Rail transit carbon fiber composite vehicle lower outer cover and manufacturing method

A technology of rail transit and composite materials, applied in the field of under-vehicle cover structure and manufacturing, which can solve the problems of low production efficiency, high site requirements, and difficult transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

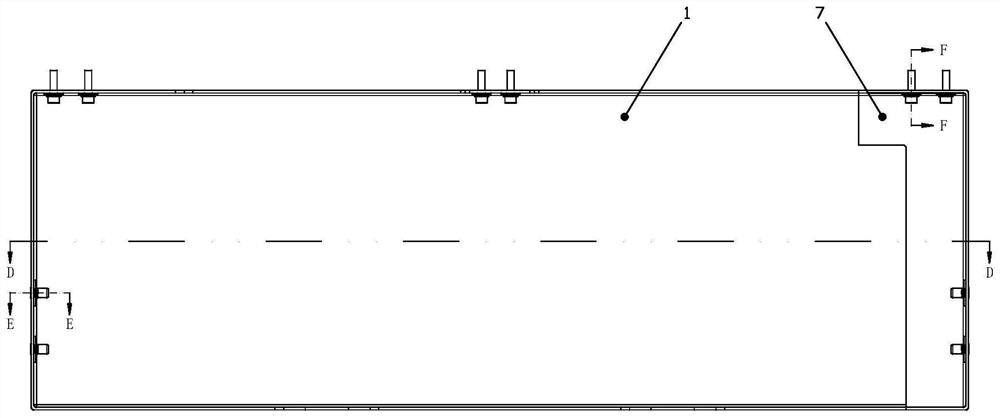

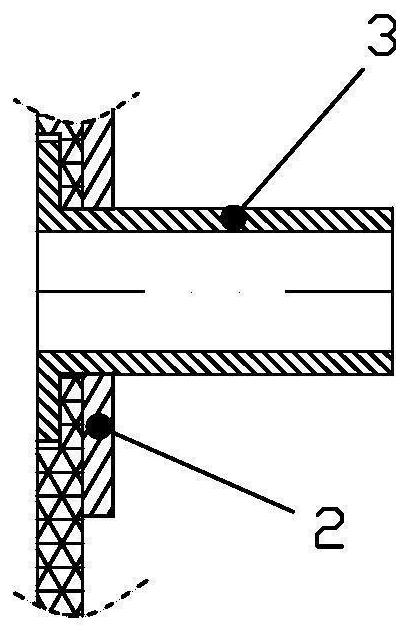

[0026] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0027] figure 1 It is a schematic diagram of the overall structure of the present invention, 2 is a D-D sectional view of the present invention, and 3 is an E-E sectional view of the present invention, Figure 4 It is the F-F cross-sectional view of the present invention, as shown in the above figure: the rail transit carbon fiber undercarriage structure provided by the present invention includes: outer cover main part 1, metal embedded part 2, outer cover auxiliary part 7, 3K appearance fabric, metal embedded part 2 Pre-buried in the main part 1 of the outer cover; the main part 1 of the outer cover and the auxiliary part 7 of the outer cover are integrally formed by carbon fiber materials, and the main part 1 of the outer cover and the auxiliary part 7 of the outer cover are bonded int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com