Method for rebuilding diversion tunnel body into flood discharging tunnel body

A technology of diversion tunnel and flood discharge tunnel, which is applied in construction, water conservancy engineering, marine engineering, etc., can solve the problems of difficulty in implementation, single application function, and low difficulty in demolishing poured concrete, and achieves the effect of reducing hydration heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method for rebuilding the diversion tunnel body of the present invention into a flood discharge tunnel body comprises the following steps:

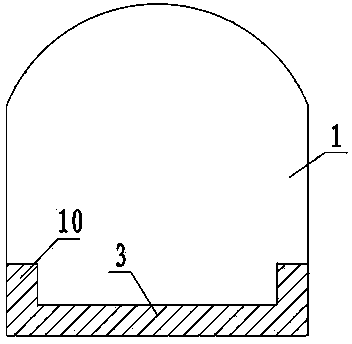

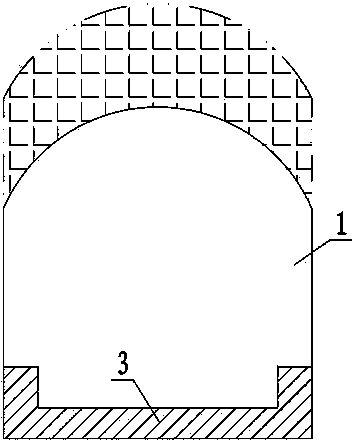

[0024] The first step: if figure 1 , 2 As shown, the section of the original diversion tunnel 1 is expanded to the designed expanded section of the flood discharge tunnel;

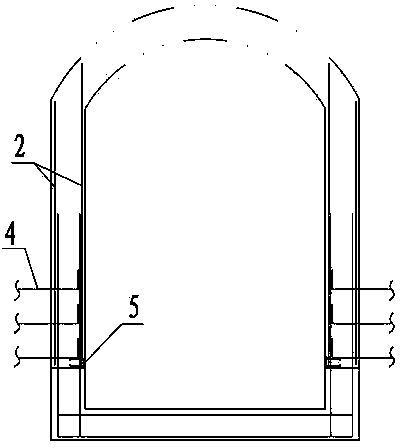

[0025] The second step: if image 3 , 4 As shown, the vertical reinforcement 2 of the tunnel side wall is installed, and the anchoring agent anchor rod 4 and the pre-embedded steel plate 5 are installed within a certain range at the junction of the precast tunnel side wall 9 and the original diversion tunnel poured side wall 10; The anchor rod 4 extends horizontally outward from the position of the vertical steel bar 2 inside the side wall of the tunnel, and the anchor rod 4 is located at the vertical steel bar 2 inside the side wall of the tunnel. Weld to steel bar 2;

[0026] Step 3: If Figure 4 As shown, pour the tunnel side wall 9 and the tunnel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com