Patents

Literature

37results about How to "Guaranteed functional requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

IoT (Internet of Things)-technology-based refuse collection management system

InactiveCN102708476AMeet extension requirementsSatisfy securityLogisticsRefuse collectionDecision management

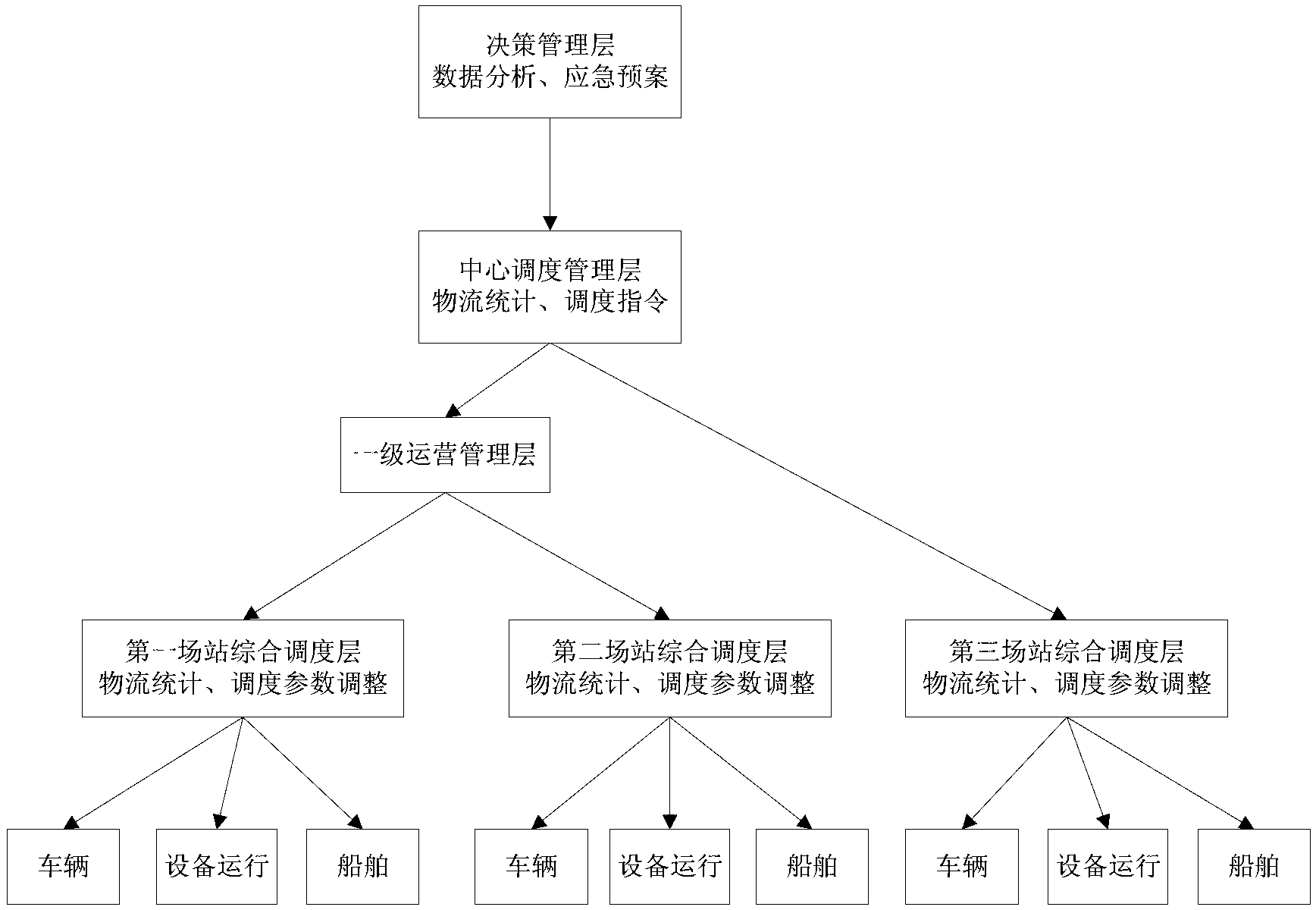

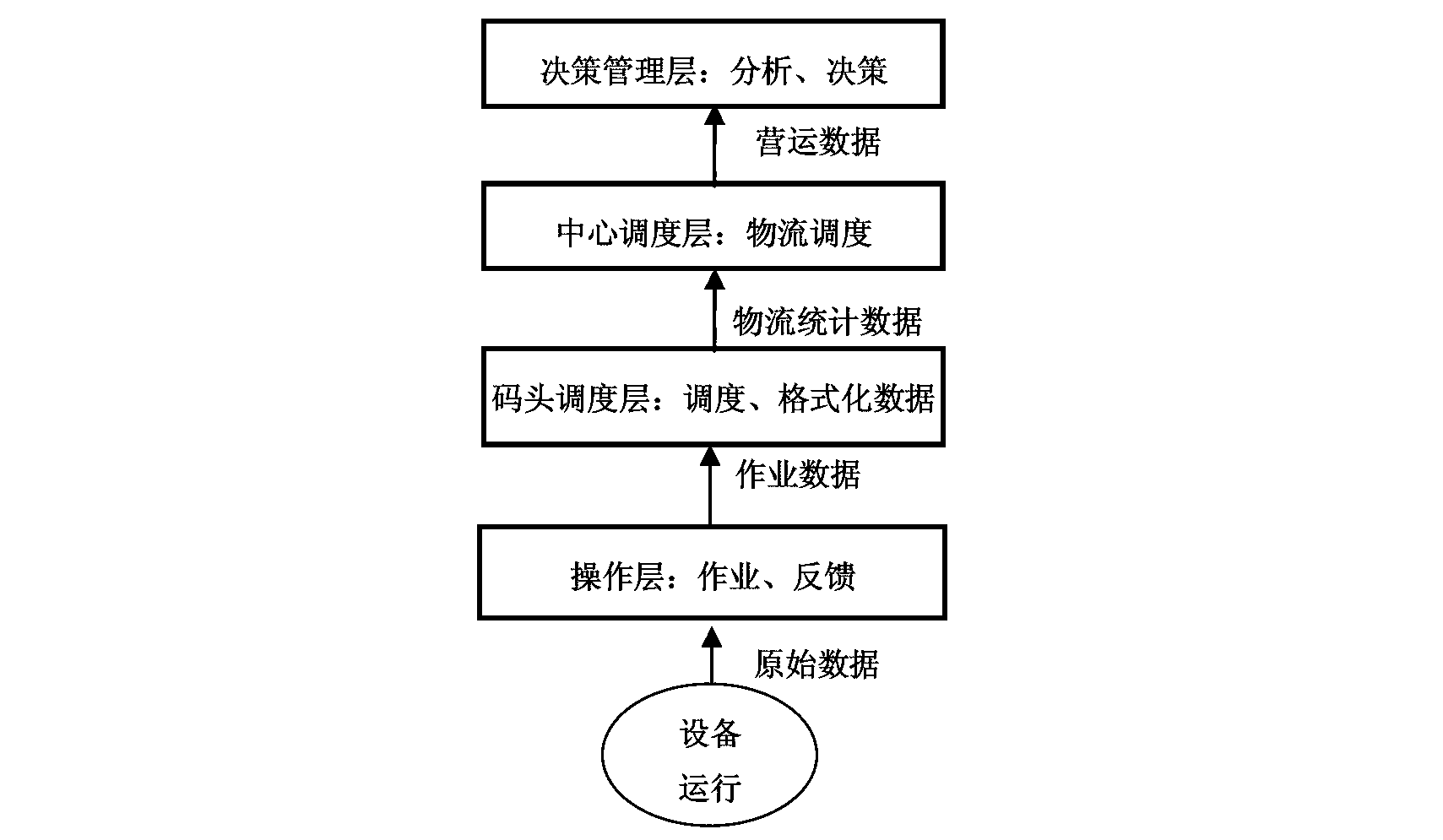

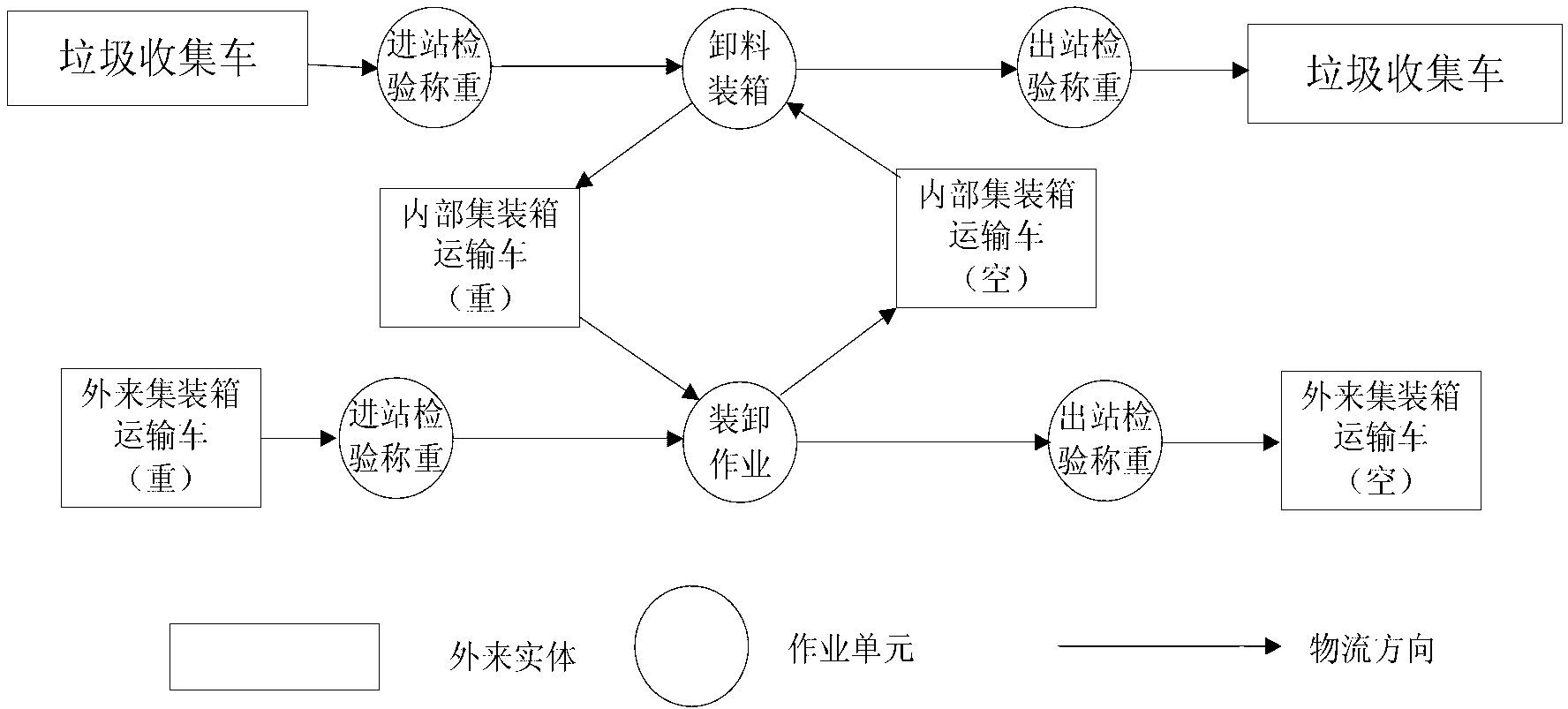

The invention provides an IoT (Internet of Things)-technology-based refuse collection management system which comprises a decision management layer, a center dispatching management layer and a dock comprehensively-dispatching management layer from top to bottom. A data processing flow of the refuse collection management system is implemented in a logistics mode, and the refuse collection management system comprises an operating layer, a wharf dispatching layer, a center dispatching management layer and a decision management layer, wherein the operating layer generates operation information and then feeds back or transfer the operating information to the wharf dispatching layer through the system and each hardware device interface, and after the operating information is formatted, final statements and final reports are formed and uploaded to the center dispatching layer, and then the center dispatching layer organizes the final statements and the final reports and then transfers operating data to the decision management layer. The refuse collection management system comprises an operation monitoring command center (as an upper dispatching center) and an operation management subsystem comprising a transfer station operation management system, a wharf and storage-yard operation management system, a ship dispatching management system, a refuse wharf short-barge operation management system, an emergency dispatching command system and a data statistical analysis and statement management system.

Owner:上海中海龙高新技术研究院

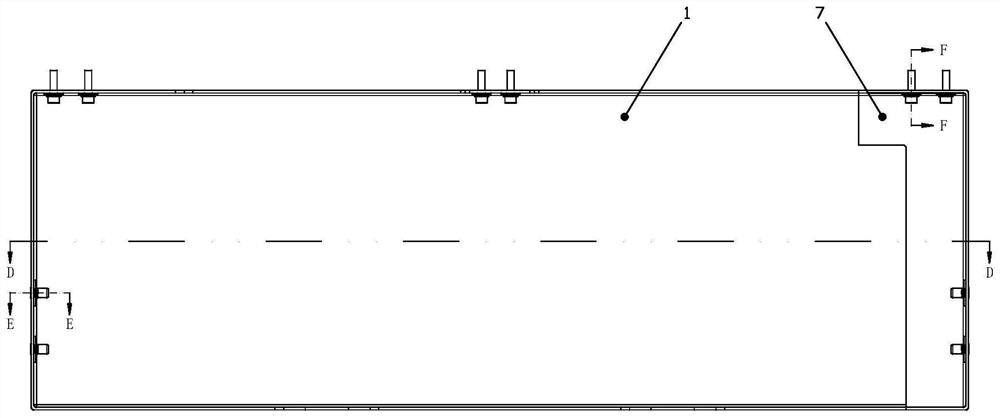

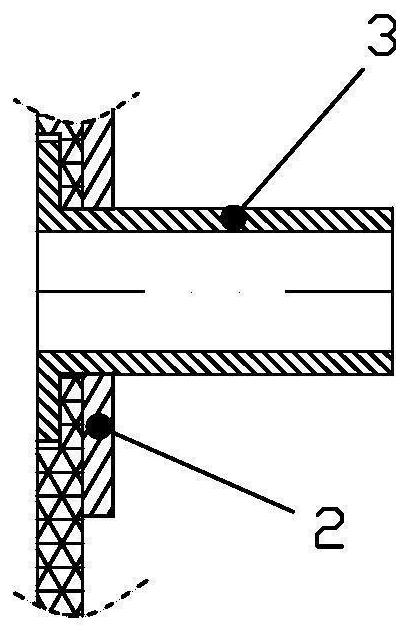

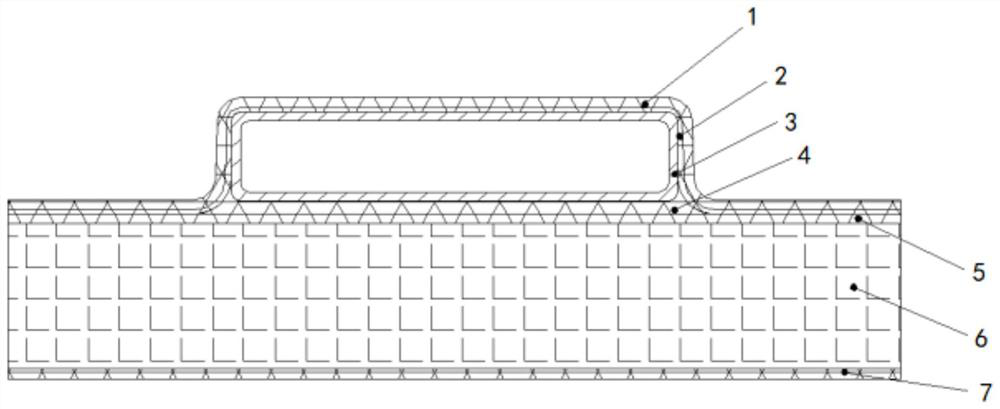

Viaduct drop-off deformation seam structure and construction method of viaduct drop-off deformation seam structure

ActiveCN102704391ADigest crackingDigest upliftBridge structural detailsBridge erection/assemblyRoad surfaceMaterials science

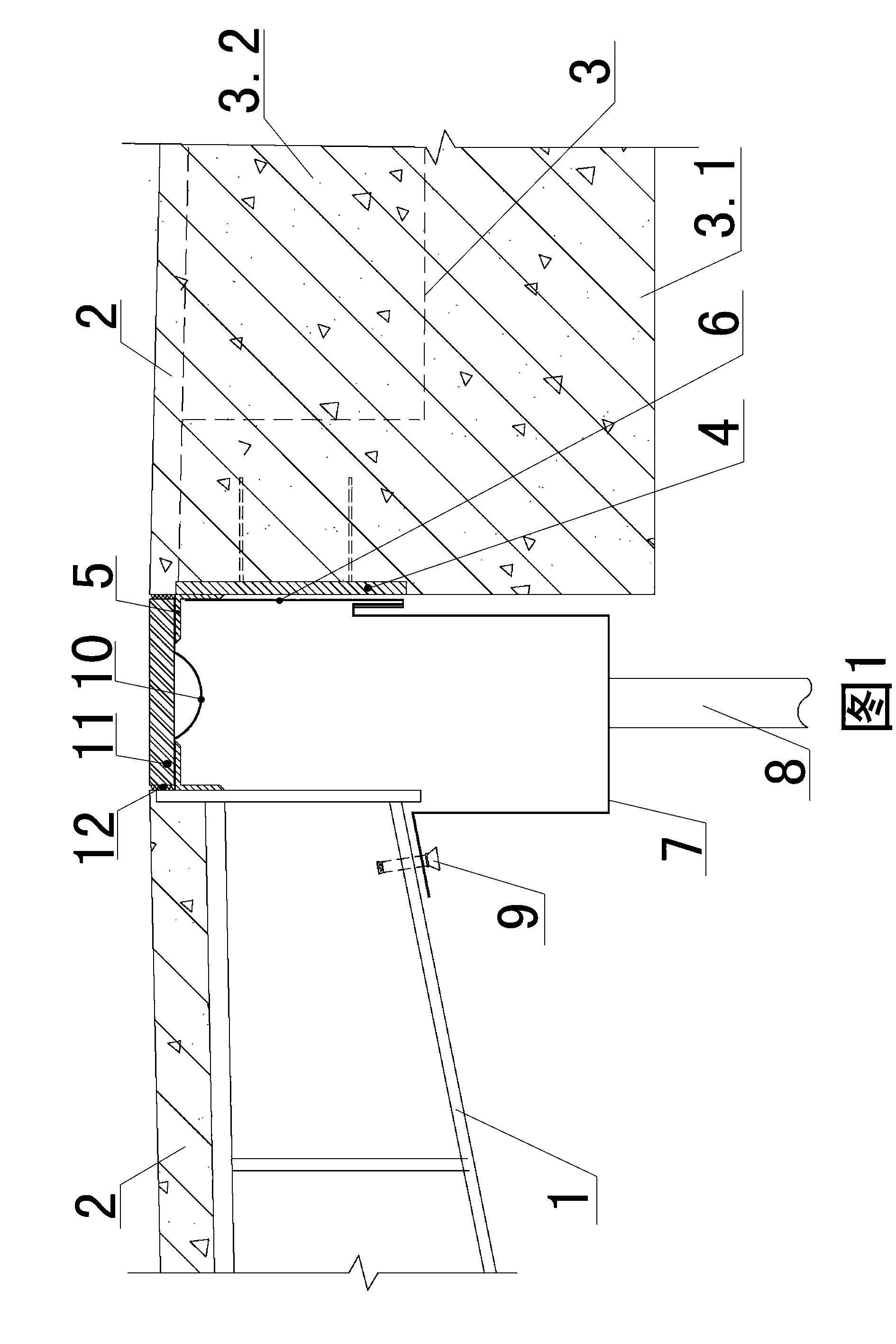

The invention relates to a viaduct drop-off deformation seam structure, which is arranged between a box type steel structure and a concrete structure, wherein one side of the concrete structure corresponding to the box type steel structure is fixedly provided with an embedded steel element, a steel support seat facing the inside of a deformation steam is correspondingly welded with the upper part of the embedded steel element and the upper part of the box type steel structure, waterproof coiled materials are paved on the steel support seat in the through length direction of the deformation seam, a steel press plate is placed on the waterproof coiled materials, and asphalt paste is respectively embedded in junction parts of the two sides of the steel press plate with the box type steel structure and the concrete structure. A groove-shaped layer board is arranged in the through length direction at the lower part of the deformation seam, one side of the groove-shaped layer board is connected with a lower wing edge of the box type steel structure, the other side of the groove-shaped layer board is fixedly connected with a hanging connecting element provided with a bent hook at the bottom end, and the upper end of the hanging connecting element is fixedly connected with the steel support seat arranged at one side of the concrete structure. The viaduct drop-off deformation seam structure solves the technical problems that the traditional pavement deformation seam structure cannot meet the requirement of various kinds of protection performance of the pavement deformation seam between a drop-off platform and a viaduct of a railway station building viaduct waiting hall under the deformation condition.

Owner:BEIJING NO 3 CONSTR ENG

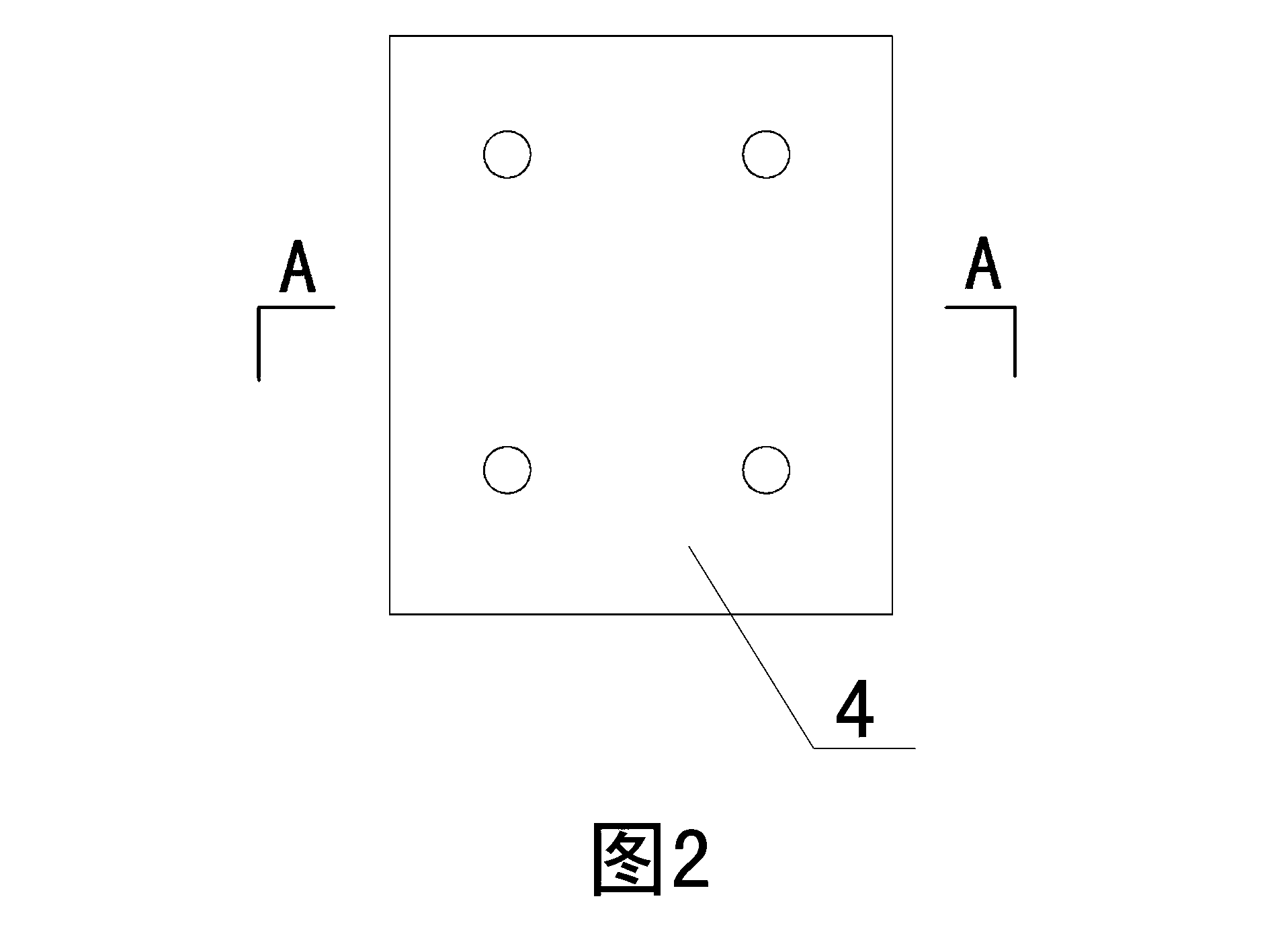

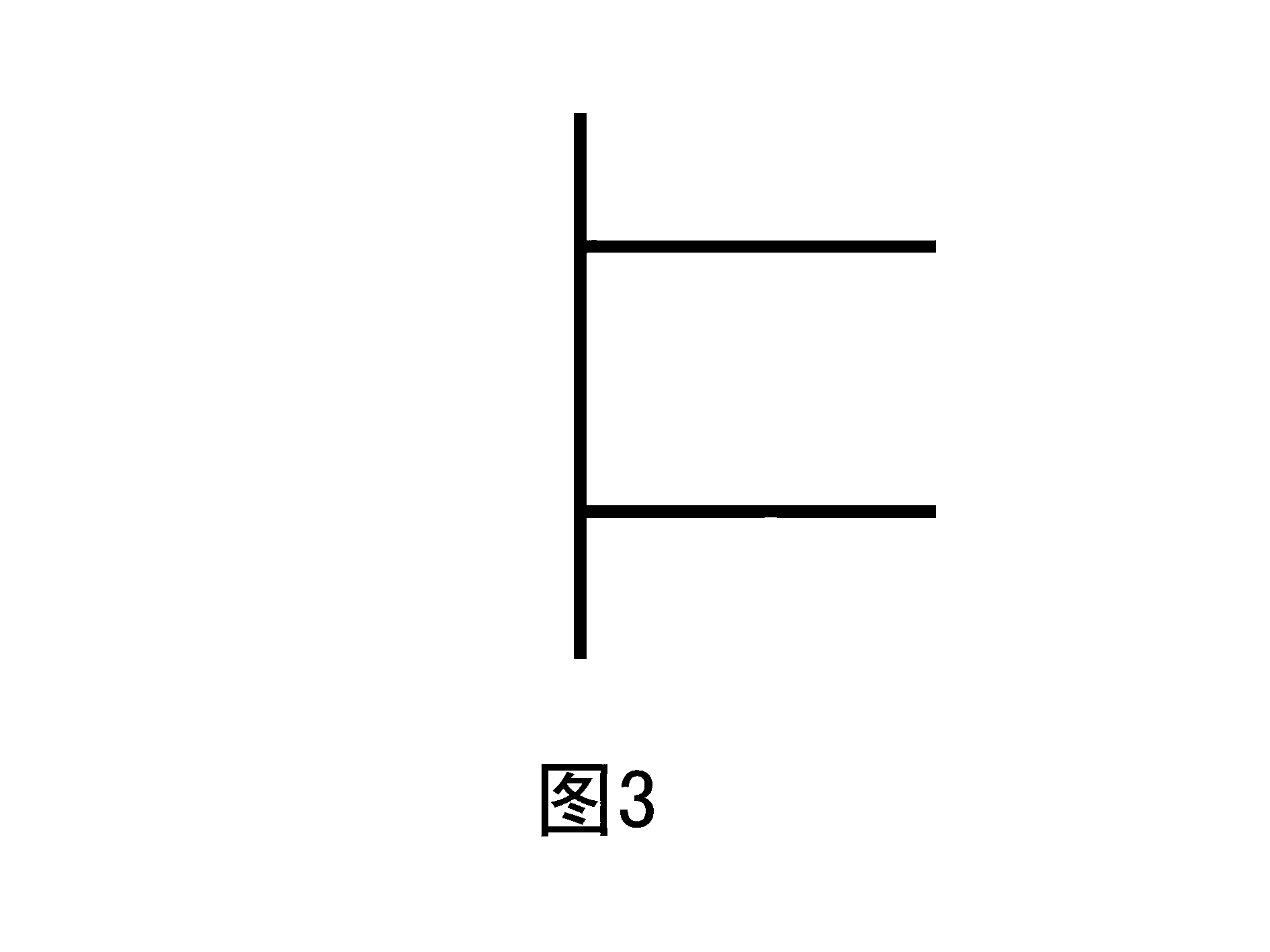

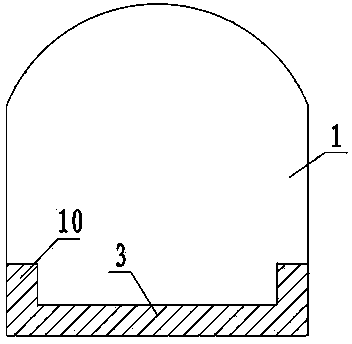

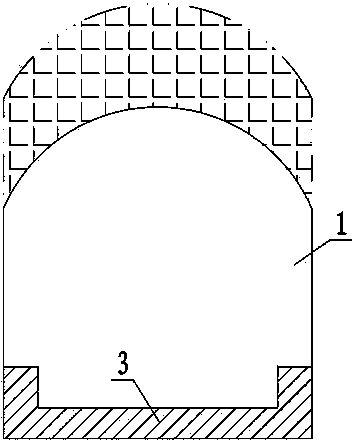

Method for rebuilding diversion tunnel body into flood discharging tunnel body

ActiveCN103388322AReduce demolitionGuaranteed functional requirementsBarrages/weirsReinforced concreteRebar

The invention discloses a method for rebuilding a diversion tunnel body into a flood discharging tunnel body. The method comprises the steps of 1, excavating the section of the original diversion tunnel body to the designed expanding excavation section of the flood discharging tunnel in an expanding mode; 2, mounting vertical reinforcing steel bars at tunnel edge walls; 3 pouring tunnel edge wall and tunnel top arch concrete according to construction demands; and 4, after the diversion is finished, pouring bottom plate concrete on an original diversion tunnel bottom plate, wherein the bottom plate concrete is poured in two layers from bottom to top, the pouring elevation of the lower concrete is higher than that of embedded steel plates; after the pouring of the lower layer concrete is finished, the upper layer concrete is poured after the reinforcing steel bars needed to be mounted in the upper layer concrete are welded with the embedded steel plates; the top face elevation of the upper layer concrete is the bottom plate elevation of the flood discharging tunnel after rebuilding; the strength level of the lower layer concrete is lower than that of the upper layer concrete. The method for rebuilding the diversion tunnel body into the flood discharging tunnel body has the main advantages of omitting the demolishing of poured reinforcing steel bar concrete in the built diversion tunnel, and ensuring the function demands on the tunnel in different periods.

Owner:YELLOW RIVER ENG CONSULTING

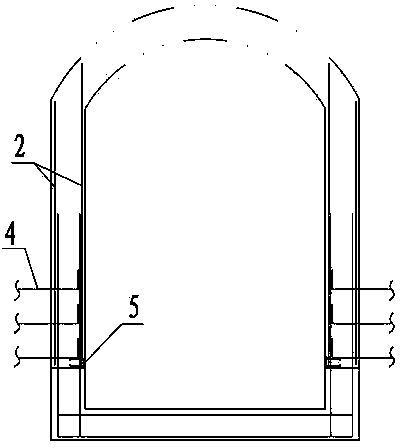

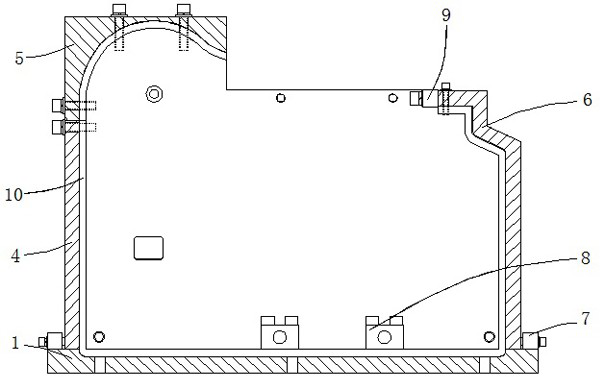

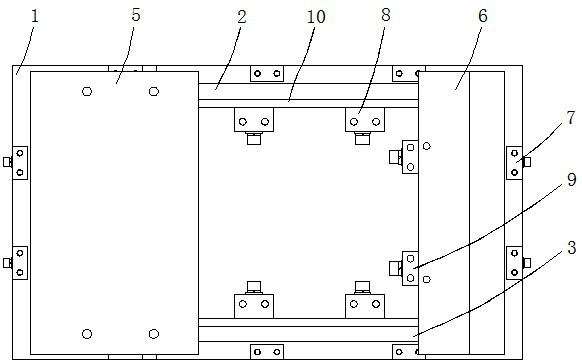

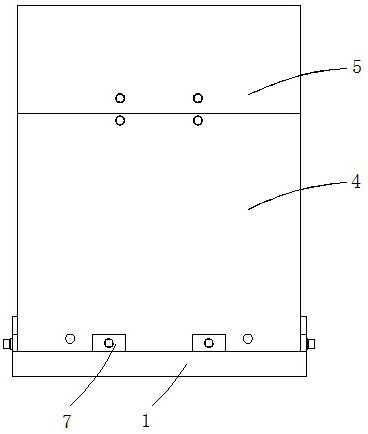

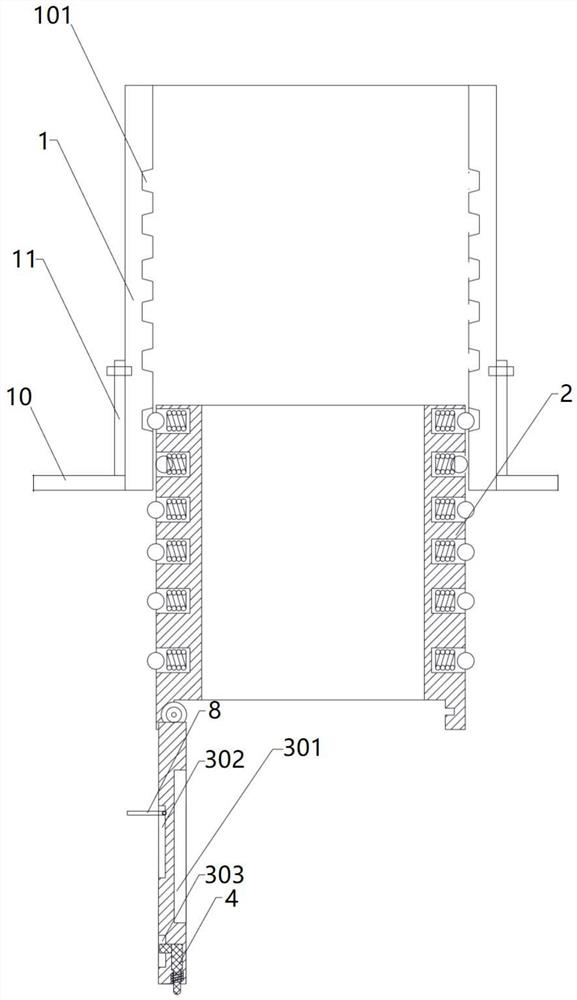

Ceiling finished product access hole device capable of being opened and closed

PendingCN108265873AGuaranteed functional requirementsImprove the safety of useCeilingsEconomic benefitsBuilding construction

The invention discloses a ceiling finished product access hole device capable of being opened and closed. The ceiling finished product access hole device comprises a light steel keel fixing device, anon-off device and a finished product access hole, wherein the finished product access hole is formed in a gypsum board ceiling. The on-off device comprises a drawing-pulling rod, a fixed sliding railand a moving sliding rail. A close plate of the finished product access hole is fixed to the bottom of the drawing-pulling rod through a connecting piece, a finished product access hole frame is arranged on the periphery of the finished product access hole, the fixed sliding rail is arranged on a keel of the gypsum board ceiling through the light steel keel fixing device, the drawing-pulling rodis movably arranged on the moving sliding rail, the moving sliding rail is connected with the fixed sliding rail through an arc-shaped connecting piece, and the moving sliding rail can rotate relativeto the fixed sliding rail. According to the ceiling finished product access hole device capable of being opened and closed, the access hole device and the periphery of the gypsum board ceiling are consistent, the opening and closing are convenient, brushing and touching to the gypsum board ceiling are avoided when the access hole is opened, a ceiling structure or integrity of the access hole aredamaged, the occupied space is small, the operation is flexible, parts can realize industrialized production, the construction progress is accelerated, and good economic benefits can be achieved.

Owner:ZHEJIANG YASHA DECORATION

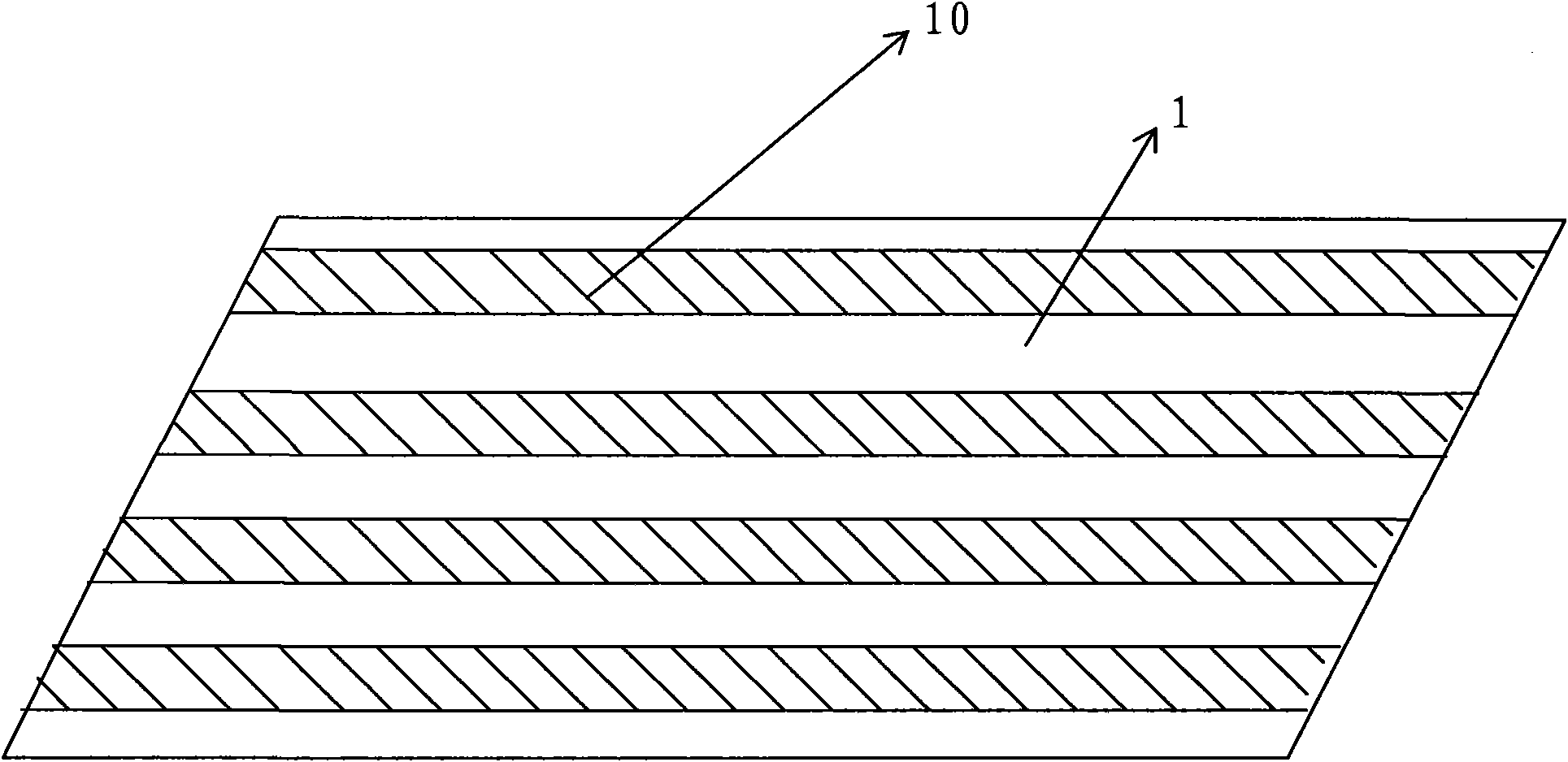

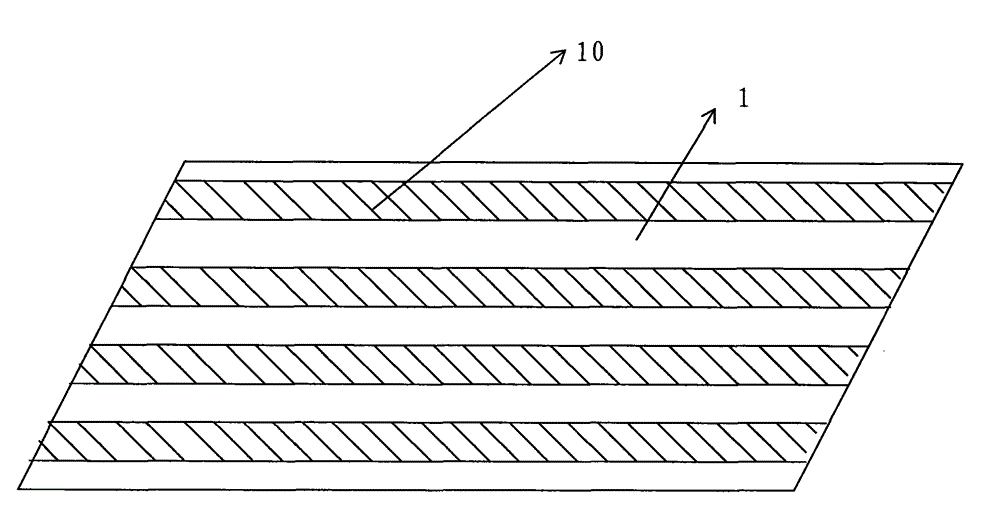

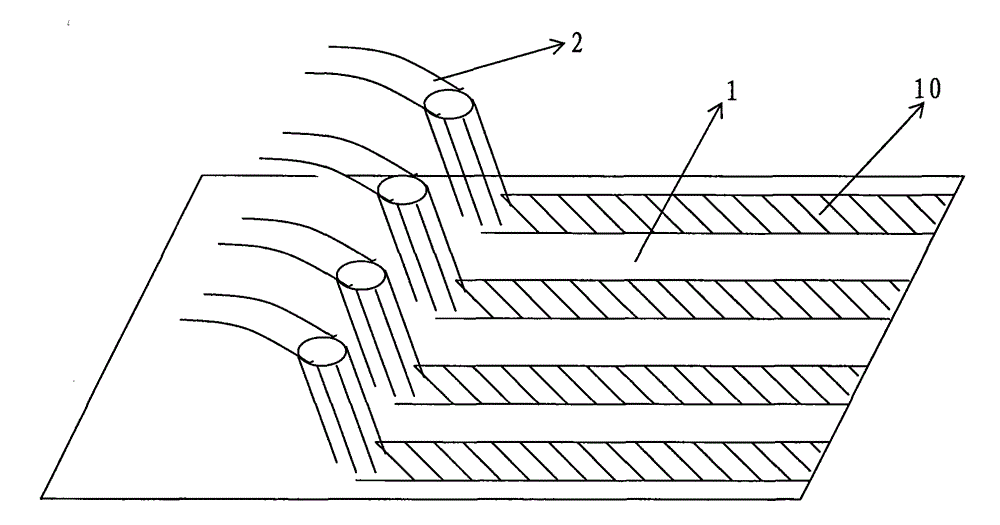

Nonwoven material prepared through discontinuous type functional treatment and preparation method thereof

ActiveCN101812778AEasy to transformReduce investmentFibre treatmentNon-woven fabricsHuman bodyMedicine

The invention discloses a nonwoven material prepared through discontinuous type functional treatment and a preparation method thereof. The nonwoven material basement is processed through discontinuous type functional treatment to form functional areas which are arranged discontinuously. The preparation method of the invention can be used to perform various functional treatments to nonwoven material basement, the equipment modification is easy, the investment is low, the preparation method can not conflict with the production technology of the common nonwoven fabric, the existing equipment and process can also be used; and therefore, the method is easy to realize and the production cost is low. The nonwoven material prepared through discontinuous type functional treatment of the invention can have different functions; the material can be freely cut into multiple pieces with small breadth along the transverse breadth direction, for example the nonwoven material with small breadth in the arrangement manner of 'non-treatment + functional treatment + non-treatment' can be prepared; and the amount of raw material used in functional treatment can be reduced, the cost is saved, and the bad effects of some raw materials to human body can be lowered.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

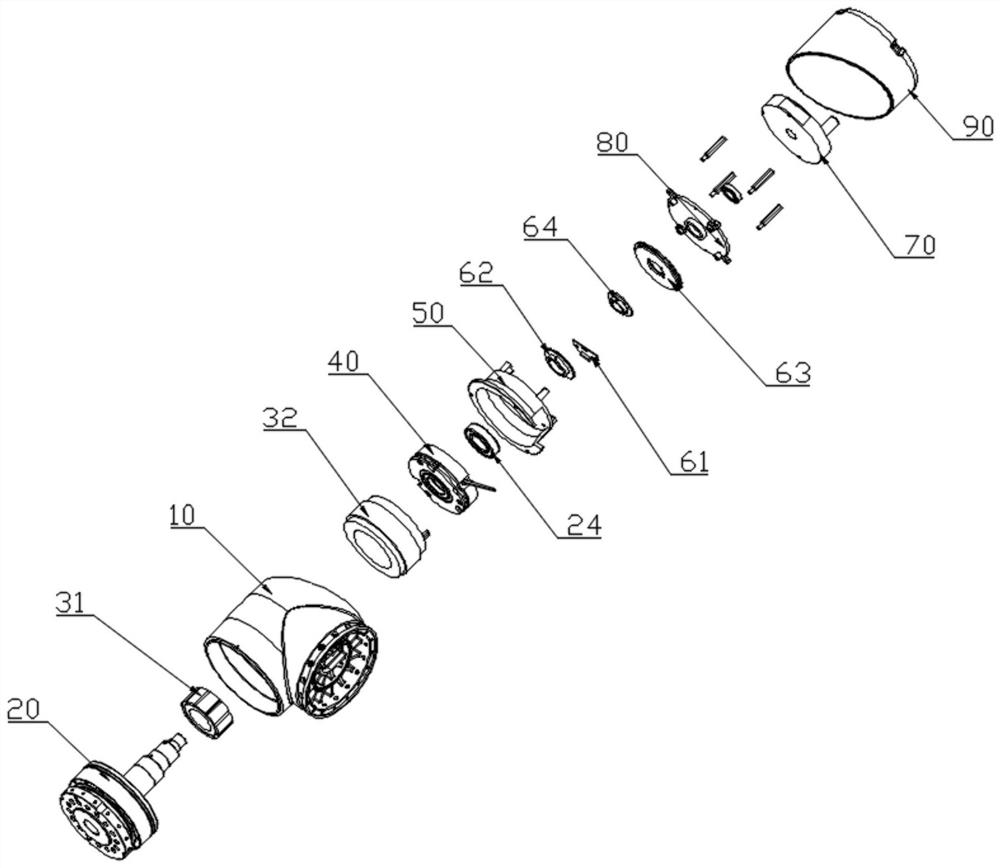

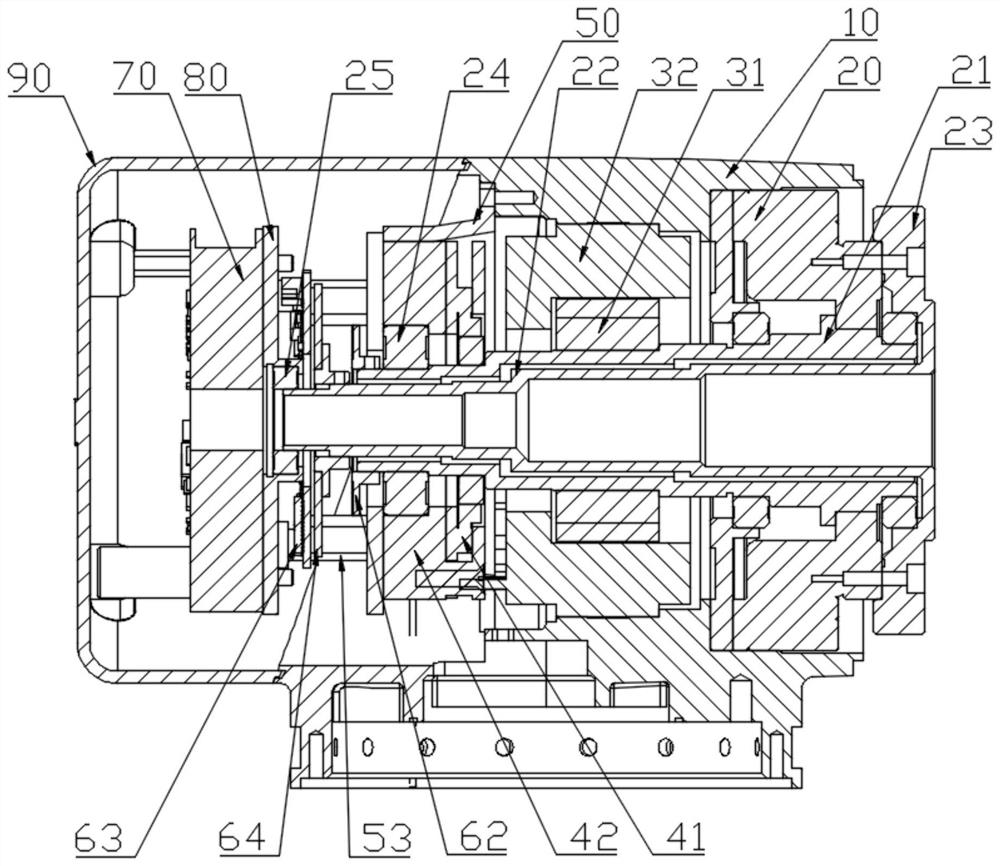

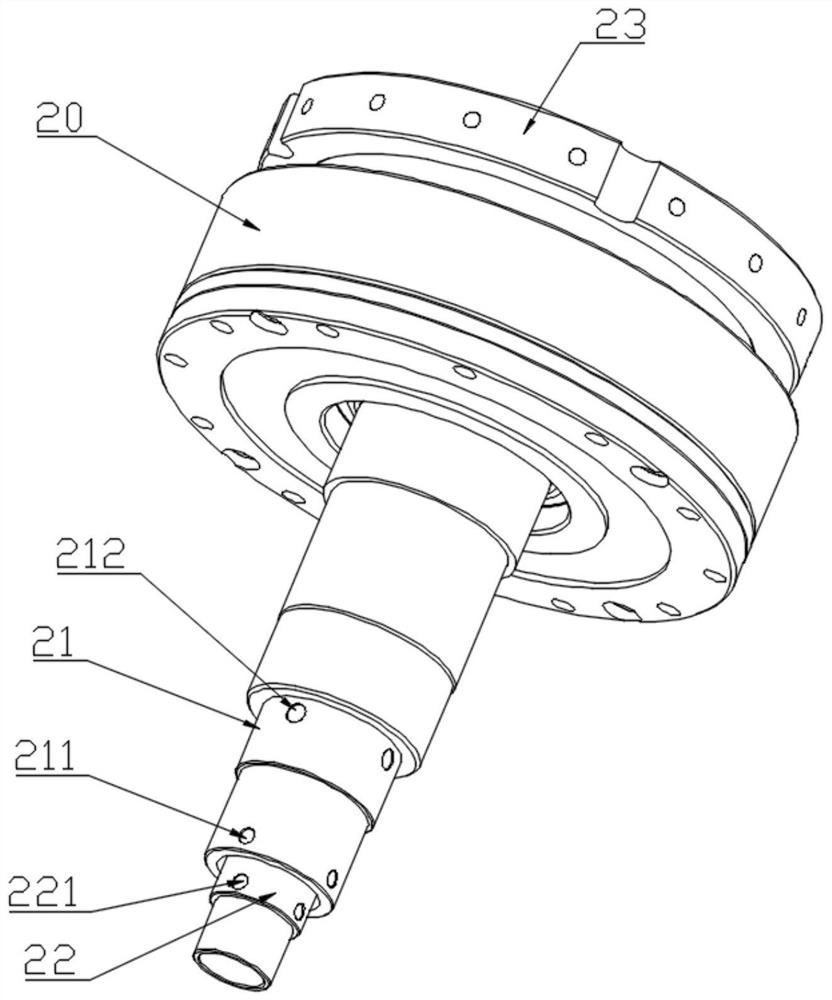

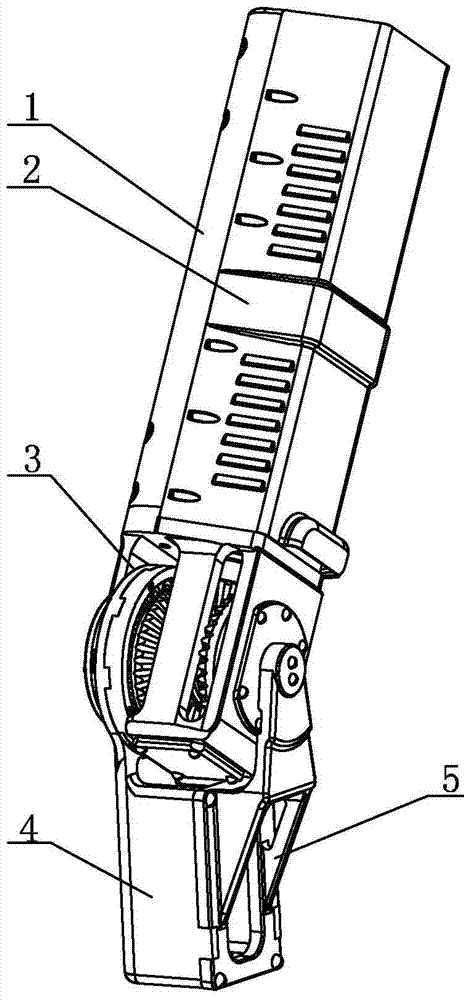

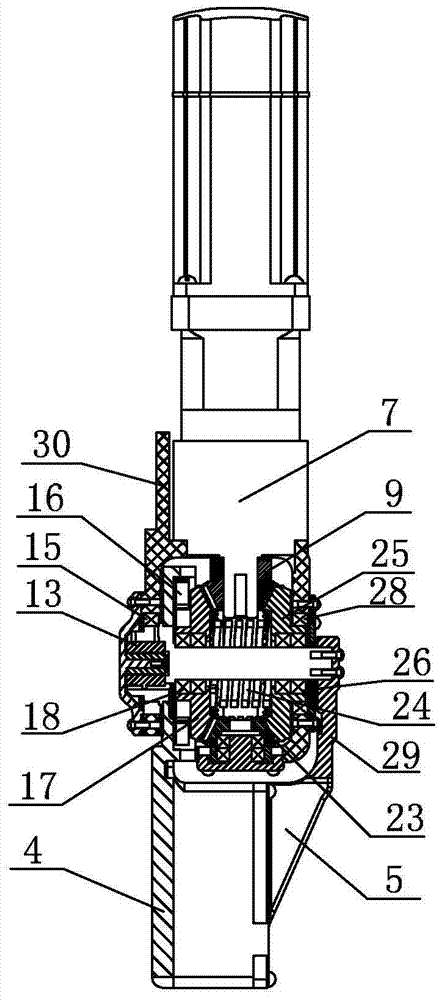

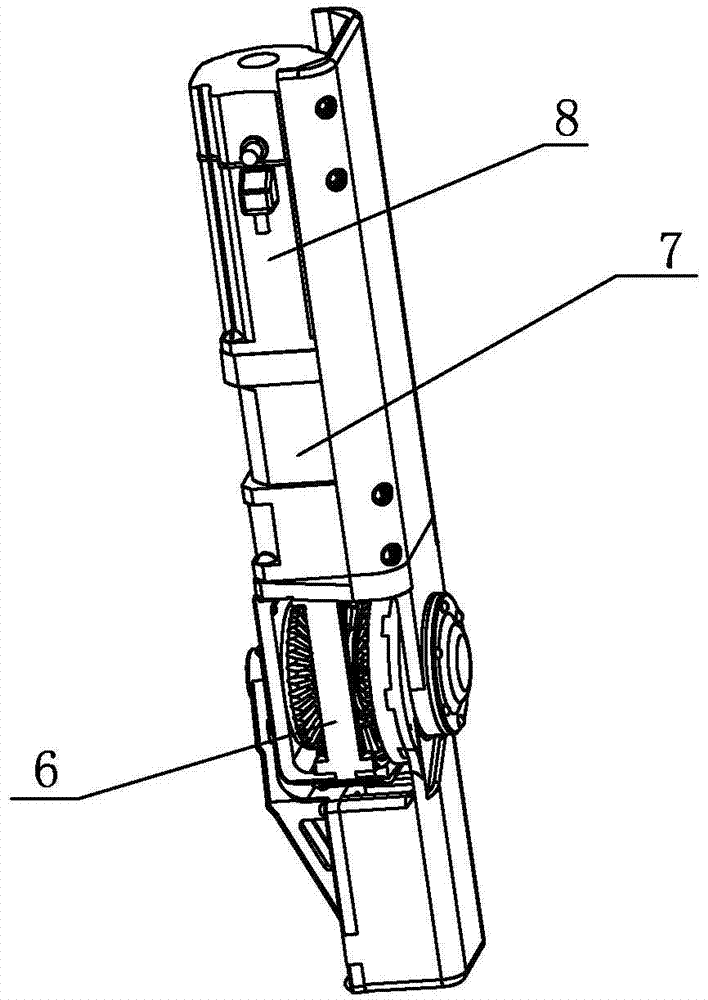

Novel collaborative robot joint module

The invention relates to a novel collaborative robot joint module. The novel collaborative robot joint module comprises a joint body, a harmonic reducer, a motor, a brake, a brake mounting seat, an input end encoder, an output end encoder and a driver, wherein the harmonic reducer is arranged in the first end of the joint body and provided with an input shaft and an output shaft; the input shaft is sleeved at the outer side of the output shaft; and the output shaft penetrates through the harmonic reducer, a connecting disc is arranged at the first end of the output shaft, and the second end of the output shaft extends out of the second end of the input shaft. The brake is fixed through the brake mounting seat, a rotor of the brake is located at the side close to the motor, so that the brake is inversely installed, an input bearing is designed in the brake, the design length of the input shaft of the harmonic reducer is greatly shortened, the rigidity of the input shaft is improved, meanwhile, the diameter of an inner hole of the harmonic reducer is increased, and wire passing is facilitated.

Owner:伯朗特机器人股份有限公司

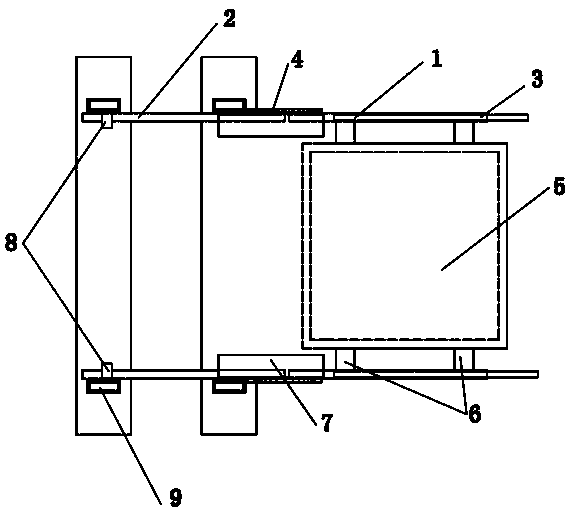

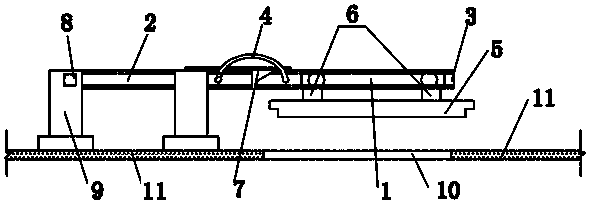

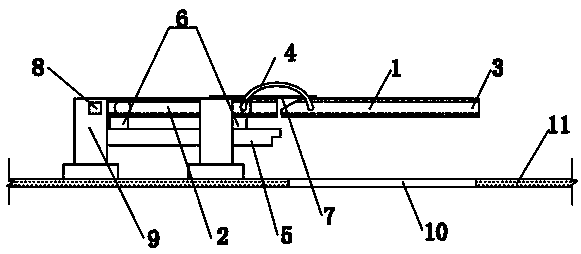

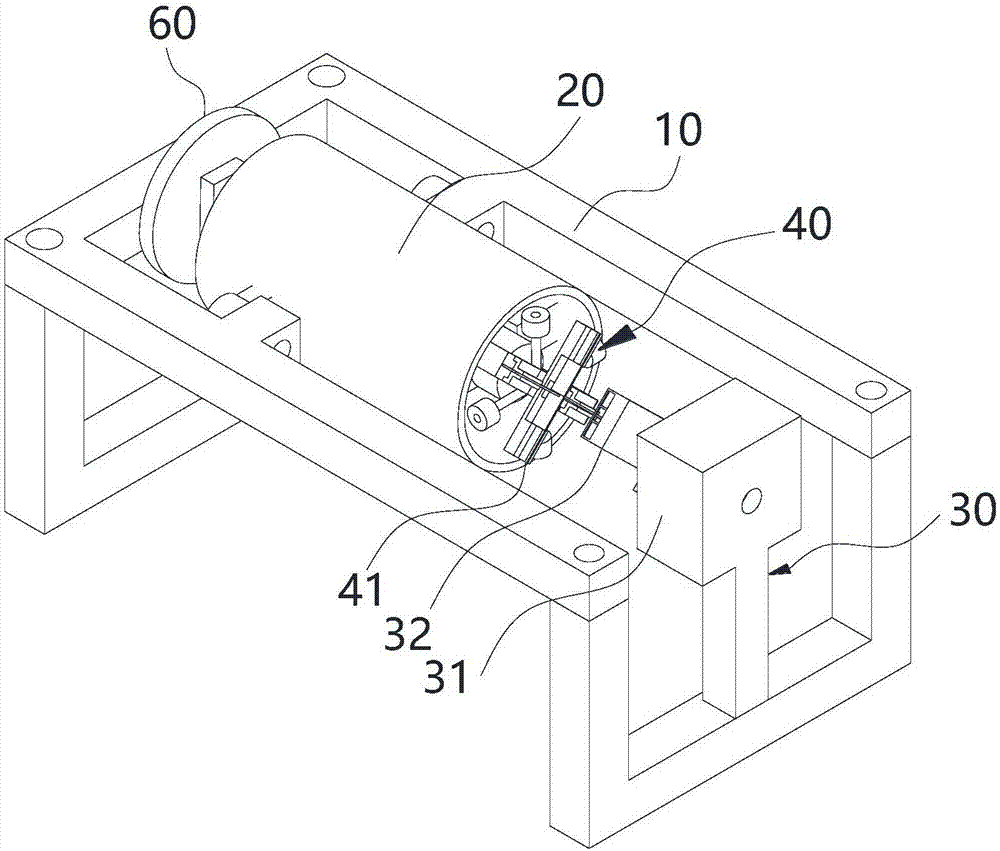

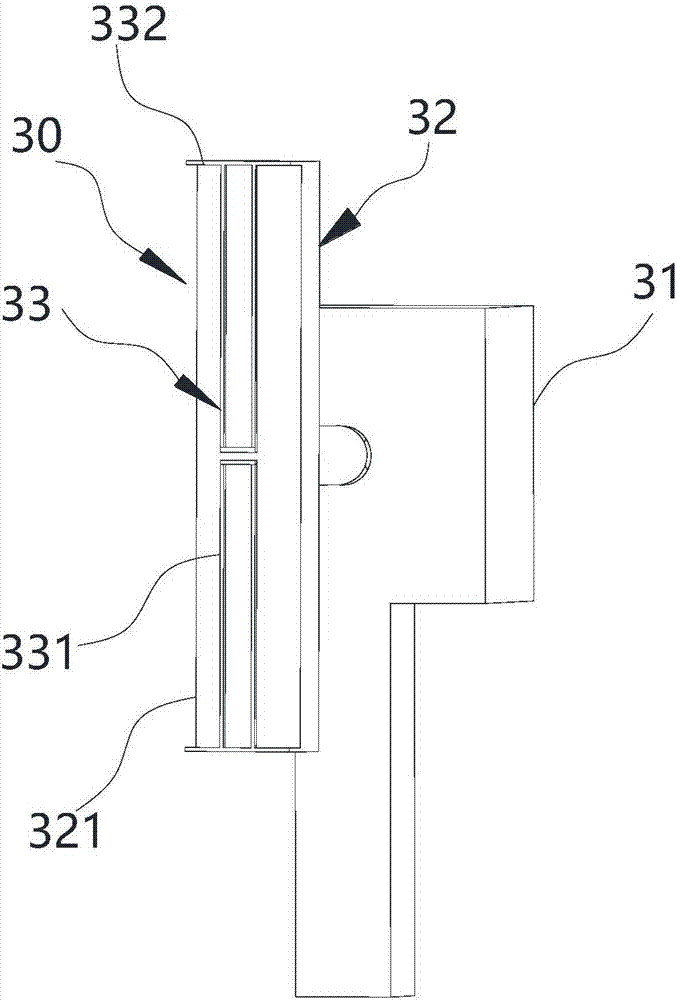

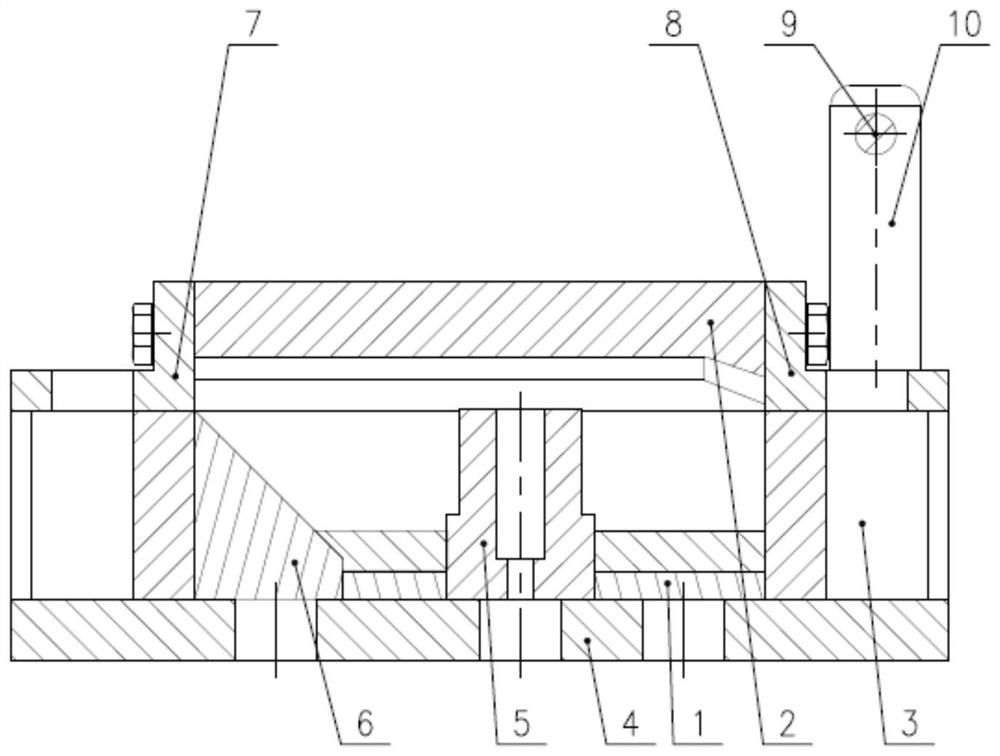

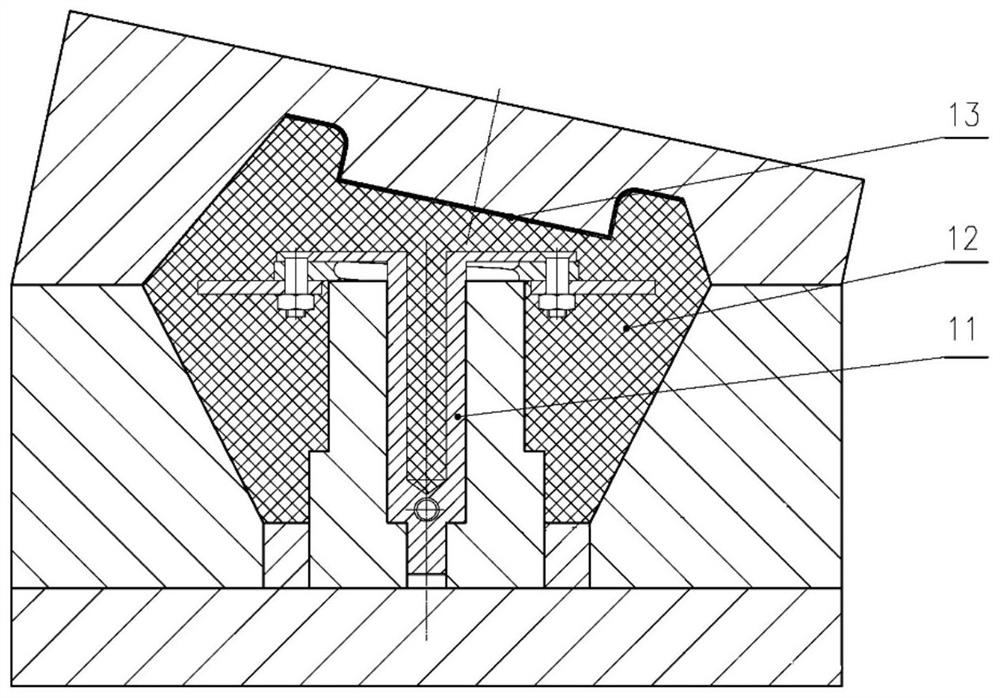

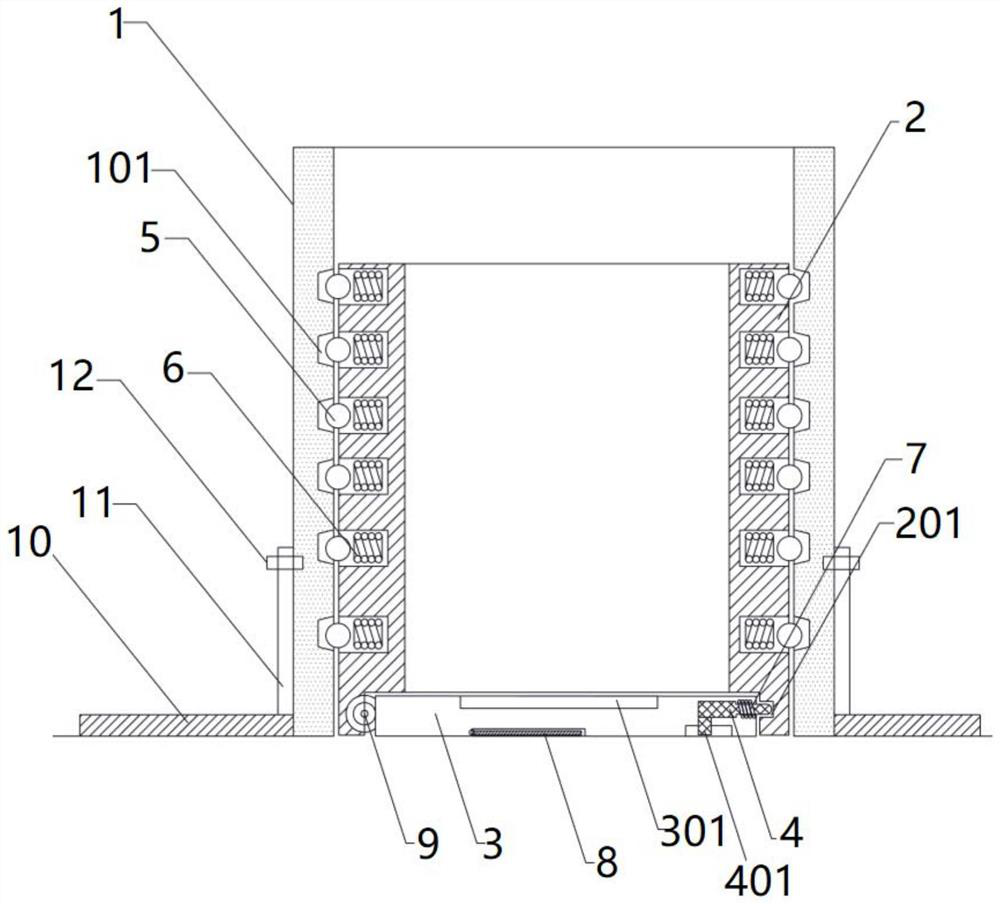

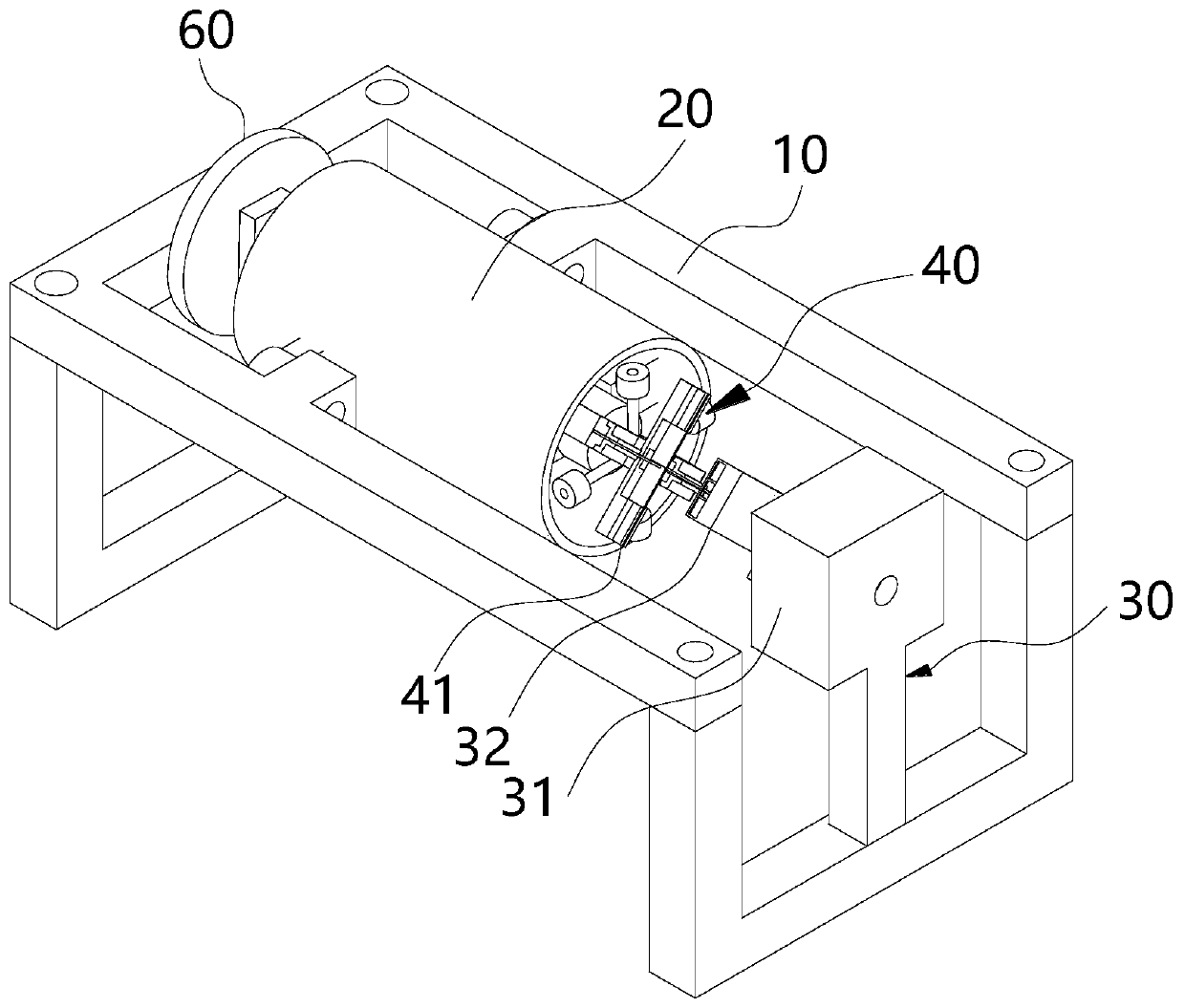

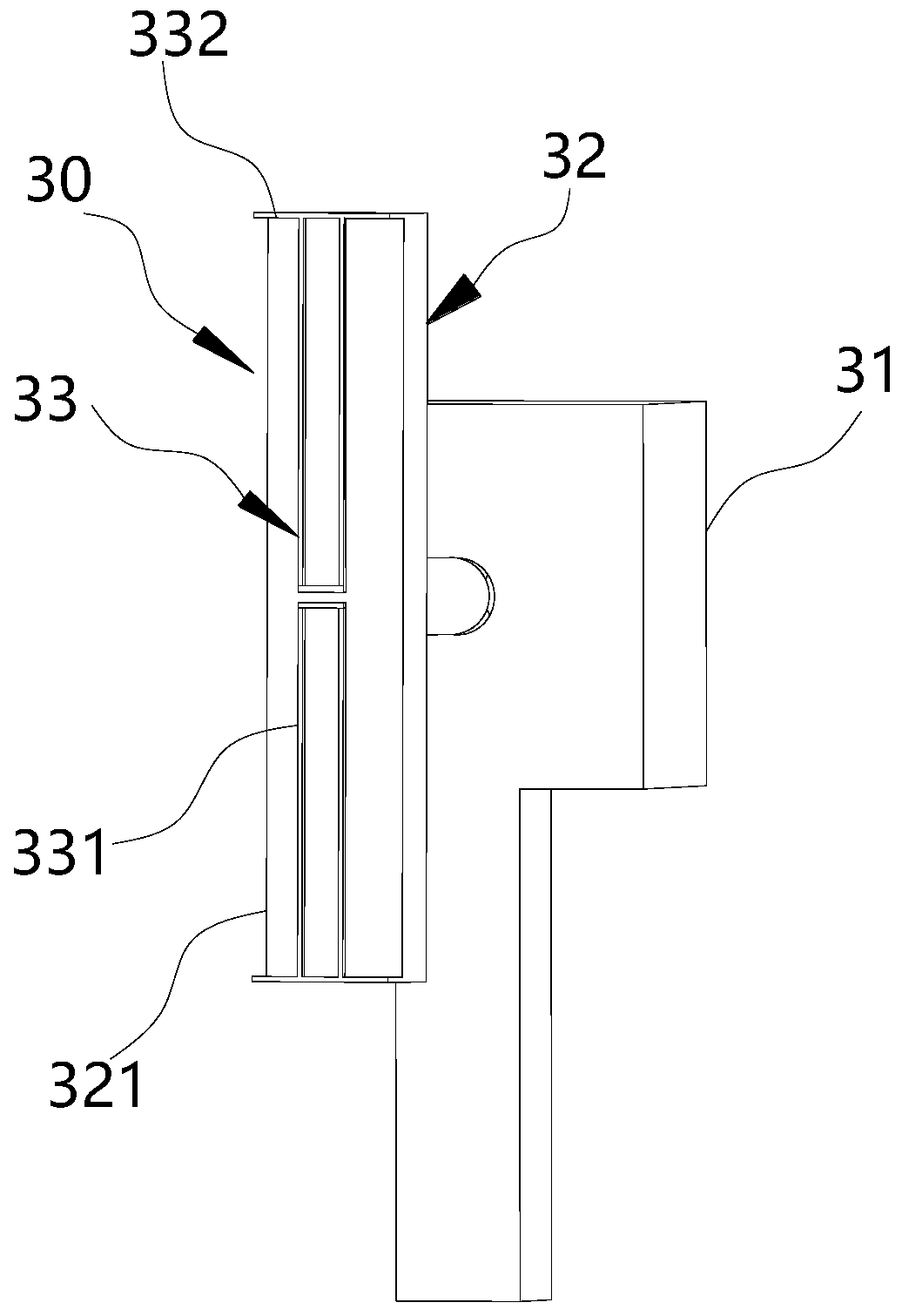

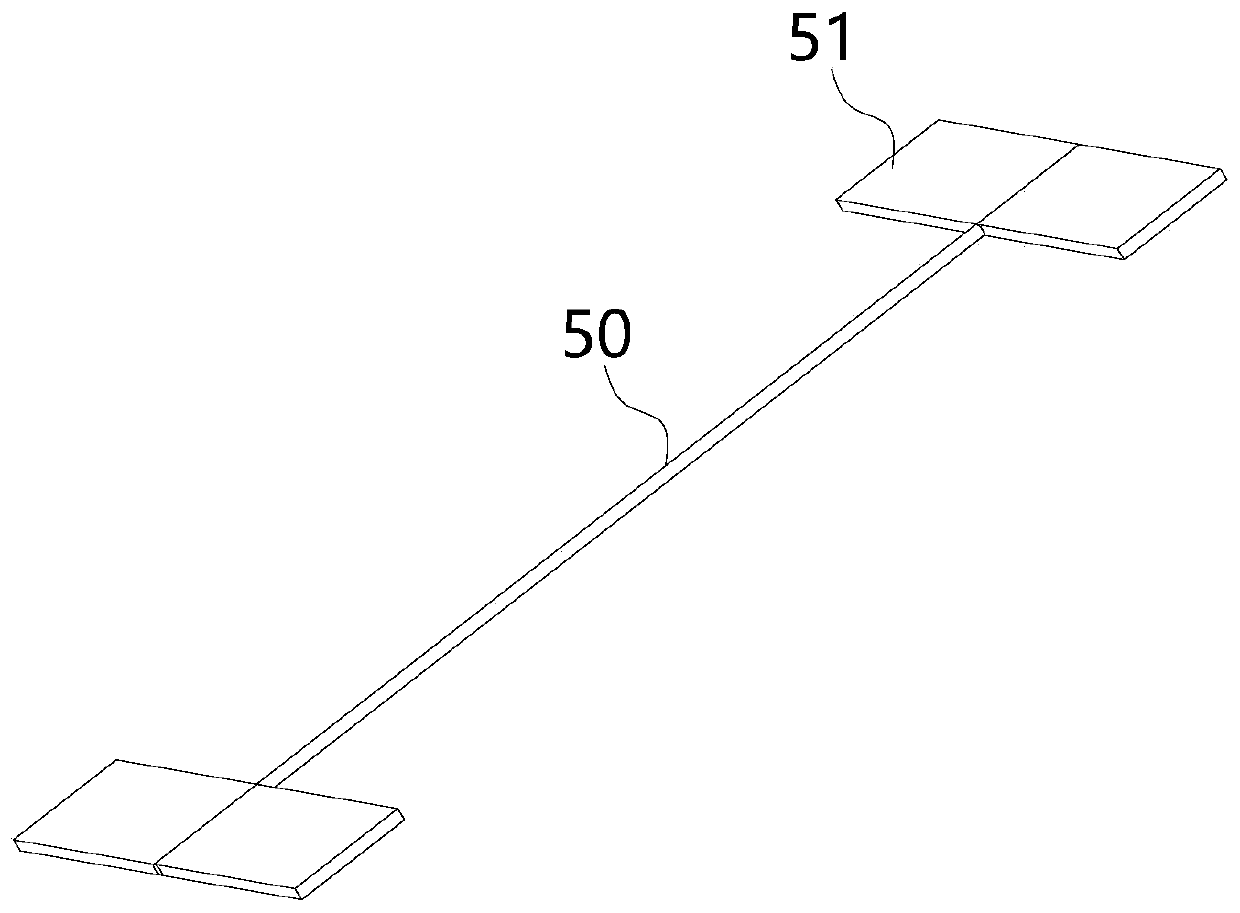

Horizontal-type test apparatus and test method for measuring torsion property of material under electron microscope

ActiveCN107219133AReduce volumeOvercoming the Limitations of Geometric ConstraintsStrength propertiesMeasurement deviceMicroscope

The invention provides a horizontal-type test apparatus and test method for measuring a torsion property of a material under an electron microscope. The horizontal-type test apparatus comprises a framework, a first clamping part, a second clamping part, a control apparatus and an electron microscope; the first clamping part is installed on the framework and comprises a fixed clamp for clamping a test sample in a rotating manner; the second clamping part is installed on the framework and is oppositely and horizontally separated from the first clamping part and comprises an electromagnetic driving apparatus, a movable clamp for clamping the test sample, and an angle measuring apparatus; the control apparatus is used for setting a test method and controlling an experimental process; and the electron microscope is used for in-situ observing the variation of a test sample in the experimental process. By adopting the horizontal-type test apparatus and test method, the problem of an additional torque caused by the mass eccentricity of a rotating part after the test sample is horizontally arranged can be solved, and the apparatus can work horizontally, so that the electron microscope can realize the in-situ observation. By adopting two rotatable clamping ends, a large-angle multi-circle loading experiment of the test sample can be realized.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

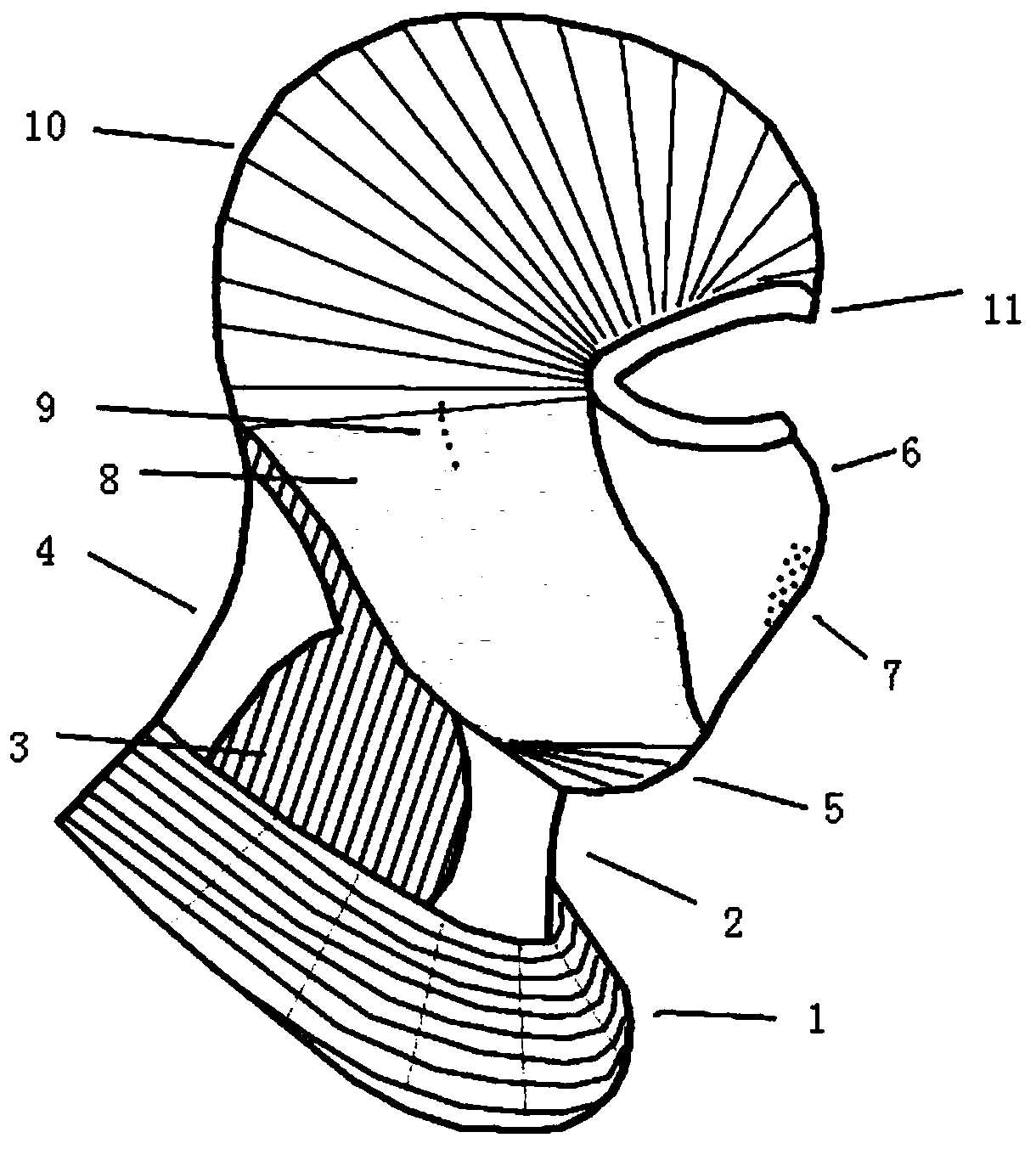

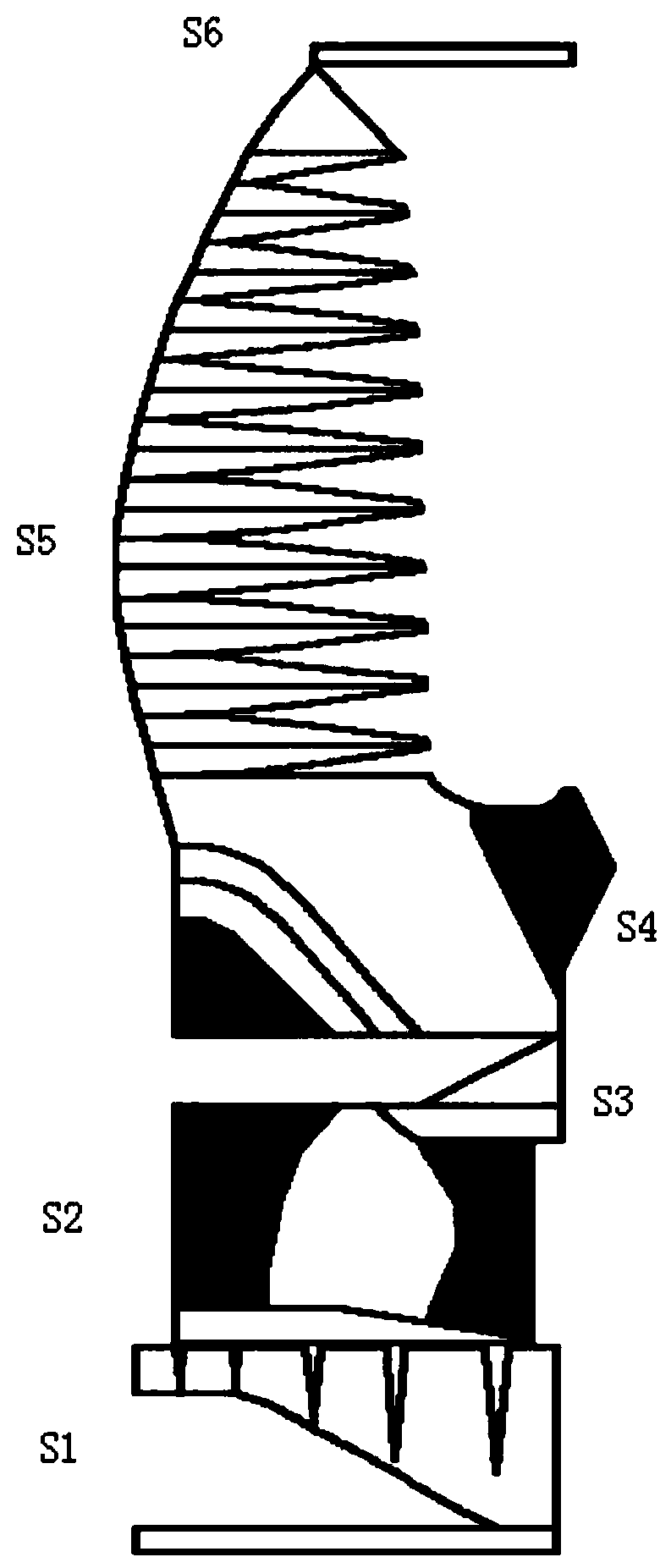

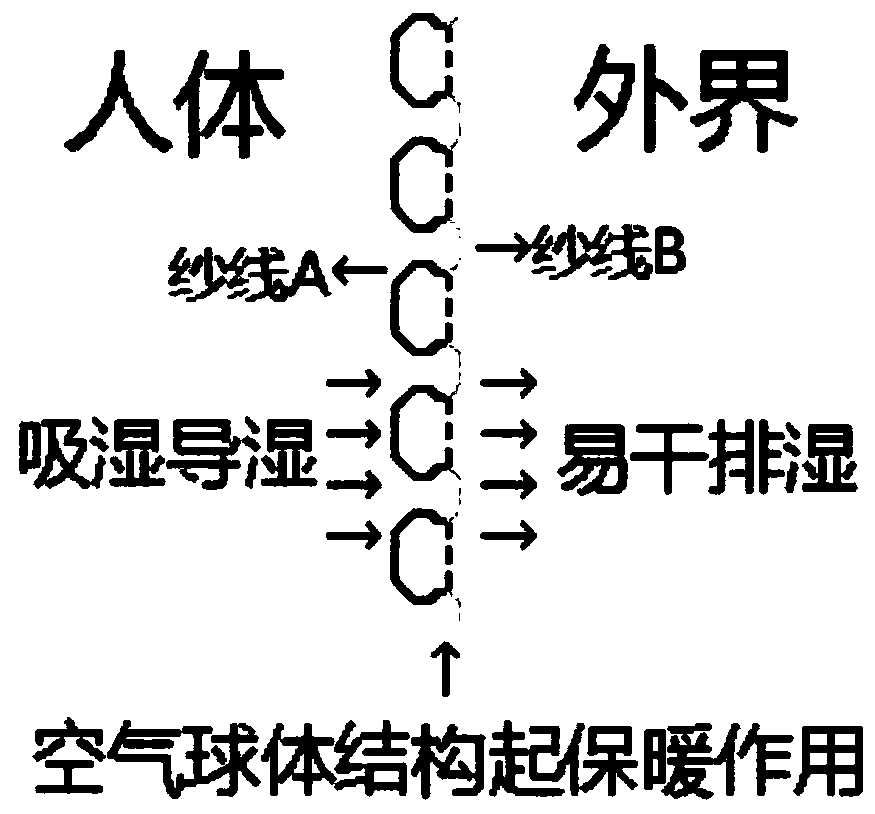

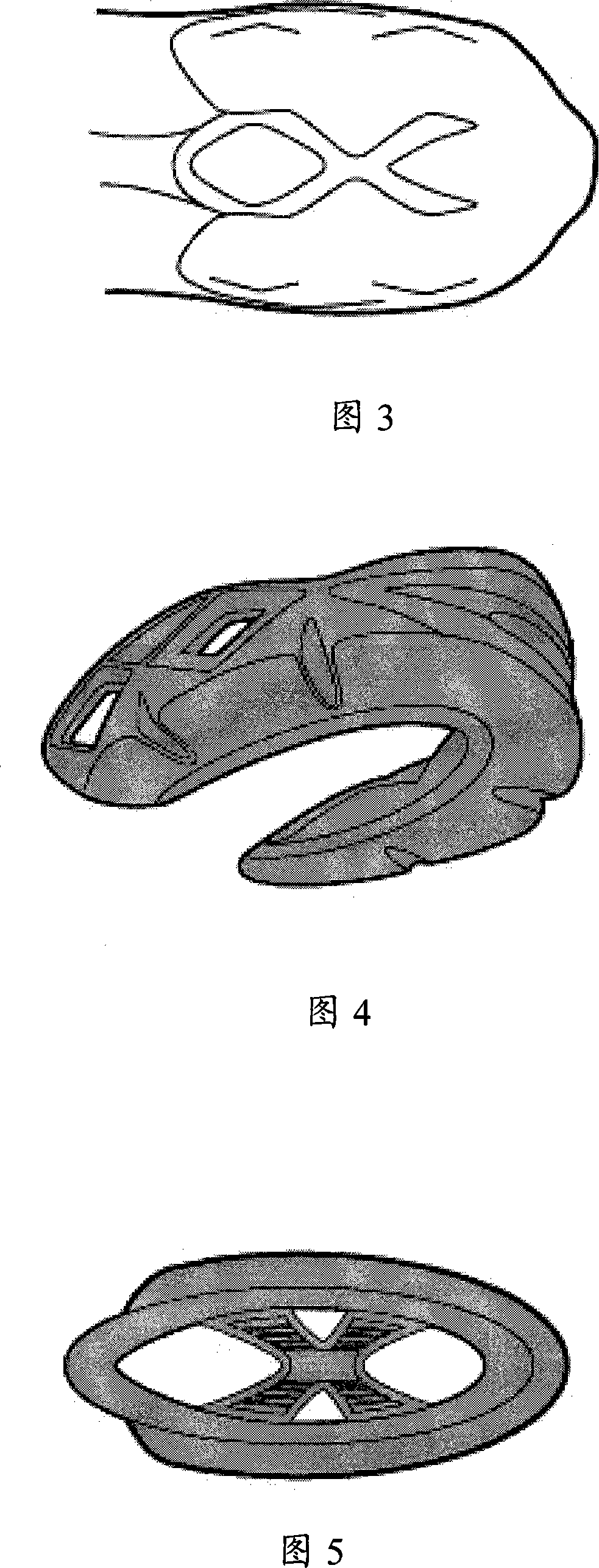

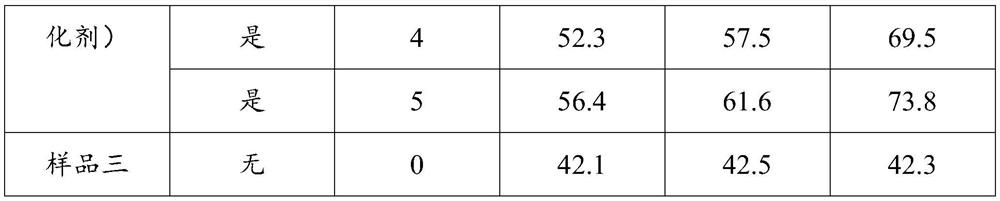

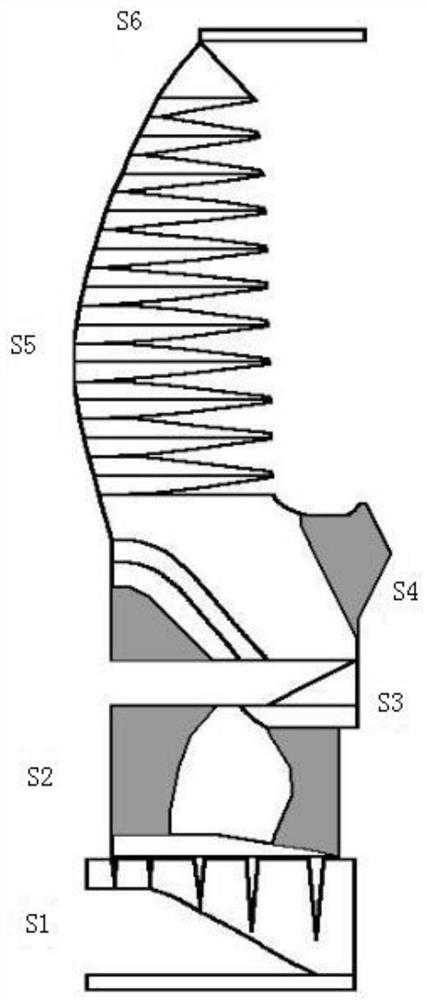

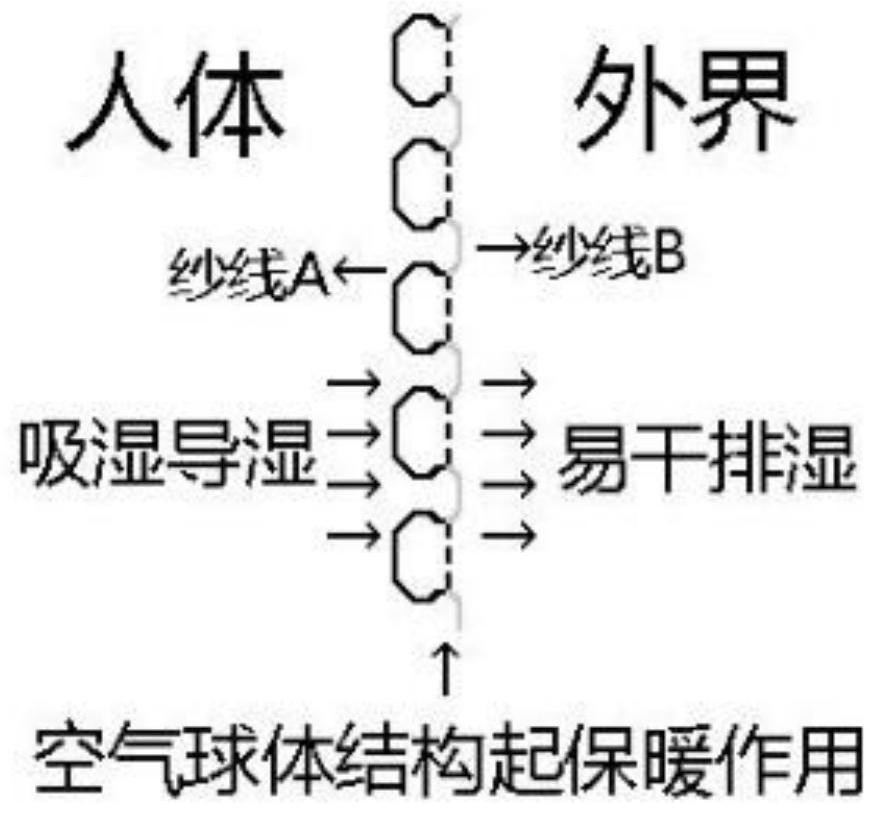

Fully-formed knitted sports face guard and knitting method thereof

ActiveCN111358070ARich texture colorHuge market potentialWeft knittingHeadwearYarnStructural engineering

The invention discloses a fully-formed knitted sports face guard and a knitting method thereof. The face guard comprises a helmet type face guard cover body, wherein the face guard cover body is integrally formed by knitting wet-permeable and easy-to-dry yarns; the front neck, the rear neck and the front face of the face guard cover body are woven to form a spherical knitted structure with moisture-conducting and warm-keeping functions; a head cover part is formed at the head part of the face guard cover body according to a wet-conducting and warm-keeping function spherical knitted structure formed and knitted according to the head structure; two eyes of the face guard cover body are fitted with the eyes in an idling knitting manner, and the mouth and nose parts of the face guard cover body are subjected to needle moving and hole picking knitting on the basis of the spherical knitted structure with the wet-conducting and warm-keeping functions to enhance the air permeability. The fully-formed knitted sports face guard can be woven into a face guard structure which is fitter and comfortable according to the head structure of a human body, the defects of a traditional process are overcome, the face guard is more fit and comfortable to wear, and meanwhile the functional requirements of all areas are met.

Owner:嘉兴市蒂维时装有限公司

Rail transit carbon fiber composite vehicle lower outer cover and manufacturing method

InactiveCN112810421ASimple structureEasy to manufactureRemovable external protective coveringsDomestic articlesAutomotive engineeringCarbon fiber composite

The invention relates to a rail transit carbon fiber composite vehicle lower outer cover and a manufacturing method. The lower outer cover structurally comprises an outer cover main part, a metal embedded part, an outer cover auxiliary part and 3K appearance fabric, and the metal embedded part is embedded in the outer cover main part; the outer cover main part and the outer cover auxiliary part are integrally formed by adopting a carbon fiber material, the outer cover main part and the outer cover auxiliary part are bonded into a whole, and 3K appearance fabric is bonded on the whole outer surface after the outer cover main part and the outer cover auxiliary part are bonded into a whole. The lower outer cover is a rail transit appearance decoration assembly which is formed by a carbon fiber composite material through autoclave external curing forming and machining appearance combination. The lower outer cover is wide in application range, simple in structure and easy to manufacture and implement, has the light-weight effect and has the advantages that the appearance of the texture of the carbon fiber cloth is consistent, the functional requirement is met, and meanwhile the manufacturing cost is greatly reduced, and the manufacturing period is greatly shortened.

Owner:上海晋飞碳纤科技股份有限公司

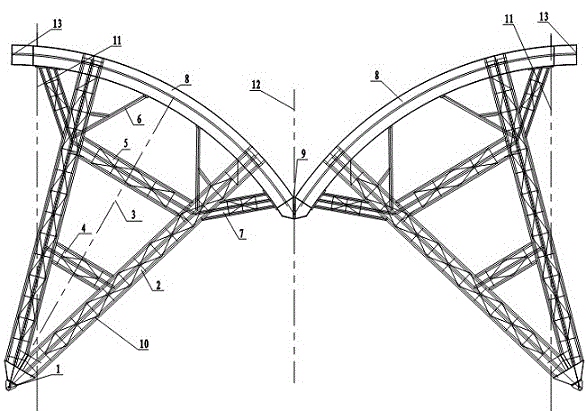

Railed arc double-door flood control gate

The invention discloses a railed arc double-door flood control gate. The railed arc double-door flood control gate comprises door hinges which are symmetrically fixed on both banks of a river; fan-shaped gates are connected on the railed arc double-door flood control gate respectively through the two symmetrical door hinges; each fan-shaped gate is hinged to the corresponding door hinge through two main supporting arms; an arc rail corresponding to each fan-shaped gate is arranged at the bottom of the fan-shaped gate; each fan-shaped gate rotates along the arc rail, with the door hinge corresponding to the fan-shaped gate as a center, to close or open the two fan-shaped gates so as to close or open the control gate. The railed arc double-door flood control gate is simple in structure; the railed arc double-door flood control gate ensures barrier-free sailing inside a wide sailing channel, so that the river has relatively good passability; the railed arc double-door flood control gate can meet a requirement of a controller on relatively high passability; the railed arc double-door flood control gate is easy to maintain, low in cost and succinct in arrangement, and gives consideration to an attractive appearance, so that the railed arc double-door flood control gate can be harmonious with surrounding buildings better.

Owner:NANJING LEAOWEI ELECTRICAL

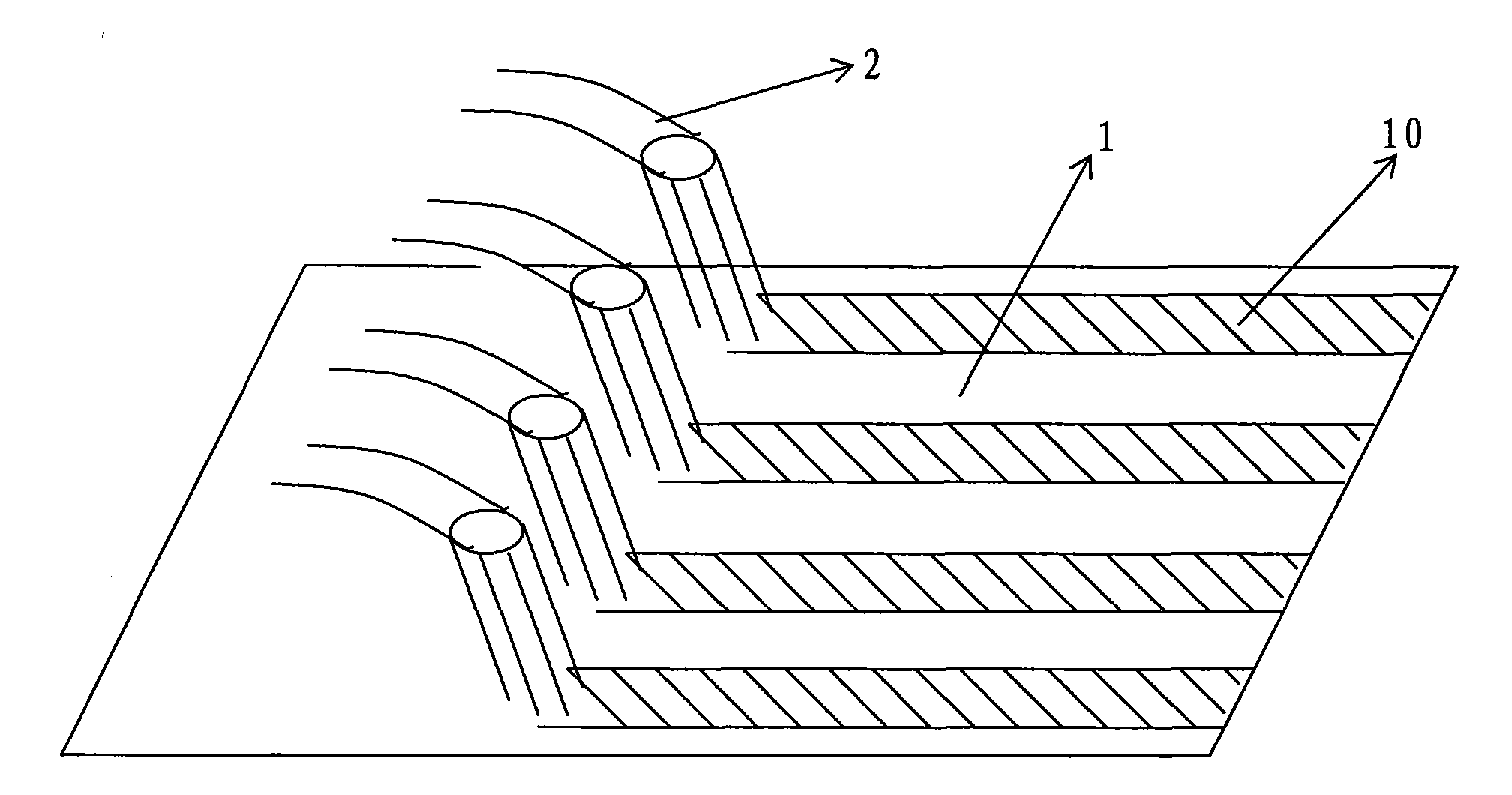

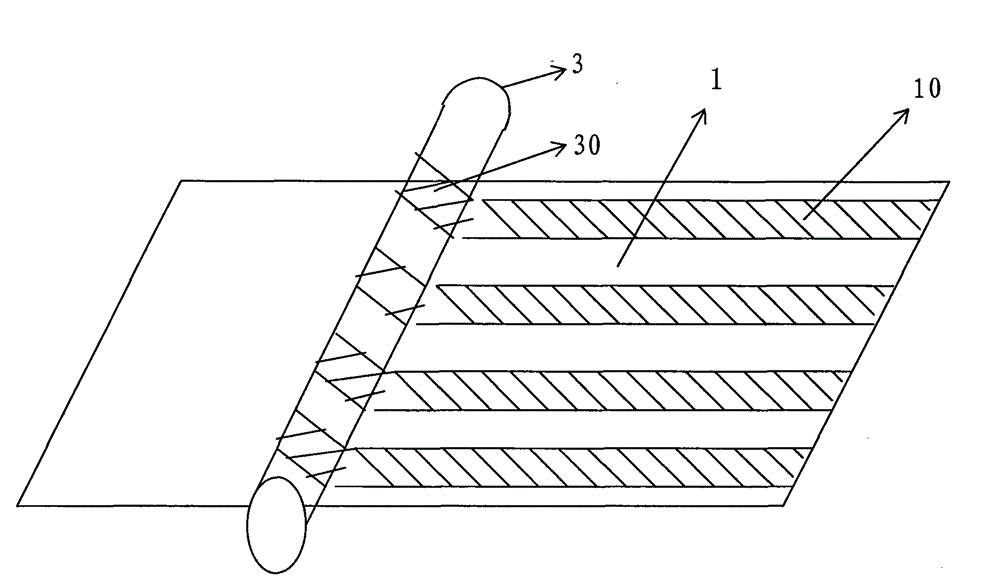

Carbon fiber product embedded pipe body forming structure and forming method

PendingCN114683579AHigh strengthSimple structureSynthetic resin layered productsLaminationFiberManufacturing cost reduction

The invention provides a carbon fiber product embedded pipe body forming structure and method, and the structure sequentially comprises an outer skin, an upper reinforcing layer, an embedded pipe body, a lower reinforcing layer, a sandwich foam layer and an inner skin from outside to inside, the outer skin, the upper reinforcing layer, the embedded pipe body, the lower reinforcing layer, the sandwich foam layer and the inner skin are integrally formed through a carbon fiber composite material forming process; wherein the upper reinforcing layer and the lower reinforcing layer are made of carbon fiber prepreg or woven cloth. The invention has the characteristics of wide application range, high structural strength, simple structure, simplicity in manufacturing and implementation, low processing cost, high precision and the like, has the effect of light weight, and greatly reduces the manufacturing cost and the manufacturing period while ensuring the functional requirement.

Owner:上海晋飞碳纤科技股份有限公司

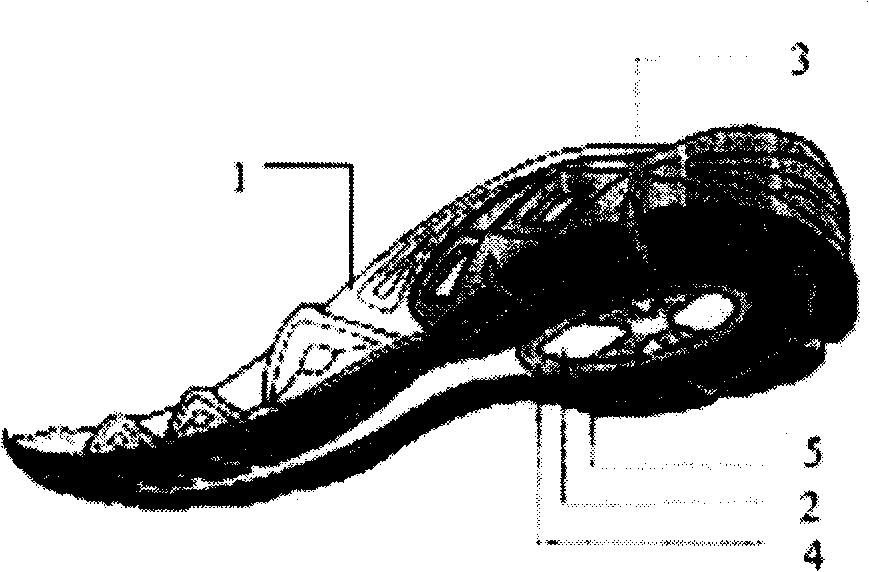

Large-output-force robot flexible energy-storing joint based on gravity energy storing

The invention discloses a large-output-force robot flexible energy-storing joint based on gravity energy storing and relates to a flexible driving device used for a robot. The large-output-force robot flexible energy-storing joint based on gravity energy storing aims to solve the problems that due to the linear type force output of an existing series elastic actuator of a robot joint, the structure is not compact, occupied space is large, power required by a motor is large, and accurate force output control and accurate position control of the joint are not facilitated. The large-output-force robot flexible energy-storing joint based on gravity energy storing comprises an upper limb connecting plate, an upper limb motor shell, a joint gearbox, a lower limb connecting plate, a lower limb support, a speed reducer, a rotary transformer, a motor provided with an encoder, an series elastic body and a torsion spring, wherein the joint gearbox comprises a shell body, a third bevel gear, a fourth bevel gear, a first bevel gear, a second bevel gear and a joint shaft, the series elastic body comprises an inner ring body, an outer ring body and at least four groups of wavy clips, the inner ring body and the outer ring body are concentric, and the at least four groups of wavy clips which are integrated are connected between the inner circle and the outer circle of the inner ring body in the circumferential direction and between the inner circle and the outer circle of the outer ring body in the circumferential direction. The large-output-force robot flexible energy-storing joint based on gravity energy storing is applied to the field of robots.

Owner:HARBIN INST OF TECH

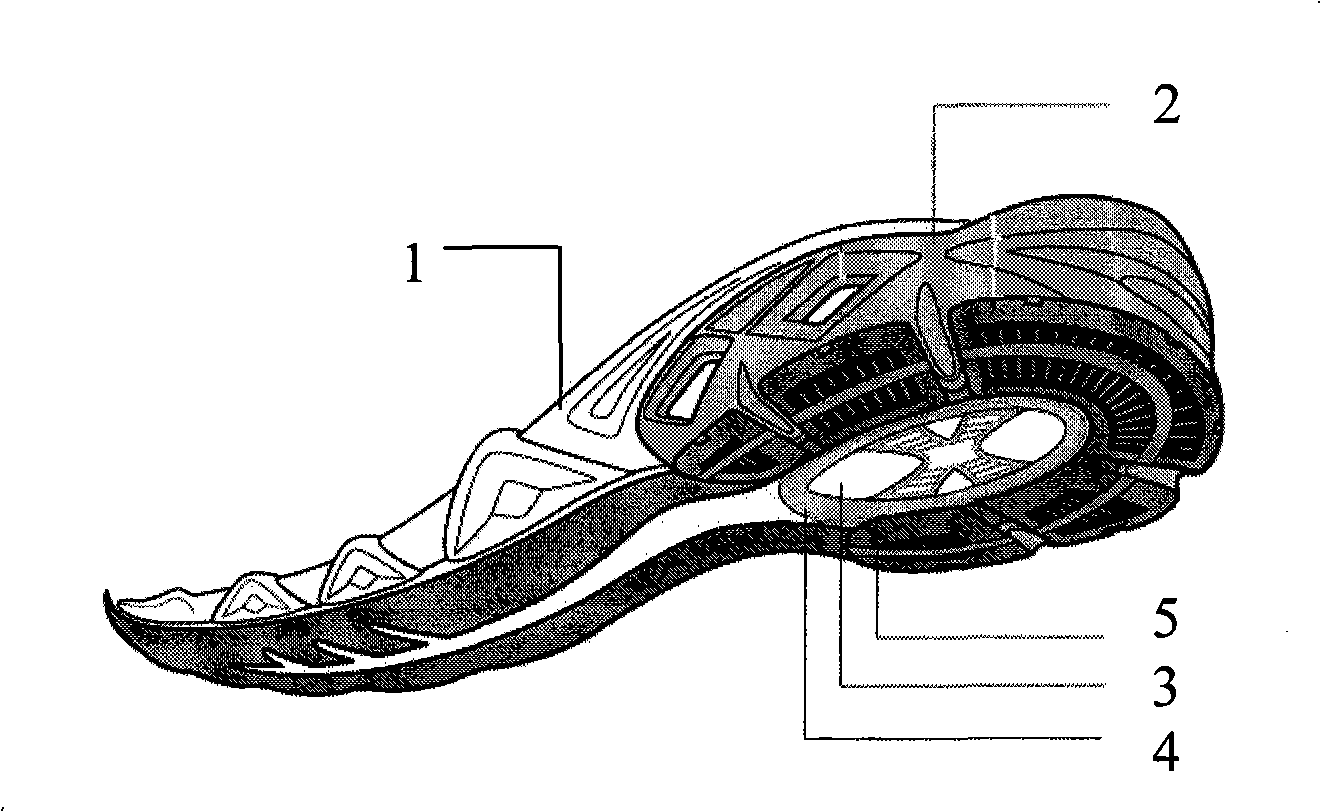

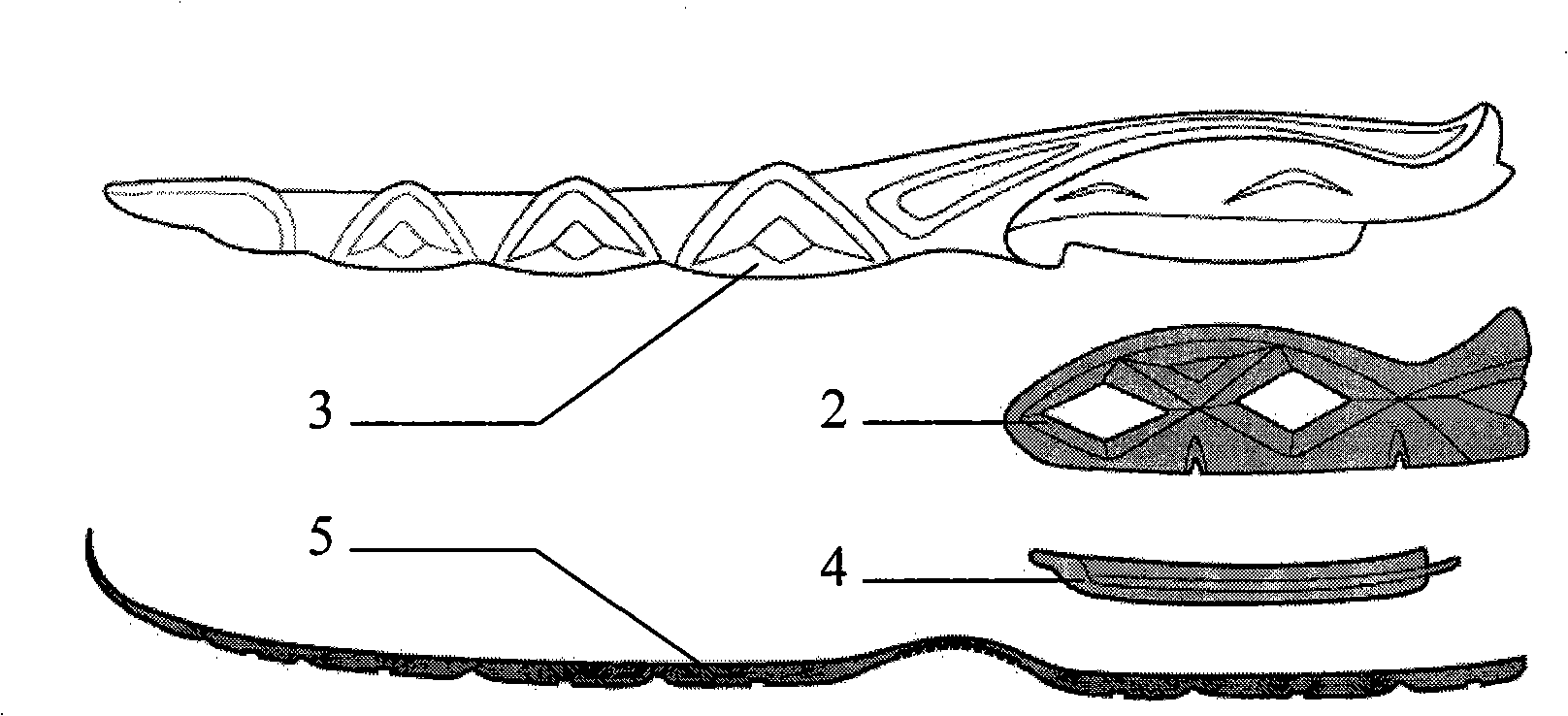

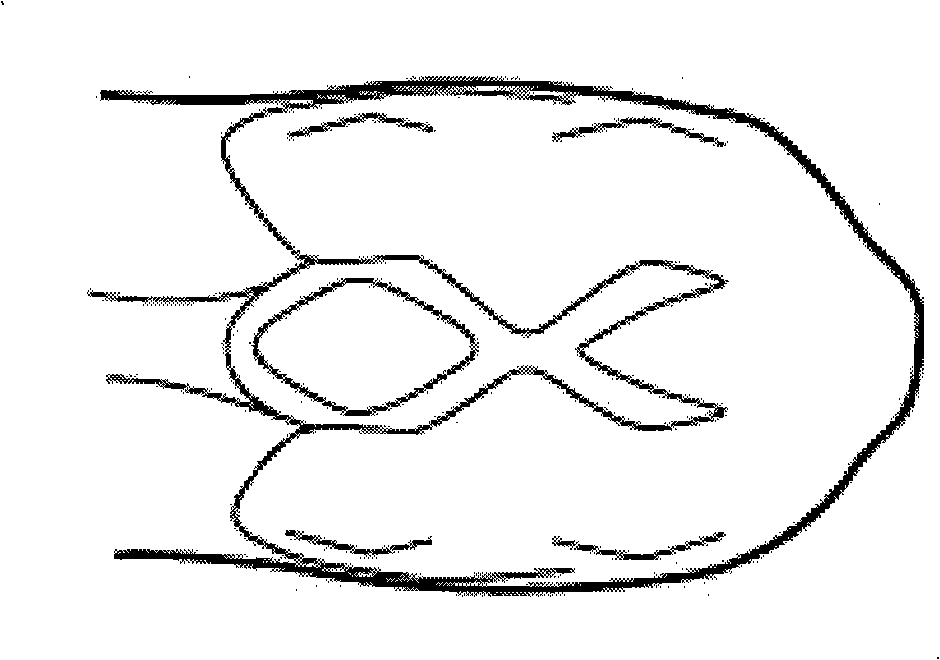

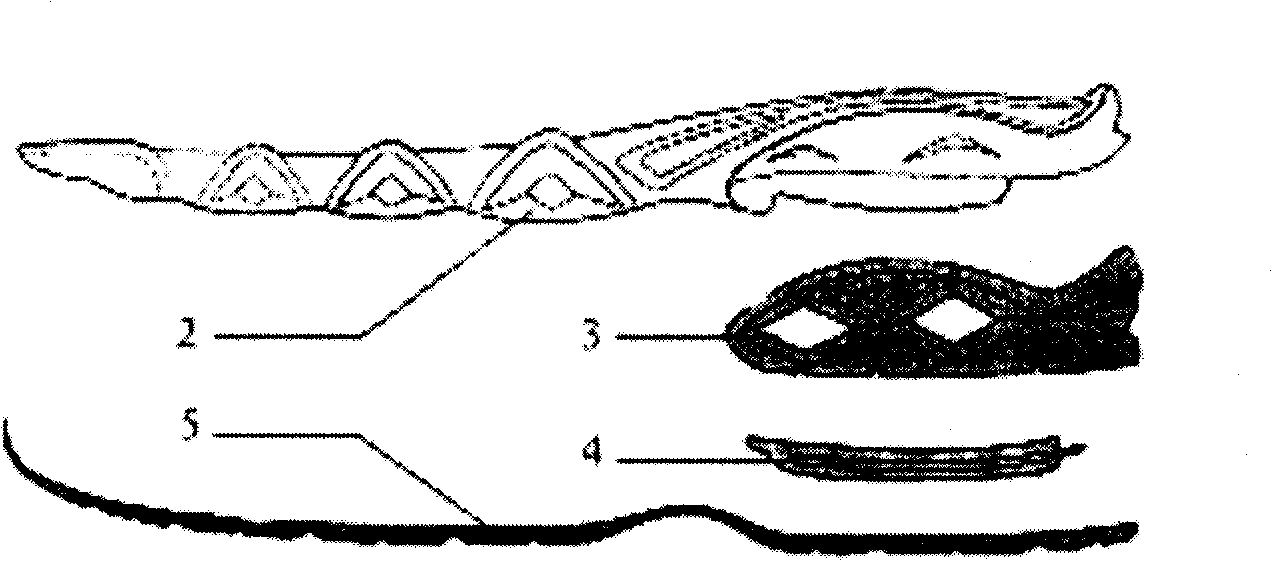

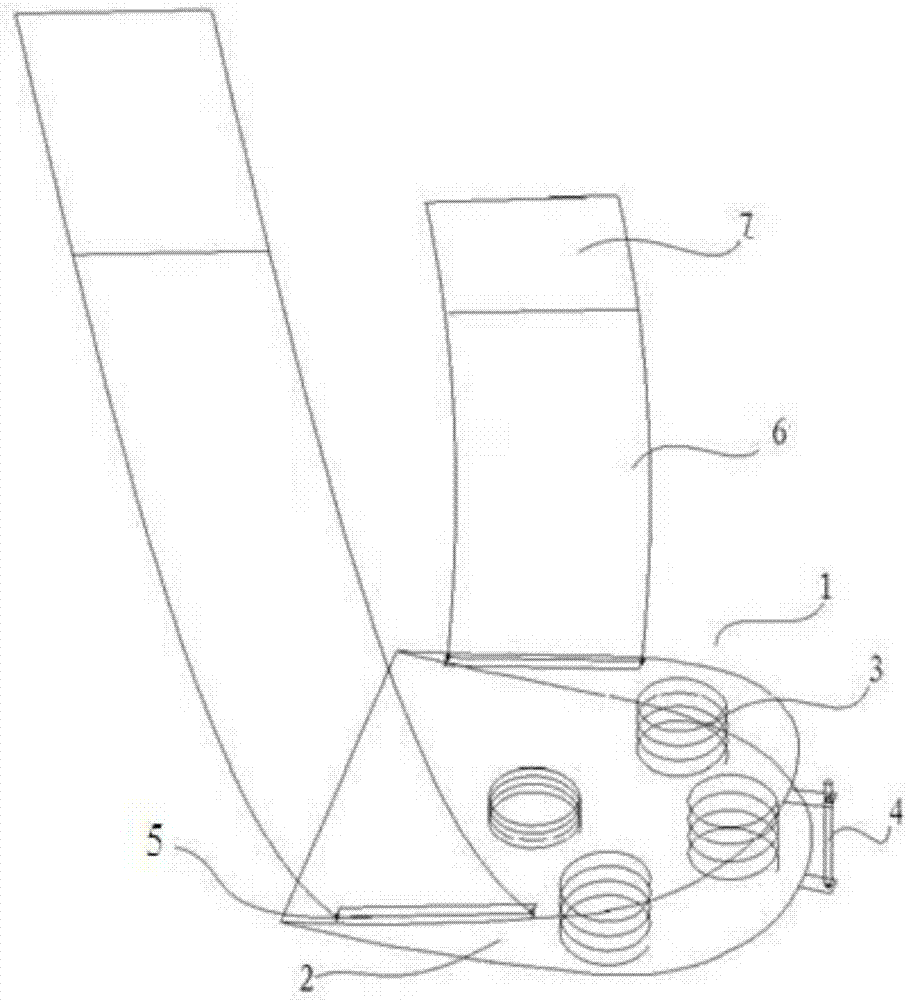

Shock-absorbing sport shoes

InactiveCN101406333AGuaranteed functional requirementsGuaranteed cutFootwearEngineeringSystems design

The invention discloses a sports shoe with a endow type shock mitigation system, which consists of an endow type EVAMD, functional components with an endow type three-dimensional shock absorbing structure arranged on a sole heel part and the inside and the outside of the shoe, endow type shock absorbing accessories of a secondary buffer shock absorbing TPU, and an endow type shock absorbing structure of a rubber outer sole. The design details of the endow type shock mitigation system are fully designed according to requirements of the outside of the heel to the inner turning stability during the sporting touchdown. The sports shoe can also be applied to other sporting casual shoes.

Owner:晋江联诚投资有限公司

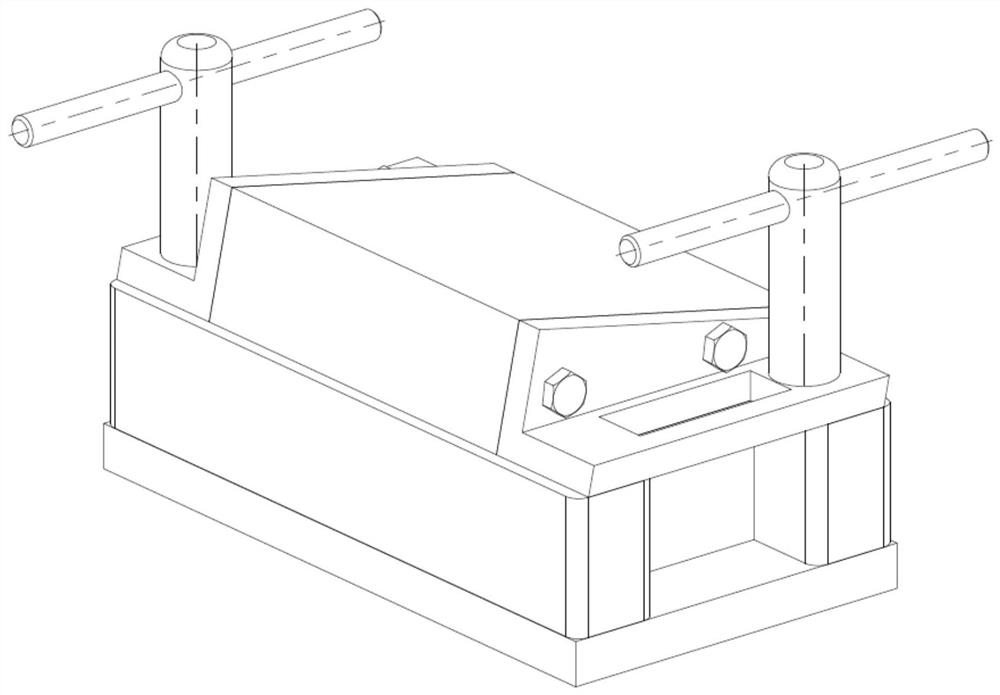

Special-shaped adapter integrated forming die and method

PendingCN111645248AGuaranteed dimensional accuracy requirementsGuaranteed functional requirementsDomestic articlesIntegrated designWear resistance

The invention provides a special-shaped adapter integrated forming die. The special-shaped adapter integrated forming die comprises a bottom plate, wherein a die frame is vertically and fixedly connected to the bottom plate, an upper die is rotatably fixed in the middle of the die frame, and the upper die, the die frame and the bottom plate form a hollow cavity; the top face of the upper die is parallel to the plane of an adapter guide rail groove to be formed, and the top face of the upper die is not parallel to the upper surface of the bottom plate. The invention further provides a special-shaped adapter integrated forming method. According to the forming die, various dimensional precision requirements and functional requirements of an adapter are ensured, and the economical efficiency and the practicability are high; a polytetrafluoroethylene film is effectively prevented from falling off, and the integrity of the adapter is ensured; not only is the effective sliding of the adapteron the guide rail surface ensured, but also the requirements of wear resistance, high temperature resistance and adhesion resistance are met; the positioning requirement is guaranteed, the inclined drawing design is met, and the structure and function integrated design is met; and the requirements of economical efficiency, manufacturability, practicability and operability of die design are met.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

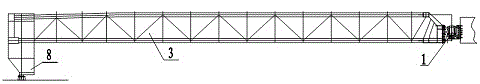

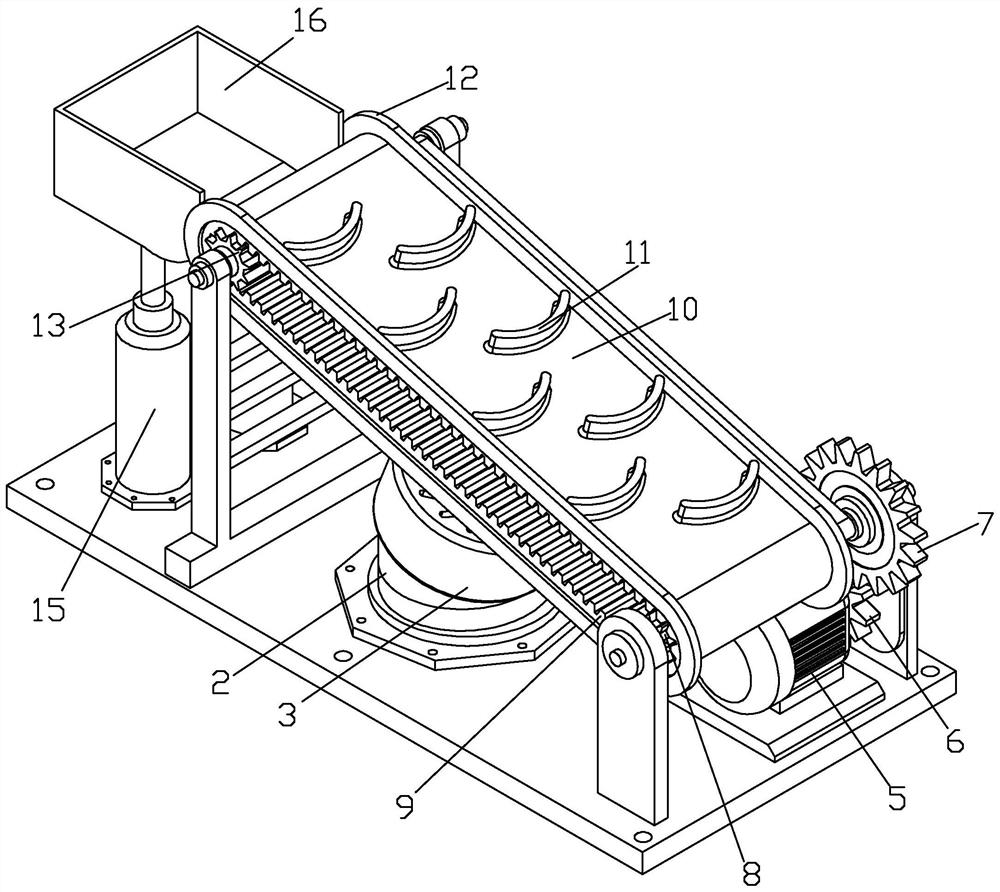

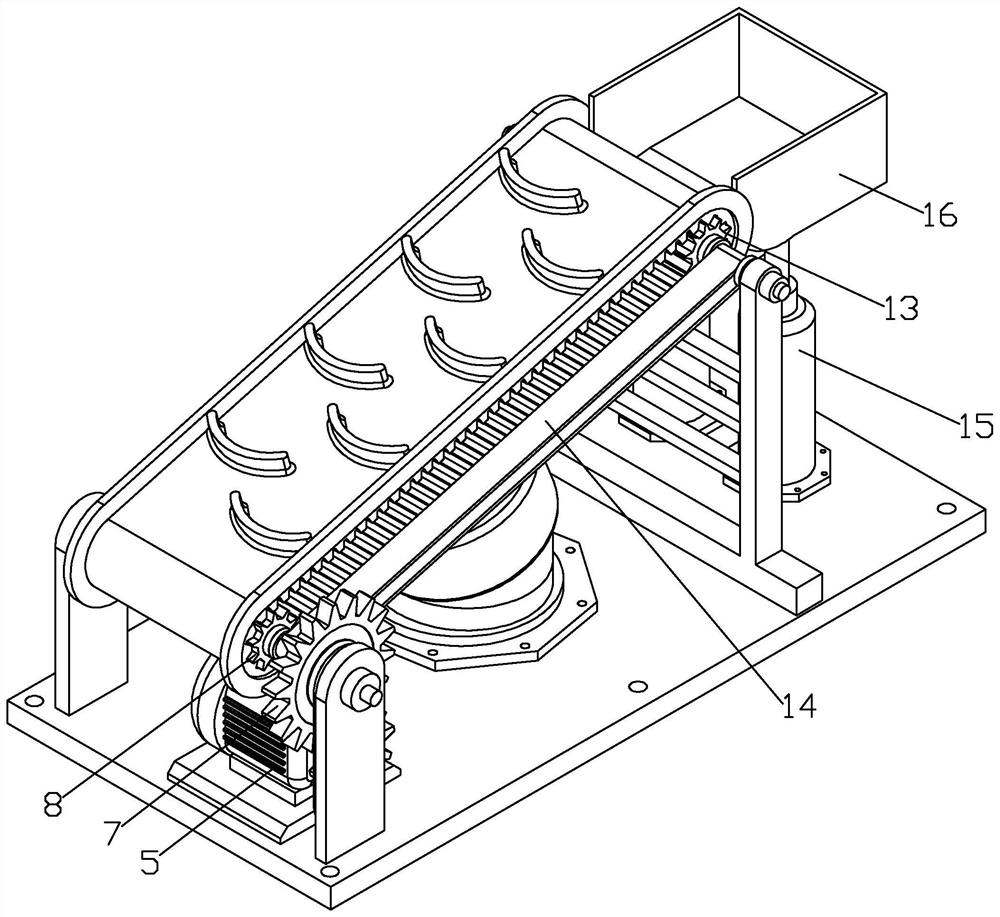

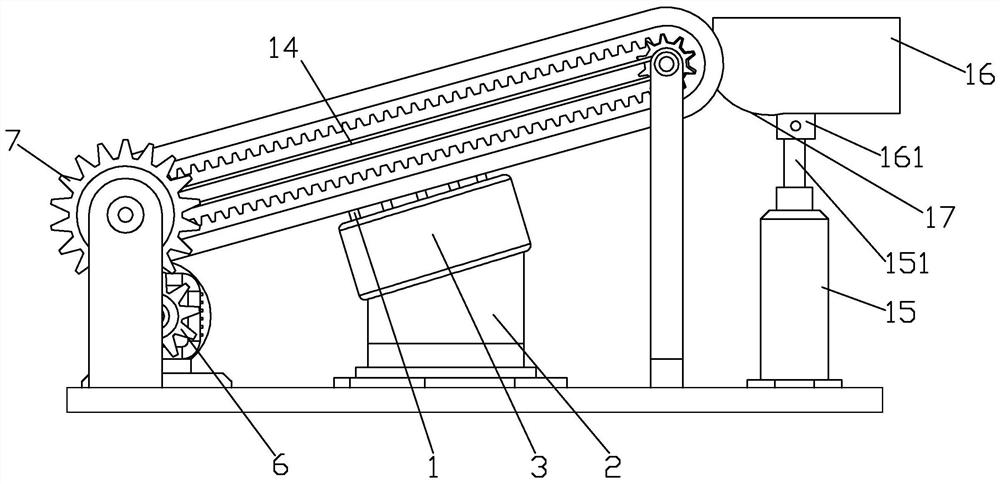

Non-standard automatic equipment for feeding

InactiveCN112265781APrevent slippingGuaranteed itinerary accuracyConveyorsConveyor partsHydraulic cylinderControl engineering

The invention discloses non-standard automatic equipment for feeding. The equipment comprises a feeding belt; the feeding belt is wound into a ring shape; a tooth eye belt is glued to the inner side of the feeding belt; the front side and the rear side of the tooth eye belt are arranged on a first driving tooth roller and a second driving tooth roller in an engaged and wound mode correspondingly;the first driving tooth roller is connected with a motor for synchronous driving; the feeding belt is obliquely arranged at an angle, and the surface of the feeding belt is kept smooth; material baffles which are staggered left and right at intervals are arranged on the surface of the feeding belt in the conveying direction of the feeding belt; the upper end of the feeding belt is an output end; alifting groove used for receiving materials is adjacently formed in the output end and conducts overturning discharging through a rotating air cylinder arranged at the bottom of the lifting groove; and the lifting groove is driven by a hydraulic cylinder arranged at the bottom to ascend and descend. The non-standard automatic equipment for feeding can prevent the feeding belt from slipping, so that the accuracy of the running stroke of the feeding belt is guaranteed; and orderly feeding is achieved through the material baffles, so that the materials can be collected and transferred in a centralized mode through the lifting groove formed in the output end, and the overall production efficiency and the functional requirements are met.

Owner:WENZHOU POLYTECHNIC

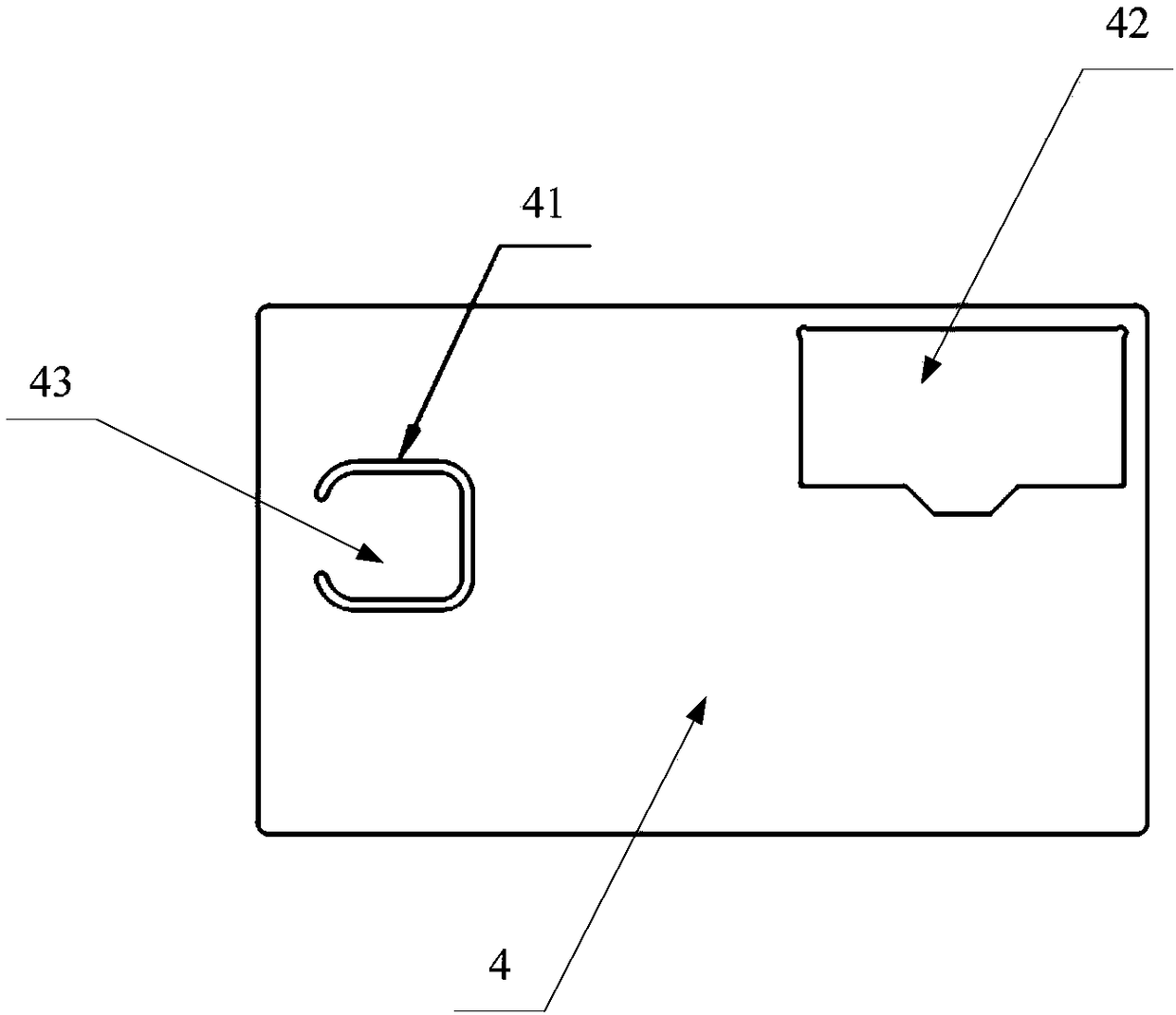

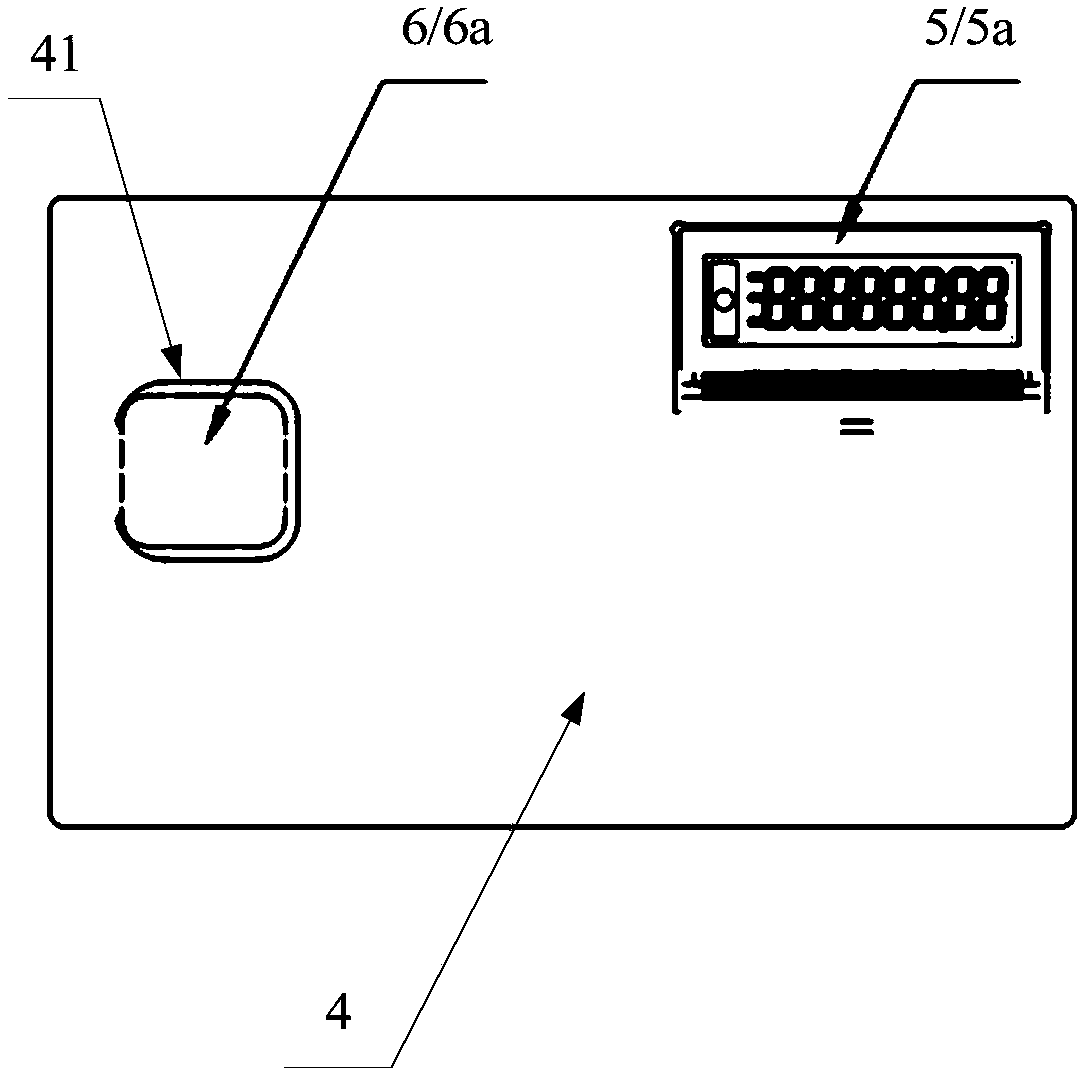

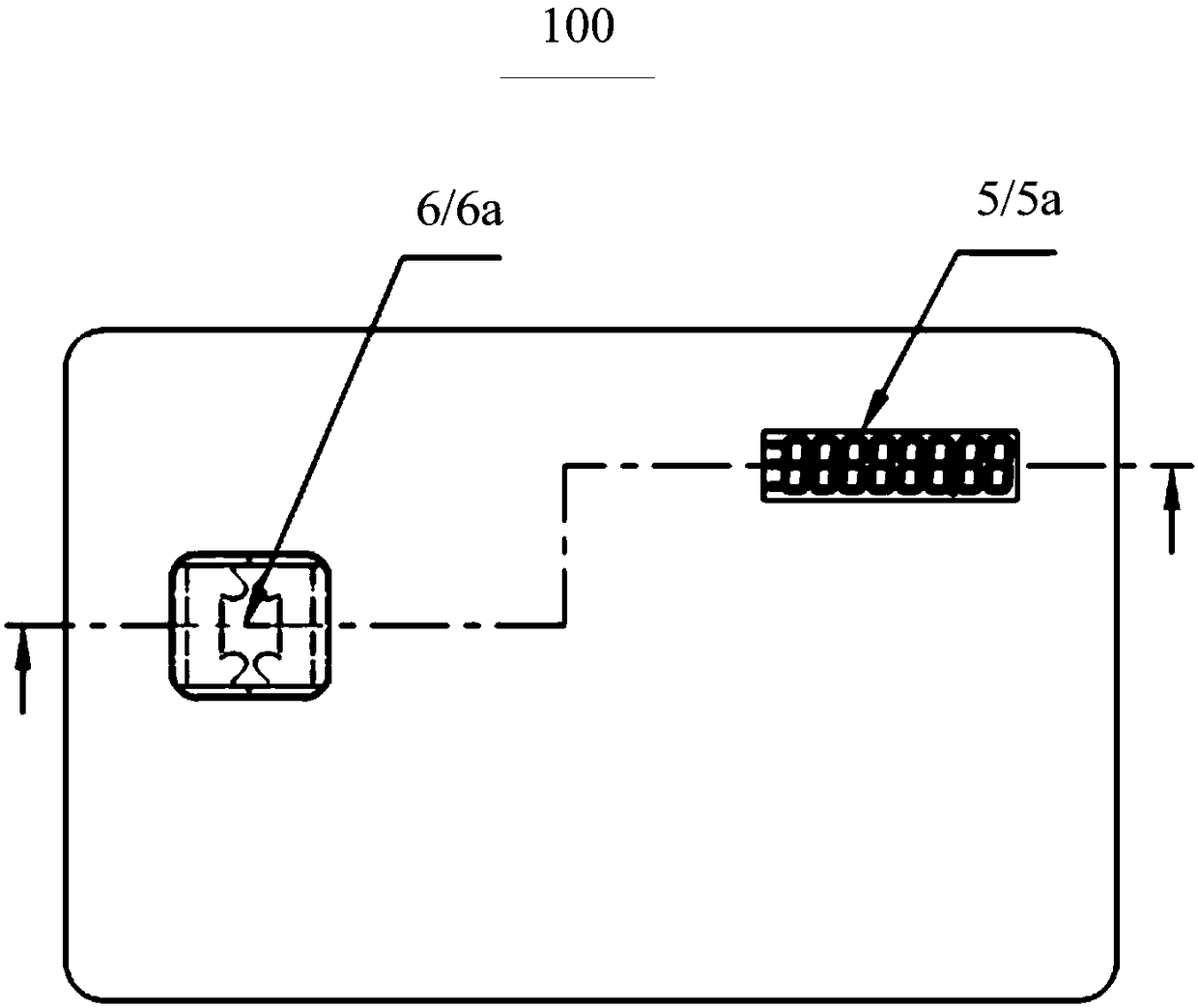

FPCB (flexible printed circuit board) board, smart card and packaging method thereof

PendingCN108282958AGuaranteed Appearance RequirementsGuaranteed Functional RequirementsFinal product manufacturePrinted circuit aspectsProcess errorEngineering

The invention discloses an FPCB (flexible printed circuit board) board, a smart card and a packaging method thereof. The FPCB board is provided with a first component and a second component, the FPCBboard is provided with a through groove at the position of the second component, and the through groove is used for providing a deformation space for the FPCB board when the second component and the first component are positioned on the smart card, so that processing errors of the two components can be adjusted through the deformation, the two components on the FPCB board can be fixedly positionedat correct positions of the smart card, and poor appearance or poor functions of the smart card due to deflection, caused by production and processing errors, of the two components can be avoided. Inaddition, appearance and functional requirements of the components on the smart card are guaranteed, and smart card production yield is increased.

Owner:SHENZHEN EXCELSECU DATA TECH

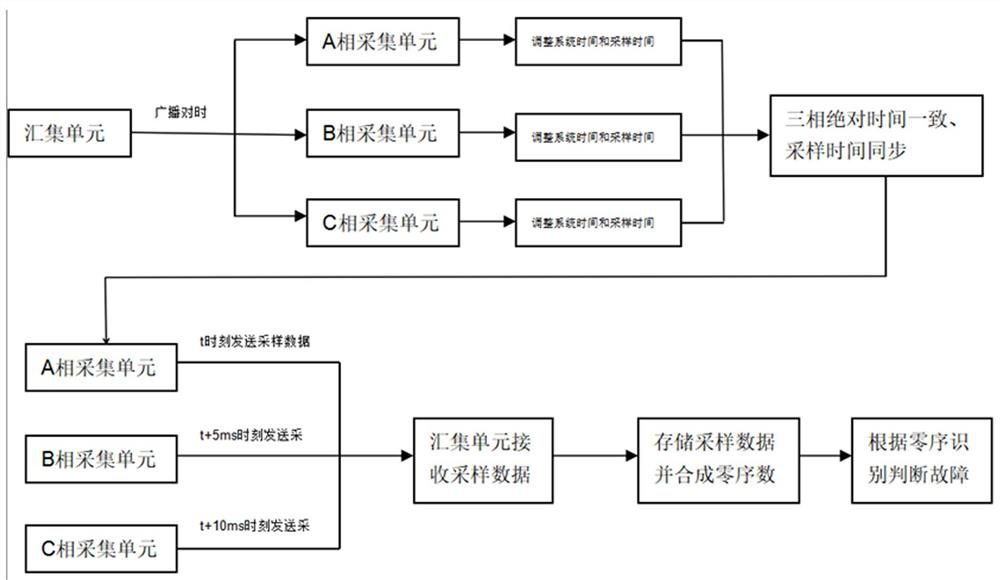

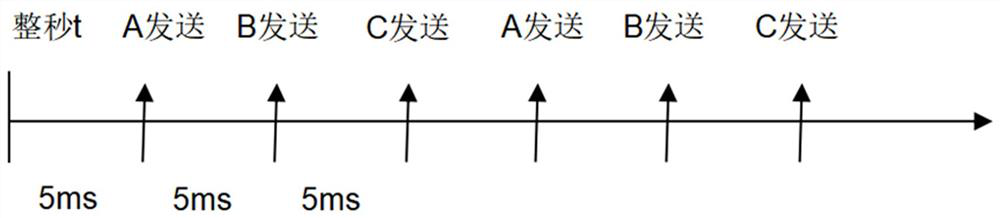

Line fault detection method for synchronous synthesis of data among multiple devices

ActiveCN112433178AGuaranteed functional requirementsSynchronize system timeFault location by conductor typesShort-circuit testingEmbedded systemMultiple device

The invention provides a line fault detection method for synchronous synthesis of data among multiple devices, which belongs to the field of fault indicator systems in power systems. The method is realized based on a three-phase acquisition unit and a collection unit in a fault indicator system, and the three-phase acquisition unit and the collection unit realize data interaction by means of a wireless communication module. The three-phase acquisition unit comprises an A-phase acquisition unit, a B-phase acquisition unit and a C-phase acquisition unit, synchronization of system time and sampling time among all the units is ensured by improving equipment and a detection method, and synchronous sampling data are transmitted to the collection unit in real time to synthesize real-time zero flow and zero voltage for transient state study and judgment, so that the fault recognition rate is improved.

Owner:SHIJIAZHUANG KE ELECTRIC

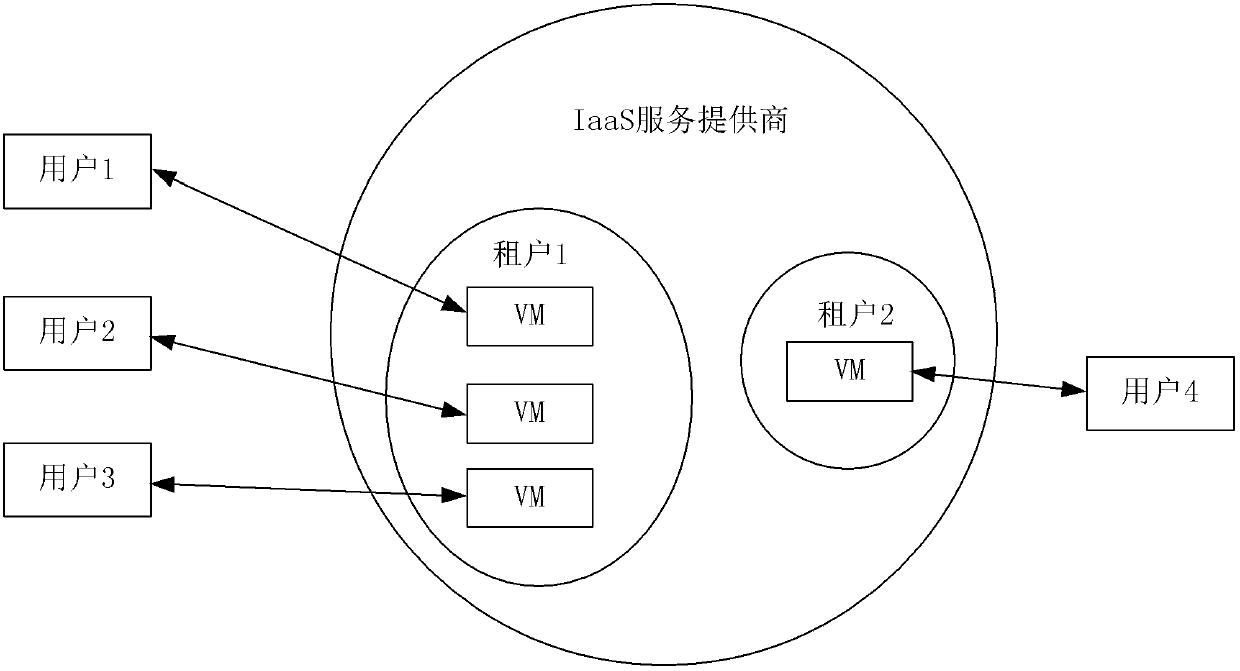

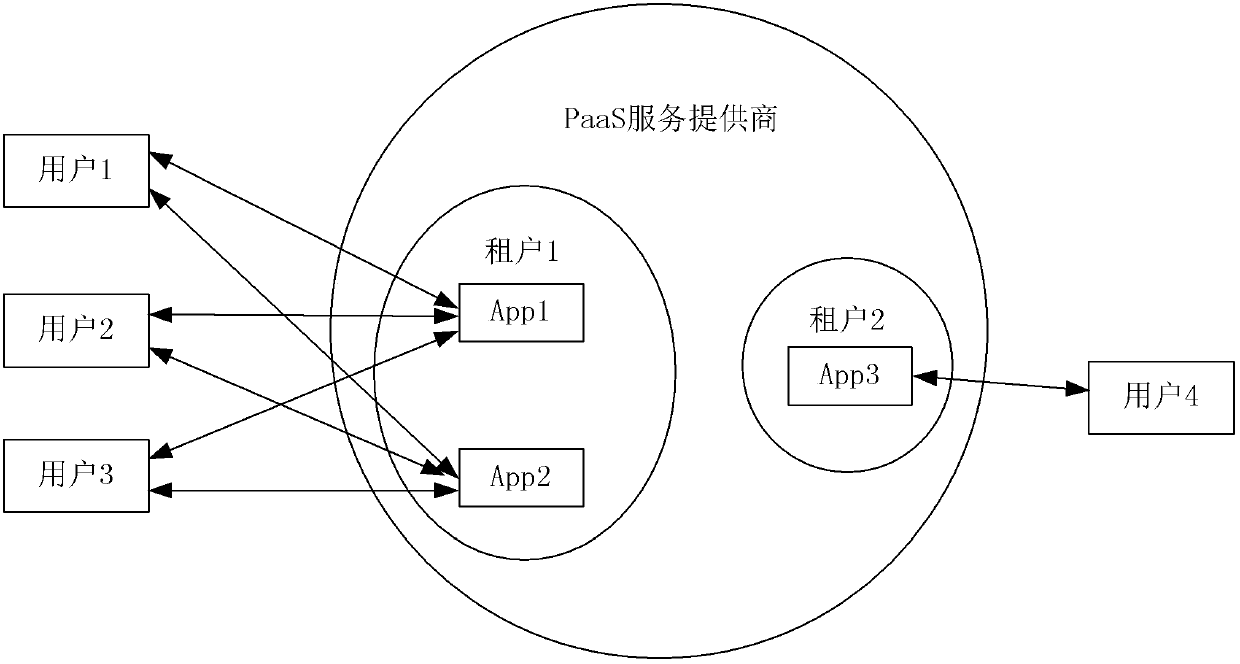

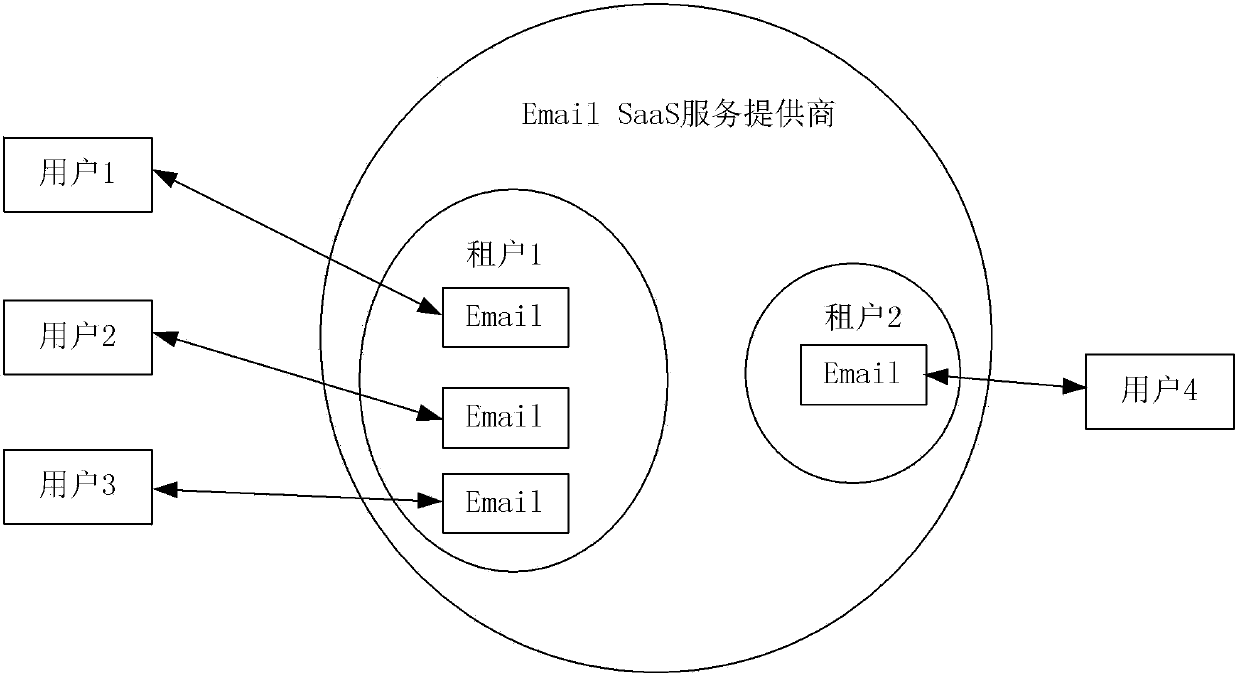

Configuration, generation method and device of cloud environment audit log and/or security event

ActiveCN103428177BImprove trustConfidenceData switching networksService-level agreementComputer module

The invention discloses a method and device for configuring and generating audit logs and / or security events in a cloud environment. In a multi-tenant cloud computing environment, cloud tenants are provided with audit logs and related information assets in the cloud that meet their needs. and / or security incidents. The generation method includes: configuring the audit log and / or security event of the cloud tenant that the cloud computing service provider (CSP) needs to provide in the service level agreement (SLA); the CSP generates the cloud tenant according to the configuration in the SLA audit logs and / or security events. The generating device includes an SLA module and a generating module. Adopting the method and device of the present invention helps to improve the confidence and trust of cloud tenants in the CSP, and satisfies the differentiated requirements of different tenants.

Owner:ZTE CORP

Shock-absorbing sport shoes

The invention discloses a damping sports shoe with a forming damping system, which consists of a forming EVAMD part, functional parts with a forming three-dimensional damping structure arranged on a sole heel part and the hollow part of the inside and the outside of the shoe, a secondary buffer damping TPU forming damping accessory, and a forming damping structure of a rubber outer sole. The design details of the forming damping system are fully designed according to requirements of the outside of the heel to the inner turning stability during the sporting touchdown. The sports shoe can also be applied to other sporting casual shoes.

Owner:晋江联诚投资有限公司

Packaging box manufacturing mold

PendingCN114872237AGuaranteed Functional RequirementsGood impact resistancePackage recyclingDomestic articlesAssembly disassemblyEngineering

The packaging box manufacturing mold comprises an outer mold bottom plate, an outer mold left upper plate and a jacking block, an outer mold front plate and an outer mold rear plate are arranged on the upper sides of the front end and the rear end of the outer mold bottom plate in an attached mode correspondingly, and an outer mold left lower plate and an outer mold right plate are arranged on the upper sides of the left end and the right end of the outer mold bottom plate in an attached mode correspondingly; the outer mold left upper plate is connected to the upper side of the outer mold left lower plate in an attached mode. The jacking block is located on the upper surface of the outer end of the outer mold bottom plate, and the inner sides of the outer mold bottom plate, the outer mold front plate, the outer mold rear plate, the outer mold left lower plate, the outer mold left upper plate and the outer mold right plate are wrapped with inner mold plates which are connected with the outer mold bottom plate, the outer mold front plate, the outer mold rear plate, the outer mold left lower plate, the outer mold left upper plate and the outer mold right plate in an And the inner sides of the front and rear ends of the outer mold left lower plate and the outer mold right plate are respectively attached and connected with an outer mold front plate and an outer mold rear plate. According to the packaging box manufacturing mold, the manufacturing mold can be conveniently assembled and disassembled, parts can be conveniently replaced, the service life of the packaging box manufacturing mold is long, and the manufacturing mold has good impact resistance.

Owner:重庆力昇特装科技有限公司

Nonwoven material prepared through discontinuous type functional treatment and preparation method thereof

ActiveCN101812778BEasy to transformReduce investmentFibre treatmentNon-woven fabricsBasementNonwoven fabric

The invention discloses a nonwoven material prepared through discontinuous type functional treatment and a preparation method thereof. The nonwoven material basement is processed through discontinuous type functional treatment to form functional areas which are arranged discontinuously. The preparation method of the invention can be used to perform various functional treatments to nonwoven material basement, the equipment modification is easy, the investment is low, the preparation method can not conflict with the production technology of the common nonwoven fabric, the existing equipment andprocess can also be used; and therefore, the method is easy to realize and the production cost is low. The nonwoven material prepared through discontinuous type functional treatment of the invention can have different functions; the material can be freely cut into multiple pieces with small breadth along the transverse breadth direction, for example the nonwoven material with small breadth in thearrangement manner of 'non-treatment + functional treatment + non-treatment' can be prepared; and the amount of raw material used in functional treatment can be reduced, the cost is saved, and the bad effects of some raw materials to human body can be lowered.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

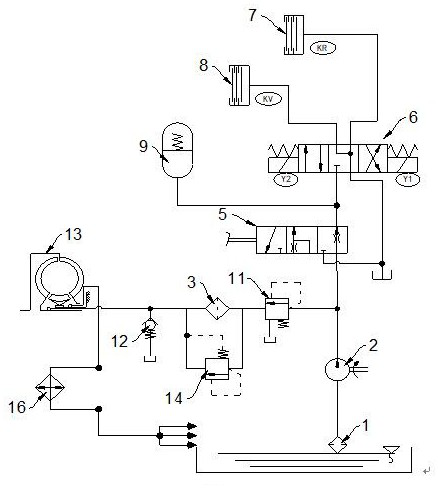

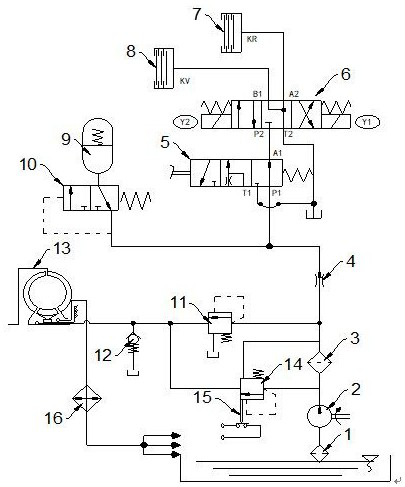

Small-tonnage forklift gearbox hydraulic control system

PendingCN114352584ATimely maintenanceReduce wearServomotor componentsPump assembliesControl systemLubrication

The small-tonnage forklift gearbox hydraulic control system comprises an oil tank, a coarse oil filter is embedded in the oil tank, an oil supply pump is arranged outside the oil tank, and an output port of the coarse oil filter is connected with an input port of the oil supply pump. When the fine oil filter is blocked through the whole control system, the alarm system can be stimulated to remind an operator of timely maintenance; according to the whole control system, when the fine oil filter is blocked, oil supply of the backward clutch and the forward clutch is cut off under the condition that oil supply of the torque converter is guaranteed, the abrasion degree and the ablation degree of friction plates are reduced to the minimum, and the economic loss and the operation risk of the whole vehicle are also reduced; the installation position of the fine oil filter can also detect the total flow of the oil supply pump, the leakage condition of the oil supply pump can be detected, and whether the leakage condition of the whole control system meets the heat dissipation and lubrication requirements or not can be measured by comparing the flow at the outlet of the torque converter.

Owner:采埃孚合力传动技术(合肥)有限公司

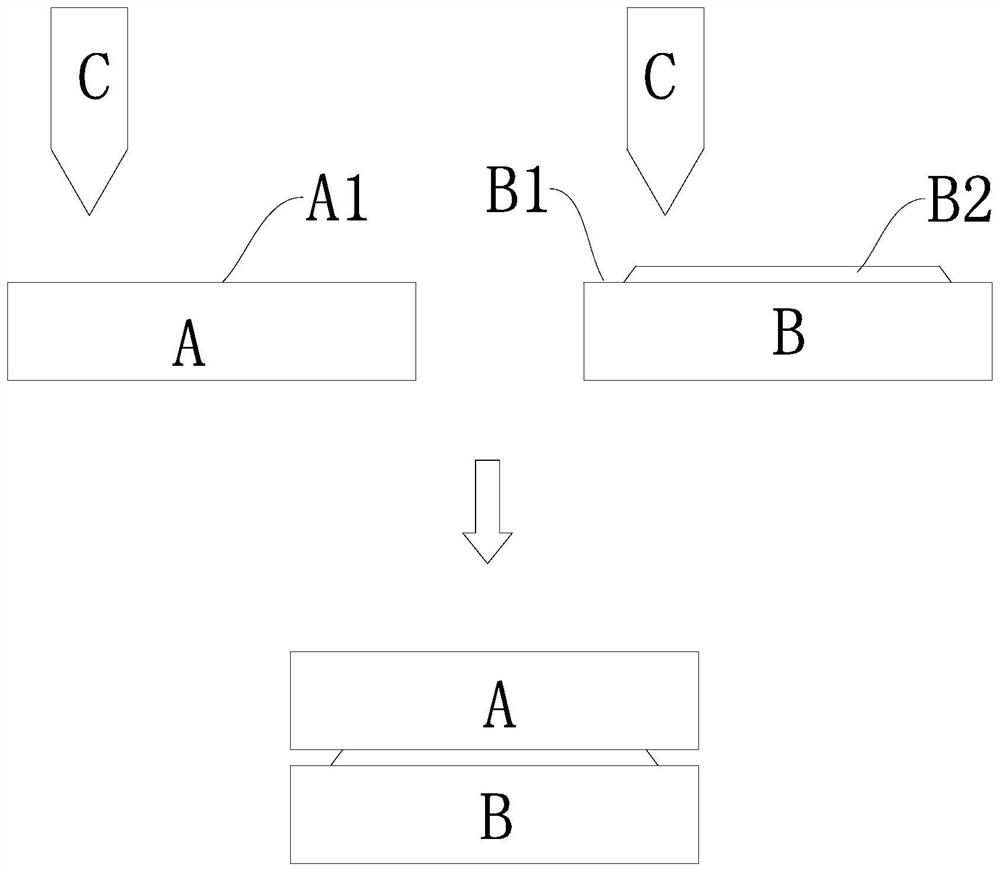

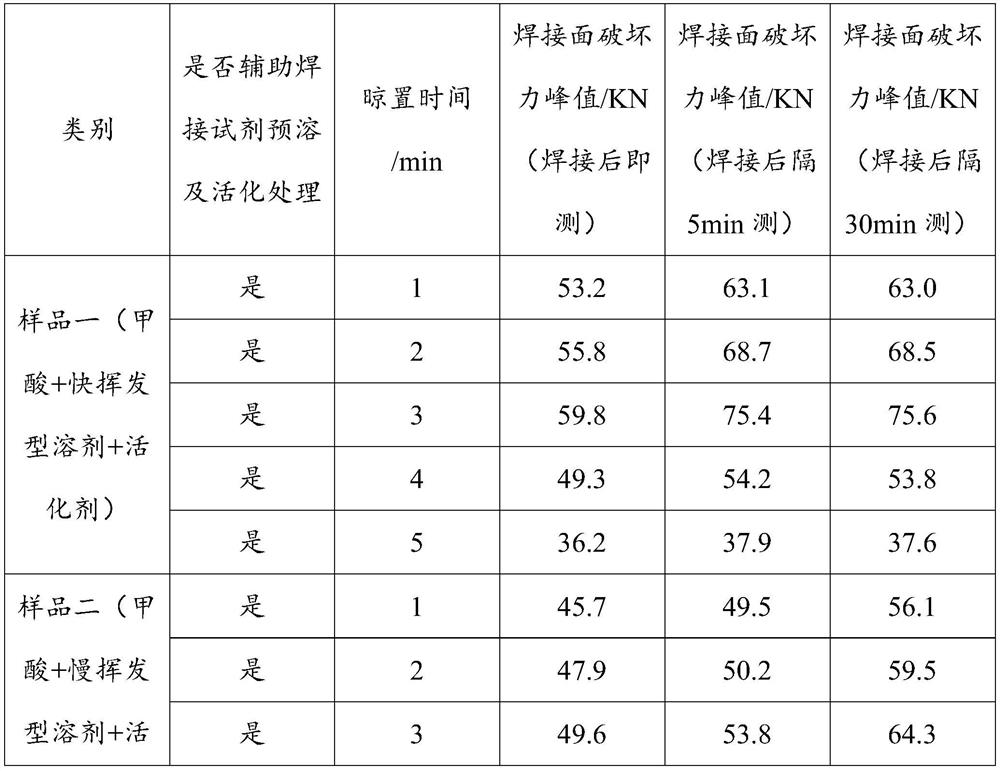

Method for reducing difficulty of ultrasonic welding of engineering plastics

PendingCN111823601AReduced Power RequirementsGuaranteed Strength RequirementsUltrasonic weldingEngineering plastic

The invention discloses a method for reducing the difficulty of ultrasonic welding of engineering plastics. The method is characterized by comprising the following steps that S1, before ultrasonic welding of the engineering plastics, an auxiliary welding reagent is coated on the welding surface of the engineering plastics in advance, and the auxiliary welding reagent comprises an activating agent.According to the method, the welding surface of the engineering plastic is treated by selecting the auxiliary welding reagent, so that the surface of the engineering plastic is subjected to ultrasonic welding after being subjected to pre-dissolving and activating treatment, and then only low-power ultrasonic welding equipment is needed for wave generation welding, so that the welding difficulty can be reduced, the strength and function requirements of a welding assembly are guaranteed, the power requirement of welding equipment is lowered, cost is saved, and meanwhile unification and standardization of the equipment are promoted.

Owner:XIAMEN RUNNER IND CORP

A fully formed knitted sports face protector and its knitting method

ActiveCN111358070BRich texture colorHuge market potentialWeft knittingHeadwearYarnStructural engineering

The invention discloses a fully formed knitting sports face protector and a knitting method thereof, comprising a helmet-type face protector body, the face protector body is formed by knitting moisture-conducting and easy-to-dry yarn integrally, the front and rear necks of the face protector body and The front face is braided to form a spherical knitted structure with moisture-conducting and warm-keeping functions. The head of the face shield body is knitted according to the head structure to form a spherical knitted structure with moisture-conducting and warm-keeping functions to form the head cover. The eyes of the face shield body are idling knit The method is to fit the eyes, and the mouth and nose of the face shield body are also woven on the basis of the spherical knitting structure with moisture-wicking and warm-keeping functions to enhance air permeability. The fully formed knitted sports face protector can be woven according to the structure of the human head to form a more fit and comfortable face protector structure, which solves the shortcomings of traditional techniques, makes it more fit and comfortable to wear, and at the same time ensures the functional requirements of each area.

Owner:嘉兴市蒂维时装有限公司

Shoe sole shock absorber

PendingCN107136648AReduce shockGuaranteed functional requirementsFasteningsHuman bodyElastic component

The invention discloses a shoe sole shock absorber. The shoe sole shock absorber comprises a wedge-shaped device suitable for a shoe sole; the wedge-shaped device comprises two metal sheets which form a wedged angle; at least one elastic component for shock absorption is arranged in a wedged space between the two metal sheets; a screw rod for adjusting the size of the wedged angle and adjusting the initial elastic force of the shock absorber is arranged at the opening direction position of the wedged angle of the metal sheets, and is locked by a nut. The shock absorber can buffer the action force between feet and the ground when a person is under a dynamic condition by utilizing the buffer performance of the wedge-shaped device and the elastic component, enables the weight of the human body to be distributed at the sole reasonably, reduces the impact on ankles and knees by the gravity of the human body, reduces shock which a brain and a spine are subjected to, guarantees the functional requirement of movement and protects the body; the shock absorber has high applicability and can meet the requirements of different shoe shapes and sizes.

Owner:江苏省安全生产科学研究院

A hidden inspection port

ActiveCN109707095BImprove connection strengthInhibit sheddingCeilingsStructural engineeringMechanical engineering

The invention discloses a concealed inspection port, which comprises a fixed installation assembly and an inspection plate arranged on the fixed installation assembly; the fixed installation assembly includes an installation sleeve fixed on the installation plane, and the lower end of the installation sleeve is level with the installation plane; the installation sleeve There is an adjustment sleeve that can move along the extension direction of the installation sleeve and extend out of the lower end of the installation sleeve. The access plate is movably installed at the lower end of the adjustment sleeve. The access plate can open or close the port at the lower end of the adjustment sleeve; one side of the access plate is hinged on the The lower port of the adjustment sleeve; the present invention adopts a hidden installation method to install on the corresponding use plane, which can not only ensure that the inspection plate is consistent with the surroundings of the installation plane, but also realize the opening and closing of the inspection port, and ensure the functional requirements of the inspection port , which occupies a small space and is flexible in operation; has high practical value and promotion value, and can be widely used in the field of architectural decoration.

Owner:CHONGQING CHUANGGAO DECORATION ENG CO LTD

A horizontal test device and test method for measuring the torsional performance of materials under an electron microscope

ActiveCN107219133BGuaranteed functional requirementsReduce volumeStrength propertiesMeasurement deviceTest sample

The invention provides a horizontal-type test apparatus and test method for measuring a torsion property of a material under an electron microscope. The horizontal-type test apparatus comprises a framework, a first clamping part, a second clamping part, a control apparatus and an electron microscope; the first clamping part is installed on the framework and comprises a fixed clamp for clamping a test sample in a rotating manner; the second clamping part is installed on the framework and is oppositely and horizontally separated from the first clamping part and comprises an electromagnetic driving apparatus, a movable clamp for clamping the test sample, and an angle measuring apparatus; the control apparatus is used for setting a test method and controlling an experimental process; and the electron microscope is used for in-situ observing the variation of a test sample in the experimental process. By adopting the horizontal-type test apparatus and test method, the problem of an additional torque caused by the mass eccentricity of a rotating part after the test sample is horizontally arranged can be solved, and the apparatus can work horizontally, so that the electron microscope can realize the in-situ observation. By adopting two rotatable clamping ends, a large-angle multi-circle loading experiment of the test sample can be realized.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

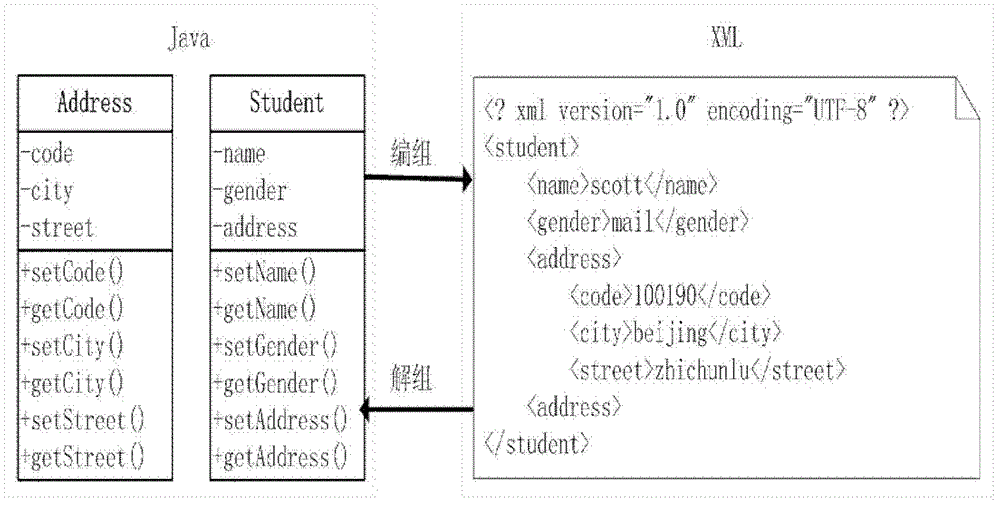

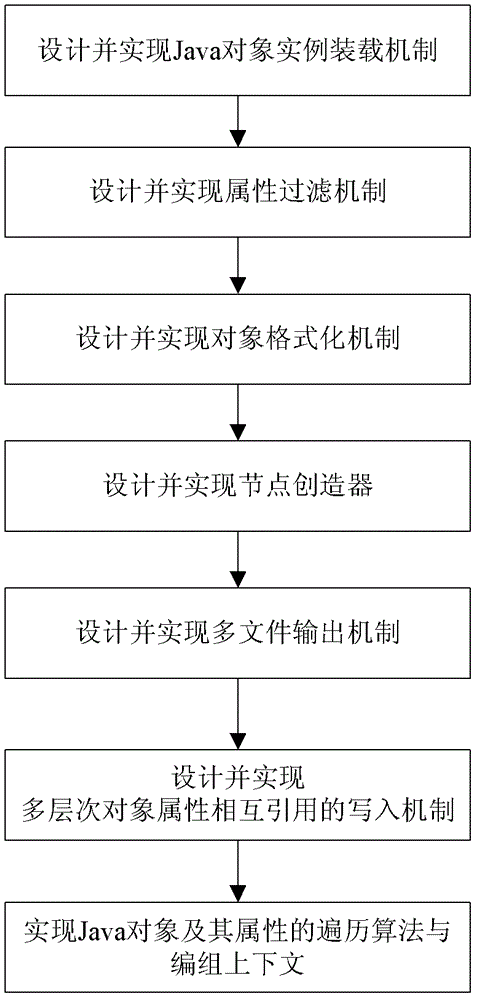

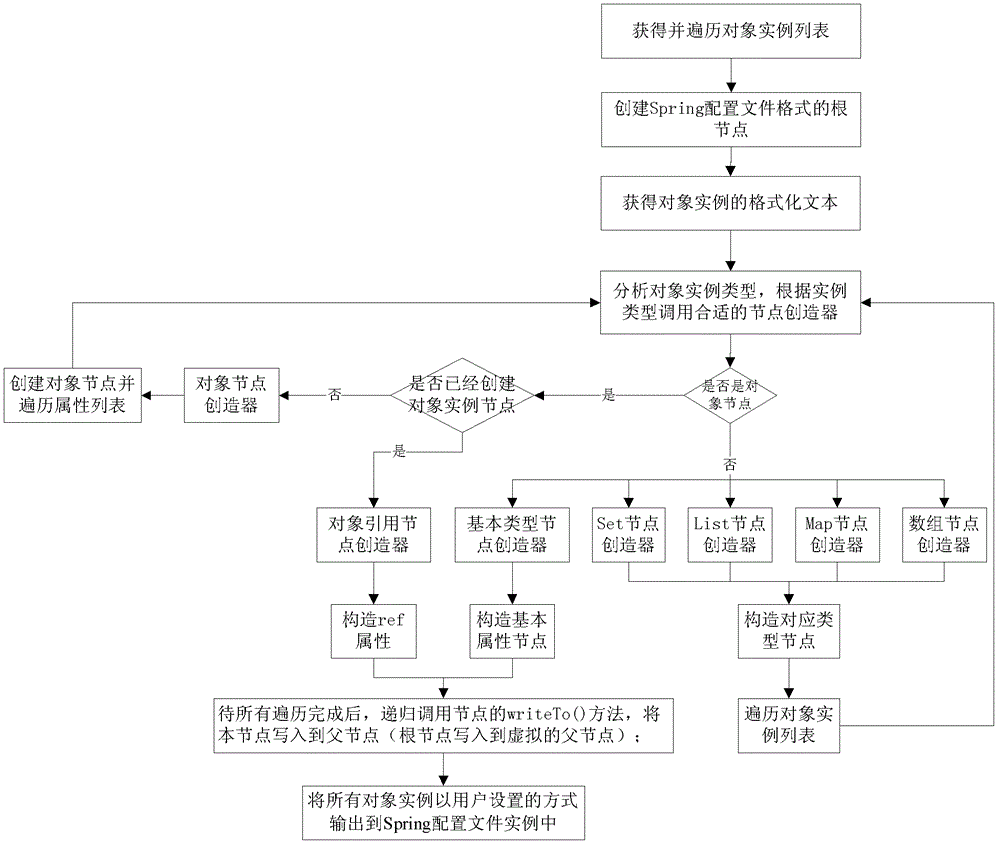

A method for generating spring IOC configuration files

ActiveCN102609255BCorrect unmarshallingSimple configurationSpecial data processing applicationsSpecific program execution arrangementsProgramming languageInversion of control

The invention provides a generation method for a Spring IOC (Inversion of Control) configuration file. The generation method comprises the following steps of 1) loading one or more Java object instances, reading and filtering attribute lists of all the Java object instances to be marshaled; 2) establishing a corresponding node creation device and defining a writing-in rule; 3) generating nodes of the Spring IOC configuration file by the node creation device according to the writing-in rule, and writing in the Java object instances and attributes of the Java object instances in the nodes; and 4) outputting all the nodes to the Spring IOC configuration file according to different output modes. According to the generation method, the Java object instances can be mutually quoted, and the generated Spring IOC configuration file can be unmarshaled correctly by a Spring framework; in addition, the flexibility and the marshaling efficiency are high, thereby greatly simplifying the configuration work and facilitating the user of users.

Owner:北京中科北龙科技有限责任公司

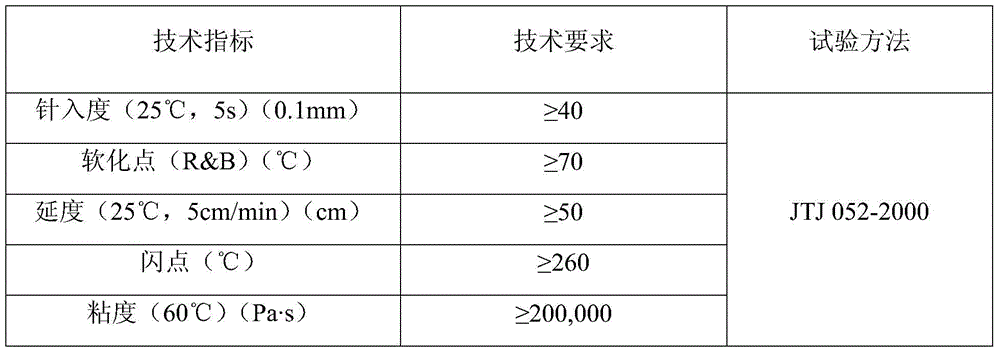

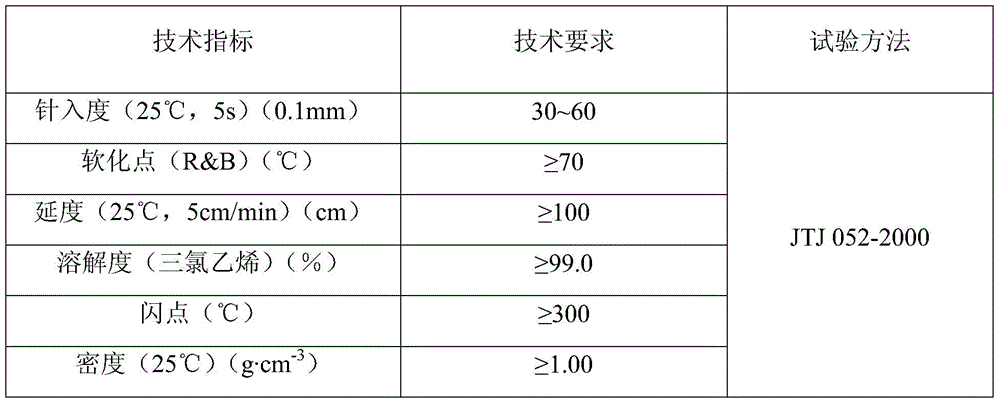

A kind of anti-rutting pavement structure and laying method thereof

ActiveCN105672080BGuaranteed functional requirementsPrevent infiltrationIn situ pavingsSanderVisibility

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

Shot blasting cleaning method for casting machining

InactiveCN112518593AEasy to handleGood lookingBlast gunsAbrasive machine appurtenancesMachiningPeening

The invention relates to a shot blasting cleaning method for casting machining. The shot blasting cleaning method comprises the following steps that a machined casting to be subjected to shot blastingcleaning is degreased, washed and dried; a shot blasting abrasive material is selected and is thrown into shot blasting line equipment after cleaning and drying; the casting is placed in a shot blasting chamber of the shot blasting line equipment, and shot blasting treatment is conducted on the casting; shots adhering to the casting are brushed off; and the casting obtained after shot blasting treatment is inspected, and inspection and acceptance records are made. Compared with the prior art, pre-cleaning treatment is conducted on the machined casting, the mixed abrasive material is adopted as the shot blasting abrasive material, the problem that the color is dark is solved, and the shot blasting cleaning treatment effect of the casting is improved; and reasonable shot blasting parametersof a shot blasting gun are set, follow-up cleaning is conducted in the shot cleaning chamber, so that roughness of the surface of the casting is effectively reduced, the appearance performance and mechanical performance of the casting are improved, and then the functional requirements of the casting are met.

Owner:TIANJIN ZHONGDA PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com