Thrust bar lightening method and lightened thrust bar

A thrust rod, lightweight technology, applied in the direction of the cantilever mounted on the pivot, suspension, transportation and packaging, etc., can solve the problem of light weight impact, to achieve the effect of reducing weight, reducing weight and increasing extrusion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

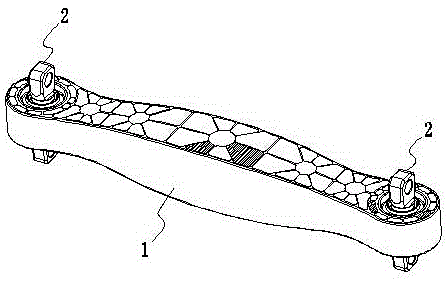

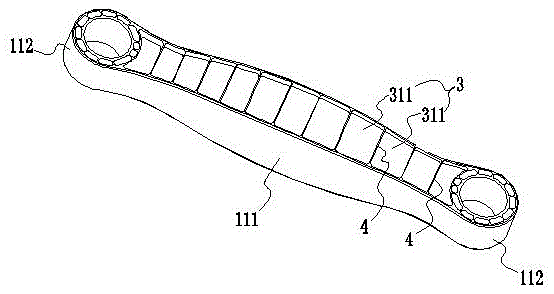

[0041] Embodiment 1: as Figure 1 to Figure 4 As shown, a thrust rod lightening method, the thrust rod lightening method is that the rod body 1 and the mandrel 211 of the elastic ball hinge 2 are both made of polymer materials and molded by injection molding at one time, and the opposite two sides of the rod body 111 are molded at one time. They are all arranged as side surfaces with discontinuous grooves 1, which include a plurality of sub-grooves 3 distributed sequentially along the length direction of the rod body 111 (that is, two or more than two sub-grooves). Groove 1), on the groove bottom surface of each sub-groove-3, a plurality of convex ribs 4 (that is, two or more than two ribs) are arranged, so that each sub-groove-3 is covered by multiple The rib 4 is divided into a plurality of small grooves 311 (that is, two or more small grooves). In this embodiment, the rod body 111 is set in a rectangular shape, and the two ball heads 5 are set in a hollow Cylindrical.

[...

Embodiment 2

[0054] Embodiment 2: as Figure 9 As shown, compared with Embodiment 1, the difference is that: the plurality of ribs 4 arranged on the bottom surface of the groove of each sub-groove-3 are parallel to each other, and the plurality of ribs 4 are all parallel to the rod body. The main body 111 is arranged in the lengthwise direction, so that the arrangement can form a symmetrical structure, so that the stress conditions of all parts of the rod body are basically the same, and the product will not be damaged in advance due to excessive stress at a local position.

Embodiment 3

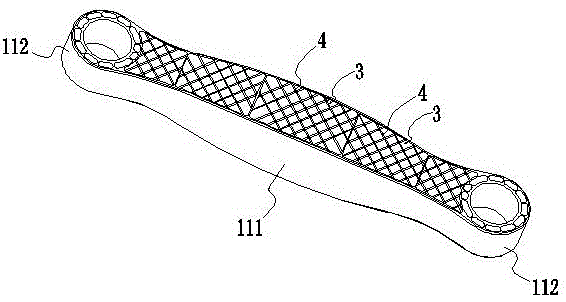

[0055] Embodiment 3: as Figure 10 As shown, compared with Embodiment 1, the difference is that: the plurality of ribs 4 arranged on the bottom surface of the groove of each sub-groove-3 are parallel to each other, and the plurality of ribs 4 are all along the vertical direction of the rod body. The length direction of the body is set, which can increase the bending resistance of the product, and has achieved the purpose of reducing the cross-sectional area and reducing the weight of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com