Nonwoven material prepared through discontinuous type functional treatment and preparation method thereof

A technology of nonwoven materials and manufacturing methods, which is applied in the direction of nonwovens, fiber treatment, textiles and papermaking, etc., can solve the problems of hindering the application of functional nonwoven materials and high cost, and achieve reduced adverse effects, low production costs, and reduced The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Interval functional treatment of nonwoven materials

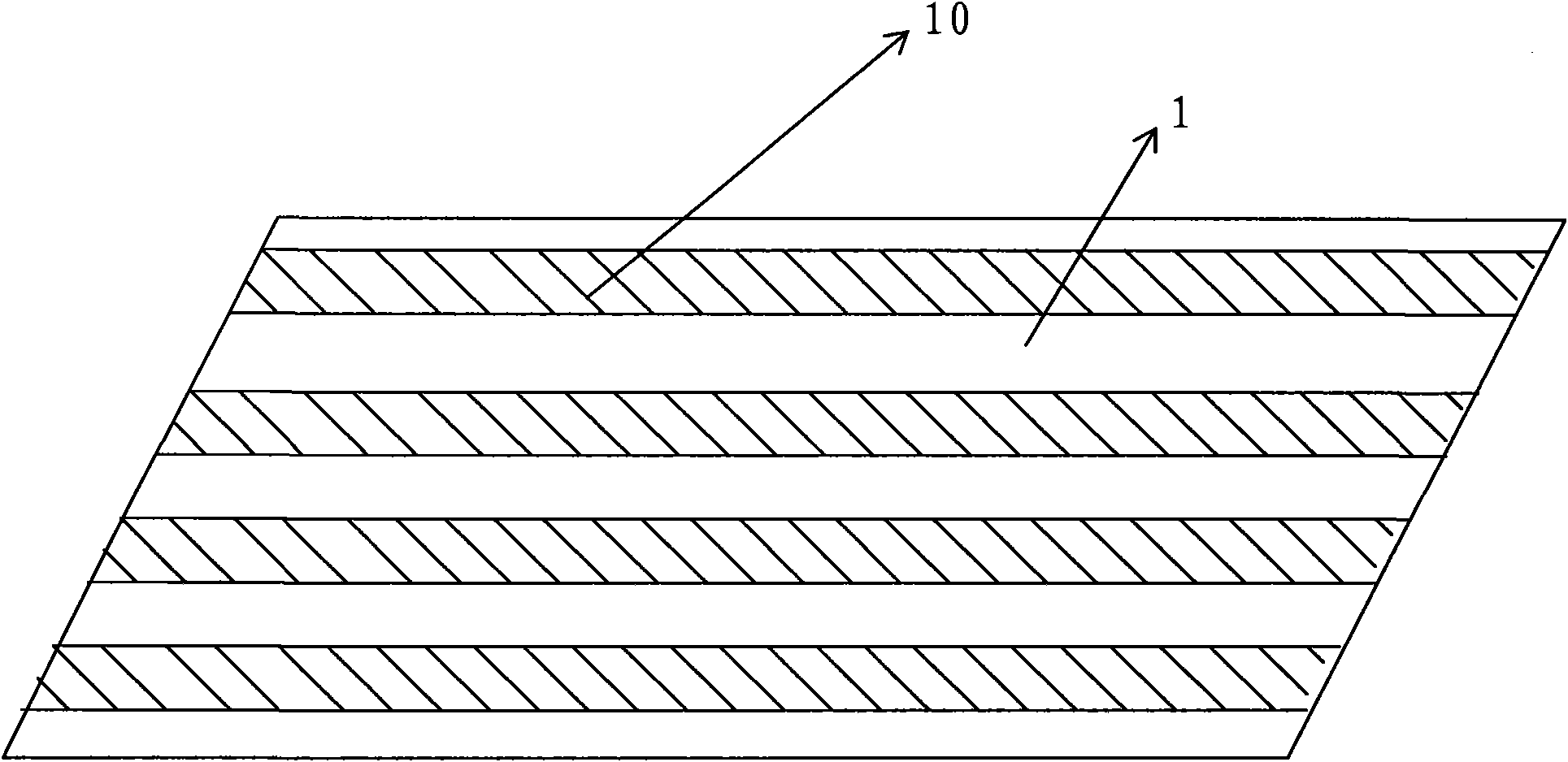

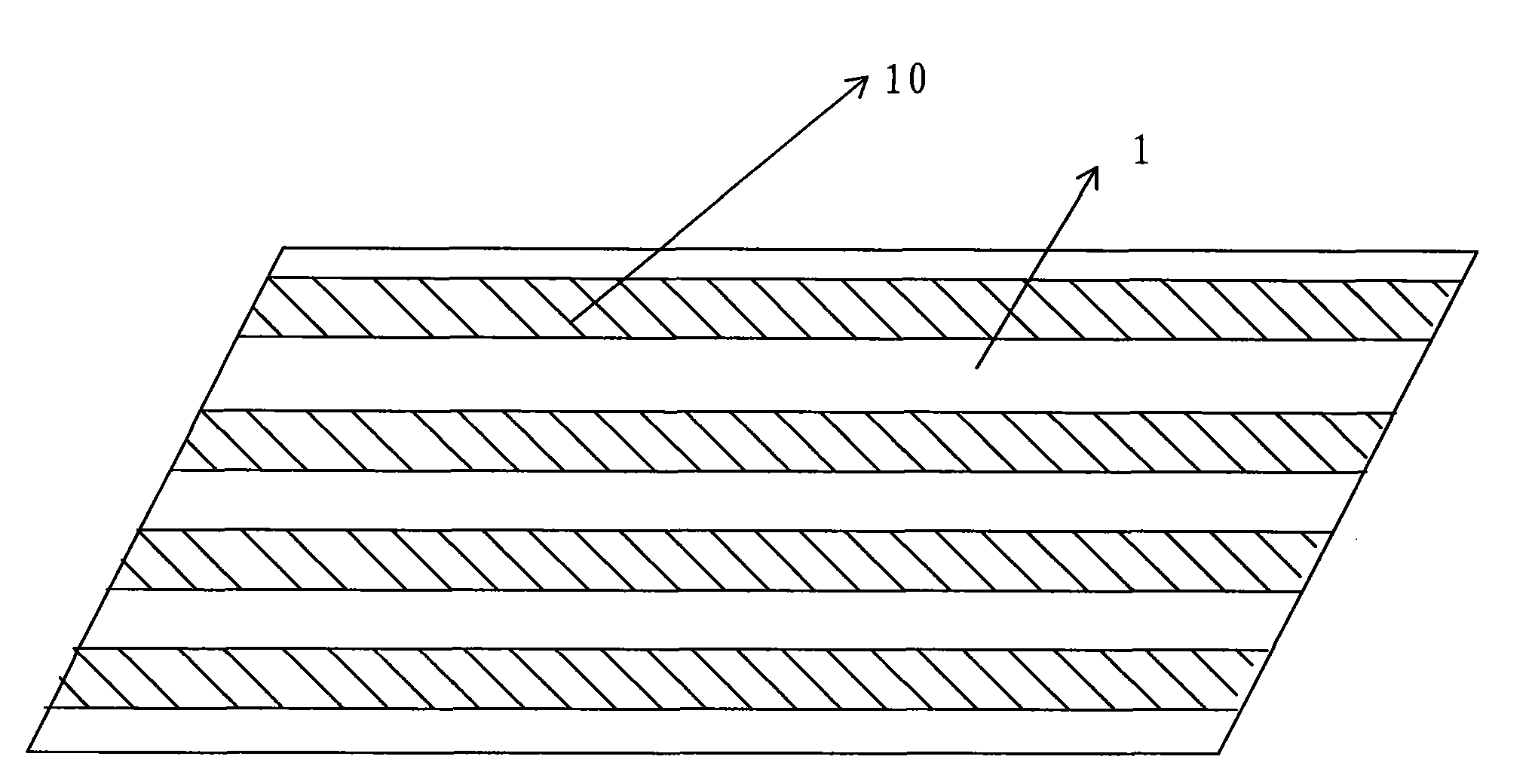

[0021] As shown in FIG. 1 , on a non-woven material (ordinary non-woven fabric) substrate 1 , through a functional treatment process, functional treatment is performed by spaced arrangement to form spaced functional regions 10 . The functional treatment includes one or more of hydrophilic treatment, antibacterial treatment, vitamin treatment, aloe treatment and mint fragrance treatment.

Embodiment 2

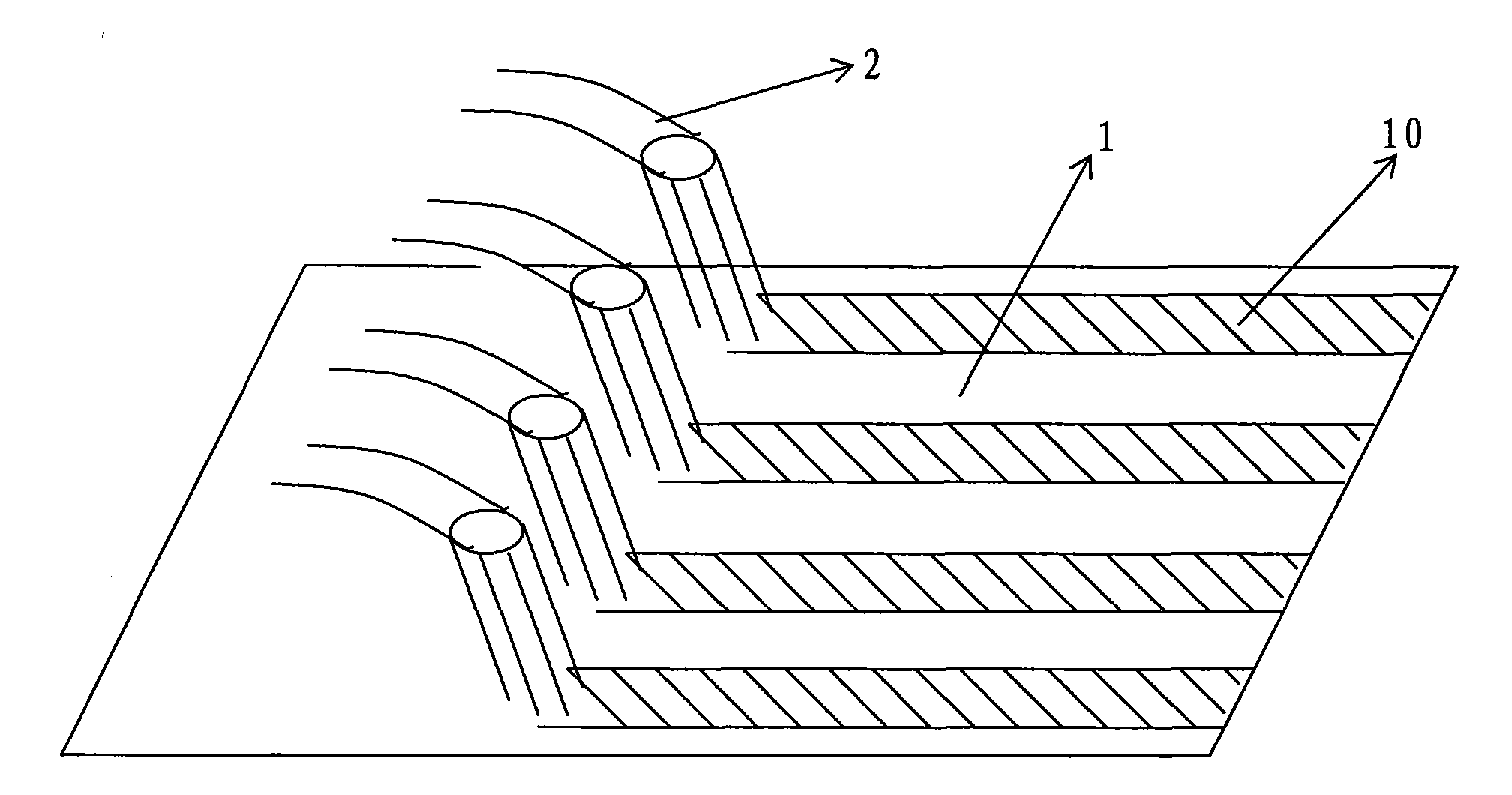

[0022] Embodiment 2: Interval spray gun spraying functional treatment

[0023] As shown in FIG. 2 , the interval-type functional treatment of the nonwoven material in Embodiment 1 adopts the process of spraying with a spray gun. The spray guns 2 are arranged at intervals of a certain distance, and the functional treatment oil is transported by the oil pipeline, and the non-woven material substrate 1 is sprayed at intervals, that is, along the transverse direction of the non-woven material substrate 1, functional treatment is formed at intervals to form a functional coating. The processing area 10 forms a compartmentalized functionally processed nonwoven material. For example, the width of the non-woven material substrate 1 is 7.2 meters, and the spraying width of one spray gun is 0.1 meters, with an interval of 0.3 meters in the middle, 18 spray guns can be arranged to form 18 functional treatment areas 10 with a width of 0.1 meters. , 18 untreated areas with a width of 0.3 m...

Embodiment 3

[0024] Example 3: Functional treatment of convex oil roller coating

[0025] As shown in FIG. 3 , the interval-type functionally treated nonwoven material in Example 1 adopts the process method of convex oil roller coating. In the convex oil roller 3, protrusions 30 are evenly arranged according to a certain distance, and the oil agent can be discharged, and the functional treatment oil agent is transported by the oil pipeline, and the non-woven material substrate is carried out by interval roller coating, that is, along the non-woven material substrate. In the transverse direction of the woven material base material, functionally treated areas 10 are formed at intervals to form an interval functionally treated nonwoven material. For example, the width of the non-woven material base material is 7.2 meters, the width of the oil roller protrusions 30 is 0.1 meters, and the interval between the protrusions 30 is 0.3 meters, 18 protrusions can be arranged to form 18 0.1 meters 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com