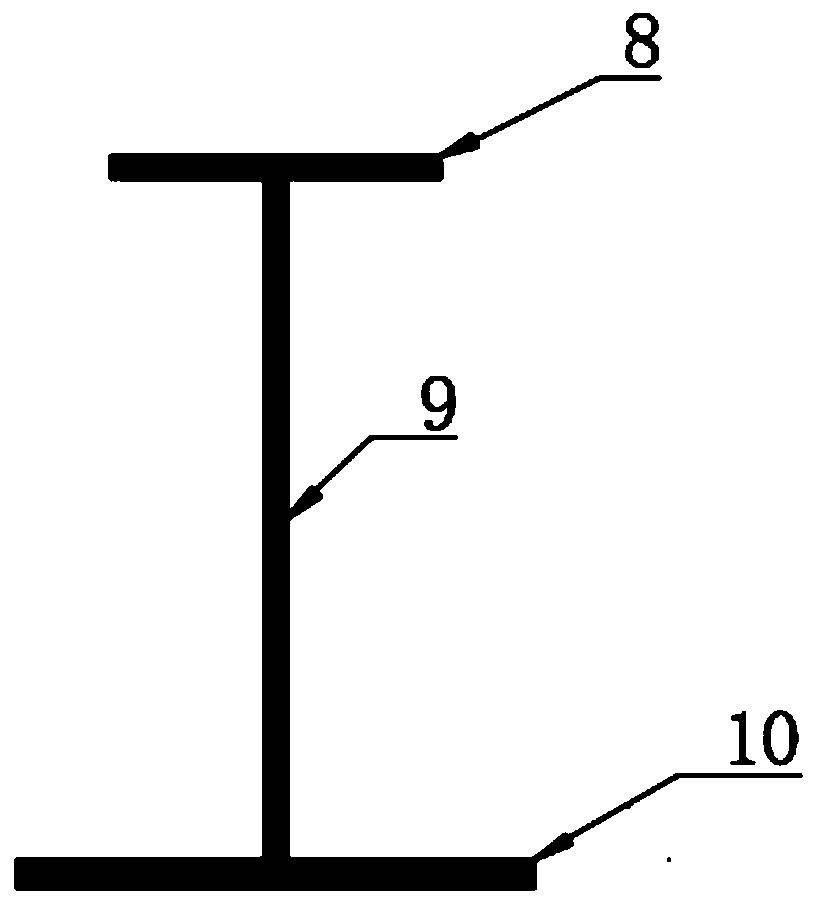

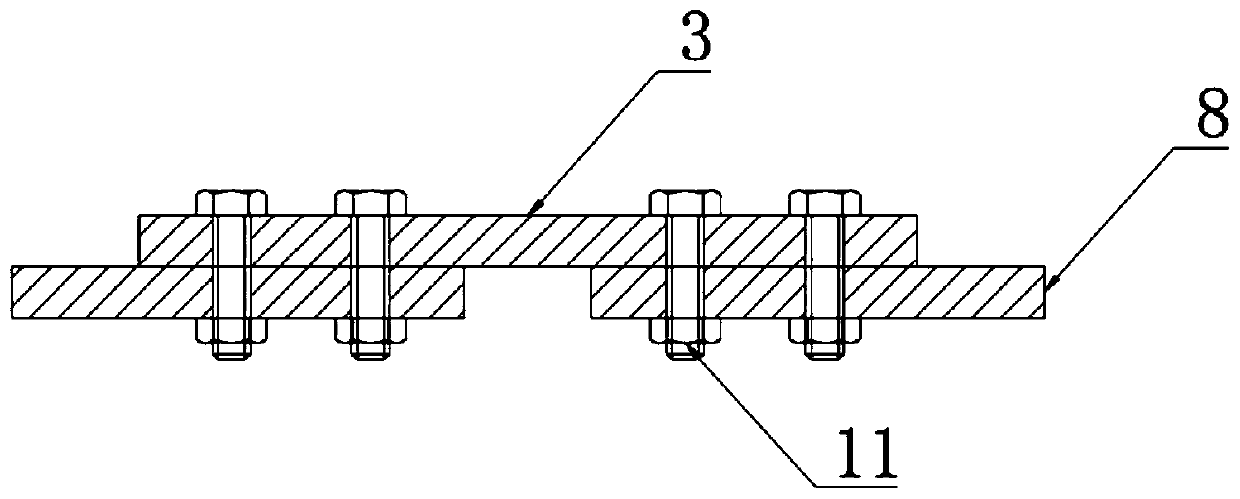

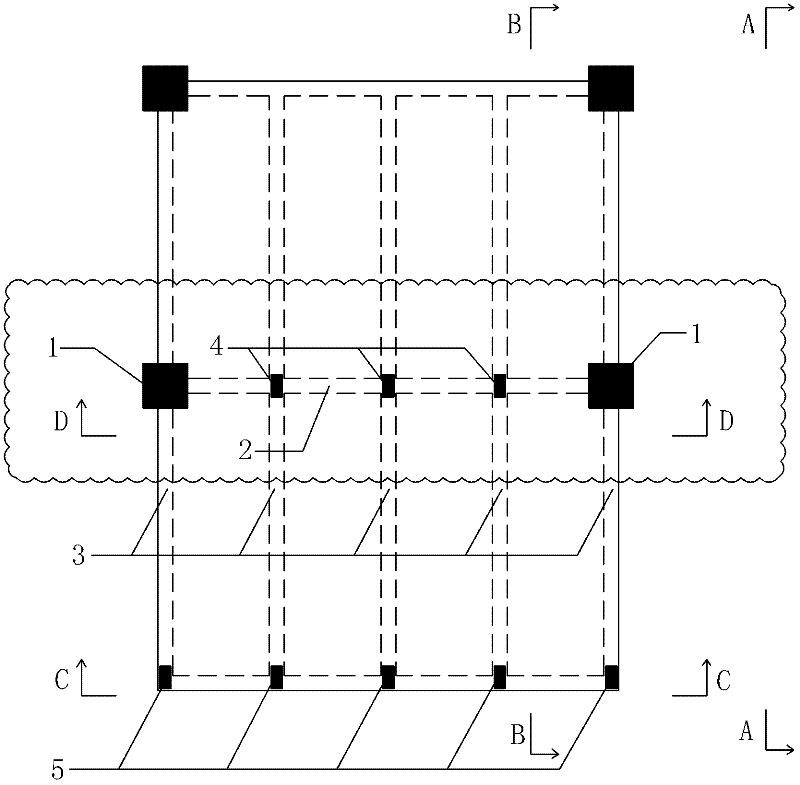

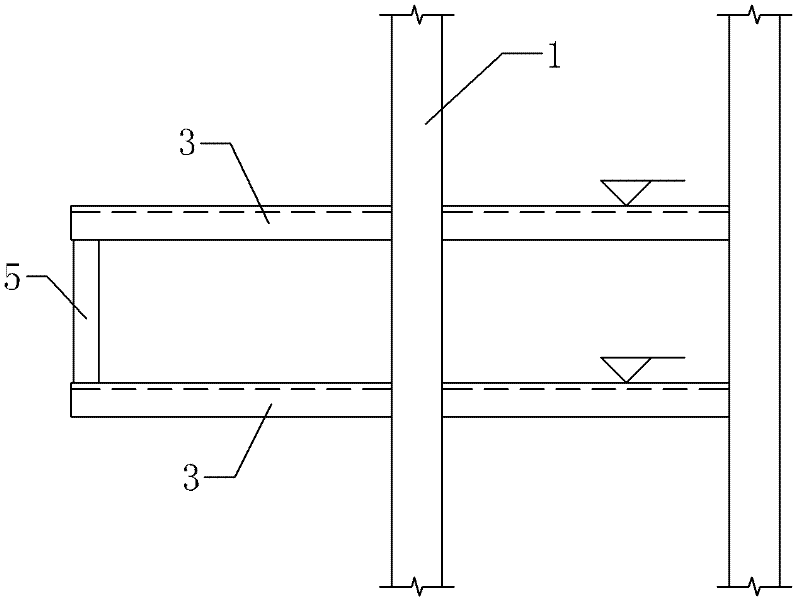

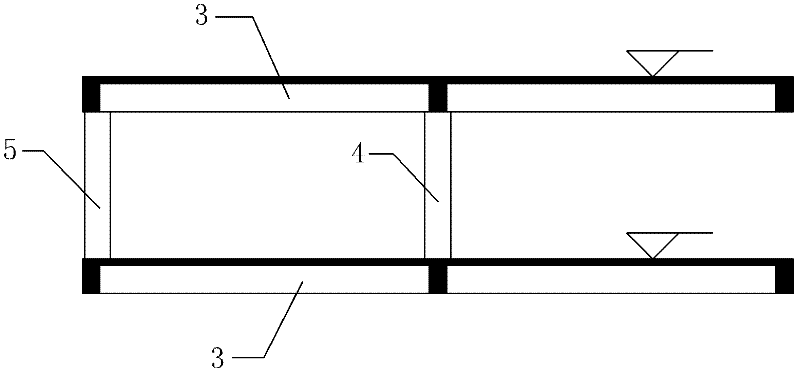

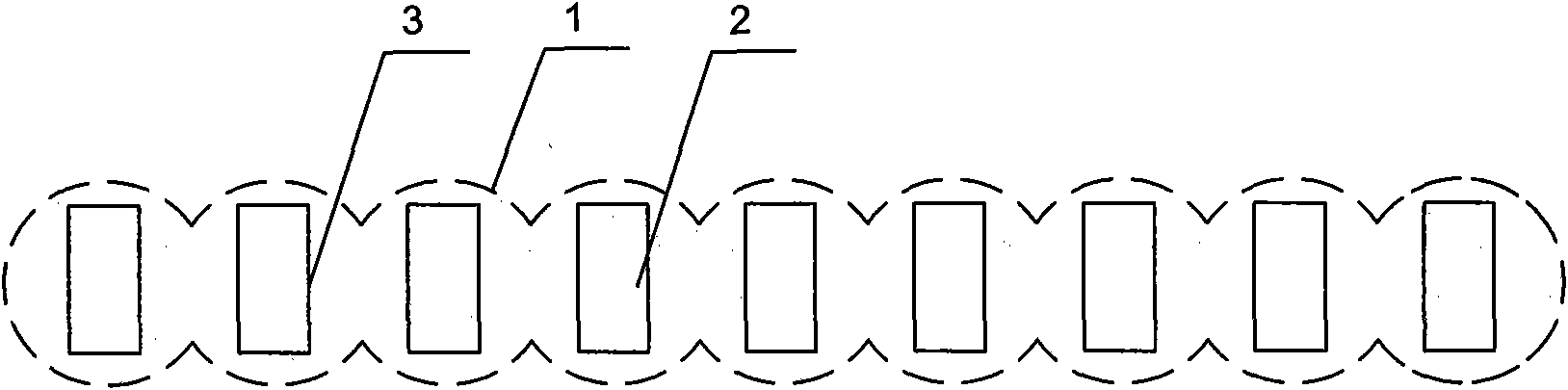

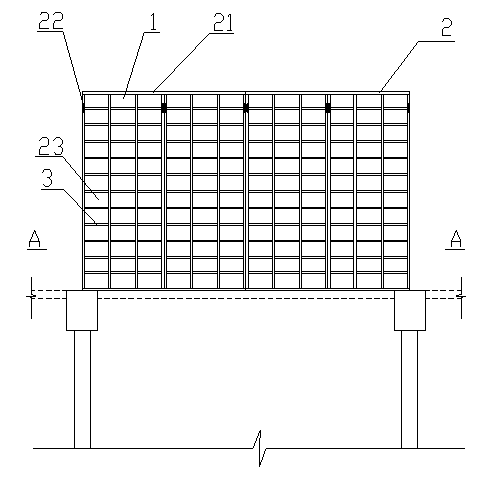

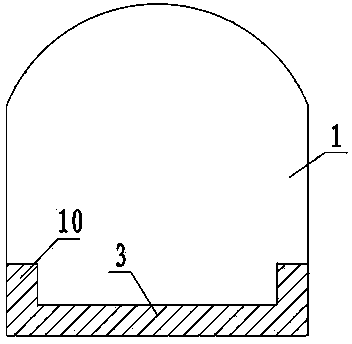

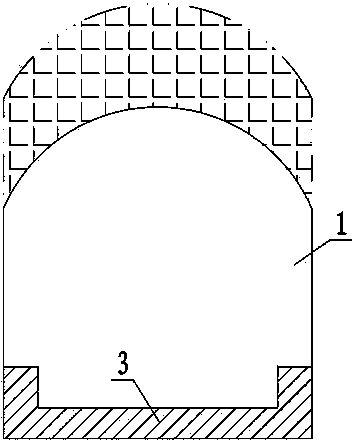

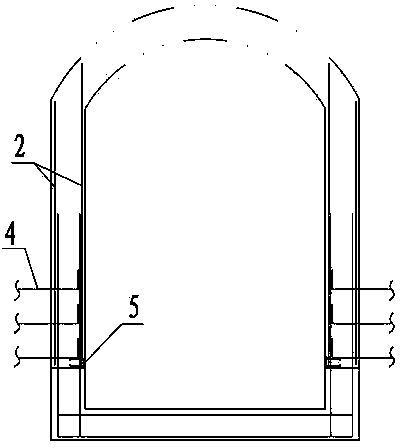

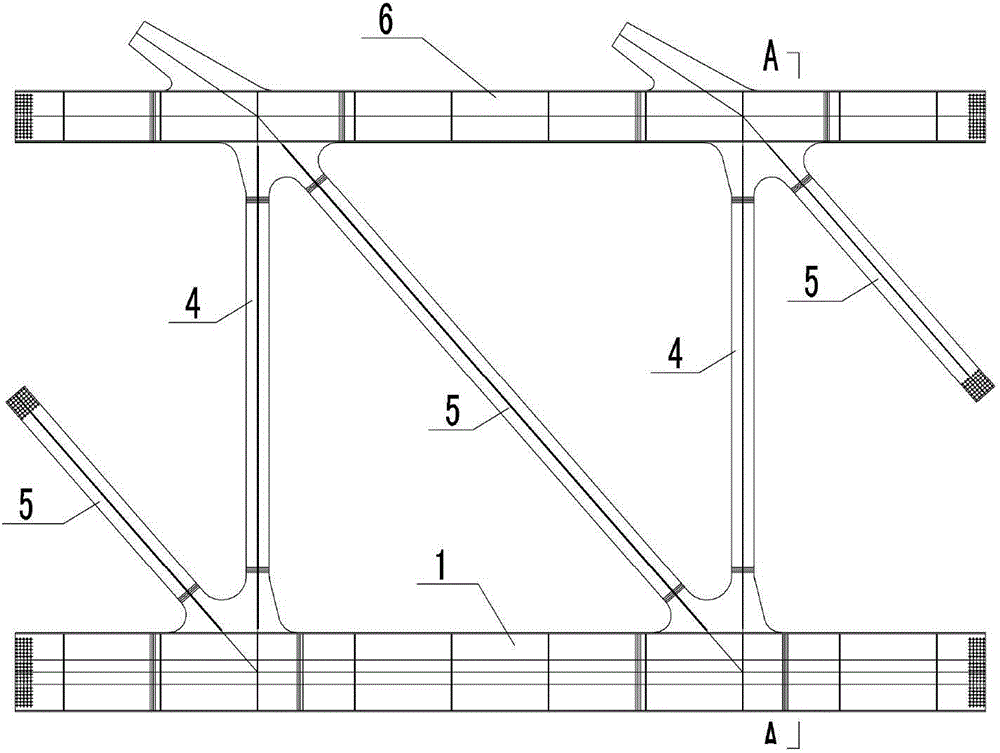

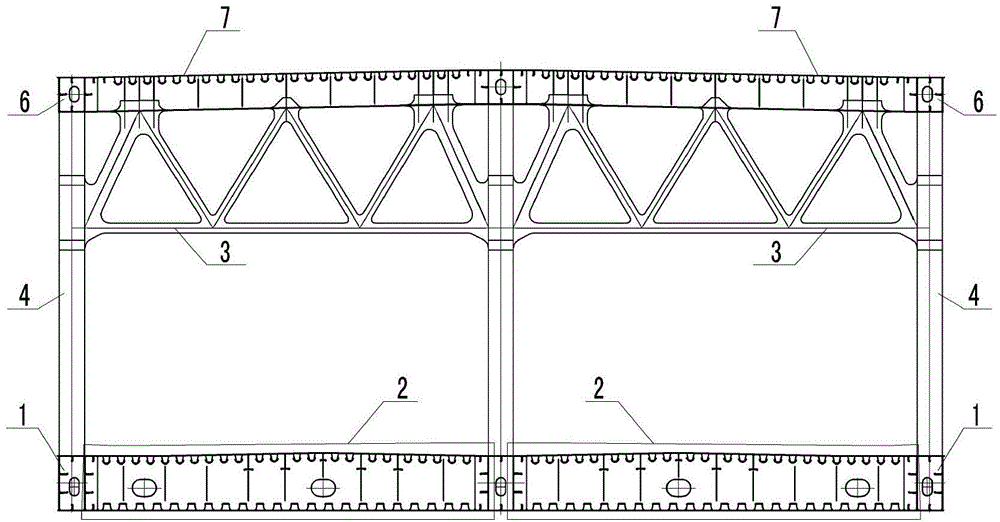

Double-layer vierendeel truss structure system of large cantilever structure

The invention discloses a double-layer vierendeel truss structure system of a large cantilever structure, comprising a floor frame. The floor frame comprises frame columns (1), frame beams (2) and cantilever beams (3). The double-layer vierendeel truss structure system of the large cantilever structure is characterized in that a plurality of main truss columns (4) are arranged between the upper and lower frame beams (2) of the floor, the upper and lower frame beams (2) of the floor are connected with the main truss columns (4) to form a first-layer vierendeel truss structure, a plurality of auxiliary truss columns (5) are arranged between the upper and lower cantilever beams (3) of the floor, the upper and lower cantilever beams (3) of the floor are connected with the auxiliary truss columns (5) to form a second-layer vierendeel truss structure, and the first-layer vierendeel truss structure and the second-layer vierendeel truss structure are connected to form the double-layer vierendeel truss structure system of the large cantilever structure. The double-layer vierendeel truss structure system of the large cantilever structure has a simple structure and is convenient to construct. A space frame structure system is formed by two layers of vierendeel trusses. The double-layer vierendeel truss structure system of the large cantilever structure can meet the structure stress and deformation requirement under the condition of adopting the small beams.

Owner:广州市设计院集团有限公司

Prefabricated part composite cement soil wall and construction method thereof

ActiveCN101666085AReduce dosageGood cross-section mechanical propertiesBulkheads/pilesMaterials scienceCement

The invention relates to the field of a novel space enclosing structure in a design and construction method of deep foundation, in particular to a prefabricated part composite cement soil wall and a construction method thereof. The prefabricated part composite cement soil wall comprises a plurality of cement soil piles which are internally provided with cement soil; the adjoining cement soil pilesare occluded with each other; and each cement soil pile is internally inserted with a strip-shaped prefabricated part. The construction method of the prefabricated part composite cement soil wall comprises the following steps of: locating and setting lines; excavating guide ways; setting drillers; locating the drillers and constructing the cement soil piles; setting locating frames for the piles;and inserting the prefabricated parts. The invention effectively reduces the construction cost on the basis of meeting the force requirement of the space enclosing structure of trenches and guaranteeing the security. The invention belongs to a novel space enclosing structure form with low cost, less environmental impact, safety and high efficiency, and can perfect the space enclosing structure form in the field of underground construction, so as to further meet the requirement of engineering construction.

Owner:SHANGHAI CONSTRUCTION GROUP

Large-cantilever steel box beam with highway and railway on same layer

The invention discloses a large-cantilever steel box beam with a highway and a railway on the same layer. The large-cantilever steel box beam comprises a box beam top board and cantilever top boards, wherein the cantilever top boards are located on the longitudinal outer sides of the box beam top board, the highway is arranged on the cantilever top boards, the railway is arranged on the box beam top board, the two longitudinal sides of the lower end face of the box beam top board are supported by load bearing structures, a box beam bottom board is arranged between the bottoms of the load bearing structures, and a box type structure is defined by the box beam top board, the load bearing structures and the box beam bottom board. According to the large-cantilever steel box beam with the highway and the railway on the same layer, the highway and the railway are arranged on the same layer, so that compared with a steel box beam with a traditional layered arrangement mode, the large-cantilever steel box beam has the advantages that the line elevation is small, the length of an approach bridge is small, the occupied range of the grade separation is small, project investment can be saved, the vision is wide, the landscape is good, and the novel large-span highway and railway combined construction bridge arrangement mode is achieved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

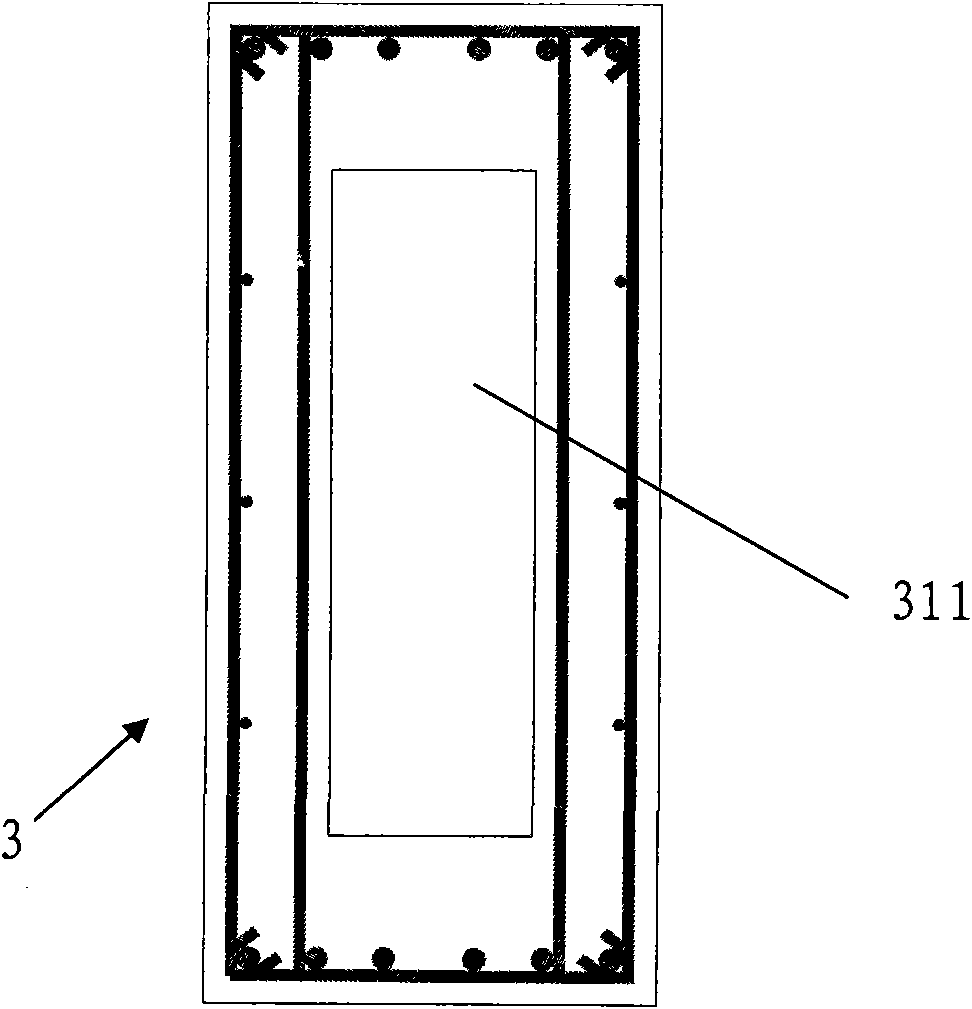

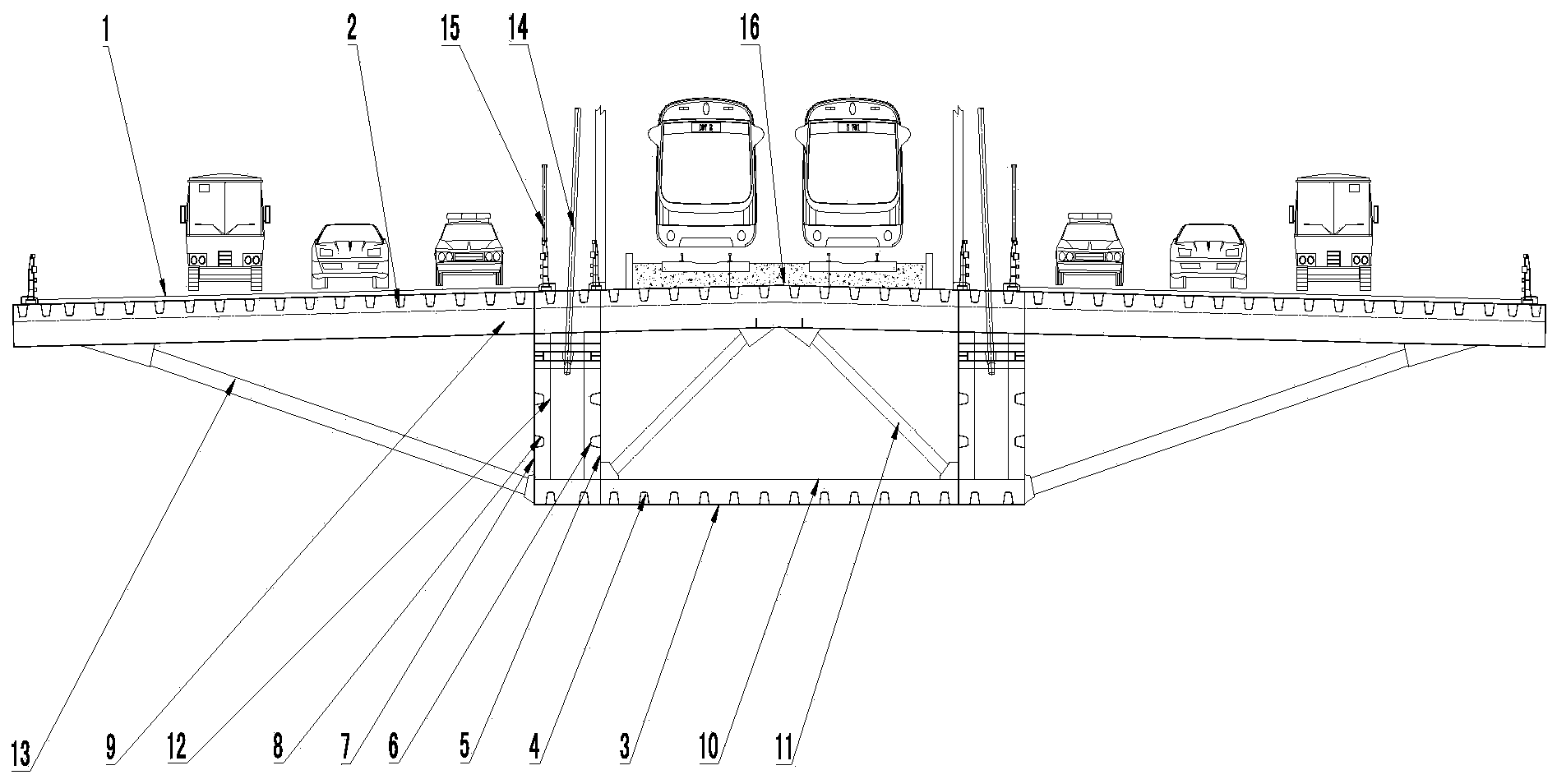

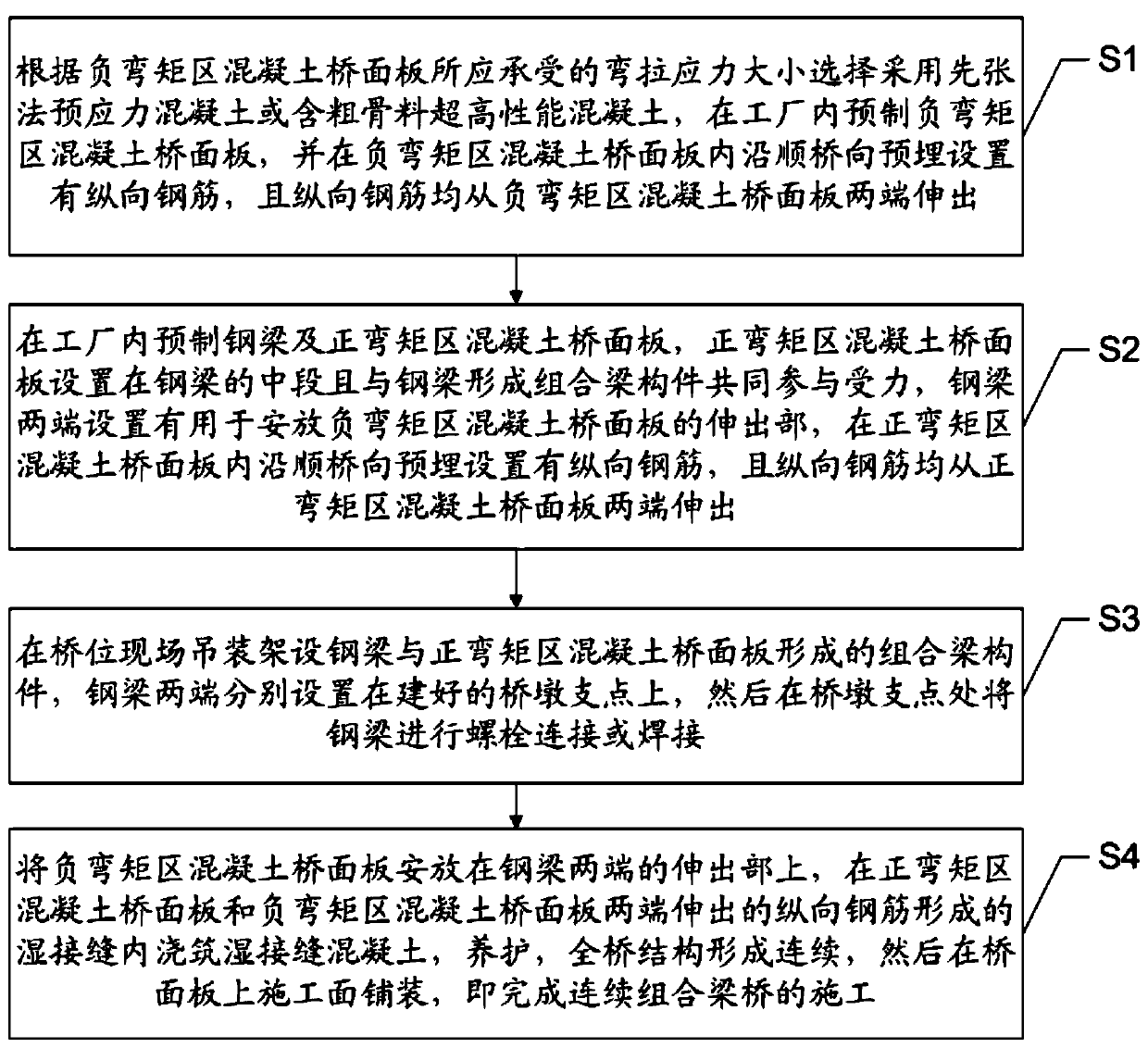

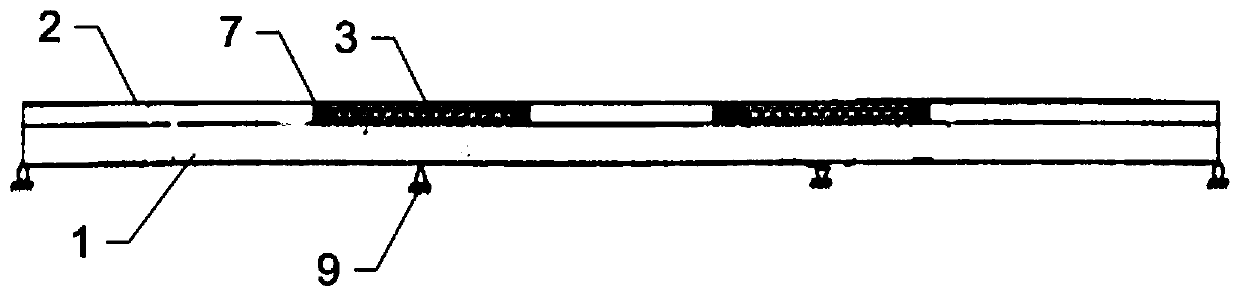

Construction method of continuous composite beam bridge and continuous composite beam bridge

PendingCN110846996ASolve technical problems such as increasing the amount of on-site wet work without combinationLow costBridge structural detailsBridge erection/assemblyAggregate (composite)Pre stress

The invention discloses a construction method of a continuous composite beam bridge and the continuous composite beam bridge. The construction method of the continuous composite beam bridge includes the following steps that S1, pre-tensioned prestressed concrete or ultra-high-performance concrete containing coarse aggregate is selected, and a concrete bridge deck slab in a hogging moment zone is prefabricated in a factory; S2, a steel beam and a concrete bridge deck slab in a sagging moment zone are prefabricated in the factory and connected to form a composite beam component; S3, the composite beam component is hoisted and erected on a bridge pier at the site of the bridge location; S4, the concrete bridge deck slab in the hogging moment zone is placed on the composite beam component to be connected with the concrete bridge deck slab in the sagging moment zone, maintenance is conducted, and then the construction surface on the bridge deck slab is paved to complete the construction ofthe continuous composite beam bridge. According to the construction method of the continuous composite beam bridge and the continuous composite beam bridge, the technical problems of an existing continuous composite beam bridge that prestressing of the concrete in the hogging moment zone is poor, cracking is easy, the compression resistance capacity is weak, consequently, the bearing capacity of the bridge is affected, and durability is poor can be solved, and the technical problem that the bridge deck slabs are not combined and thus the field wet construction amount is increased is further solved.

Owner:湖南省交通水利建设集团有限公司

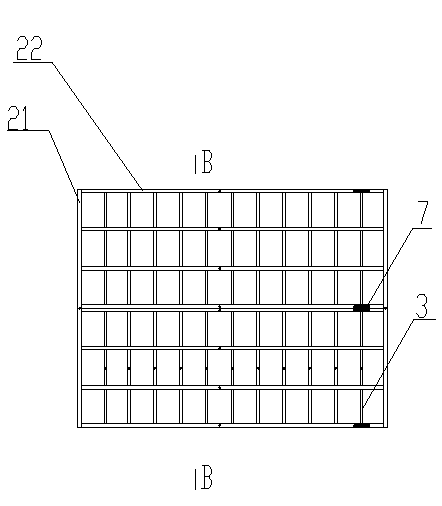

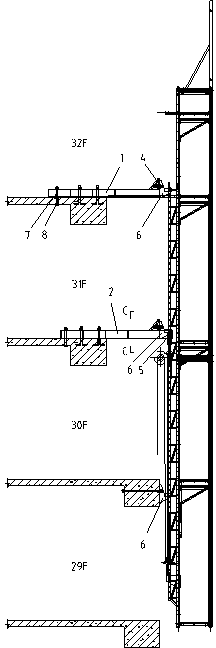

Large cantilever unit type protective canopy suitable for high-rise building construction

ActiveCN103321438AImprove impact resistanceImprove securityBuilding material handlingEngineeringTongue and groove

The invention provides a large cantilever unit type protective canopy suitable for high-rise building construction, which comprises a plurality of protective canopy units, wherein each protective canopy unit comprises two vertical main beams, a plurality of horizontal main beams, secondary beams, handrails, a first panel, a second panel, a traction device and a connection device; the horizontal main beams are perpendicularly connected between the two vertical main beams, so as to form a framework plane; the secondary beams are arranged in the framework plane, and are perpendicular to the horizontal main beams; handrails are perpendicular to the framework plane; the first panel is paved on the framework plane; the second panel is paved and fixed between the handrails; one end of the traction device is fixedly connected to the main structure of a building; the other end of the traction device is fixedly mounted with the main structure of the building; one end of the connection device is fixed on the horizontal main beams; the other end of the connection device is fixedly mounted to the main structure of the building; certain included angles are formed between the connection device and the horizontal main beams; the protective canopy units are connected into a whole through tongue-and-groove connection.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

Method for rebuilding diversion tunnel body into flood discharging tunnel body

ActiveCN103388322AReduce demolitionGuaranteed functional requirementsBarrages/weirsReinforced concreteRebar

The invention discloses a method for rebuilding a diversion tunnel body into a flood discharging tunnel body. The method comprises the steps of 1, excavating the section of the original diversion tunnel body to the designed expanding excavation section of the flood discharging tunnel in an expanding mode; 2, mounting vertical reinforcing steel bars at tunnel edge walls; 3 pouring tunnel edge wall and tunnel top arch concrete according to construction demands; and 4, after the diversion is finished, pouring bottom plate concrete on an original diversion tunnel bottom plate, wherein the bottom plate concrete is poured in two layers from bottom to top, the pouring elevation of the lower concrete is higher than that of embedded steel plates; after the pouring of the lower layer concrete is finished, the upper layer concrete is poured after the reinforcing steel bars needed to be mounted in the upper layer concrete are welded with the embedded steel plates; the top face elevation of the upper layer concrete is the bottom plate elevation of the flood discharging tunnel after rebuilding; the strength level of the lower layer concrete is lower than that of the upper layer concrete. The method for rebuilding the diversion tunnel body into the flood discharging tunnel body has the main advantages of omitting the demolishing of poured reinforcing steel bar concrete in the built diversion tunnel, and ensuring the function demands on the tunnel in different periods.

Owner:YELLOW RIVER ENG CONSULTING

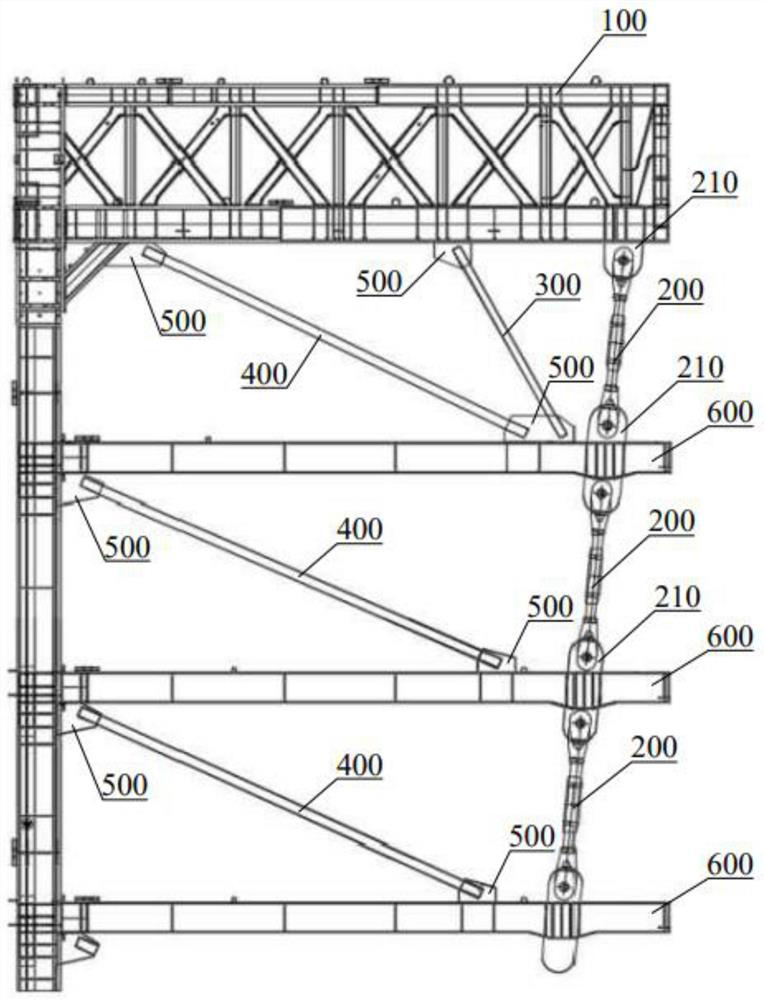

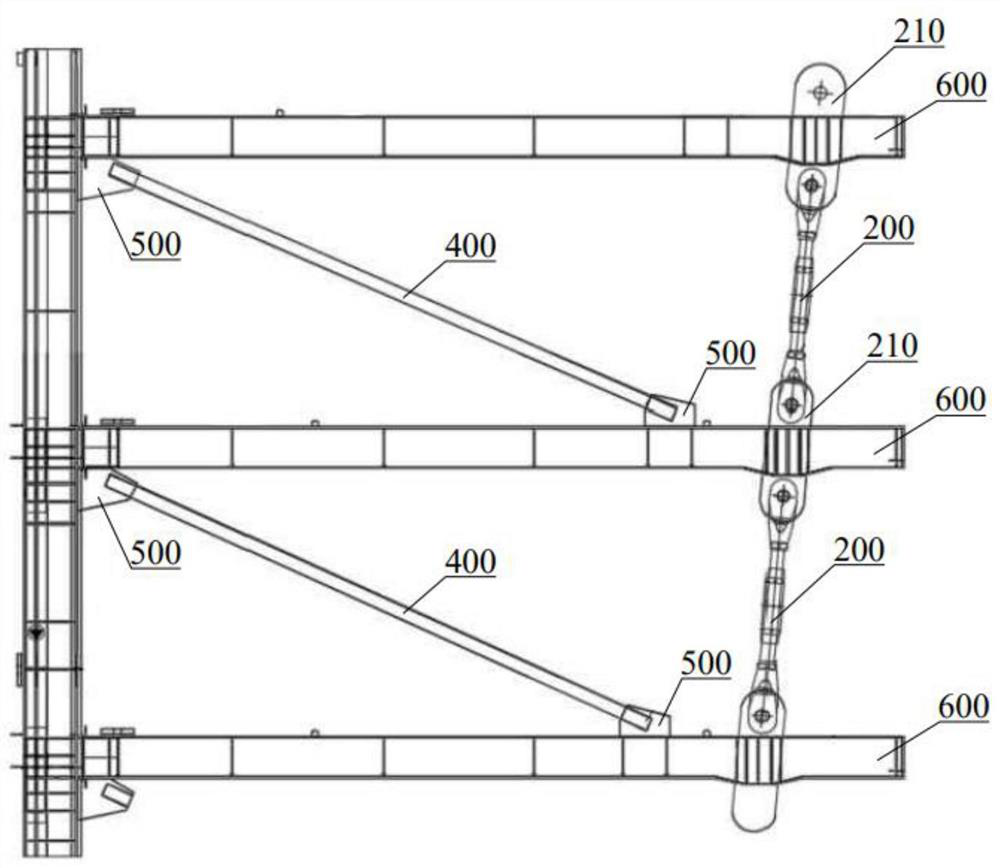

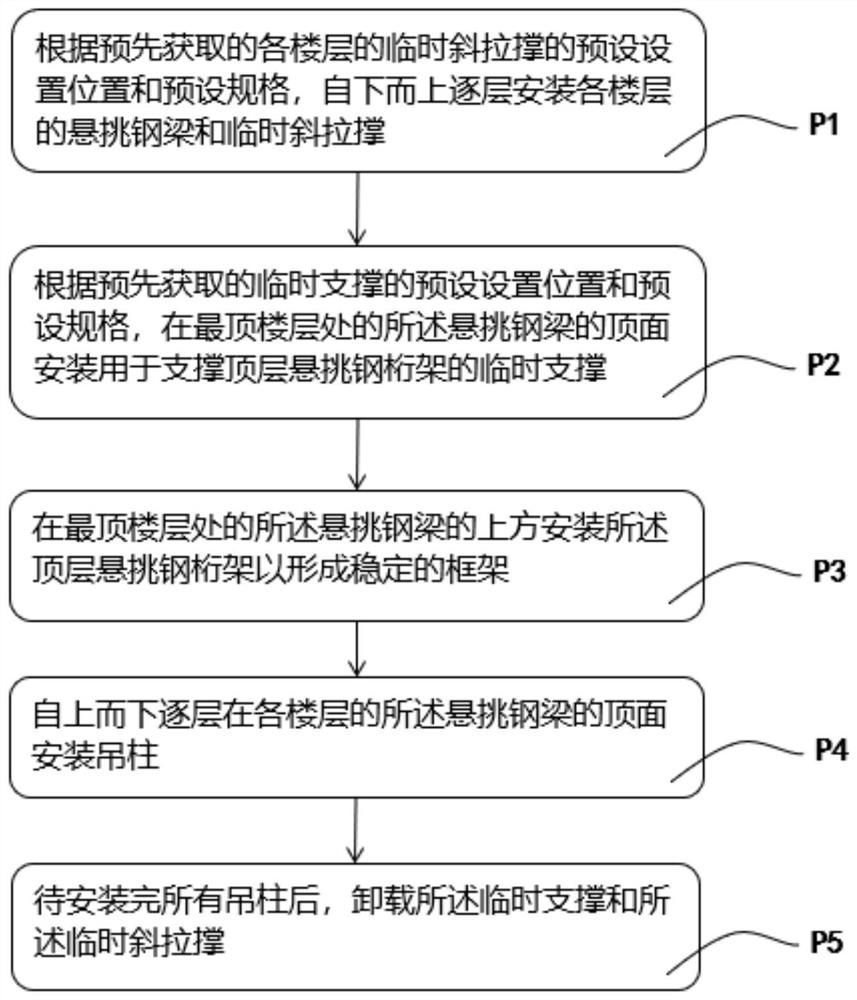

Construction method of suspension steel structure

ActiveCN112814395ASolve the installationGuaranteed stabilityBuilding material handlingArchitectural engineeringCantilever

The invention provides a construction method of a suspension steel structure. The construction method comprises the steps that according to the preset positions and preset specifications of temporary diagonal tension braces of all floors obtained in advance, cantilever steel beams and the temporary diagonal tension braces of all the floors are installed layer by layer from bottom to top; according to the preset positions and preset specifications of temporary supports obtained in advance, the temporary supports used for supporting a top-layer cantilever steel truss are installed on the top faces of the cantilever steel beams of the topmost floor; the top-layer cantilever steel truss is installed above the cantilever steel beams located on the topmost floor to form a stable frame; hanging columns are installed on the top faces of the cantilever steel beams of all the floors layer by layer from top to bottom; and after all the hanging columns are installed, the temporary supports and the temporary diagonal tension braces are unloaded. According to the construction method, the stress requirement of the hanging columns can be met, construction is safe and controllable, the construction quality and precision can meet the design requirement, the construction efficiency is improved, and the construction cost is reduced.

Owner:SHANGHAI MECHANIZED CONSTR GRP

All-welded box girder combination section constructing method

ActiveCN104018427AIncreased durabilityReduce post-maintenance workloadBridge erection/assemblyBridge engineeringBox girder

The invention relates to an all-welded box girder combination section constructing method. The method comprises the specific steps that a girder is divided by making the distance length of two sections serve as one novel box girder combination section, plate units of sectional unit parts are manufactured, a girder lower chord is welded to a lower bridge surface steel box, a girder upper chord is welded to an upper bridge surface panel, a transverse bracing system is welded to a girder vertical rod, the girder vertical rod and an inclined rod are welded to the girder lower chord and the girder upper chord, and the novel box girder combination sections are formed; trial splicing is performed on adjacent novel box girder combination sections on a preset trial assembly platform, and anticorrosion coating is performed on the outer surface. All-welded box girder combinations are welded in place according to a construction order on a bridging construction site. According to the method, the girder is designed into the all-welded box girder combination sections, few hanging units are used, durability of the girder is improved, maintaining workloads during the later period are reduced, site construction is simplified, work efficiency is improved, and an installation period is shortened; the appearance is beautiful, and durability is good. The method has been successfully applied to the Shanghai-to-Nantong railway Yangtze river highway-railway dual-purpose great bridge engineering.

Owner:CHINA MAJOR BRIDGE ENERGINEERING +1

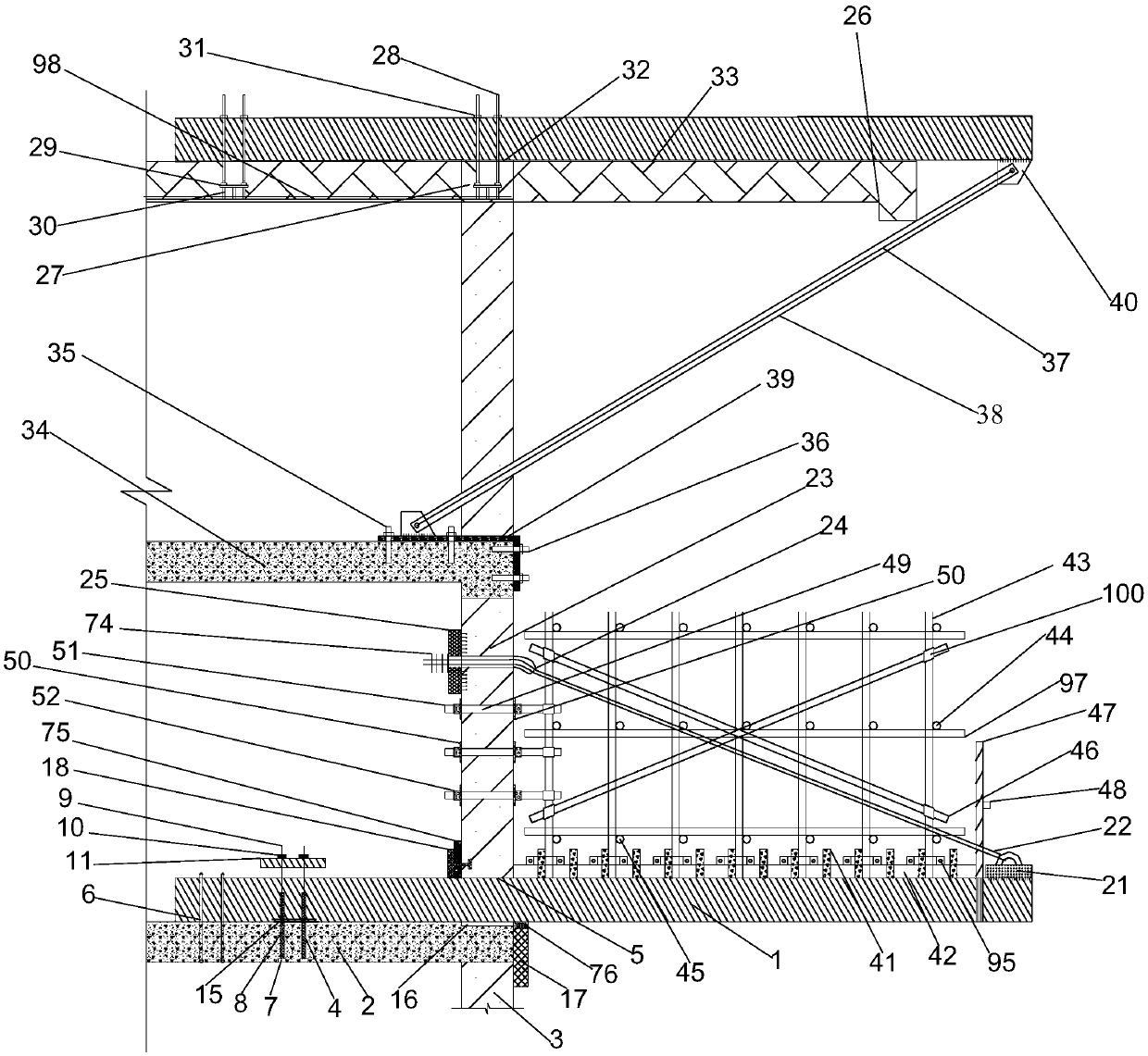

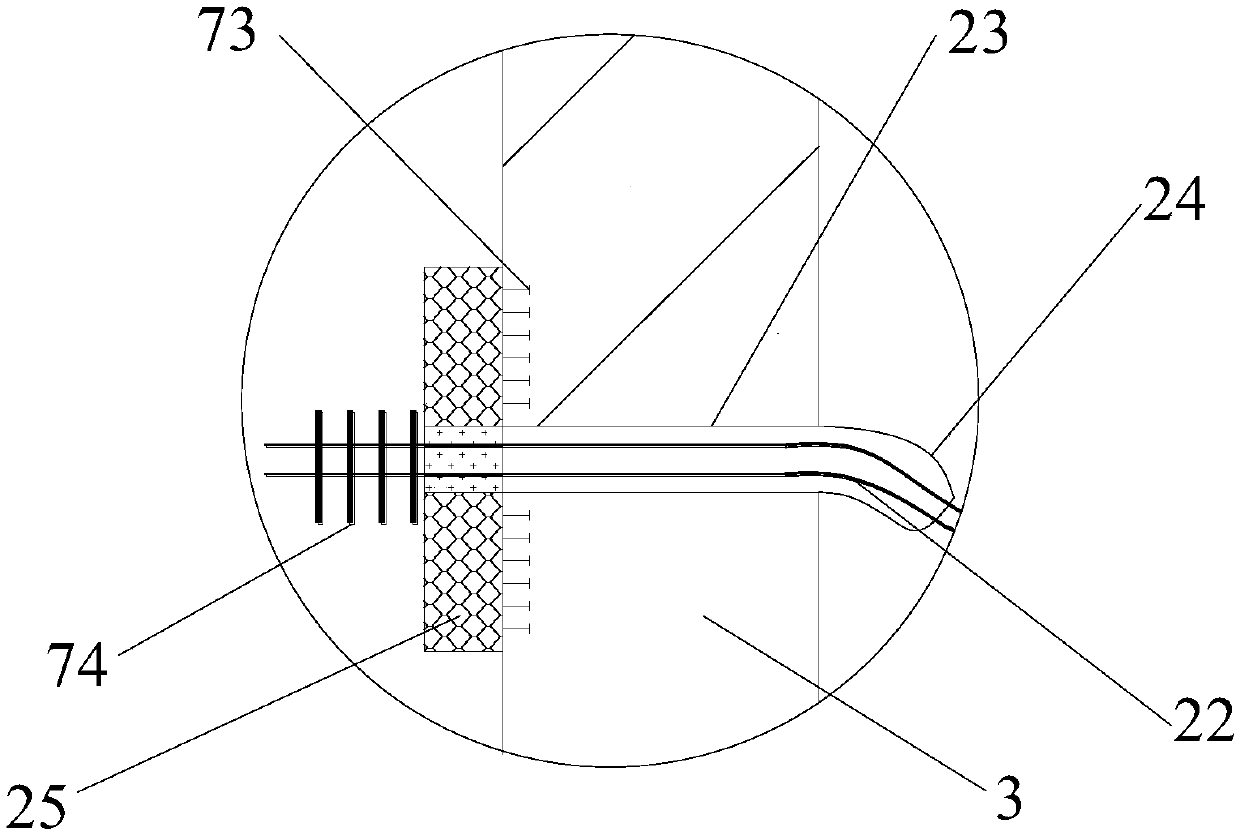

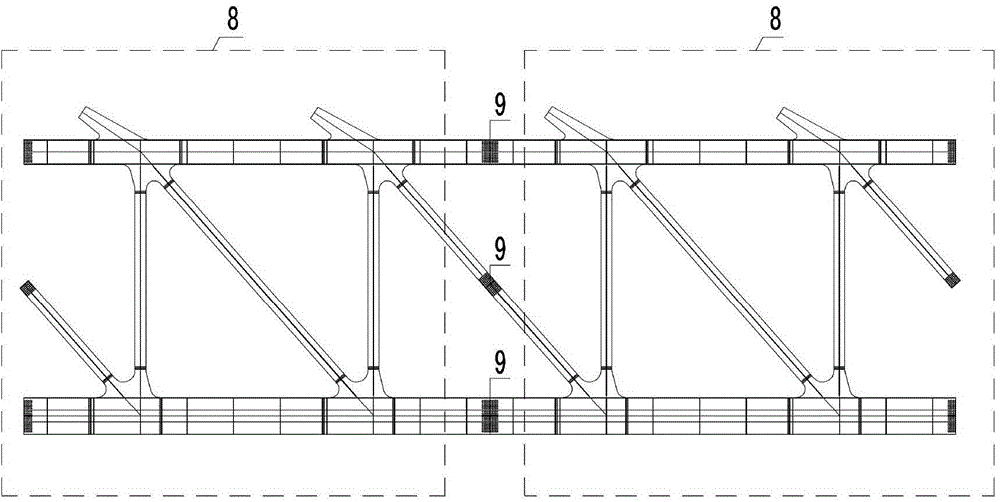

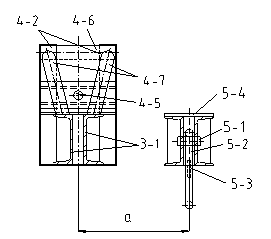

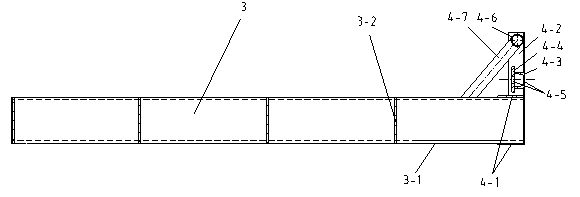

Guidance and hanging separated cantilever beam composite structure of integrated climbing frame

ActiveCN104295083AConvenient sourceSimple designScaffold accessoriesBuilding support scaffoldsFloor slabVertical plane

The invention provides a guidance and hanging separated cantilever beam composite structure of an integrated climbing frame. The guidance and hanging separated cantilever beam composite structure comprises guide steel beams and hanging steel beams, wherein the guide steel beams and the hanging steel beams have the same cantilever supporting sections, and guide seat fixing ends are arranged at the forefront ends of the cantilever supporting sections of the guide steel beams. When the guidance and hanging separated cantilever beam composite structure is installed, the guide seat fixing ends are connected with integrated climbing frame fixing attachment supports, the outward extension lengths and positions of the cantilever supporting sections of the guide steel beams enable an integrated climbing frame top fixing attachment support and the two supports below floors to form a straight line on the same vertical plane. Unit hanging ends are arranged at the forefront ends of the cantilever supporting sections of the hanging steel beams, and hanging points and frame body bearing and hanging points are vertically coaxial during installation. The tail ends of the cantilever supporting sections of the guide steel beams and the hanging steel beams are fixed to a floor slab concrete structure through T-shaped plate screws and steel base plates. When the local outline or an individual floor of a building structure using the integrated climbing frame has adduction change, the process change of the integrated climbing frame can be decreased and an installation mode can be simplified by means of the guidance and hanging separated cantilever beam composite structure.

Owner:DALIAN BRANCH OF CHINA CONSTR EIGHTH ENG DIV CORP +1

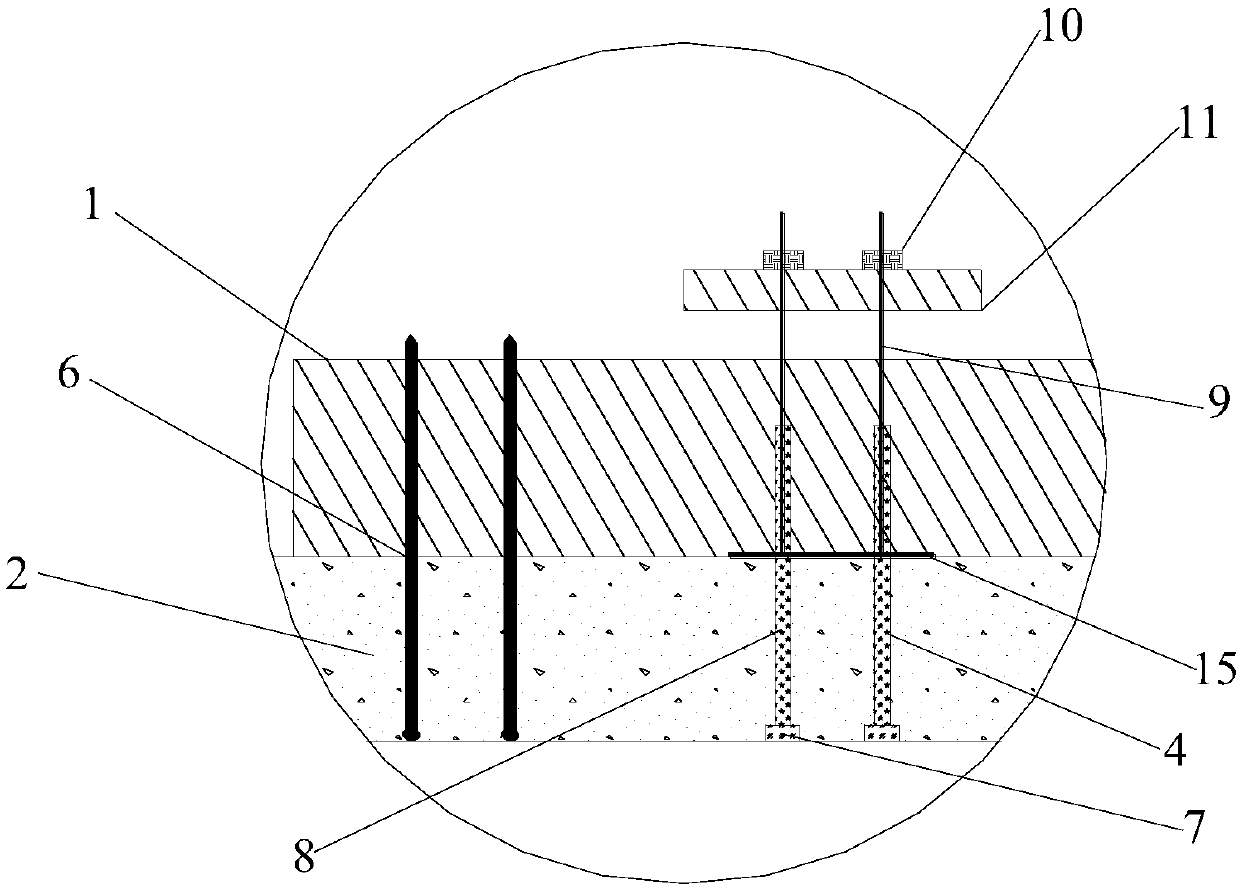

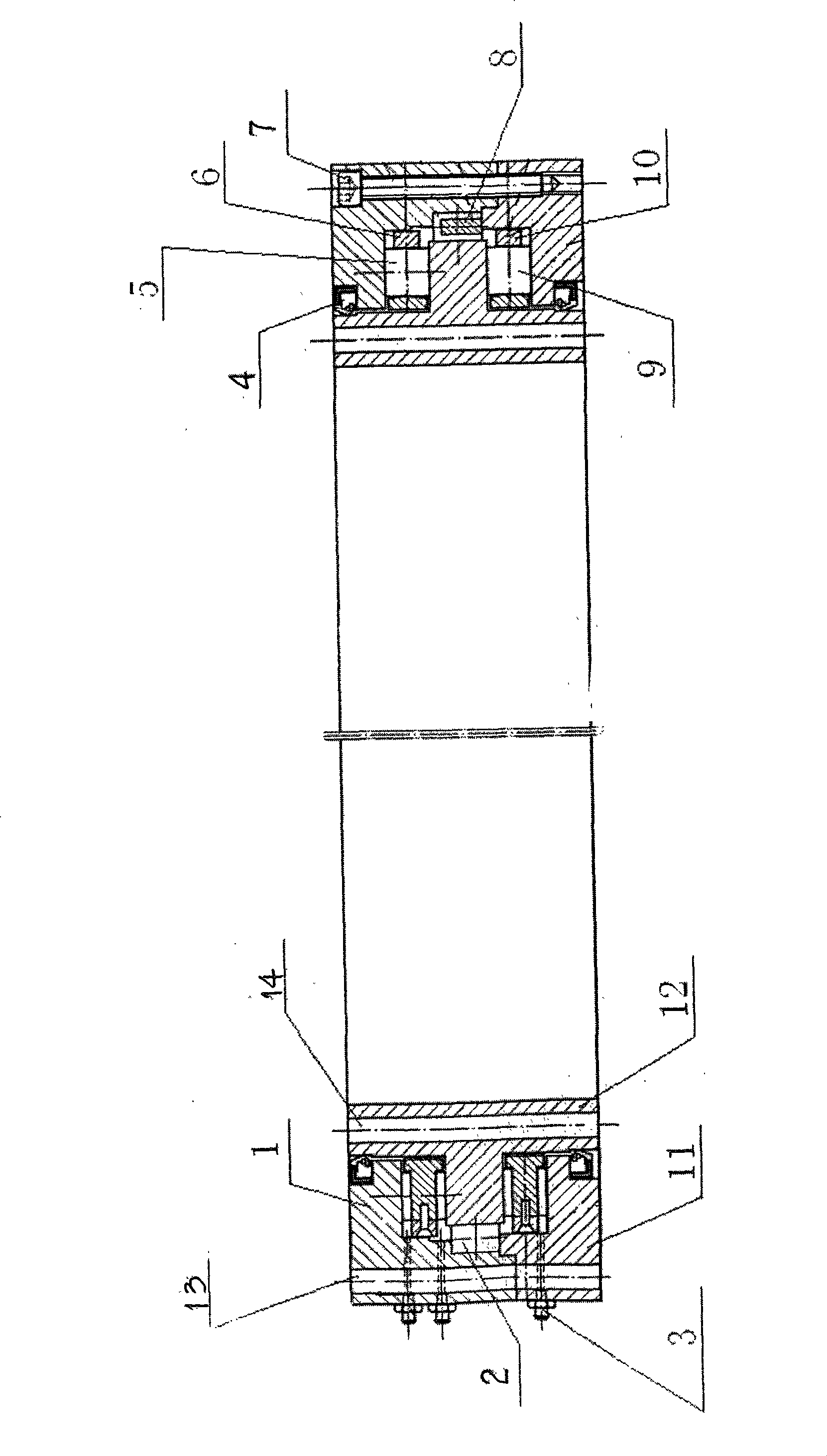

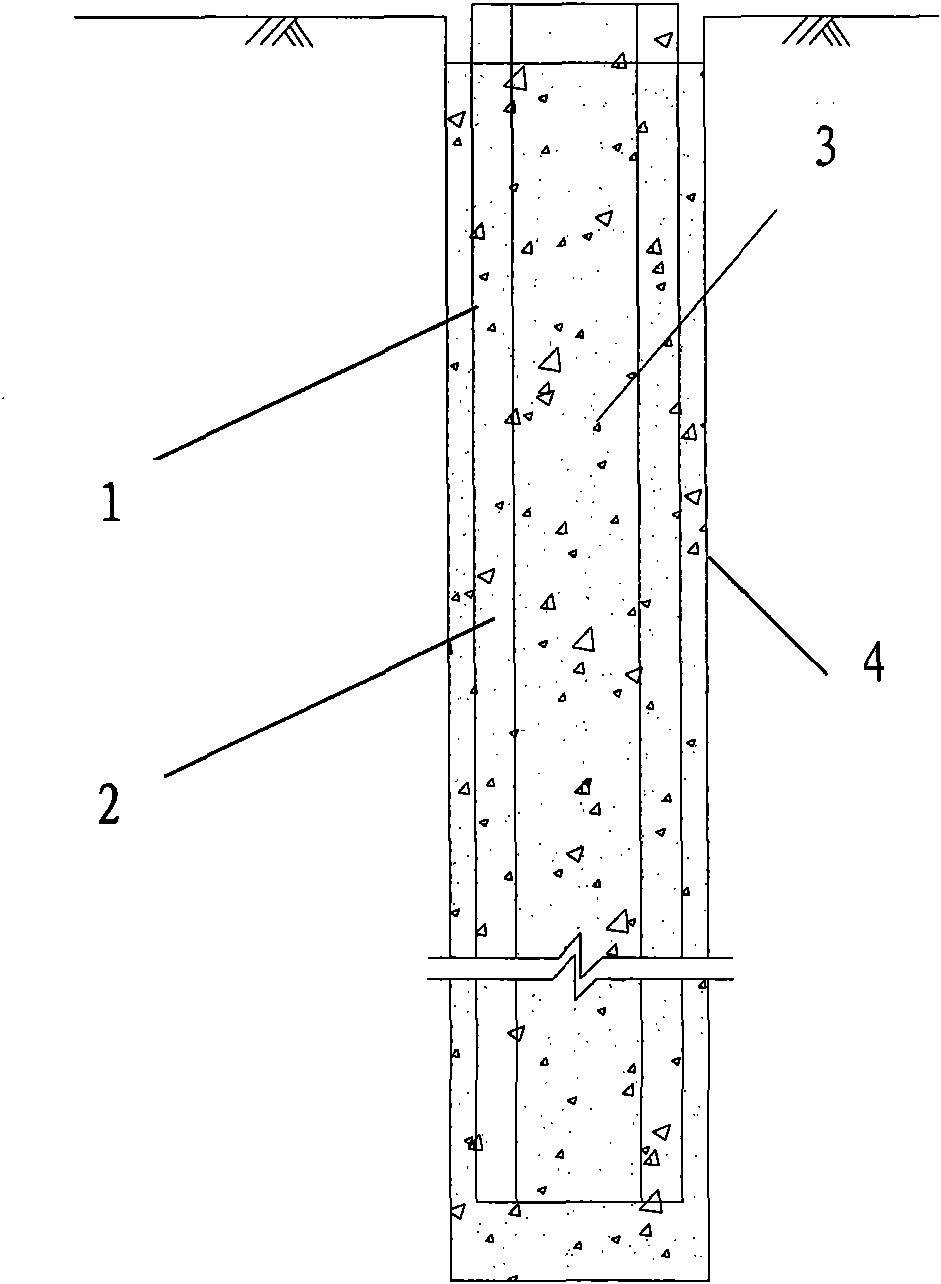

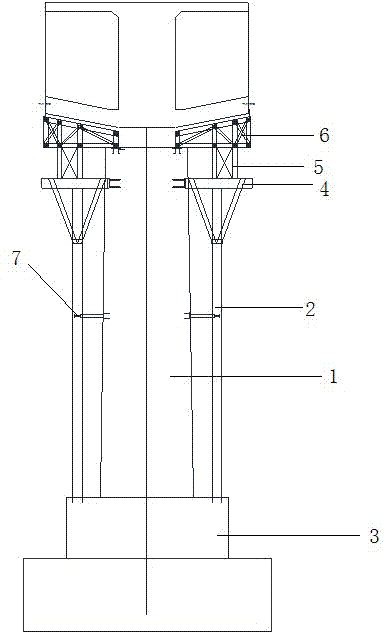

Continuous beam 0# block support and installing method

InactiveCN103669225ASafe and reliable structureMeet the force requirementsBridge erection/assemblyArray data structureContinuous beam

The invention discloses a continuous beam 0# block support structure. Each side of a pier (1) is provided with two pipe stand columns (2) supported by a concrete bearing table (3); short longitudinal beams (4) are arranged at the top ends of the stand columns (2) in a one-to-one correspondence mode, are connected with the pier, are connected with pre-buried pieces of the pier body (1) in a welded mode and are directly connected with the top ends of the stand columns (2) in a welded mode. Cross beams (5) are arranged above the short longitudinal beams (4) and are fixed through welding pieces on the short longitudinal beams (4), and the lengths of the cross beams (5) equal the width of a bridge surface. A plurality of sets of bent frames (6) are arranged above the cross beams (5), one ends of the inner sides of the bent frames (6) are connected with the pier (1) through pre-buried pieces in a welded mode, and the bent frames are fixed relative to the cross beams (5); a box beam bottom die is placed above the bent frames (6). The support structure can safely and reliably meet stress requirements under any working condition in the construction phase, the construction process is simple, fast and convenient, all key portions are clearly stressed, and checking is facilitated.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

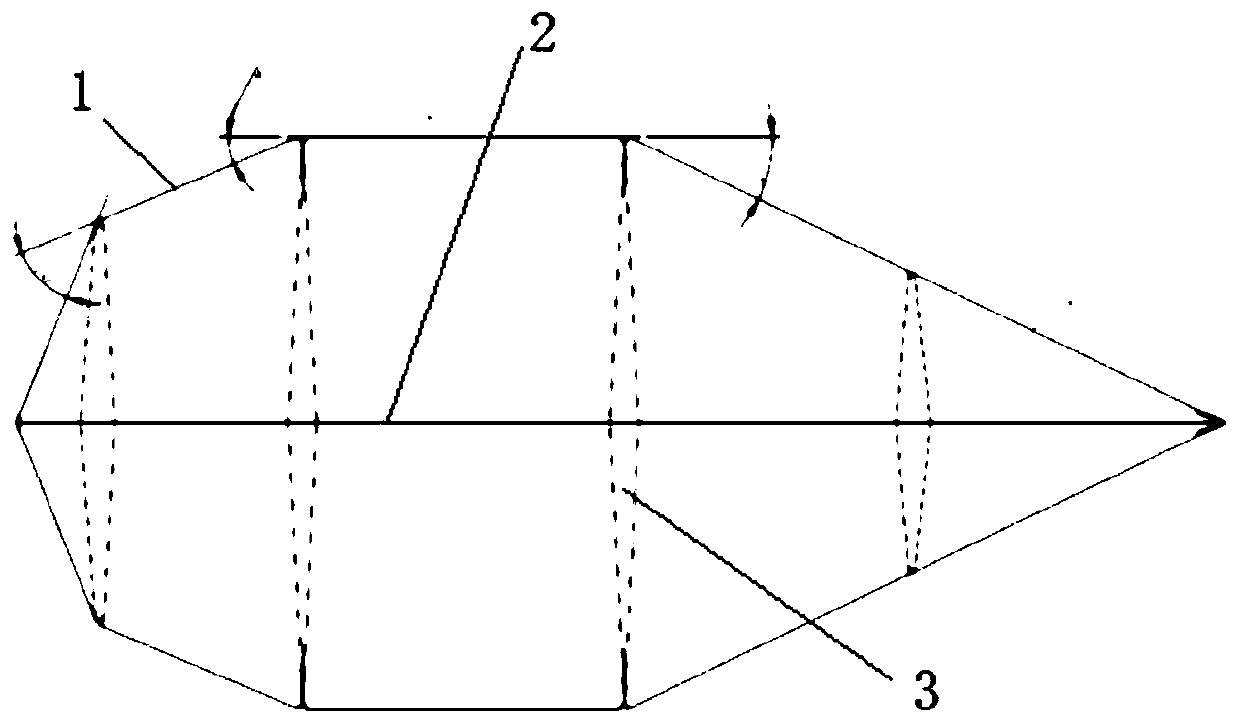

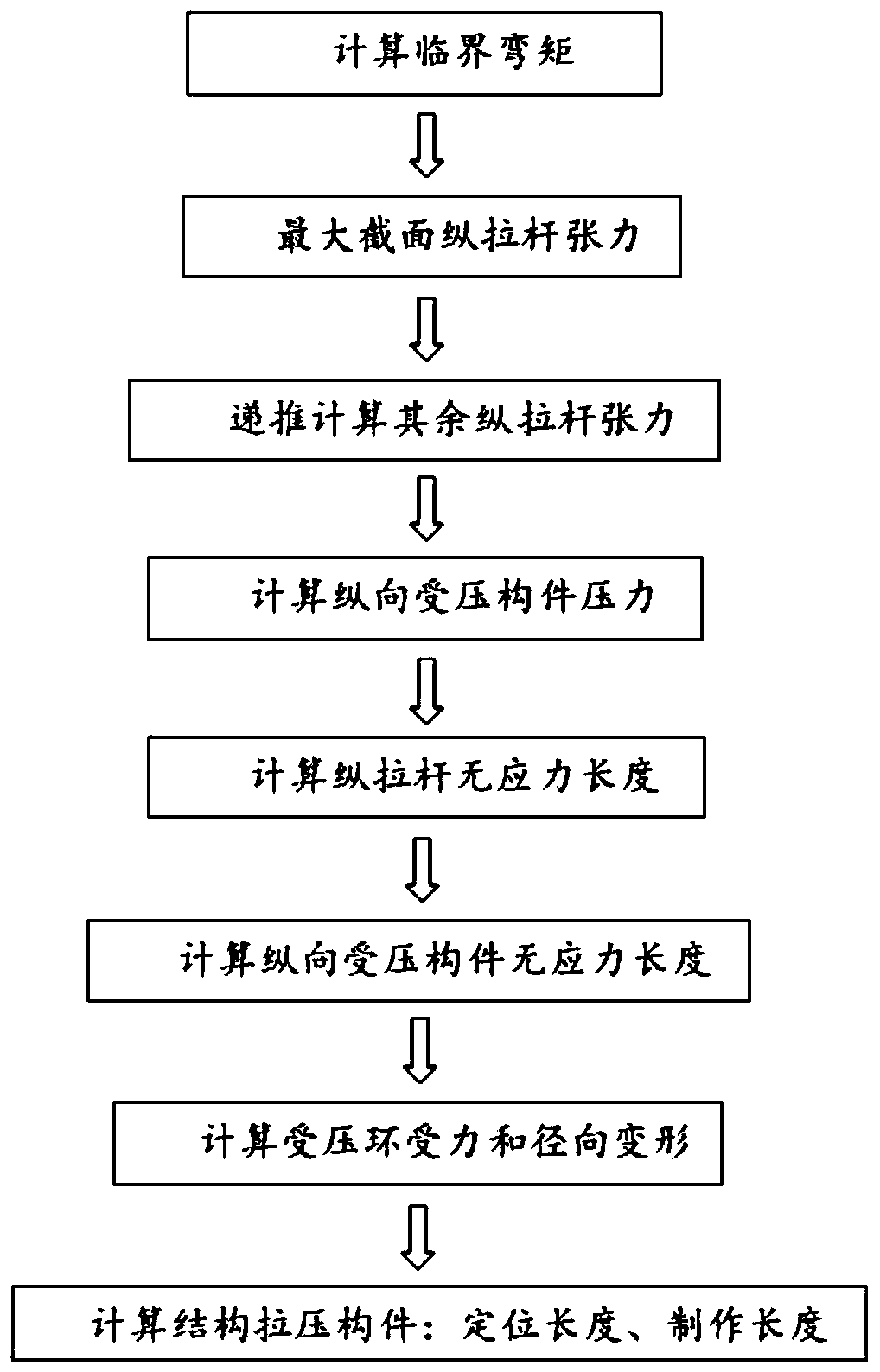

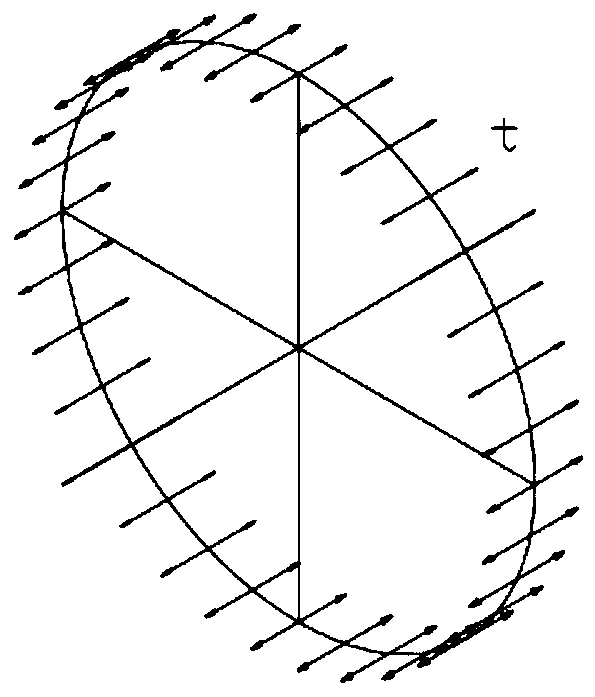

Method for determining balance form of tensioned integral structure

PendingCN110705024AEfficient determinationMeet the force requirementsMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesMechanical engineeringMechanical property

The invention discloses a method for determining a balance form of a tensioned integral structure. The method comprises the following steps: determining a critical bending moment borne by the tensioned integral structure; calculating the tension of the longitudinal pull rod; calculating the pressure of the longitudinal compression part; calculating the stretching length of the longitudinal pull rod, and calculating the unstressed length of the longitudinal pull rod; calculating the compression length of the longitudinal compression part, and calculating the unstressed length of the longitudinal compression part; calculating the stress and the radial deformation of the annular compression part; and calculating the positioning length and the manufacturing length of the longitudinal pull rodand the longitudinal compression part. The method provided by the invention can quickly and effectively determine the prestress balance morphological stress and the unstressed length of the tension-compression component, and provides a basis for manufacturing and installation; the prestress level is reasonable and feasible, and the overall stress requirement of the structure can be met; the lengthand the manufacturing length of the tension-compression component are determined, so that the tension integral structure integration is easily realized, and the prestress balance morphological mechanical property is ensured; the method is simple, efficient, small in calculation amount and easy to implement.

Owner:SHANGHAI JIAOTONG UNIV +1

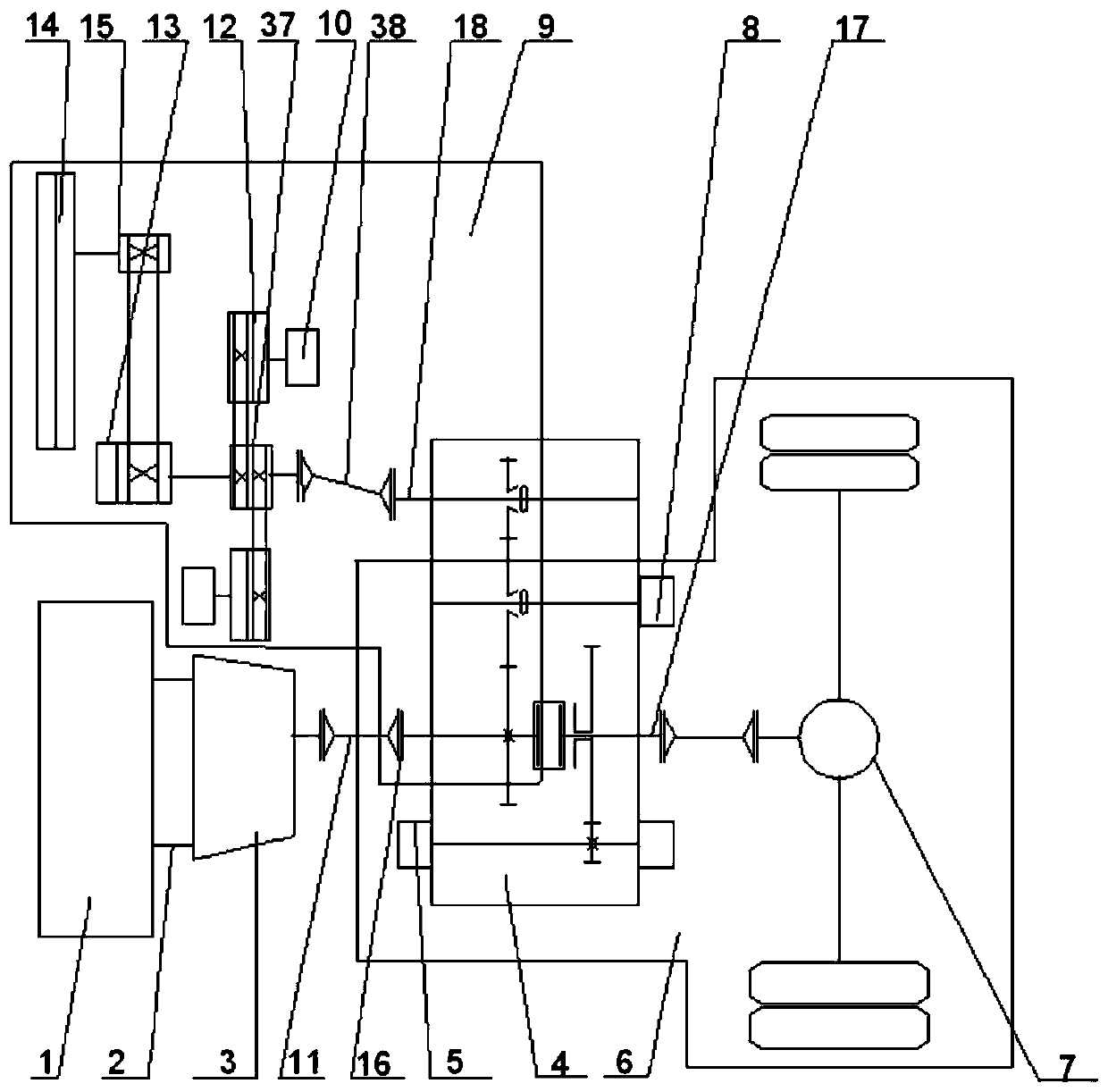

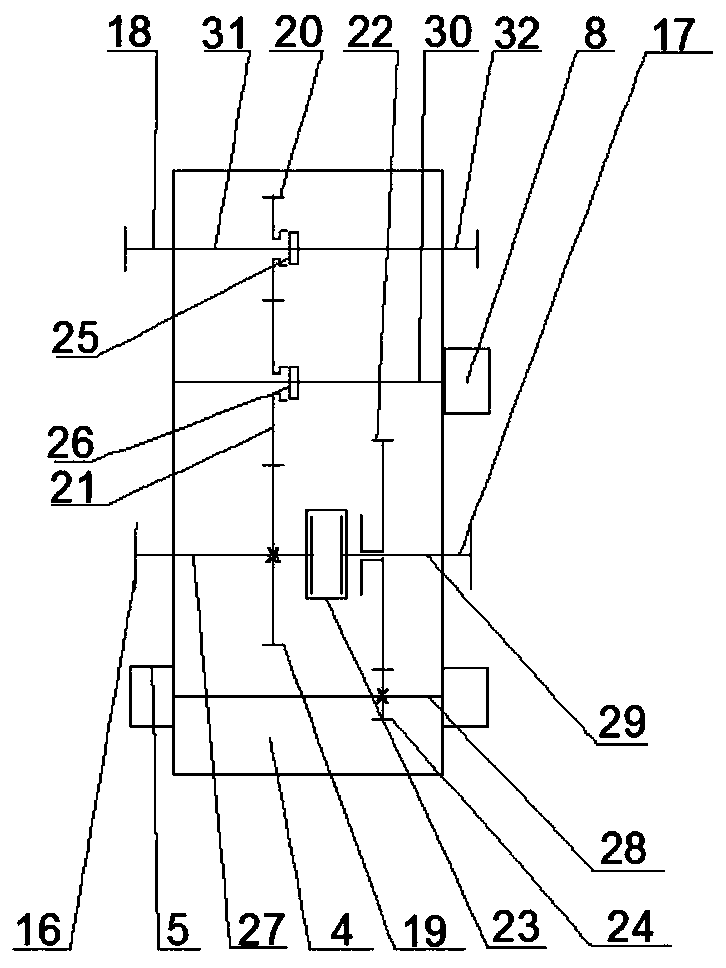

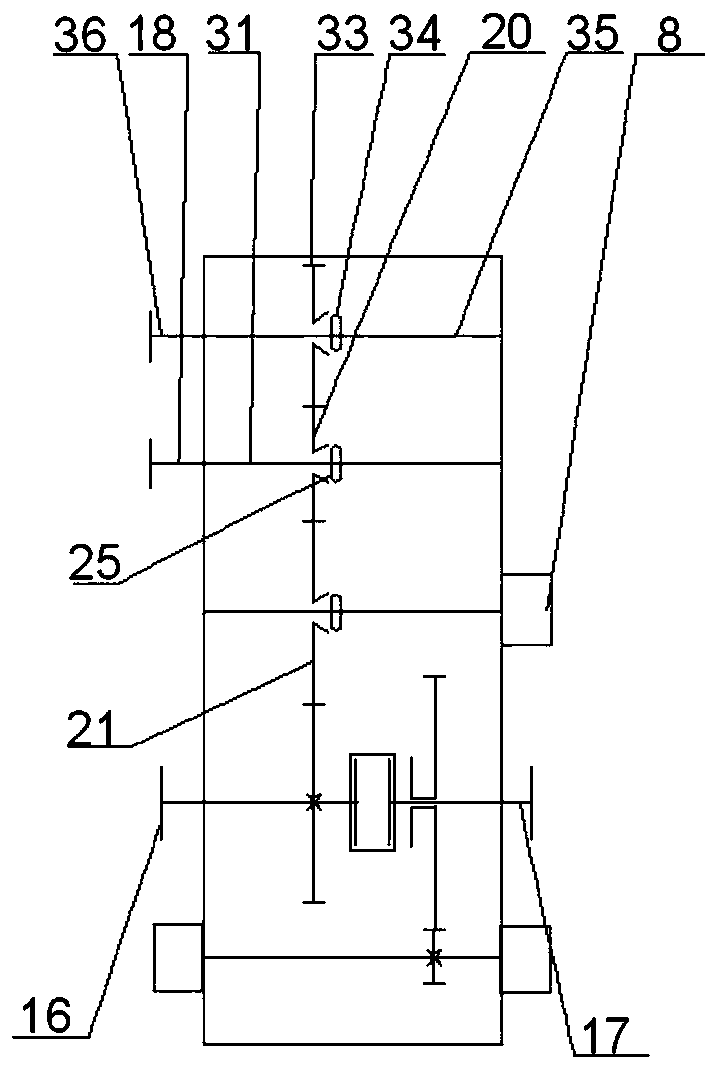

Single-engine multiple-transmission operation mode

InactiveCN110539632AReduce cooling powerLow costAuxillary drivesGearing detailsFailure rateLow speed

The invention relates to a single-engine multiple-transmission operation mode of a road pollutant removal vehicle. The single-engine multiple-transmission operation mode comprises an engine, a clutch,a gearbox, a multiple-transmission box, a chassis hydraulic walking operation mechanism and a top-mounted pure mechanical transmission operation mechanism. According to the layout mode, the size of ahydraulic oil tank can be reduced to 1 / 3-1 / 4 of the original hydraulic transmission, the heat dissipation power of a hydraulic system is greatly reduced, meanwhile multiple motors, multiple high-pressure oil pumps, multiple control valves and other components are omitted, and the space is saved; meanwhile, compared with the top-mounted hydraulic transmission, by the adoption of the top-mounted pure mechanical transmission operation, the layout is simple, the failure rate is low, the maintenance is easy, a high-power hydraulic oil heat dissipation system is omitted, and the whole vehicle costis reduced; meanwhile the hydraulic walking operation is realized, and the requirements of large-torque and ultra-low-speed operation are met; and the output power of an engine is matched through themultiple-transmission box, the ultra-low-speed hydraulic walking during operation can be met, and the mechanical force-taking requirement of a high-pressure water pump and a high-pressure fan can be met.

Owner:YANTAI HAIDE SPECIAL VEHICLE

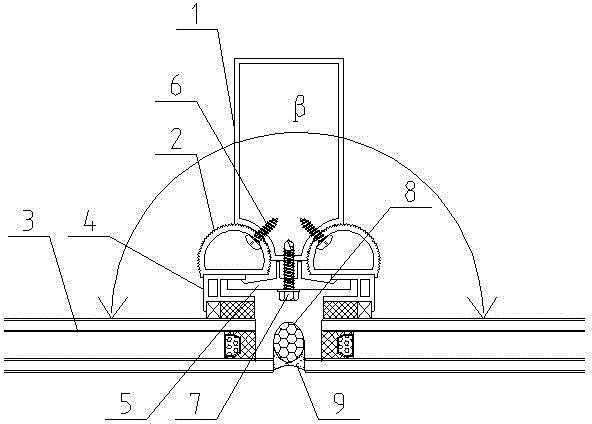

Angle-adjustable glass curtain wall system

An angle-adjustable glass curtain wall system comprises a stand column and glass panels on the two sides of the stand column. Glass attachment frames are arranged on the inner sides of the glass panels, inward concave arc faces are arranged at the bottoms of the two sides of the stand column, main keels matched through arcs are arranged in the inward concave arc faces, and attachment frame pressing blocks for pressing the glass attachment frames to the main keels are arranged below the stand column. The angle-adjustable glass curtain wall system is reasonable in structure, low in cost, capable of being suitable for construction mounting of glass curtain walls within the corner angle range of 45 degrees to 189 degrees and easy and convenient to mount, angle adjusting is easy and convenient, construction speed is high, work efficiency can be greatly improved, stress requirements can be met, and safety and reliability are achieved. On the premise of conforming to the safety, reliability and elastic connection rule, the problem that die sinking needs to be carried out on the curtain wall system under multiple corner conditions can be solved, die cost is greatly saved, and construction cost is lowered.

Owner:THE CONSTR DECORATION OF CHINA CONSTR NO 7 ENG BUREAU

L-shaped prefabricated concrete wall connection joint

The invention provides an L-shaped prefabricated concrete wall connection joint, and belongs to the technical field of construction structures. The L-shaped prefabricated concrete wall connection joint comprises a first prefabricated concrete wall body and a second prefabricated concrete wall body, wherein a longitudinal through hole is formed in the portion, on the joint side and close to the end face, of the first prefabricated concrete wall body, a longitudinal through hole is formed in the portion, on the joint side and close to the end face, of the second prefabricated concrete wall body, a plurality of transverse grooves are formed in the end face on the joint side of the first prefabricated concrete wall body, a plurality of transverse grooves are formed in the end face on the joint side of the second prefabricated concrete wall body, the top portion of each transverse groove extends into the portion, inside the corresponding longitudinal hole, of the corresponding wall body or intersects with the corresponding longitudinal hole, the first prefabricated concrete wall body and the second prefabricated concrete wall body extend on the end faces of the joint sides to form a first sheet and a second sheet respectively, an edge joint is reserved at the joint of the first sheet and the second sheet, and cast-in-place concrete is arranged in the space defined by the first sheet and the second sheet, the longitudinal holes and the transverse grooves. According to the L-shaped prefabricated concrete wall connection joint, the integrality of a prefabricated overall concrete structure can be improved, and performance of the construction structure can be improved.

Owner:初明进

Steel column free type steel beam joint construction process

ActiveCN101392558AResolve connectionIncrease heightBuilding constructionsReinforced concrete columnSteel bar

The invention relates to a building construction method, in particular to a non-steel-column type steel beam connection construction process, which solves the problem of the connection between a steel beam and a concrete structural column during the construction. The process comprises the following steps of: firstly, fabricating the steel beam and placing a template of the steel beam between concrete columns; secondly, hoisting the steel beam, putting the steel beam on the template, installing stirrups around a concrete column tendon above the steel beam, welding the stirrups with the tendon; thirdly, installing waist ribs, installing steel beam stirrups around the steel beam, installing beam penetrating steel bars which pass through the upper and lower web plates of the steel beam and are connected with the steel bars on the middle part of the concrete column through nut sleeves, installing stirrups around the concrete column steel bars on the side of the steel beam; fourthly, applying hooks onto the stirrups; and finally, erecting the template around the steel beam for pouring concrete. The construction process solves the problem of the connection between the reinforced concrete column and the steel beam without a steel column.

Owner:山西太行建设开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com