A method and system for treating domestic waste incineration fly ash wet mold bag

A technology of domestic waste incineration and treatment method, which is applied in the field of domestic waste incineration fly ash wet-process mold bag treatment, which can solve the problems of large fluctuations in fly ash composition, unavoidable treatment problems, and low utilization rate of storage capacity, so as to alleviate the shortage of land resources , The effect of expanding the utilization factor of storage capacity and simplifying the processing procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

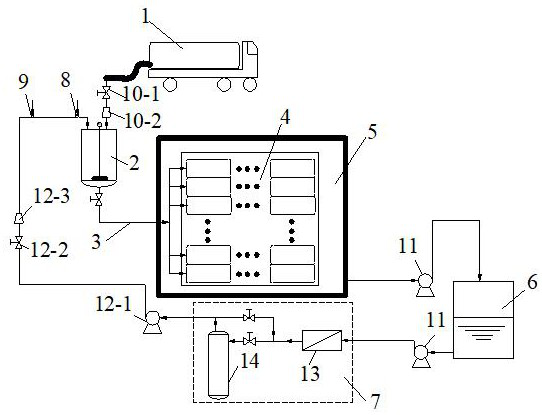

Method used

Image

Examples

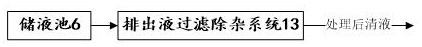

Embodiment 1

[0055] Example 1: The ratio of fly ash and water to pulping is 1:5 by weight, and the water used is the circulating water and partially supplemented landfill leachate after the effluent of the mold bag is filtered and treated by the effluent removal system in the effluent treatment system. RO concentrate, heavy metal stabilizer is sulfide inorganic chelating agent, the addition amount is 1% of fly ash dry basis, dioxin extractant is sodium lauryl sulfate anionic surfactant, addition amount is fly ash dry basis 0.5%, adopt the slurry conveying pipe with thread on the inner wall to strengthen the homogenization, desalination and detoxification of fly ash. Normal performance can be achieved when the pH of the mold bag discharge liquid is 12.5), the modified mold bag is filled with fly ash slurry and left for 6 days to achieve complete homogenization, fly ash detoxification, desalination and dehydration / water consolidation.

[0056] After dehydration / hydration and consolidation, ...

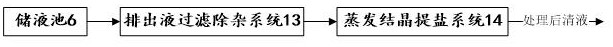

Embodiment 2

[0063] Example 2: The ratio of fly ash and water stirring and pulping is 1:10 by weight, and the water used is the circulating water after the effluent of the mold bag is processed by the effluent filtration and impurity removal system and the evaporative crystallization salt extraction system in the effluent treatment system and Part of the supplemented new water, pure acetic acid is used as the heavy metal extractant, and the addition amount is 8% of the dry basis of the fly ash, and the dioxin extractant is acetone, and the addition amount is 0.7% of the dry basis of the fly ash. The slurry conveying pipeline of the distributed spiral blades is used to strengthen the homogenization, desalination and detoxification of fly ash. The material of the mold bag is polypropylene, and the outer surface of the mold bag is modified by spraying a water-repellent finishing agent containing fluorine-containing organosiloxane (discharged from the mold bag). It can perform normal performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com