Angle-adjustable glass curtain wall system

A glass curtain wall and angle technology, applied to walls, building components, buildings, etc., can solve the problems of increasing the owner's construction cost, low construction efficiency, and increasing project cost, so as to reduce construction cost, save mold cost, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

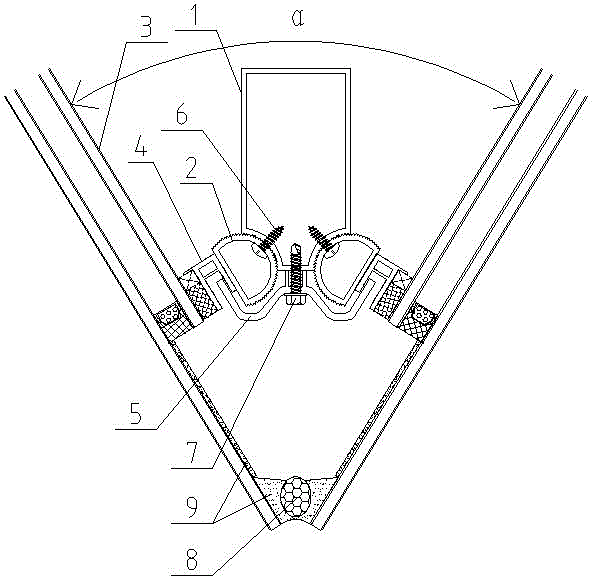

[0027] Example 1, such as figure 1 , figure 2 , Figure 7 and Figure 8 The angle-adjustable glass curtain wall system shown includes a square column 1 and glass panels 3 on both sides of the column 1, and the angle between the inner surfaces of the glass panels 3 on both sides of the column 1 is 45°~189°. The bottom of both sides of the column 1 is provided with an inner concave arc surface 11, and the inner concave arc surface 11 is provided with a tooth-shaped protrusion 12. In the inner concave arc surface 11, there is a main keel 2 matched by a circular arc. The slot 21, the main keel 2 and the column 1 are engaged with the toothed groove 21 and the toothed protrusion 12, and the main keel 2 and the column 1 are fixedly connected by the keel self-tapping screw 6. A glass frame 4 is provided on the inner side of the glass panel 3, and a frame clamp 5 for pressing the glass frame 4 to the main keel 2 is provided under the column 1, and the frame clamp 5 and the column ...

Embodiment 2

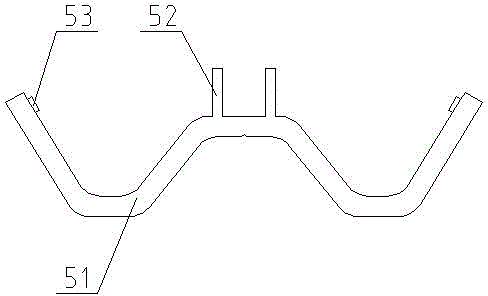

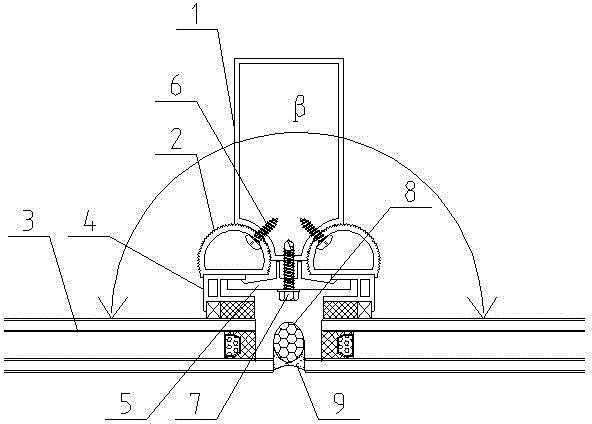

[0031] Example 2, such as image 3 and Figure 4 As shown, the difference from Embodiment 1 is that the attached frame pressing block 5 includes a "one"-shaped pressing plate 54 and two top ribs 55 on the "one"-shaped pressing plate 54 connected to the bottom of the column 1, "one" Shaped pressing plate 54 top surface is provided with the groove 56 that is positioned at top rib 55 both sides, and " one " shaped pressing plate 54 stretches in by the end of groove 56 outsides and presses on the glass attached frame 4.

[0032] In this embodiment, the included angle β between the inner surfaces of the glass panels 3 on both sides is 180°.

Embodiment 3

[0033] Example 3, such as Figure 5 and Figure 6 As shown, the difference between it and Embodiment 2 is that the bottom surface of the "one"-shaped pressing plate 54 is a concave arc shape, which can adapt to the large-angle corner installation conditions of the glass panels 3 on both sides.

[0034] In this embodiment, the included angle γ between the inner surfaces of the glass panels 3 on both sides is 189°.

[0035] The present invention is applicable to the construction and installation of the glass curtain wall whose rotation angle ranges from 45° to 189°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com