A preparation method of photothermal conversion phase change energy storage microcapsules

A phase-change energy storage and light-to-heat conversion technology, which is applied in the direction of microcapsule preparation, microsphere preparation, heat exchange materials, etc., can solve problems such as easy leakage, achieve enhanced absorption, novel and unique technical methods, and no energy consumption scattered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

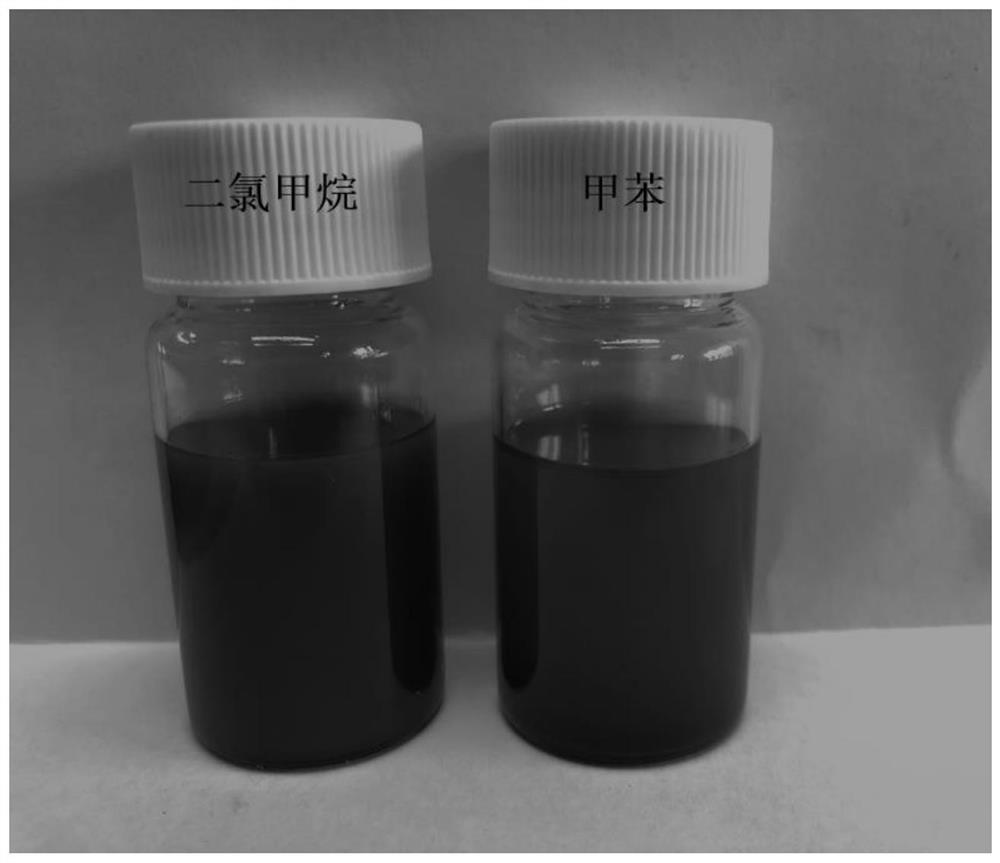

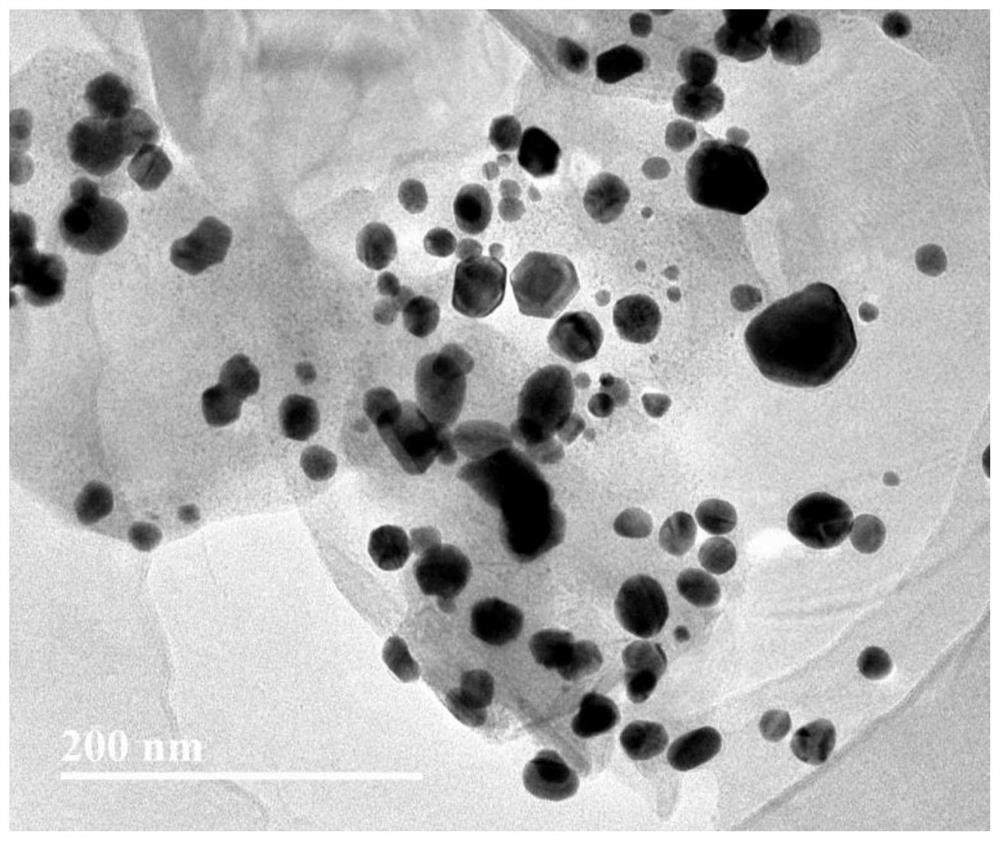

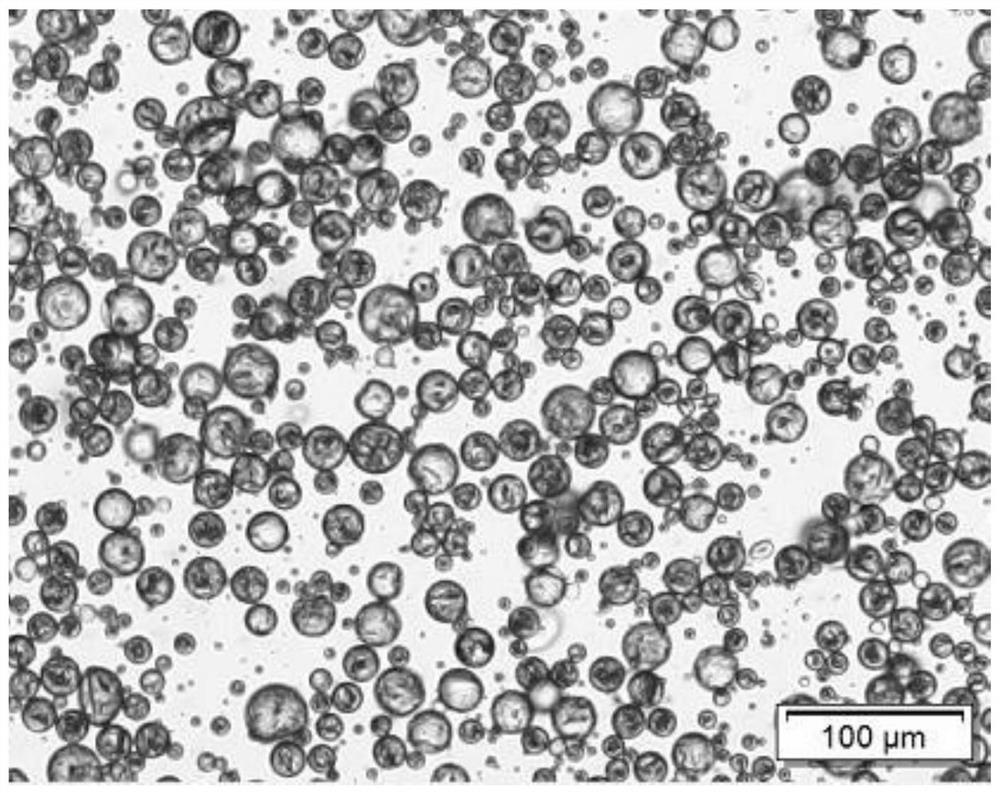

[0033] Take molybdenum disulfide 1mg / mL NMP solution 20mL, add 25mmol / L chloroauric acid aqueous solution 100 microliters and 0.1g / mL PMMA dichloromethane solution 100 microliters, centrifuge after ultrasonication for 2min to obtain the oil phase dispersion Molybdenum sulfide-gold material, disperse the material in dichloromethane and toluene, respectively, such as figure 1 As shown, it can be dispersed well. Such as figure 2 As shown, there are gold nanomaterials grown on the two-dimensional material. Take 20 mL of graphene oxide 10 mg / mL DMF solution, add 500 microliters of 25 mmol / L chloroauric acid aqueous solution and 200 microliters of 0.1 g / mL PMMA dichloromethane solution, and then centrifuge for 10 minutes to obtain the oil phase dispersed oxidation For the graphene-gold material, the material was dispersed in 10 mL of dichloromethane. Take 0.5g PMMA and 2g paraffin and dissolve in the above solvent to form an oil phase. Dissolve 0.1g of PVA (molecular weight 2W)...

Embodiment 2

[0035] Take molybdenum disulfide 1mg / mL NMP solution 20mL, add 25mmol / L chloroauric acid aqueous solution 100 microliters and 0.1g / mL PMMA dichloromethane solution 100 microliters, centrifuge after ultrasonication for 2min to obtain the oil phase dispersion Molybdenum sulfide-gold material, disperse the material in dichloromethane and toluene, respectively, such as figure 1 As shown, it can be dispersed well. Such as figure 2As shown, there are gold nanomaterials grown on the two-dimensional material. Take 20mL of NMP solution of bismuth selenide 5mg / mL, add 200 microliters of 25mmol / L chloroauric acid aqueous solution and 500 microliters of 0.1g / mL PMMA dichloromethane solution, and centrifuge for 5min to obtain the oil phase selenium Bismuth-gold material was dispersed in 20 mL of dichloromethane. Take 1g PMMA and 2g paraffin and dissolve in the above solvent to form an oil phase. Dissolve 0.5g of PVA (molecular weight 10W) in 50mL of water to form the water phase. S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com