L-shaped precast concrete wall connection

A technology of prefabricated concrete and connecting nodes, which is applied in the direction of walls, building components, buildings, etc., can solve the problems of easy cracking and affecting the mechanical performance during the use stage, and achieve the effect of improving performance, improving integrity and continuous force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

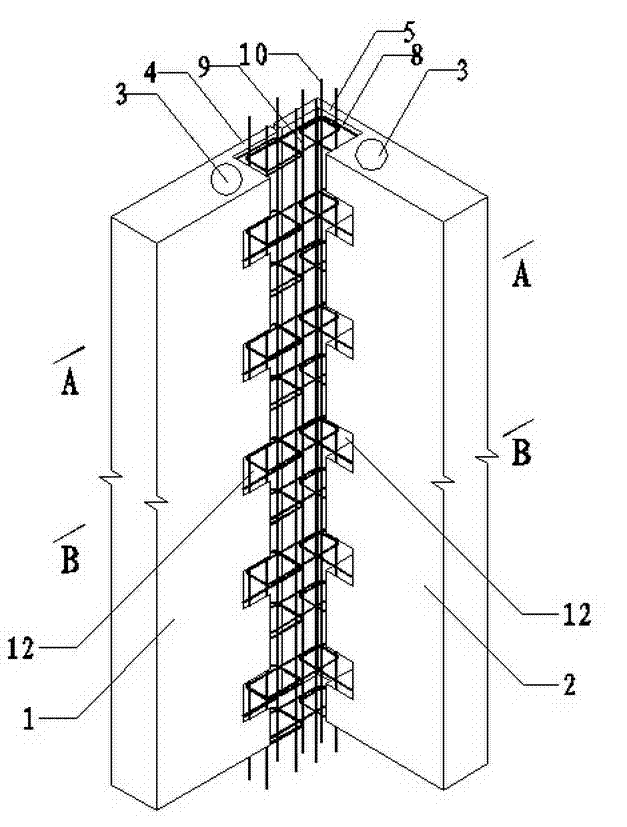

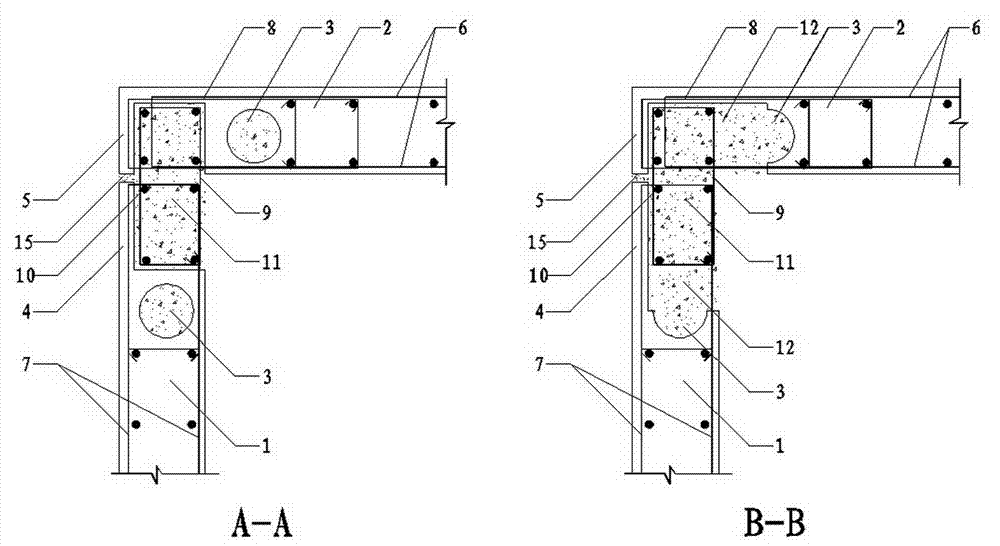

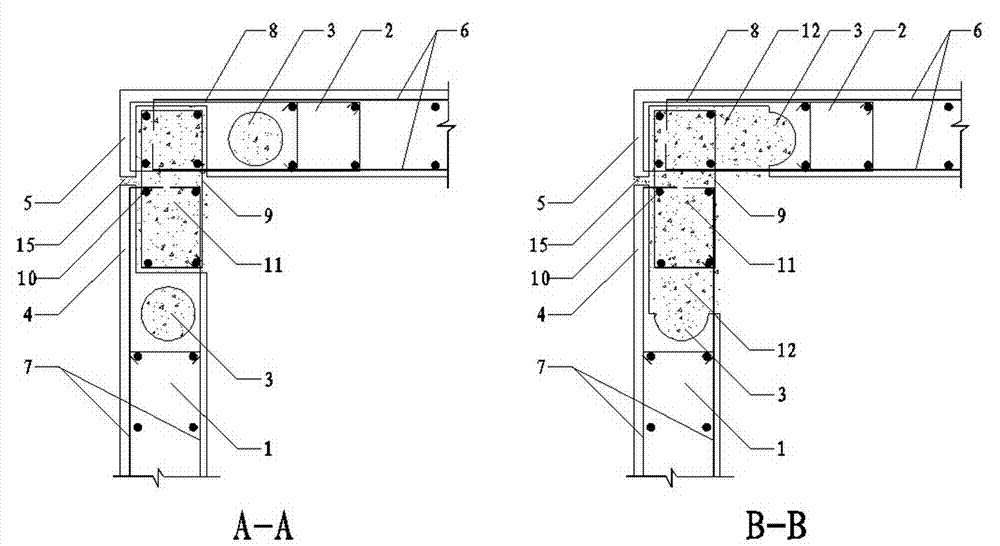

[0035] Such as figure 1 In the perspective view of the illustrated embodiment, the L-shaped precast concrete wall connection node includes a first precast concrete wall 1 and a second precast concrete wall 2, and the first precast concrete wall 1 and the second precast concrete wall The body 2 is provided with a longitudinal through hole 3 near the end surface of the node side, and the first precast concrete wall body 1 and the second precast concrete wall body 2 are provided with several transverse grooves 12 opposite to the end surface of the node side. The view is rectangular, the transverse groove 12 intersects with the longitudinal hole 3; the first precast concrete wall 1 protrudes from the first thin plate 4 at the node side end face, and the second precast concrete wall 2 protrudes the second thin plate 5 from the node side end face, A seam is left at the junction of the first thin plate and the second thin plate, and the width of the joint is preferably 15 mm; the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com