Single-engine multiple-transmission operation mode

An operation mode and single-engine technology, applied in transmission parts, mechanical equipment, auxiliary drive devices, etc., can solve problems such as high fault points, difficult maintenance, low work efficiency, and inability to meet the requirements of cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

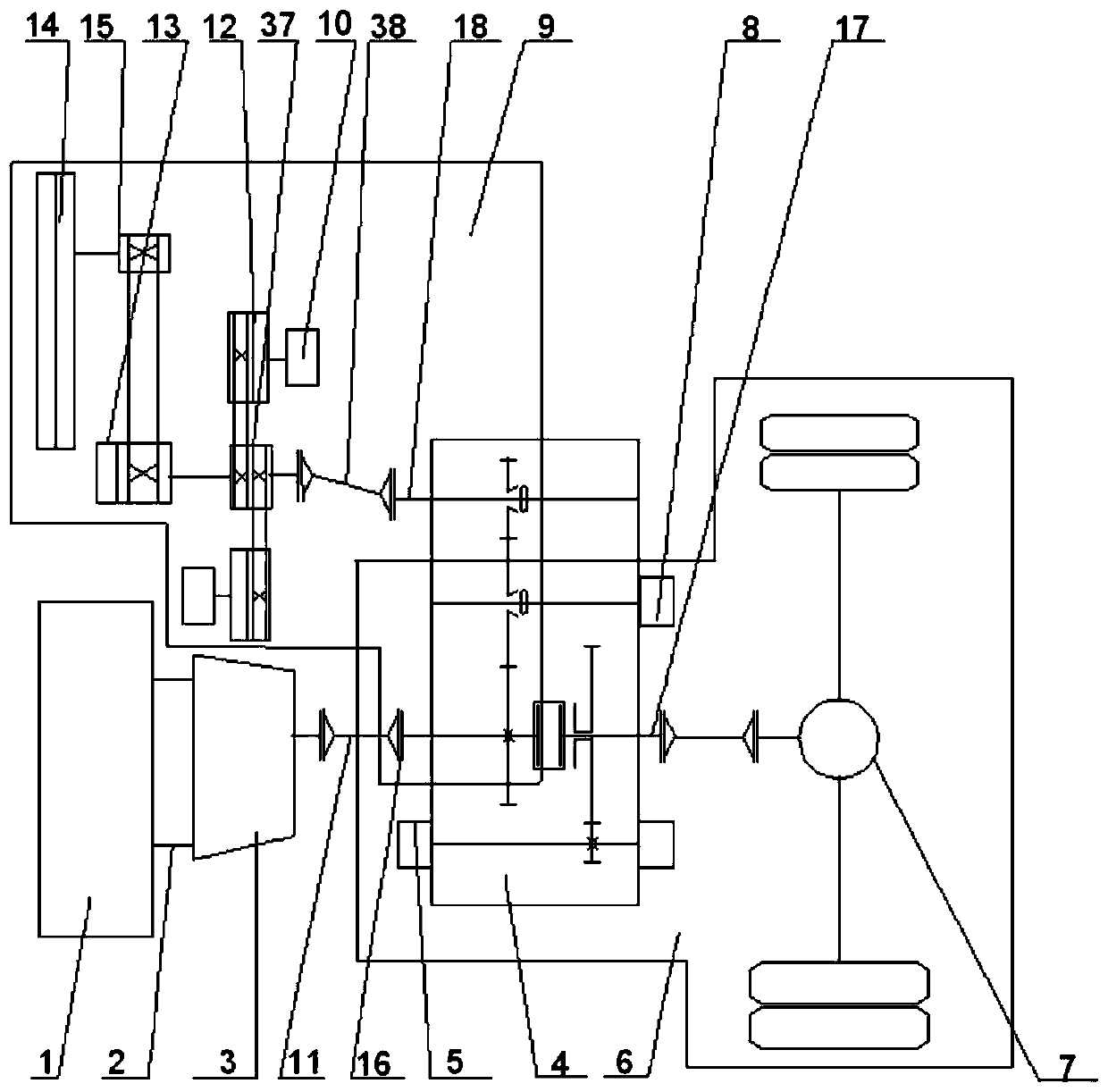

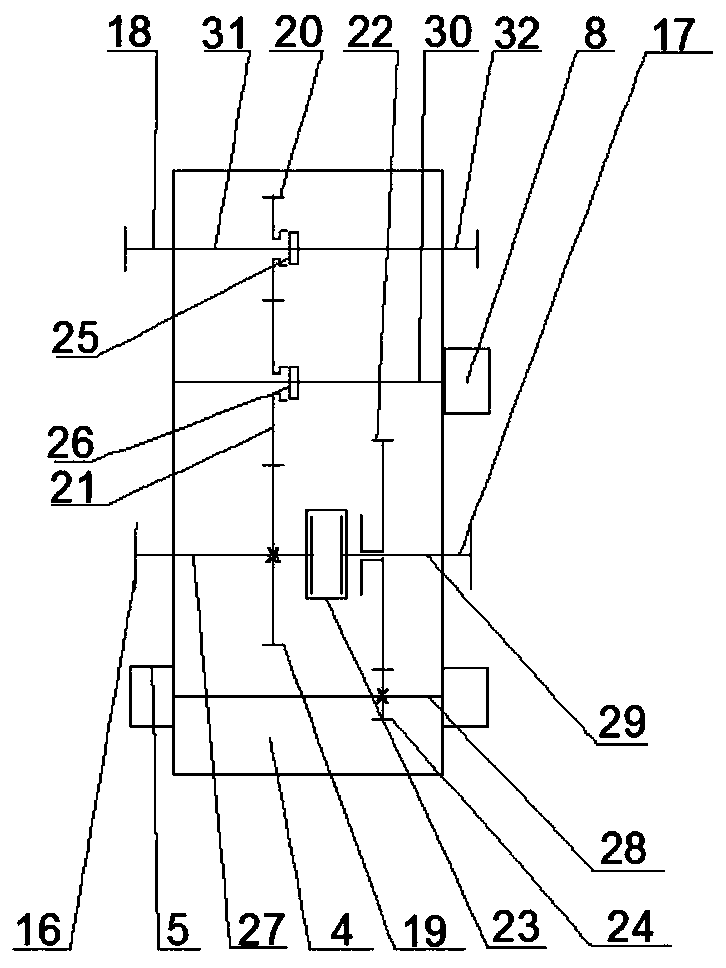

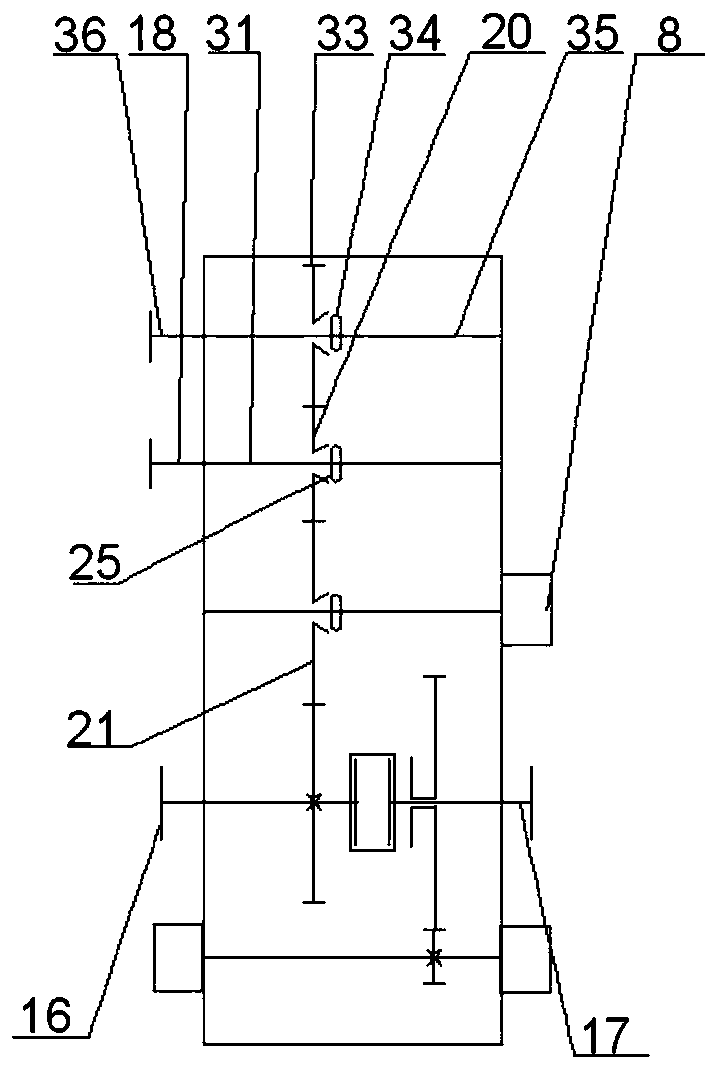

[0025] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and concrete implementation, following embodiment is only a part of embodiment of the present invention, rather than all embodiment, based on the embodiment in the present invention, those of ordinary skill in the art All other embodiments obtained under the premise of no creative work belong to the protection scope of the present invention.

[0026]In the following drawings in the present invention, those with the same numbers have the same descriptions. Among them, 1 is the engine, 2 is the clutch, 3 is the gearbox, 4 is the compound transmission box, 5 is the hydraulic motor, 6 is the hydraulic travel mechanism of the chassis, 7 is the rear drive axle, 8 is the hydraulic oil pump, and 9 is pure mechanical bodywork 10 is a high-pressure water pump, 11 is a cardan shaft, 12 is a water pump clutch, 13 is a fan clutch, 14 is a high-pressure fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com