A kind of oil-free super slippery coating and preparation method thereof

A coating and coating technology, which is applied in the field of oil-free super-slip coating and its preparation, can solve the problems of lubricating oil dissipation, greasy feeling, low transparency, etc., and achieve the solution of lubricating oil dissipation, good liquid repellency, and transparency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

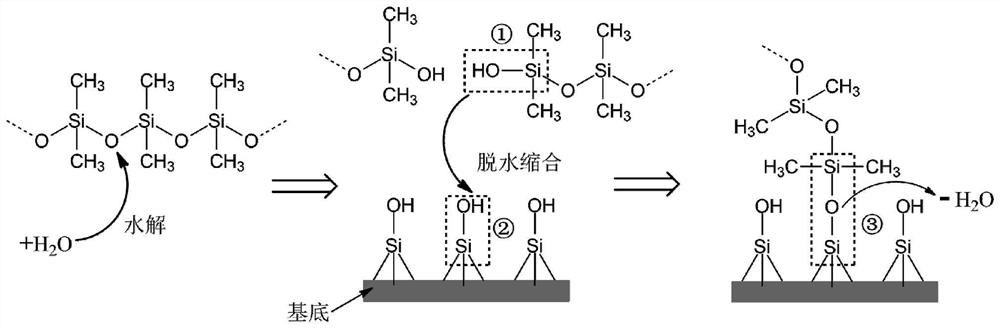

[0028] A preparation method for an oil-free super-slip coating, comprising the following steps:

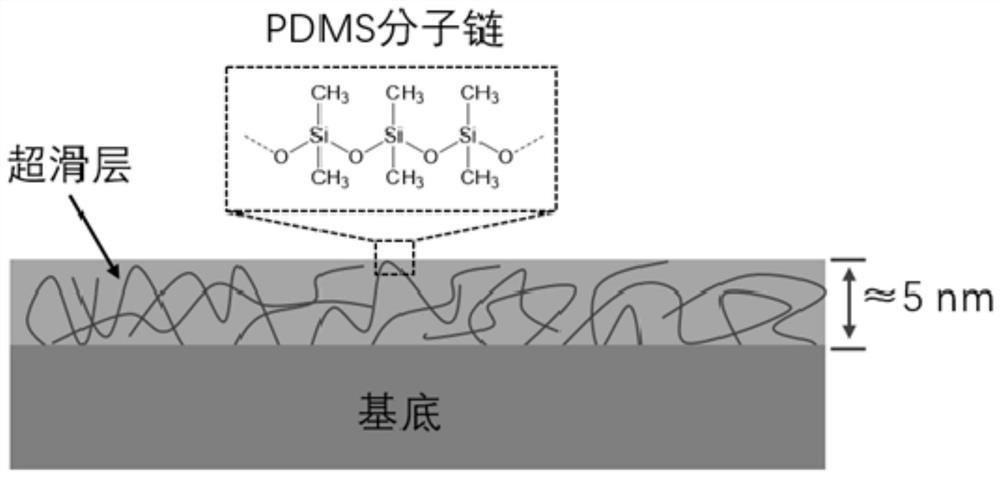

[0029] A glass substrate is selected, and the substrate is pre-cleaned by ultrasonic cleaning in acetone and ultrapure water at a power of 100W for 10 minutes; On the surface of the pre-cleaned glass substrate, the coating thickness is 500nm-2mm, and then placed horizontally at 25°C and 50% humidity for 24 hours, then ultrasonically cleaned with tetrahydrofuran, ethanol and water at a power of 100W for 5 times, and blown with nitrogen. Dries to an oil-free super slippery finish.

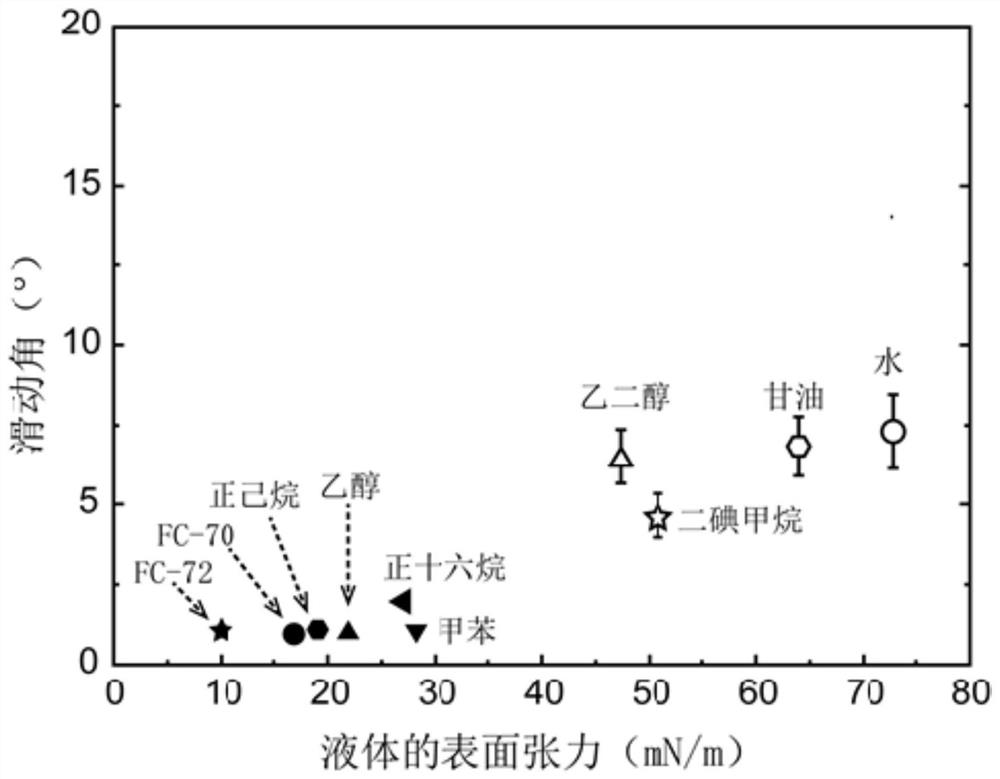

[0030] Carry out contact angle and sliding angle test on the oil-free super slippery coating gained in the present embodiment, water contact angle is 105 °, and sliding angle is 7 °; Oil (hexadecane) contact angle is 95 °, and sliding angle is 2 ° .

Embodiment 2

[0032] A preparation method for an oil-free super-slip coating, comprising the following steps:

[0033] Choose a silicon dioxide silicon wafer as the substrate, place the substrate in a mixture of 98vt% concentrated sulfuric acid and 30vt% hydrogen peroxide at a volume ratio of 7:3, heat at 90°C for 12h, and then place it in ultrapure water at 100W Ultrasonic cleaning at high power for 10 minutes; 1g of polydimethylsiloxane (molecular weight 2000-4000) was uniformly drip-coated on the surface of the pre-cleaned substrate through a dropper, with a coating thickness of 500nm-2mm; Place it horizontally for 24 hours under the condition of % humidity, then rinse it with toluene, ethanol and water for 5 times in sequence, and dry it with nitrogen to obtain an oil-free super-lubricious coating.

[0034] The contact angle and sliding angle test were carried out on the oil-free super-slip coating obtained in this embodiment, the oil (n-hexane) contact angle was 94°, and the sliding an...

Embodiment 3

[0036] A preparation method for an oil-free super-slip coating, comprising the following steps:

[0037] Ceramics were selected as the substrate. When pre-cleaning, the substrate was ultrasonically cleaned in acetone and ultrapure water at a power of 100W for 10 minutes, and then plasma treated for 30 minutes; the pre-cleaned ceramic substrate was immersed in 1g of polydimethylsiloxane ( Molecular weight is 6000 ~ 8000) liquid, the coating thickness is 500nm ~ 2mm, and then placed horizontally at 25°C and 85% humidity for 24 hours, then ultrasonically cleaned 5 times with tetrahydrofuran, ethanol and water at a power of 100W, and blown with nitrogen. Dries to an oil-free super slippery finish.

[0038] The contact angle and sliding angle tests were carried out on the oil-free super-slip coating obtained in this example, the oil (perfluoro-n-hexane) contact angle was 85°, and the sliding angle was 1.5°.

[0039] Water and various non-polar organic liquids are placed on the oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com