Method for efficient supergravity stripping of two-dimension nano materials

A two-dimensional nanomaterial and supergravity technology, applied in nanocarbon, chemical instruments and methods, chemical/physical/physicochemical processes, etc., to achieve the effect of reducing refrigeration power and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

[0028] In the present invention, unless otherwise specified, all equipment and raw materials can be purchased from the market or commonly used in this industry. The methods in the following examples, unless otherwise specified, are conventional methods in this field.

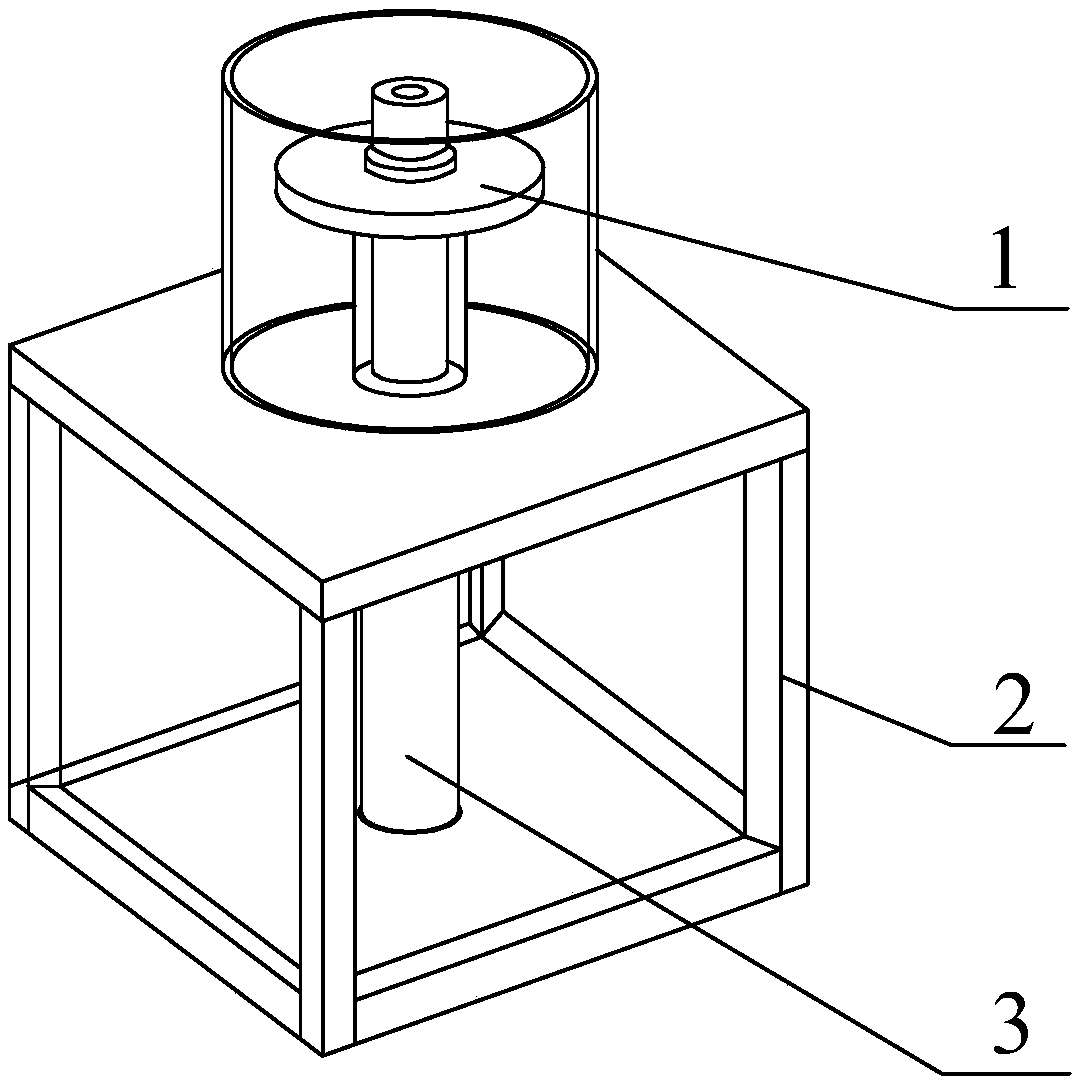

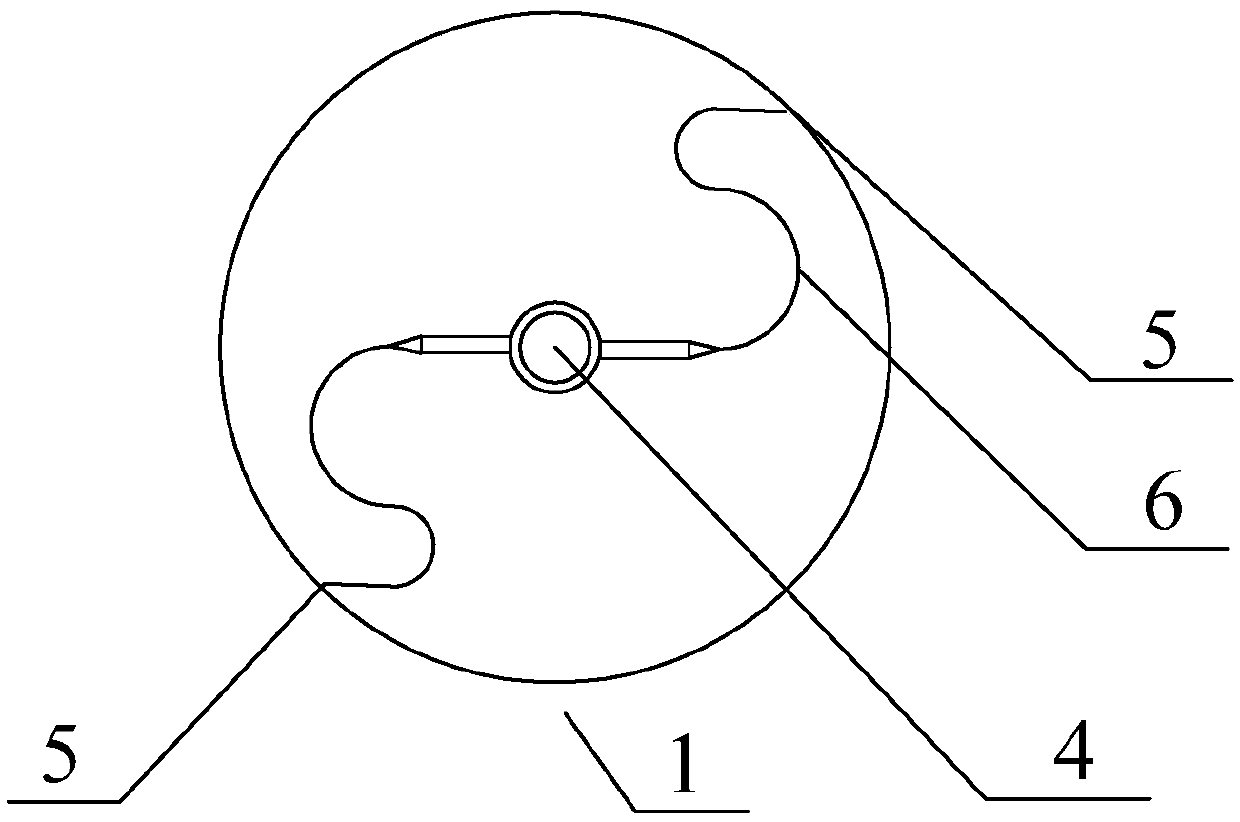

[0029] Secondary swirl flow reactor used in the present invention such as figure 1 As shown, including the turntable 1, the turntable is composed of upper and lower parts, figure 1 The part of the turntable shown in is a schematic diagram of combining the upper and lower parts of the turntable. There is a bracket 2 at the bottom of the turntable, and the turntable is fixed on the rotor of the motor 3; figure 2 The part shown in is the internal structure of the secondary rotation channel shown after opening the upper part of the tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com