Engineering operation machine

A working machine and engineering technology, applied in mechanical equipment, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve the problems of wasting energy, reducing the overall energy efficiency of the system, affecting the service life of the hydraulic system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

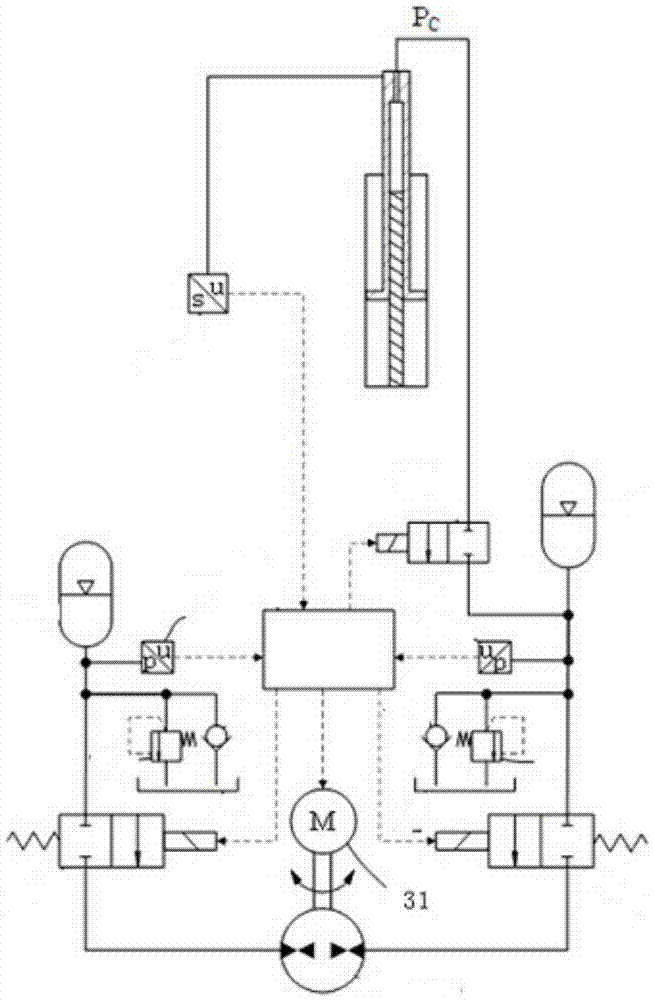

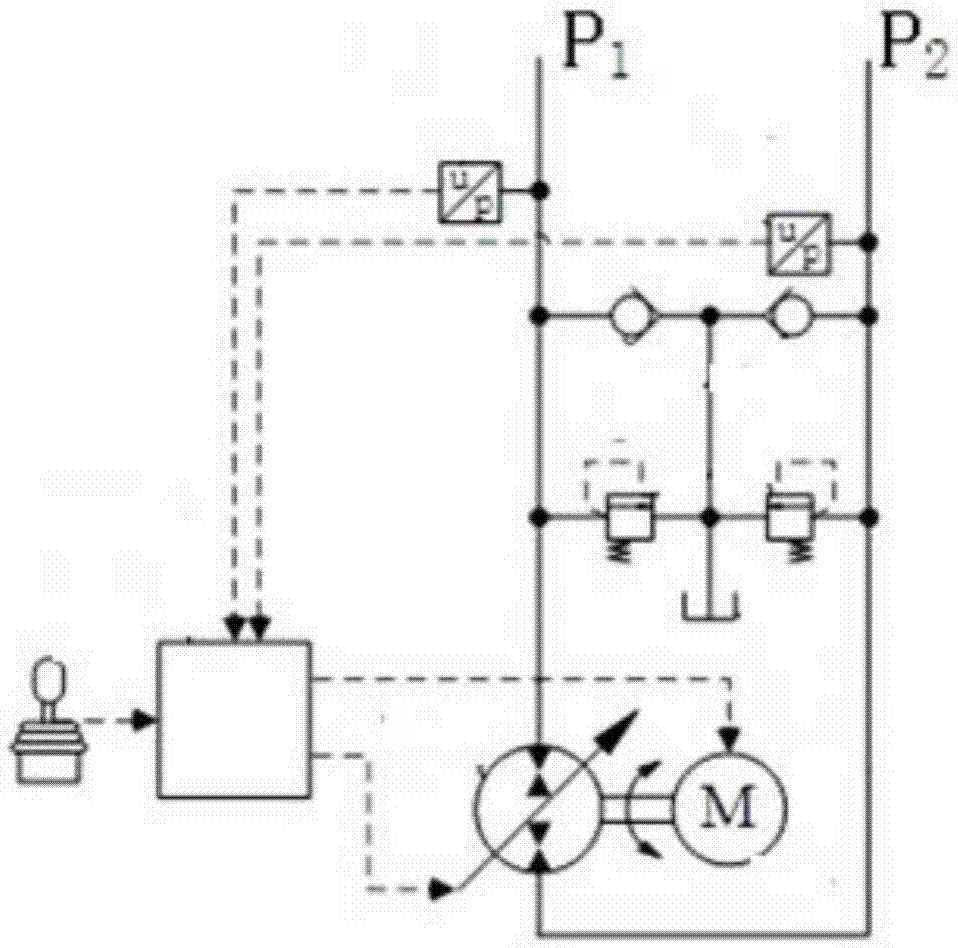

[0084] Embodiment 1: The difference between this embodiment and the existing hoisting machine is that the luffing hydraulic cylinder is a hydraulic cylinder with three cavities: an extension cavity, a retraction cavity and a recovery cavity, and the telescopic hydraulic cylinder has an extension cavity, a retraction cavity Hydraulic cylinder with three cavities of return cavity and recovery cavity ( image 3 shown).

[0085] The cylinder body of the luffing hydraulic cylinder is connected to the vehicle frame through a pin shaft, and the piston rod of the luffing hydraulic cylinder is connected to the main arm through a pin shaft. The cylinder body of the telescopic hydraulic cylinder is connected to the main arm through a pin shaft, and the piston rod of the telescopic hydraulic cylinder is connected to the telescopic arm through a pin shaft.

[0086] The luffing hydraulic cylinder is connected with the luffing recovery hydraulic system, and the telescopic hydraulic cylinder...

Embodiment 2

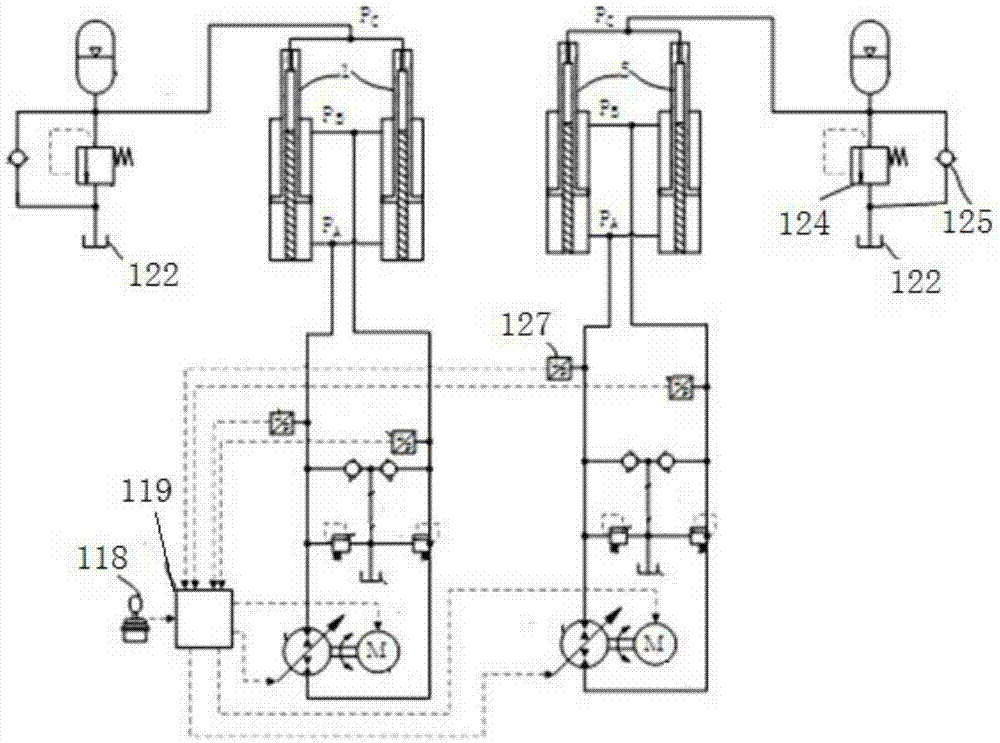

[0129] Embodiment 2: The difference between this embodiment and the existing hydraulic shovel lies in the hydraulic cylinder and the hydraulic cylinder drive system.

[0130] The two boom hydraulic cylinders and the two stick hydraulic cylinders are hydraulic cylinders with three cavities. The third working oil port P of the two boom hydraulic cylinders C The oil port is connected with the high pressure accumulator.

[0131] The oil port of the high-pressure accumulator is respectively connected to the high-pressure side of the safety valve 124 and the one-way valve 125, and the low-pressure side of the safety valve and the one-way valve are both connected to the oil tank. The permissible direction of oil flow is from the tank to the high pressure accumulator.

[0132] The boom hydraulic cylinder driving system includes a joystick 118 , a first controller 119 , a hydraulic pump motor, a prime mover, an oil tank 122 , a safety valve 124 , a one-way valve 125 and two pressure ...

Embodiment 3

[0153] Example 3: Figure 13 As shown, the difference between this embodiment and the existing loader is that the boom hydraulic cylinder is a hydraulic cylinder with three cavities, the dump bucket hydraulic cylinder is a hydraulic cylinder with three cavities, and the recovery chamber of the boom hydraulic cylinder is connected to Boom recovery hydraulic system, the recovery cavity of the dump bucket hydraulic cylinder is connected to the dump bucket recovery hydraulic system. Boom recovery hydraulic system and tipping bucket recovery hydraulic system have the same structure, including: proportional valve, balance accumulator, balance chamber overflow valve, balance chamber pressure sensor, balance chamber oil supply valve, balance chamber solenoid valve, quantitative pump, Servo motor, surge chamber solenoid valve, surge accumulator, surge chamber overflow valve, surge chamber pressure sensor, surge chamber filling valve, recovery controller. Among them, the boom recovery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com