Cooling assembly

a technology of cooling assembly and cooling chamber, which is applied in the direction of defrosting, domestic cooling apparatus, application, etc., can solve the problems of increasing the problem of climate, affecting the cooling power, and affecting the cooling effect of electronic components, so as to reduce the cooling power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

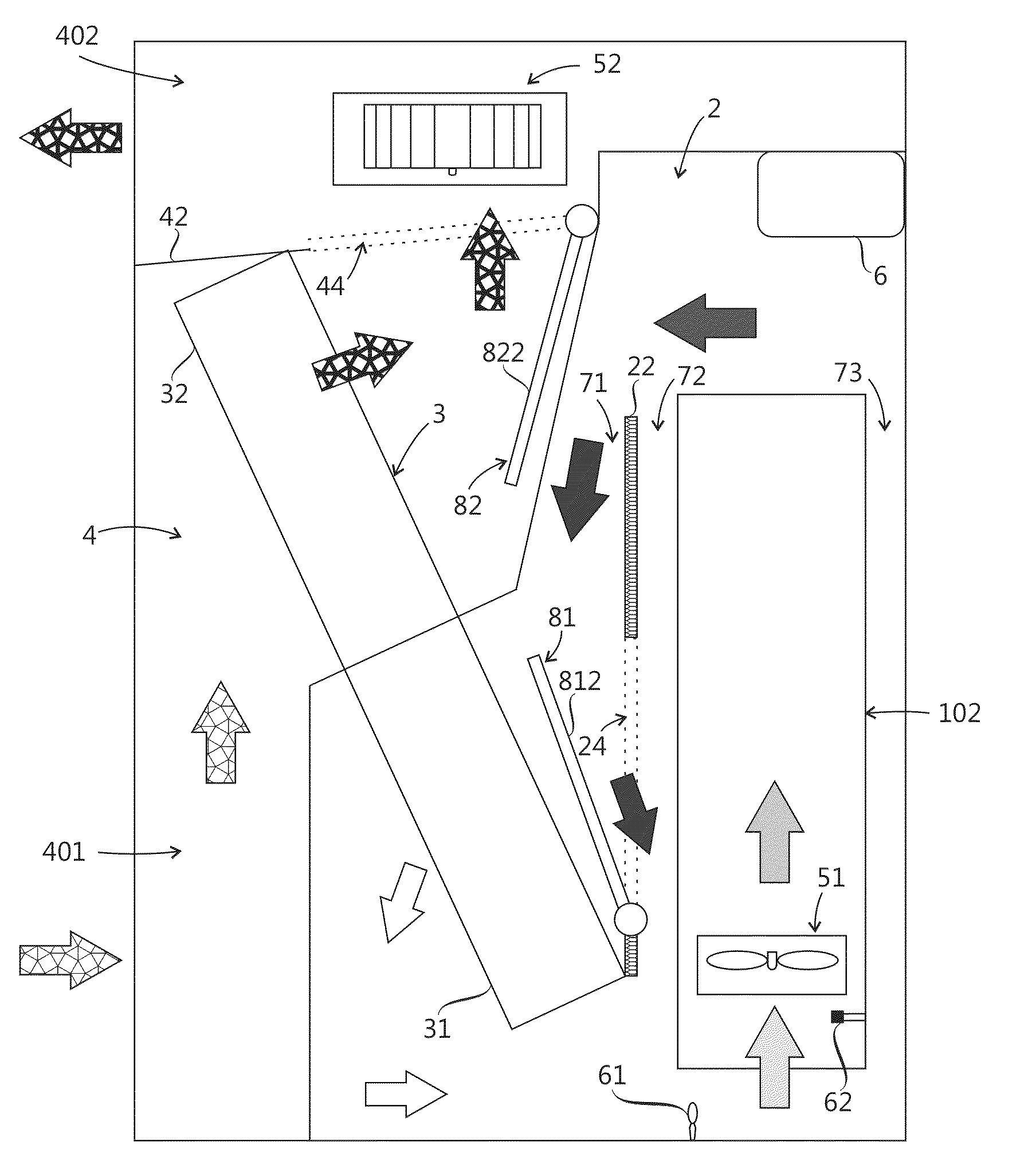

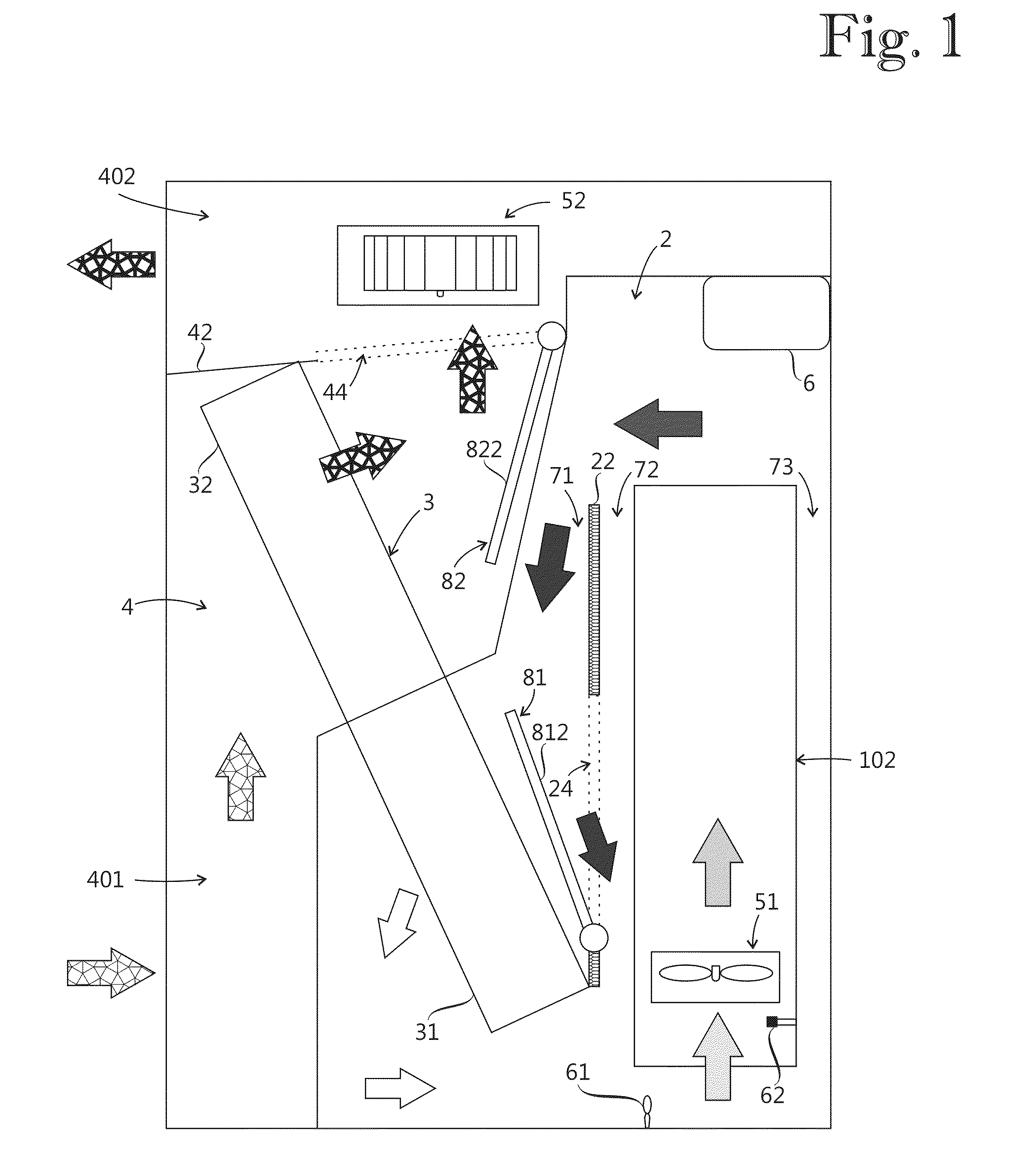

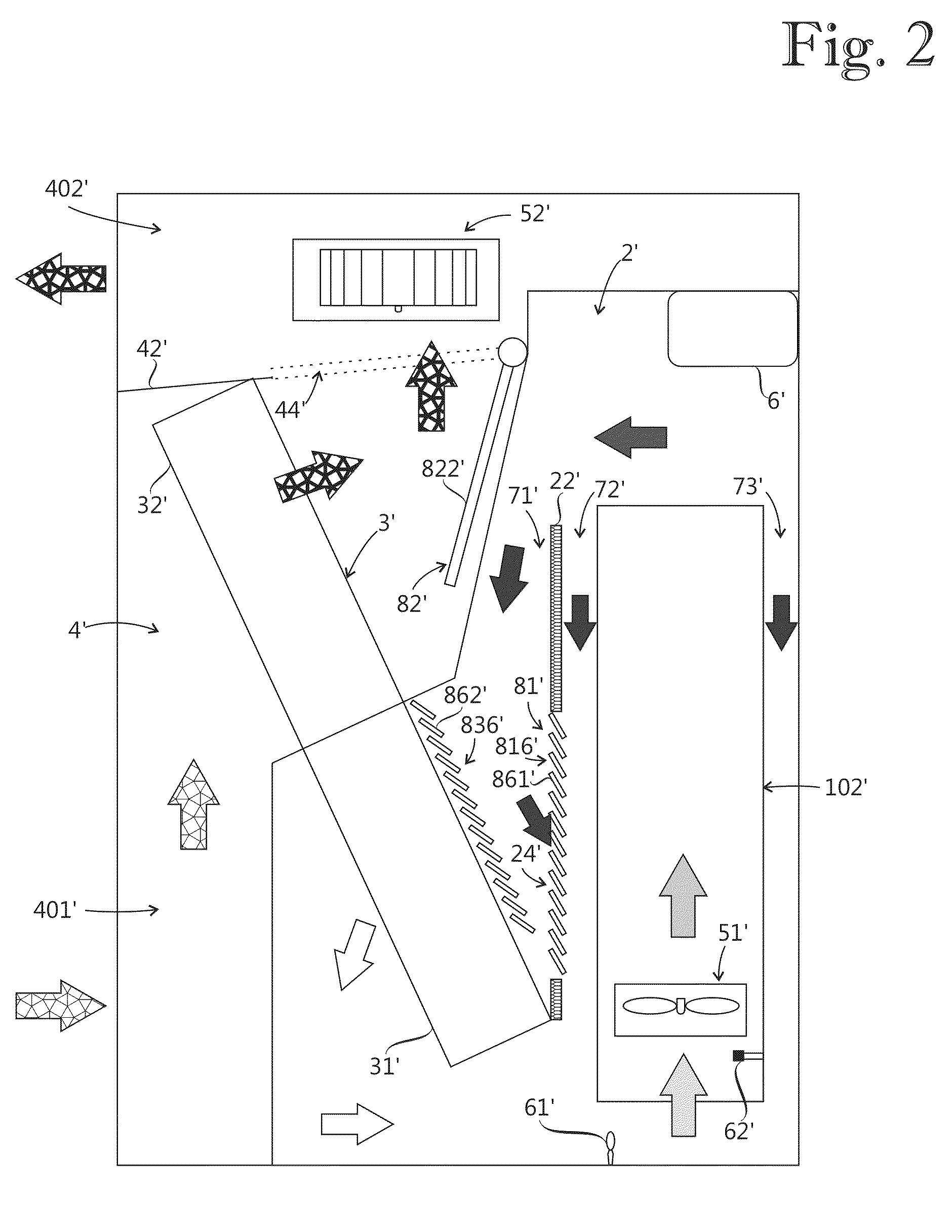

[0011]Exemplary embodiments of the present disclosure provide a cooling assembly which is capable of alleviating disadvantages caused by humidity.

[0012]Exemplary embodiments of the present disclosure are based on the idea of decreasing in predetermined operating conditions a relative humidity level in a device chamber by reducing a cooling power of a heat exchanger configured to transfer heat from the device chamber. The cooling power is reduced by a first throttle means capable of regulating a first partial flow of a cooling medium interacting with a first portion of the heat exchanger located in the device chamber. Exemplary embodiments of the present disclosure improve controllability of a heat exchanger by lowering a minimum cooling power of the heat exchanger. Decreasing cooling power of the heat exchanger raises the temperature in a device chamber thereby reducing relative humidity.

[0013]An advantage of the cooling assembly of the present disclosure is that a relative humidity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com