Continuous beam 0# block support and installing method

A technology of beams and longitudinal beams, applied in the field of continuous beam 0# block support, which can solve the problems of long demolition period, affecting the appearance of pier concrete, difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

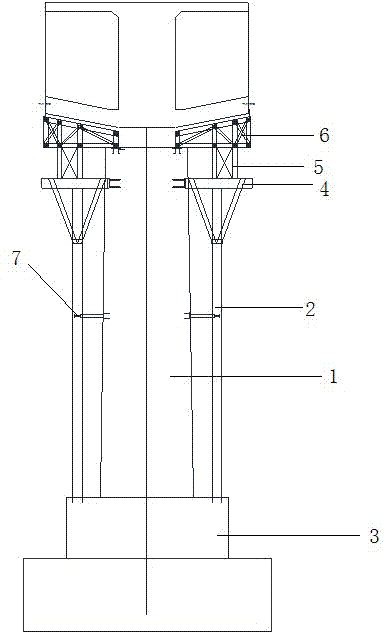

[0013] Embodiment of the present invention: there are two steel pipe columns 2 on each side of the bridge pier 1 (located below the web), the steel pipe columns 2 are directly supported on the cap concrete 3, and the longitudinal position is determined by trial calculation; The connected short longitudinal beam 4 is welded to the embedded part of the pier body 1 and directly welded to the top of the column 2; a set of crossbeams 5 is arranged above the short longitudinal beam 4, the length of which is equivalent to the width of the bridge deck, relying on the short longitudinal beam 4 The position of the welded part is fixed; an array of bent frames 6 is arranged above the beam 5, and one end of the bent frame 6 is welded to the bridge pier through an embedded part, and is relatively fixed with the beam 5, and the brackets of the bent frame 6 are connected horizontally to increase the lateral stiffness of the bent frame 6; Place the box girder bottom mold directly above the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com