Carbon fiber cable strand inner sleeve conical bonded anchorage device

A carbon fiber and inner sleeve technology, applied in structural elements, bridge parts, bridges, etc., can solve the problems of uneven force on CFRP wire, uneven radial extrusion stress of cable strands, stress concentration, etc. The effect of knowing the amount of slip, improving the uneven force and reducing the degree of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the drawings and embodiments.

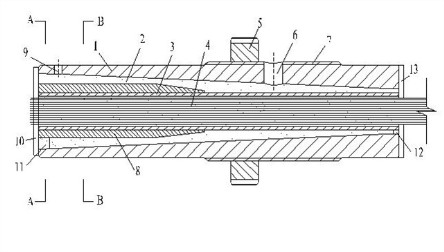

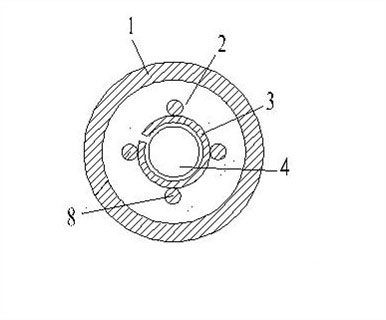

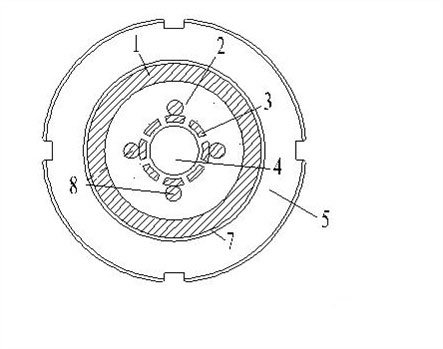

[0018] Such as figure 1 As shown, the carbon fiber strand inner sleeve tapered bonding anchor is composed of an anchor ring with an inner tapered hole 1, a sleeve 3 placed in the anchor ring to wrap the CFRP strand 4, etc. The anchor ring The outer thread 7 is sleeved with a limiting fastener nut 5, and a stiffening threaded steel bar 8 is arranged on the outer side of the sleeve 3; an vent hole 9 and a glue hole 6 are arranged on the anchor ring. The large hole end and the small hole end of the tapered hole of the anchor ring are provided with strand positioning end plugs 10 for fixing the CFRP strands. The sleeve has an axial wedge-shaped hollow groove 14, the wedge tip of the hollow groove faces the small hole end of the tapered hole of the anchor ring; one end of the stiffening threaded steel bar 8 has a wedge-shaped structure. 13 and 12 in the figure are the end pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com