Patents

Literature

44results about How to "Guaranteed Appearance Requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

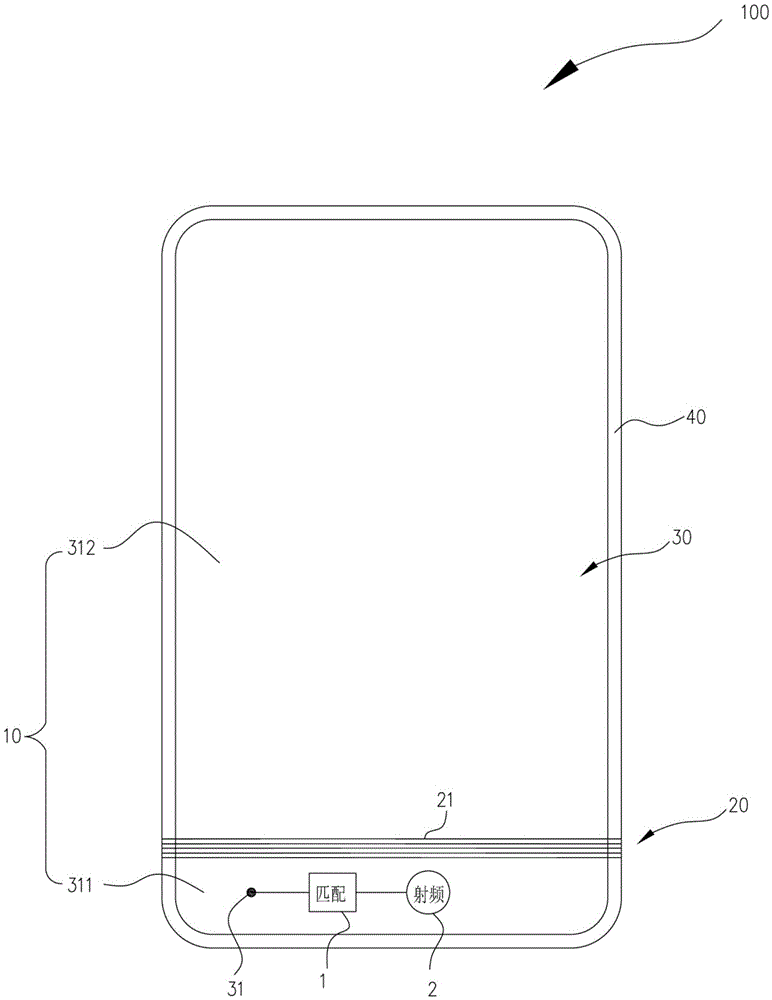

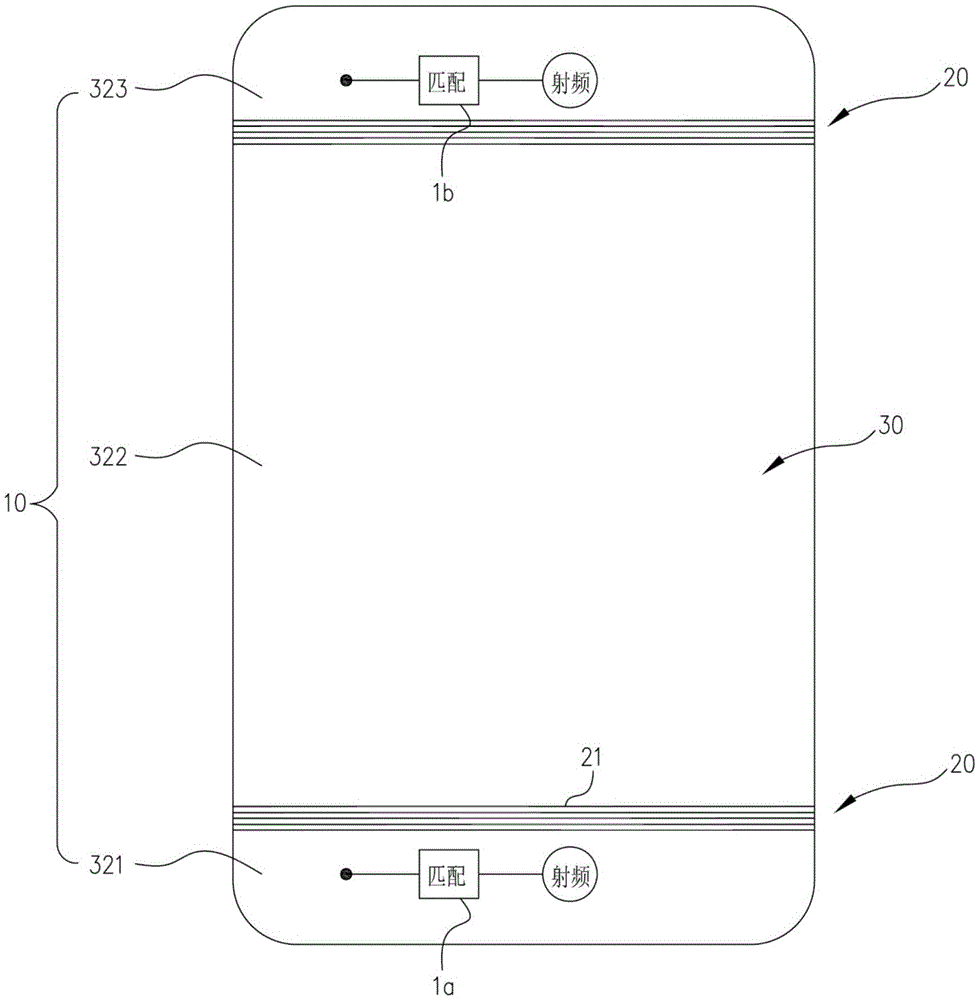

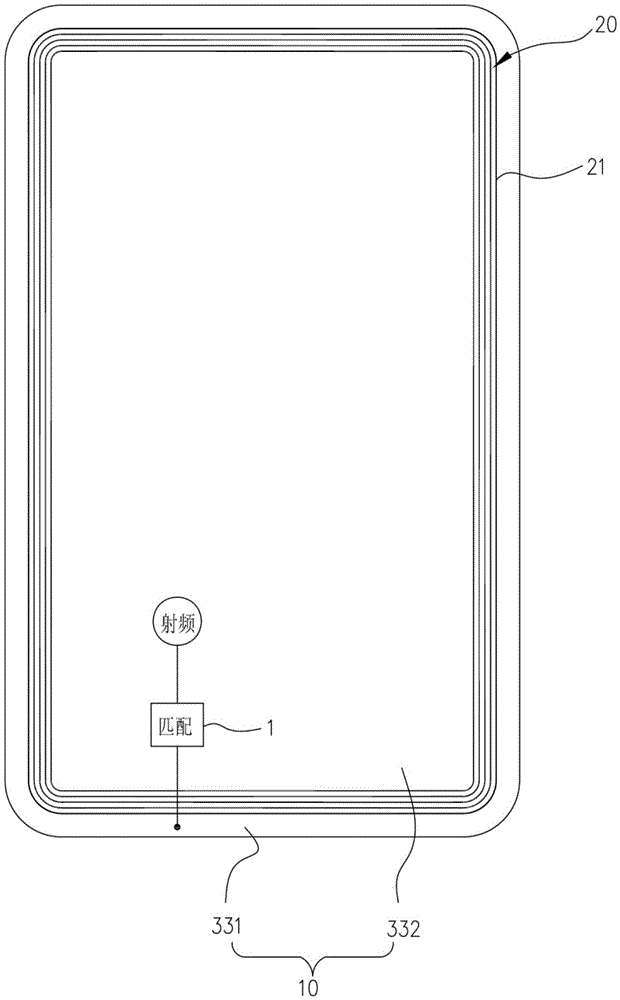

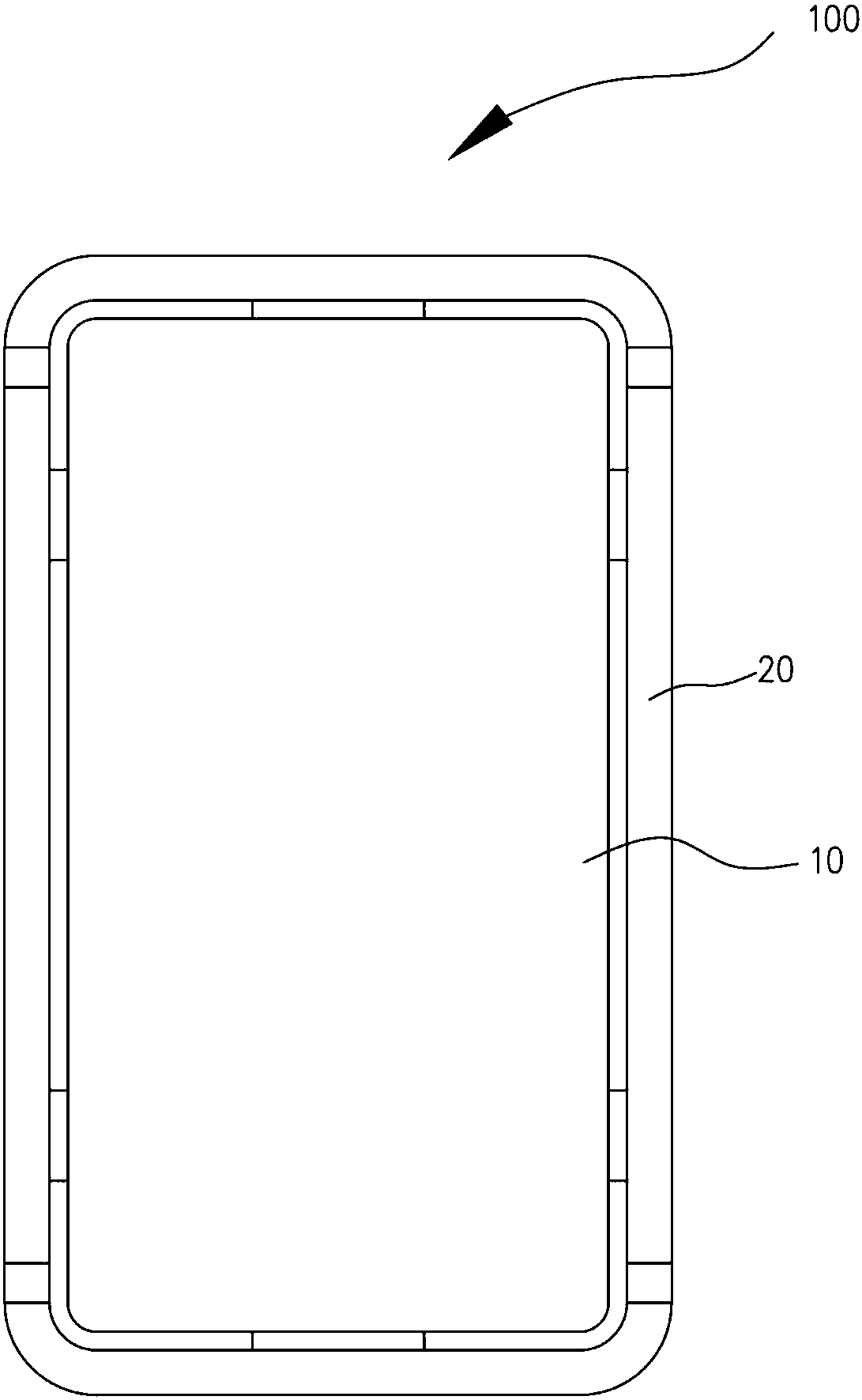

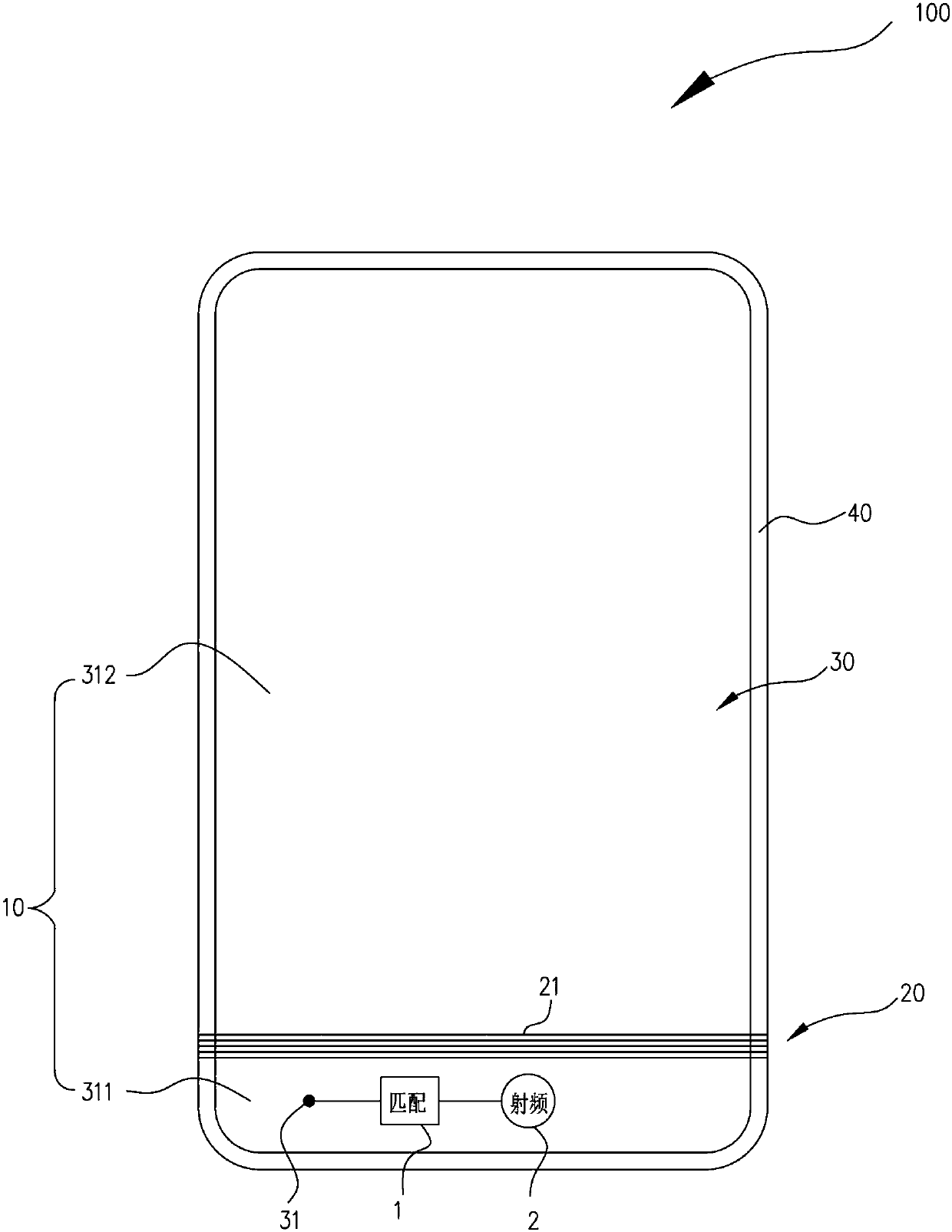

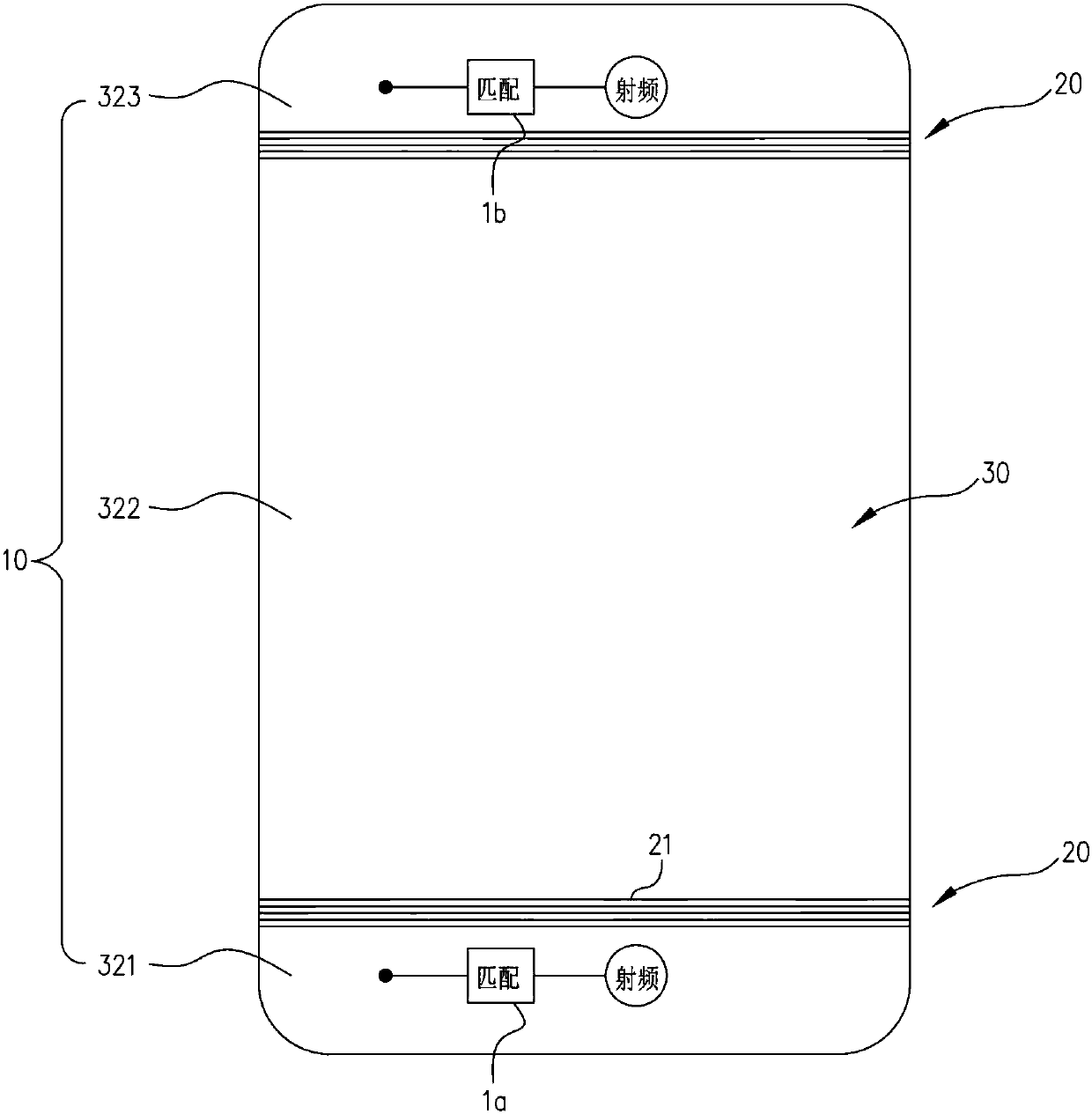

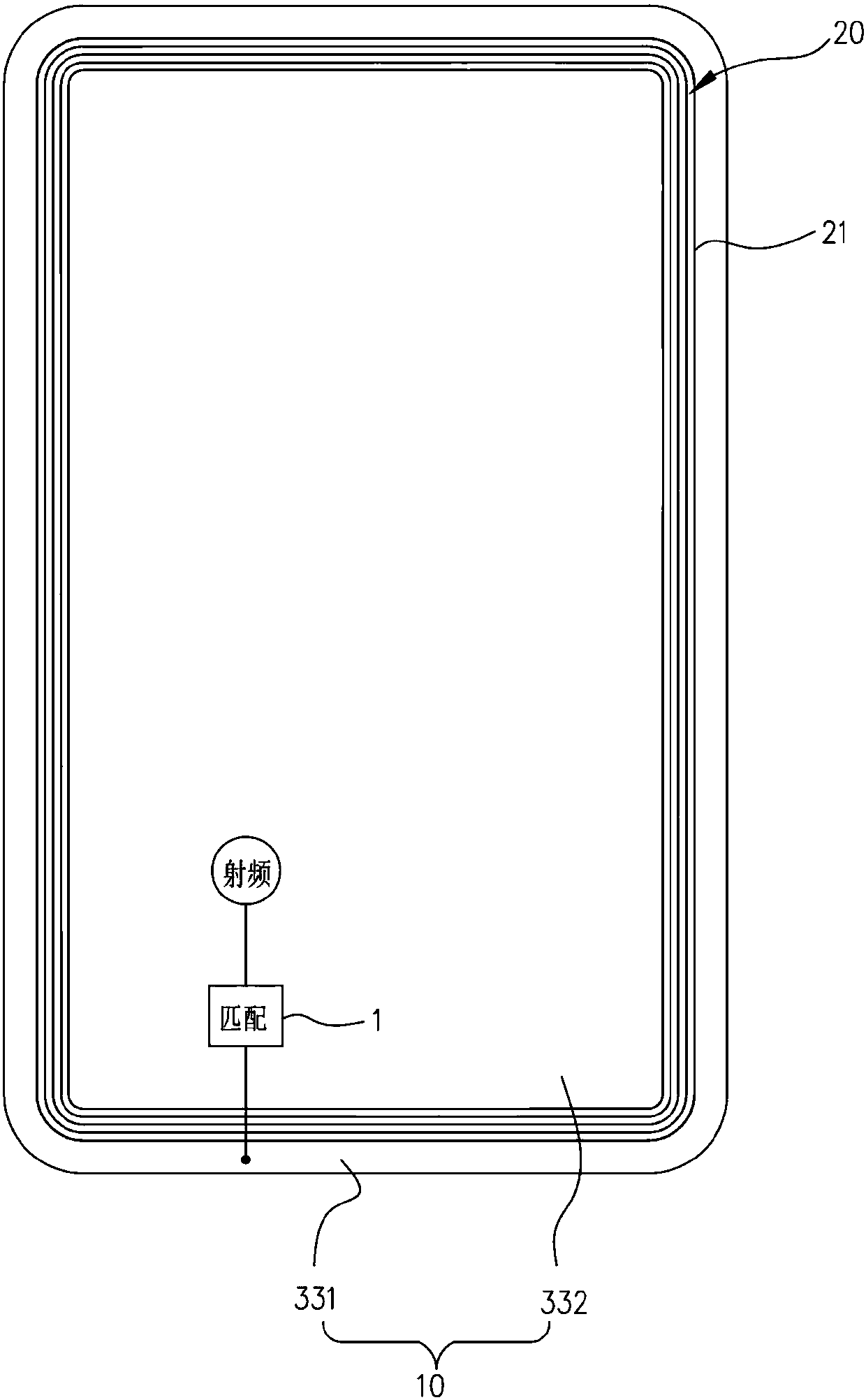

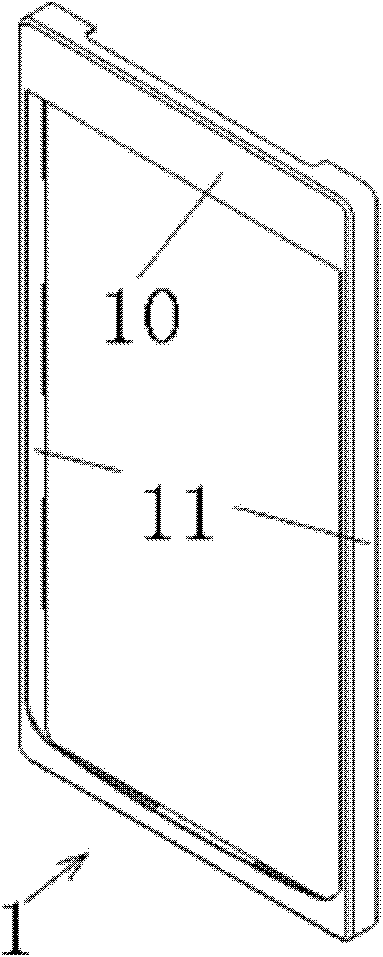

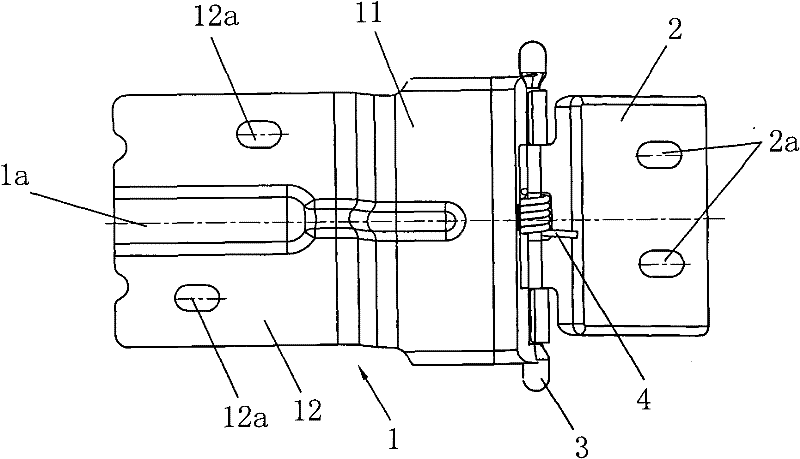

Metal terminal rear cover and terminal

ActiveCN105655706AGuaranteed Appearance RequirementsReduce the proportionSimultaneous aerial operationsDigital data processing detailsEngineeringMetal

The invention discloses a metal terminal rear cover and a terminal. The metal terminal rear cover comprises a bottom plate. At least one micro-seam belt is arranged on the bottom plate. A plurality of micro-seams are formed in each micro-seam belt. The micro-seam belts divide the bottom plate into at least two radiation parts. At least one of the radiation parts is used for being connected with a matched circuit and sending electromagnetic waves. The micro-seams are formed in the micro-seam belts, and therefore the proportion of nonmetal parts on the metal terminal rear cover is decreased; the radiation parts are connected with the matched circuit, and therefore electromagnetic waves are radiated; antenna radio frequency is achieved for the metal terminal rear cover, and therefore the antenna radio frequency efficiency is improved, the antenna radio frequency efficiency is improved when the overall appearance requirement of the terminal is ensured, and the effect of improving user experience is achieved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

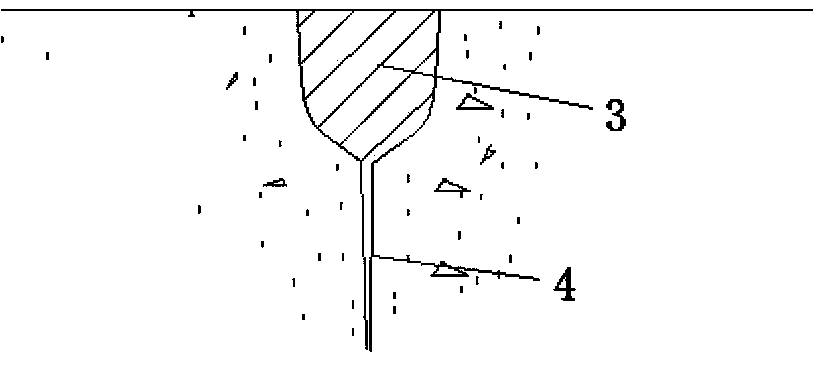

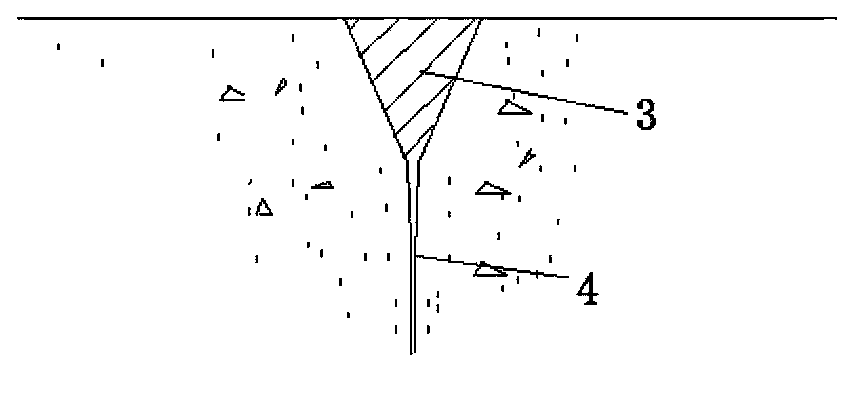

Concrete crack surface cut groove sealing and blocking structure and method

InactiveCN103437432AGuaranteed Appearance RequirementsChange stress conditionsBuilding material handlingSocial benefitsEconomic benefits

The invention discloses a concrete crack surface cut groove sealing and blocking structure and a concrete crack surface cut groove sealing and blocking method. Through adopting the small-width-to-depth-ratio cut groove sealing and blocking technology, concrete cracks can be effectively repaired or reinforced. Firstly, a proper handheld angle grinding machine is adopted, a matched and proper angle grinding machine is selected for grinding sheets, the concrete is cut into a plurality of end-to-end fold lines along the cracks or construction seams, the cutting is completed, pressure water is adopted for clean flushing, accumulated water in the grooves is naturally dried in the air or is dried through blowing, then, cementing materials are filled for seam sealing, and when the cutting seams need to be widened, a double-angle grinding machine can be adopted for grinding sheet parallel cutting. The structure and the method provided by the invention have the advantages that the construction is fast and convenient, economy and applicability are realized, the environment is protected, and good economic benefits and social benefits are realized.

Owner:CHINA GEZHOUBA GRP INT ENG

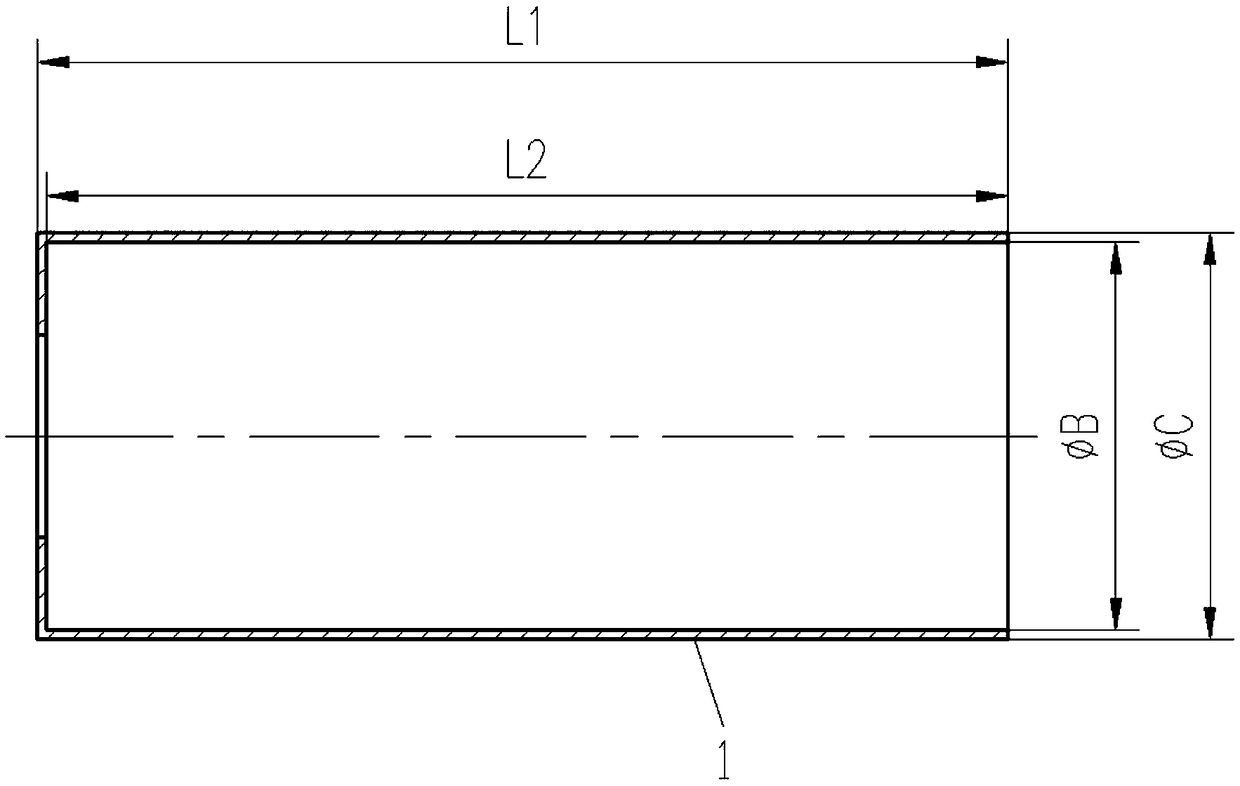

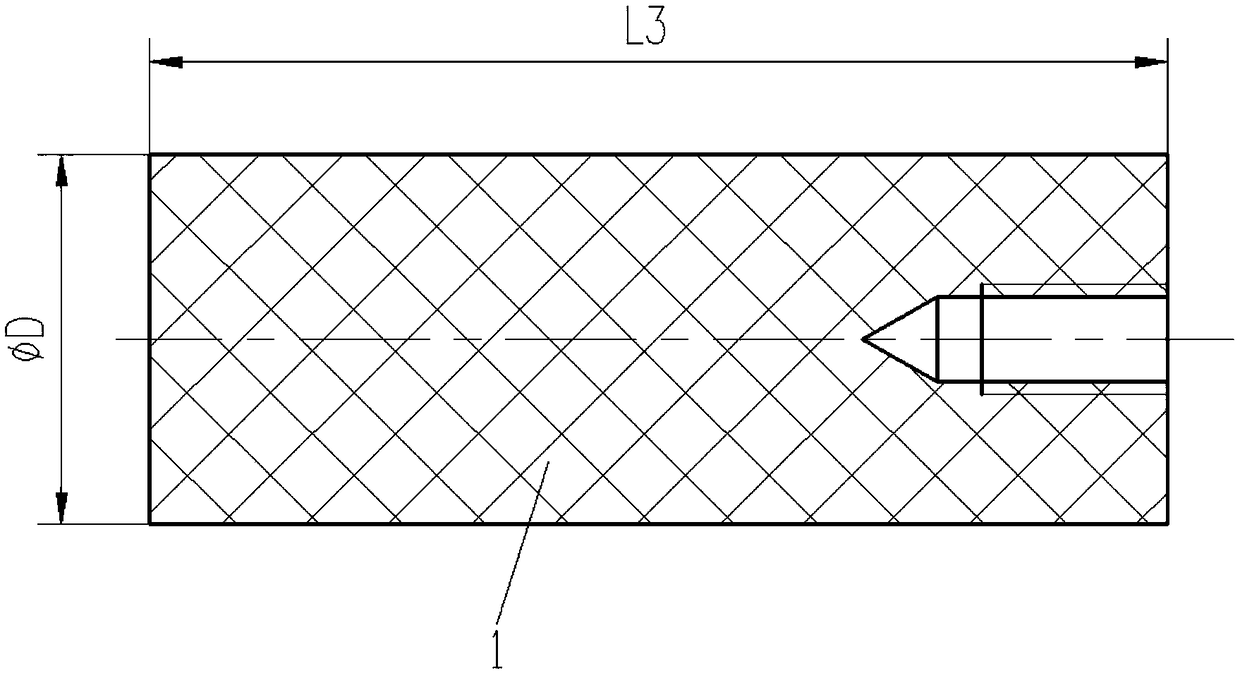

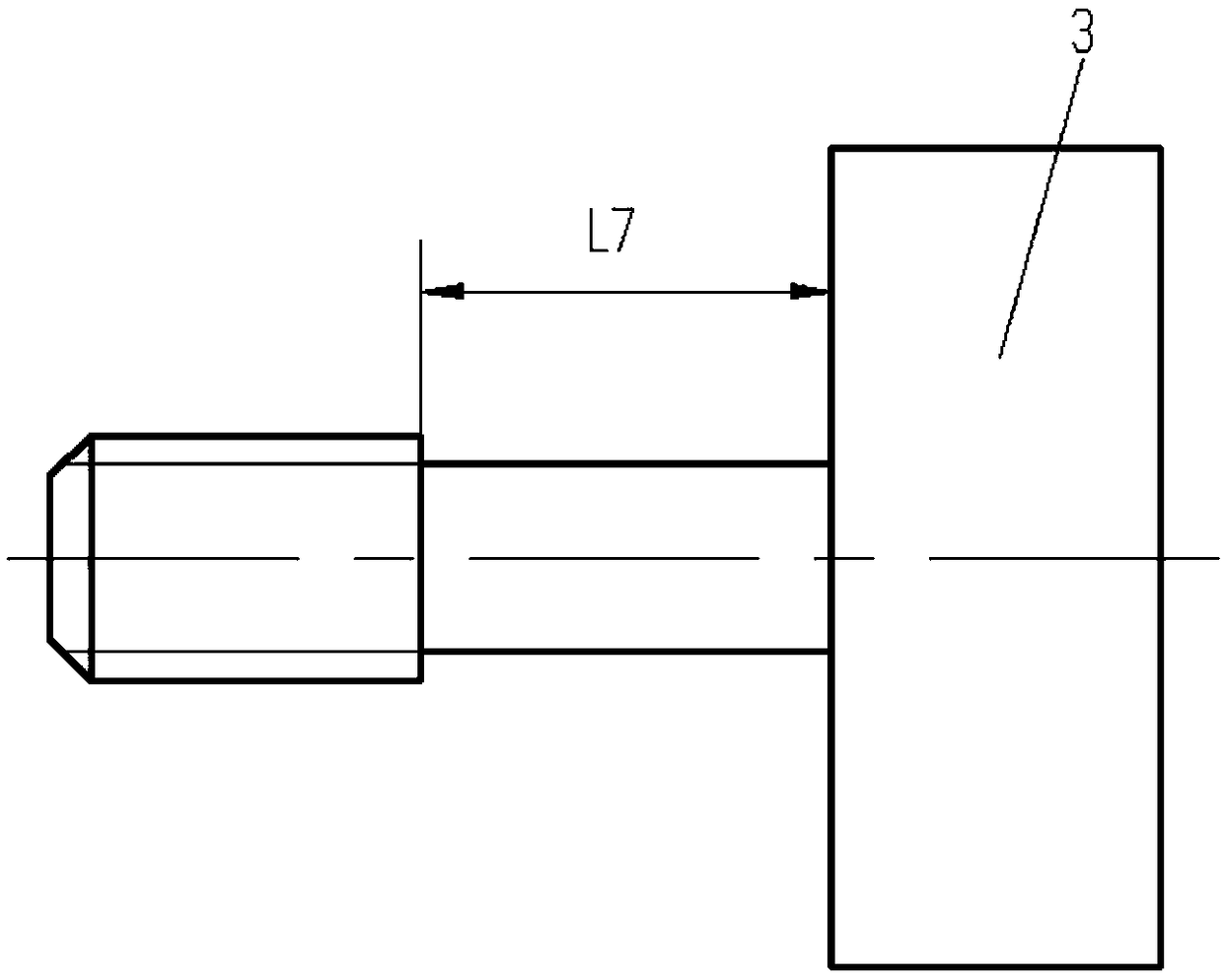

Machining method of high-precision deep and long hole thin-walled sleeve part

The invention provides a machining method of a high-precision deep and long hole thin-walled sleeve part. The machining method comprises the following steps that a rod is clamped and subjected to rough-machining forming, the machining allowance is reserved, and a process chuck is reserved; a roughly-machined workpiece is subjected to thermal treatment aging; and the process chuck of the workpieceis clamped by a lathe, finish machining of the workpiece is completed during primary clamping machining according to a workpiece drawing, and finish machining is divided into the following working steps that a core shaft, a lining and a screw are manufactured; the process chuck is clamped on the lathe, the core shaft is crammed into roughly-machined inner holes of the workpiece, and an outer circle of the part is machined to the required dimension; the screw is screwed into a core shaft threaded hole, and the core shaft is taken out of the workpiece; the lining sleeves the machined outer circle of the workpiece, the outer end face of the workpiece is machined, and the large and small inner holes and the bottom face are bored; tool setting is conducted from the bottom face, the outer end face of the workpiece is machined, and the length dimension L2 of the workpiece is ensured; and the workpiece is cut off, and the total length L1 of the workpiece is ensured. According to the machiningmethod of the high-precision deep and long hole thin-walled sleeve part, the rigidity of the part is improved, machining deformation of the part is reduced, vibration during thin-walled part machiningis reduced, and the machining quality and surface roughness are improved.

Owner:临沂产业研究院有限公司

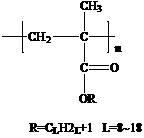

Preparation method for polymethacrylate pour point depressant

The invention provides a preparation method for polymethacrylate pour point depressant, which solves the problem that a traditional preparation method utilizes an organic solvent to serve as dehydrant, one of the shortcomings of the method is that in the esterification process, because of long time, pressure in a reaction kettle is high, the kettle extremely easily explode, second, dehydrant is usually a flammable and explosive product, especially toluene commonly used in the esterification process not only is flammable and explosive, but also has toxicity; and third, due to the fact the dehydrant is slightly soluble in water, certain amount of dehydrant is discharged to the natural world in the sewage discharge and causes environment pollution. The preparation method for the polymethacrylate pour point depressant is characterized in that the dehydrant is removed, esterification is performed through a method of vacuum pressure reduction, namely in the esterification process, water produced in the esterification process is absorbed from the reaction kettle by utilizing negative pressure, and the conversion of a esterification reaction is improved. The preparation method for the polymethacrylate pour point depressant has the advantage of overcoming the defects existing in the traditional method.

Owner:SHENYANG GREAT WALL LUBRICANT OIL

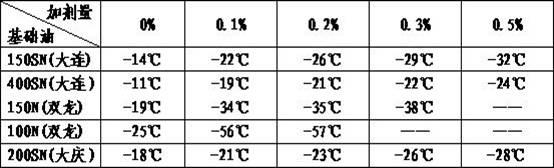

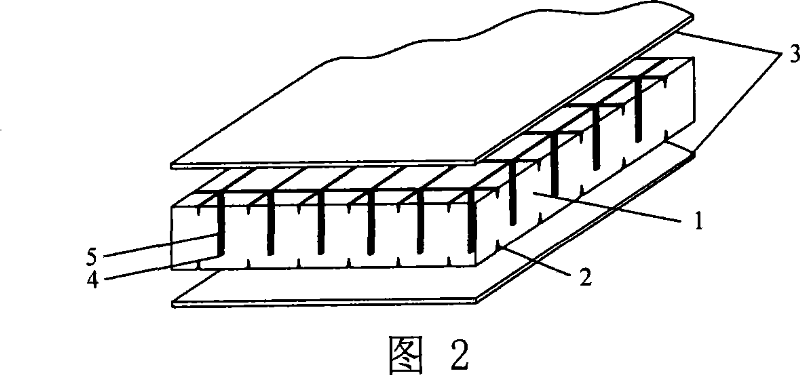

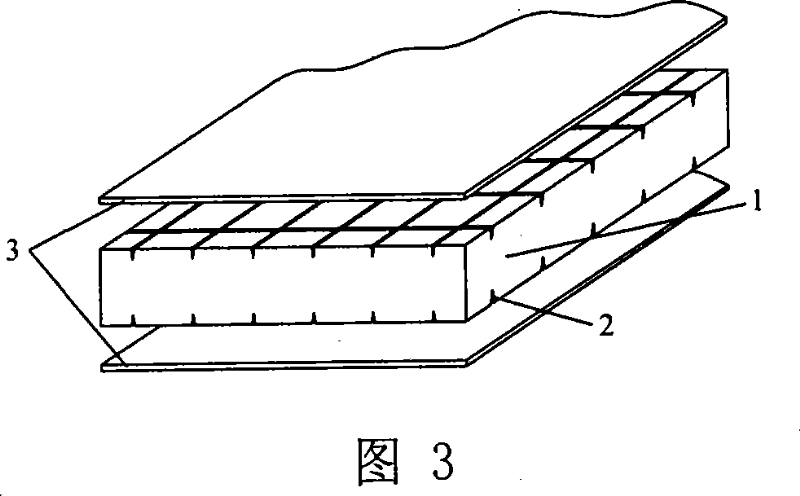

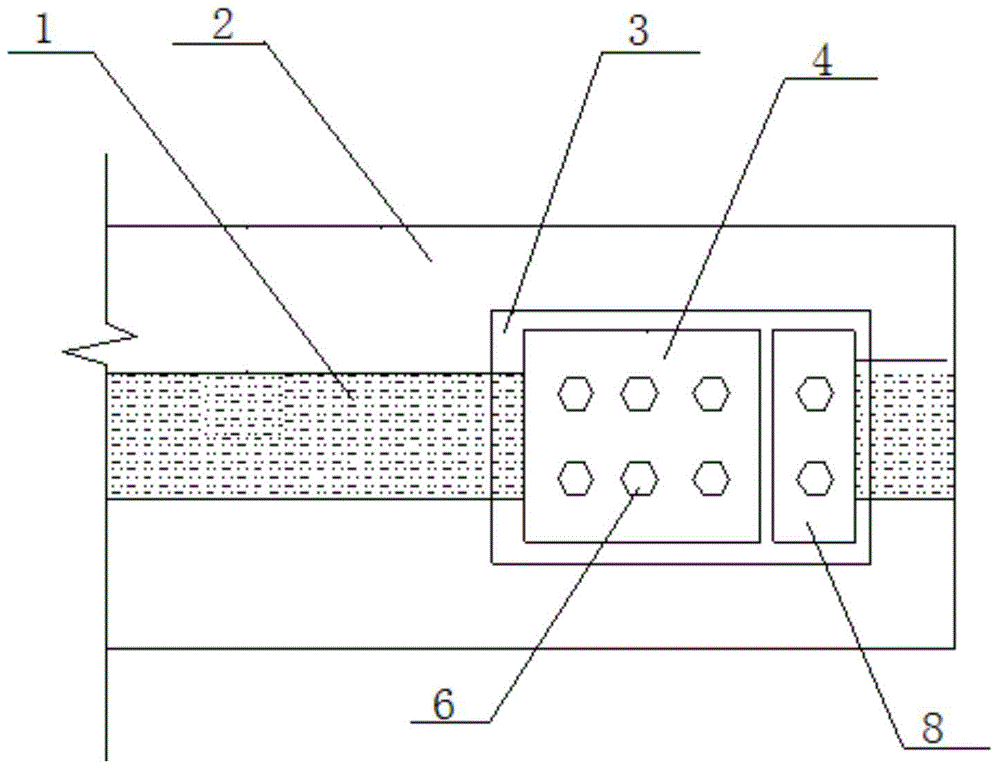

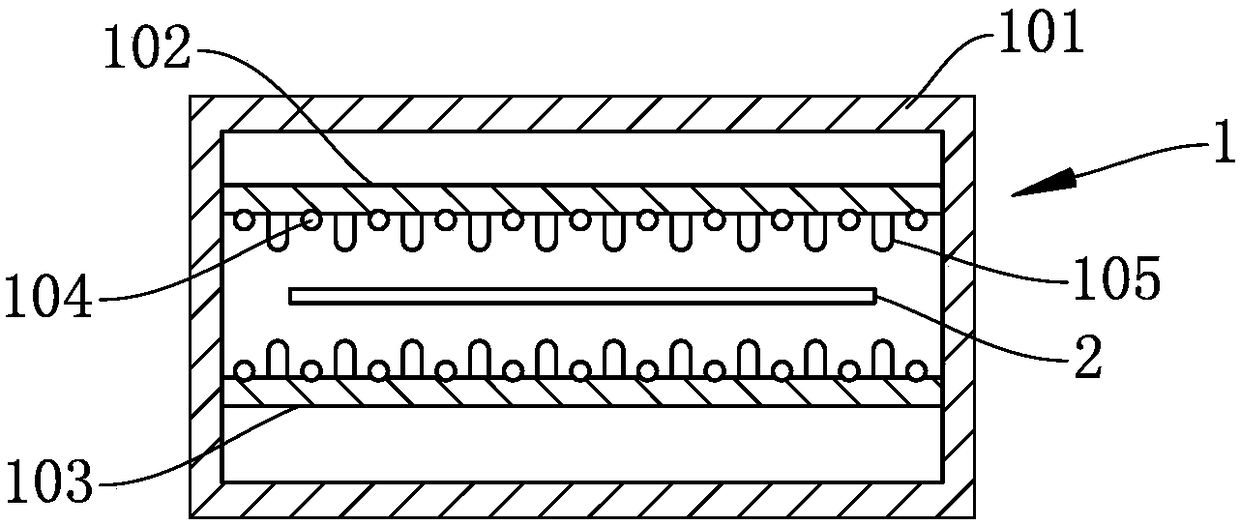

Composite material formwork

InactiveCN101042018AImprove mechanical performanceImprove bonding performanceConstruction materialForming/stuttering elementsFiberMaterials science

The composite material made mold plate comprises the core material, featuring in the slots on the surface of the core material, fiber cloth layer on the top and bottom surface of the core material, setting through holes that stuffed with resin pegs along the thickness direction of the core material at the crossing section of the slots based on requirement. It features in its lightness, high strength, obvious improvement of concrete building speed, not only being able to saving constructing expenses, but also applicable to construction under special conditions.

Owner:NANJING UNIV OF TECH

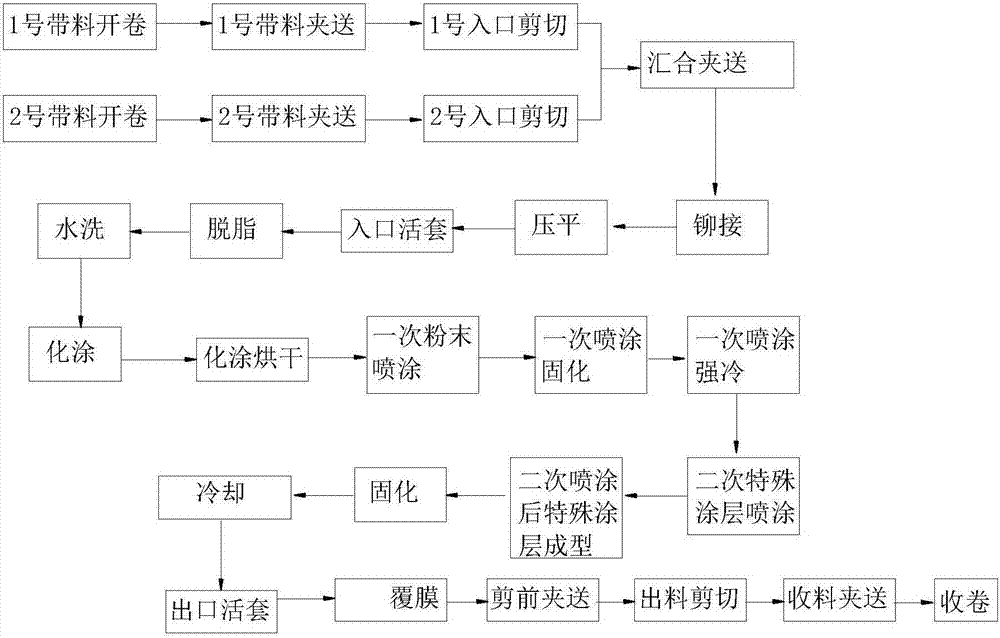

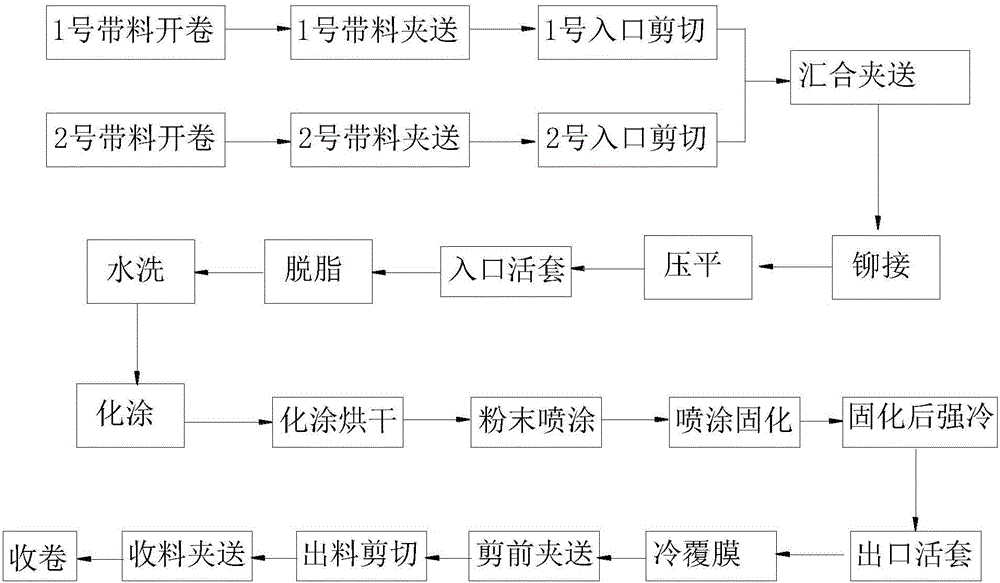

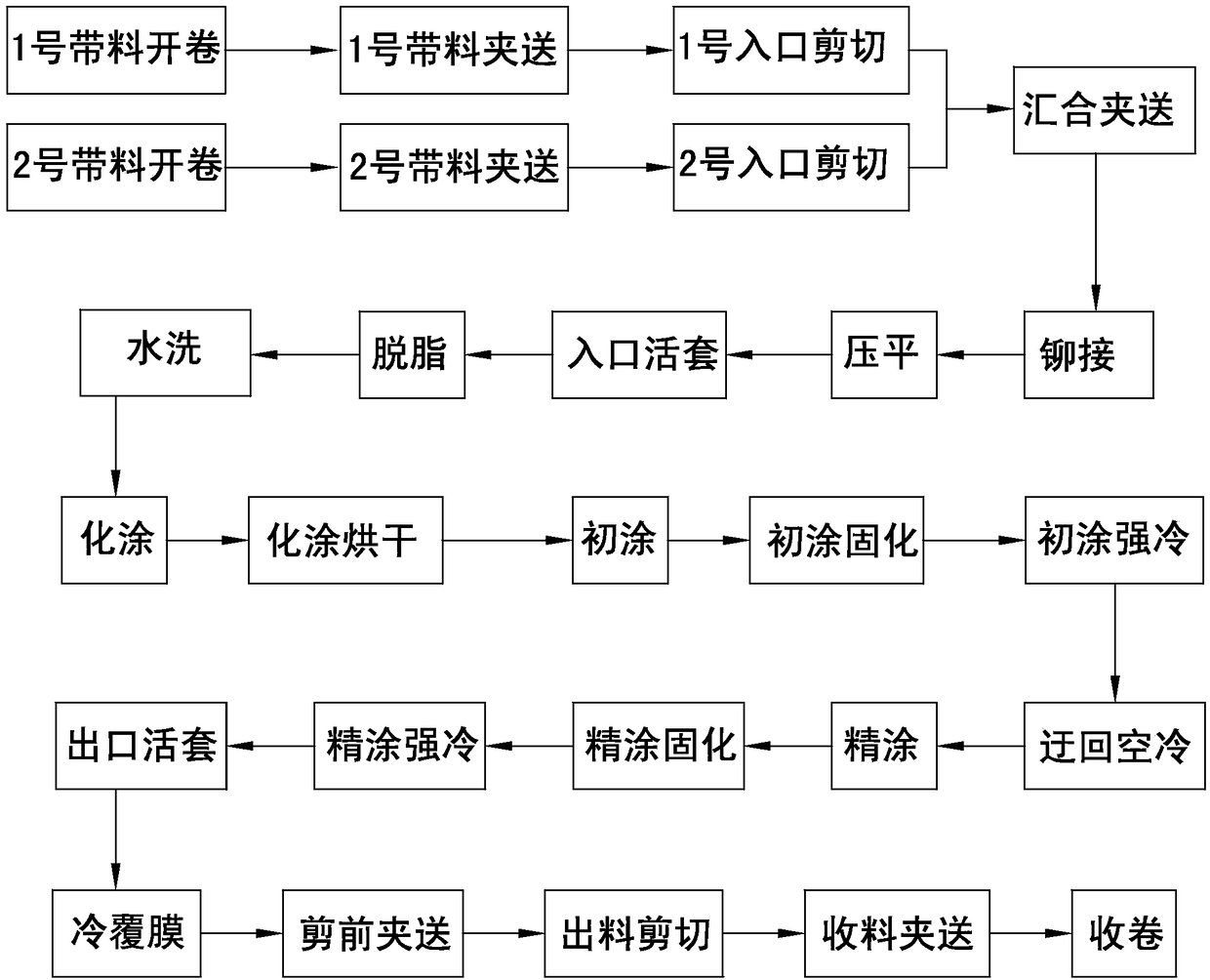

Method and device for producing color coating of steel plate

ActiveCN107053810AOvercoming technical deficienciesQuick transitionLaminationPretreated surfacesSheet steelSpray coating

The invention discloses a method for producing a color coating of a steel plate. The method for producing the color coating of the steel plate comprises the following production steps: (1a) uncoiling a 1# strip material coil: gradually uncoiling the 1# steel strip material coil with an uncoiler, so as to obtain a 1# strip material; (2a) conveying the 1# strip material in a clamped manner: conveying the 1# steel strip downstream by a clamp conveying device; (3a) subjecting the 1# strip material to entry shearing; (4) carrying out converging and clamp-conveying; (5) carrying out riveting; (6) carrying out flattening; (7) carrying out entry looping; (8) carrying out degreasing; (9) carrying out water washing; (10) carrying out chemical coating; (11) carrying out chemical coating baking; (12) carrying out primary powder spray-coating: coating the surface of the steel strip with a powder coating in a spraying manner; (13) carrying out primary spray-coating curing; (14) carrying out primary spray-coating forced cooling; (15) carrying out secondary special coating spray-coating: carrying out special coating spray-coating on the forced-cooled and primary-spray-coated material; (16) carrying out secondary special coating forming: carrying out special coating curing forming in a coating forming device; (17) carrying out exit looping; (18) carrying out cold film coating; (19) carrying out before-shearing clamp-conveying; (20) carrying out discharging shearing; (21) carrying out receiving clamp-conveying; and (22) carrying out coiling.

Owner:赛高粉末技术(滨州)有限公司

Capacitive touch screen laminating process

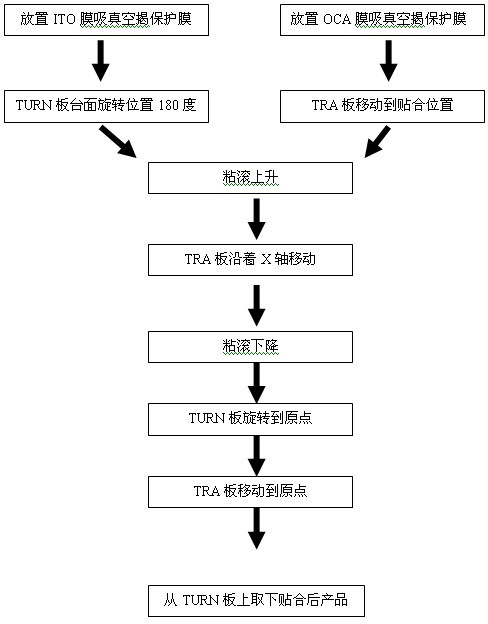

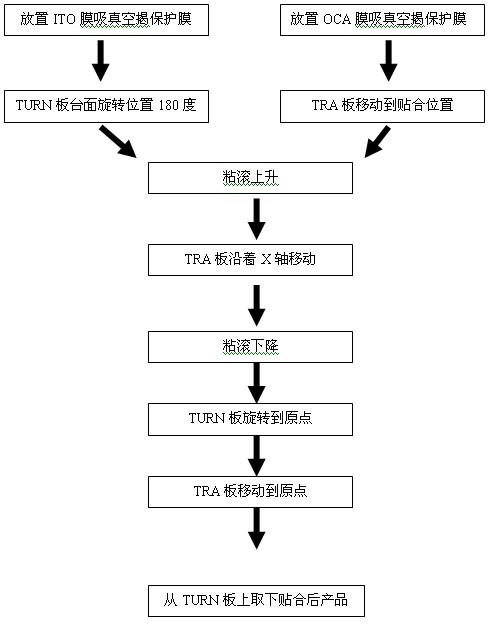

InactiveCN102303449ASolve misalignmentSolve the bubblesLaminationLamination apparatusForeign matterVacuum extraction

The invention relates to a capacitive touch screen laminating process. The process comprises the following steps: 1. selecting a lamination program according to the product model; 2. setting lamination parameters and vacuumizing the table board, wherein the pressure is -40 to -85 Kpa, the rolling shaft pressure is 400-600 g, and the shift-out speed is 30-50 cm / min; 3. clicking an original point and resetting a turning plate and a transfer plate; 4. clicking a locating needle button so that the locating needle pops up; 5. placing an optical clear adhesive (OCA) punched with locating holes on the transfer plate so as to carry out vacuum extraction; 6. placing a sheet needing to be laminated on the turning plate so as to carry out vacuum extraction; 7. removing the sheet needing to be laminated and a protective film on the OCA; 8. starting a start button so that equipment works; and 9. after the lamination, taking down the laminated sheet from the turning plate. Through the process, the problems of inaccurate alignment and bubble generation in the lamination process of the touch screen are solved, the lamination alignment precision is improved, the generation of foreign matters and bubbles is reduced, and the requirements on the product appearance are met. The lamination process is simple and fast and suitable for mass production.

Owner:TIANJIN ZHONGHUAN HI TECH

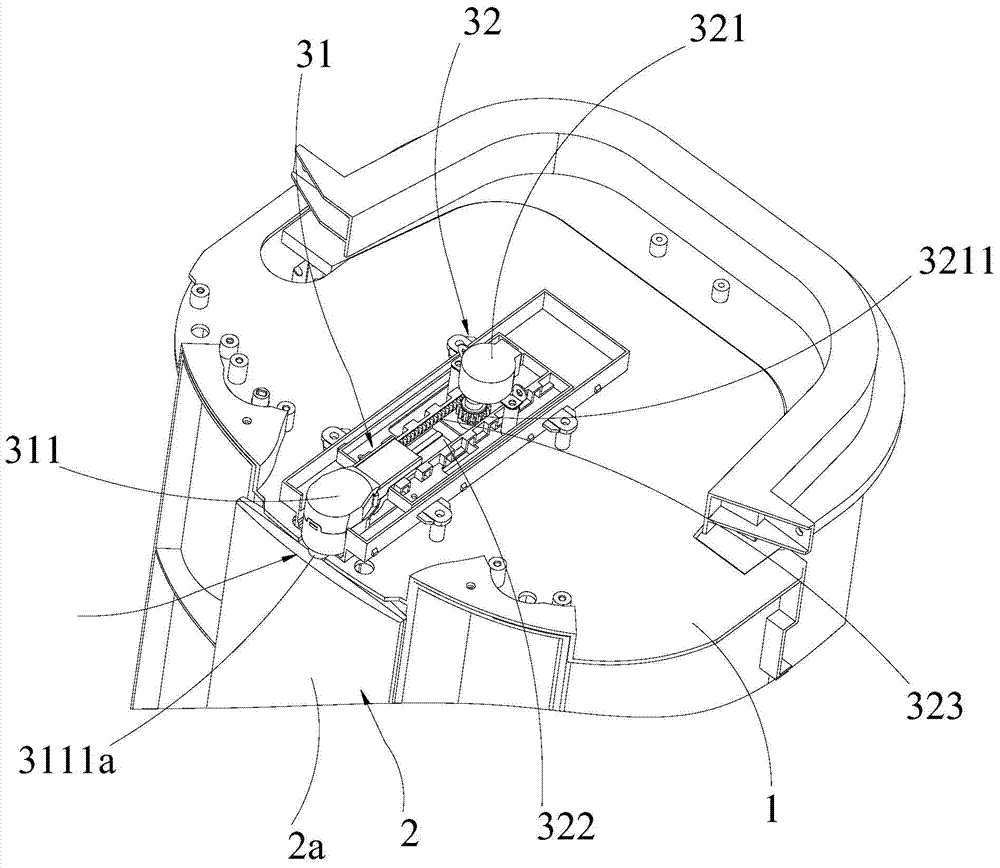

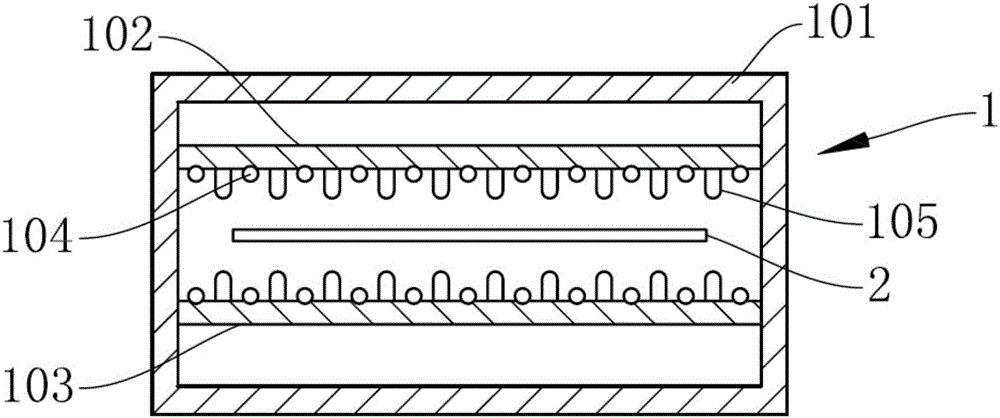

Indoor unit of air conditioner

ActiveCN103940066AGuaranteed Appearance RequirementsPlay the role of dustAir-flow control membersEngineeringElectrical and Electronics engineering

The invention relates to an air conditioner, in particular to an indoor unit of the air conditioner. The indoor unit comprises an indoor unit shell with an air outlet, wherein the indoor unit shell is provided with a door used for opening and closing the air outlet. The indoor unit comprises a drive device, wherein the drive device can drive the air outlet to be in a closed state and can drive the door to be located in the indoor unit shell and make the area of the projection, in the direction vertical to the air outlet, of the door smaller than the area of the air outlet. According to the indoor unit, the door can be used for closing the air outlet to perform a dustproof function, meanwhile, when the indoor unit works, the door can be used for opening the air outlet and be contained in the indoor unit shell, and the requirement for the appearance of the indoor unit during operating can be effectively met; besides, due to the fact that the area of the projection, in the direction vertical to the air outlet, of the door is smaller than the area of the air outlet, after the air outlet is opened, and the door is of an integrated structure in design, and when the air outlet is closed through the door, no joint lines exist on the surface of the door and the requirement for the appearance of the indoor unit is met.

Owner:MIDEA GRP CO LTD

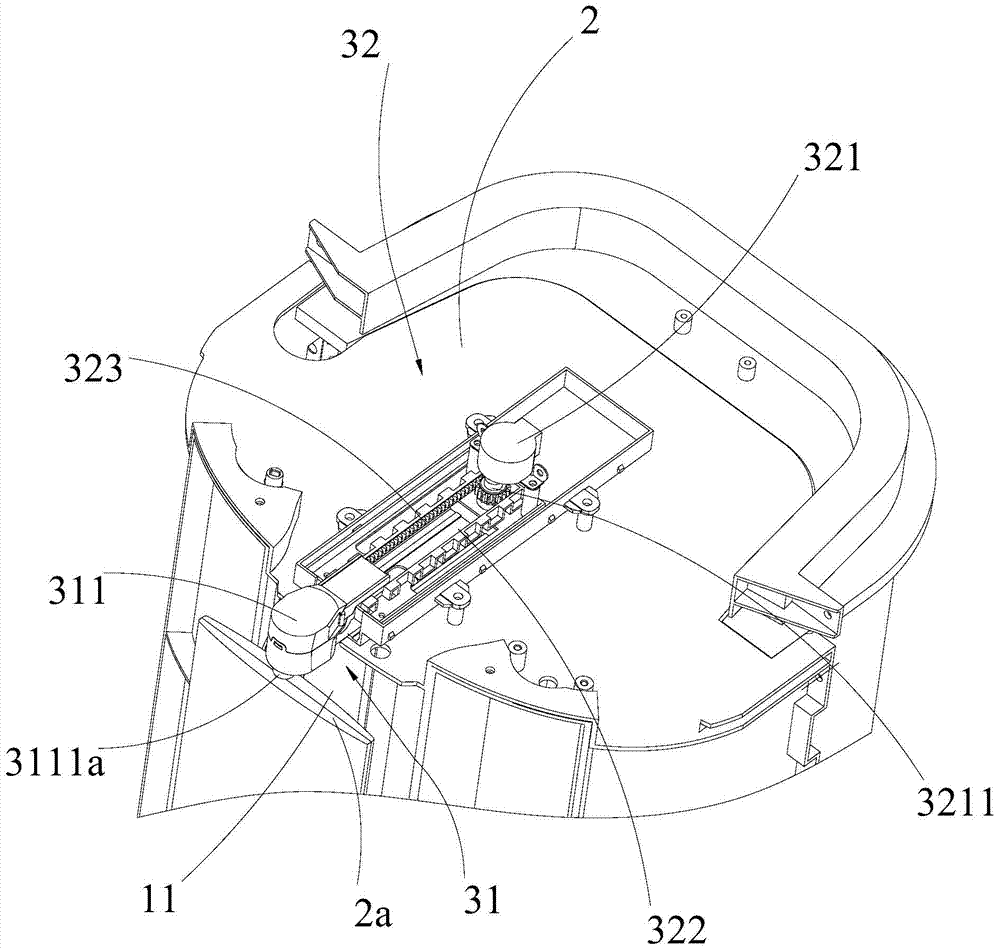

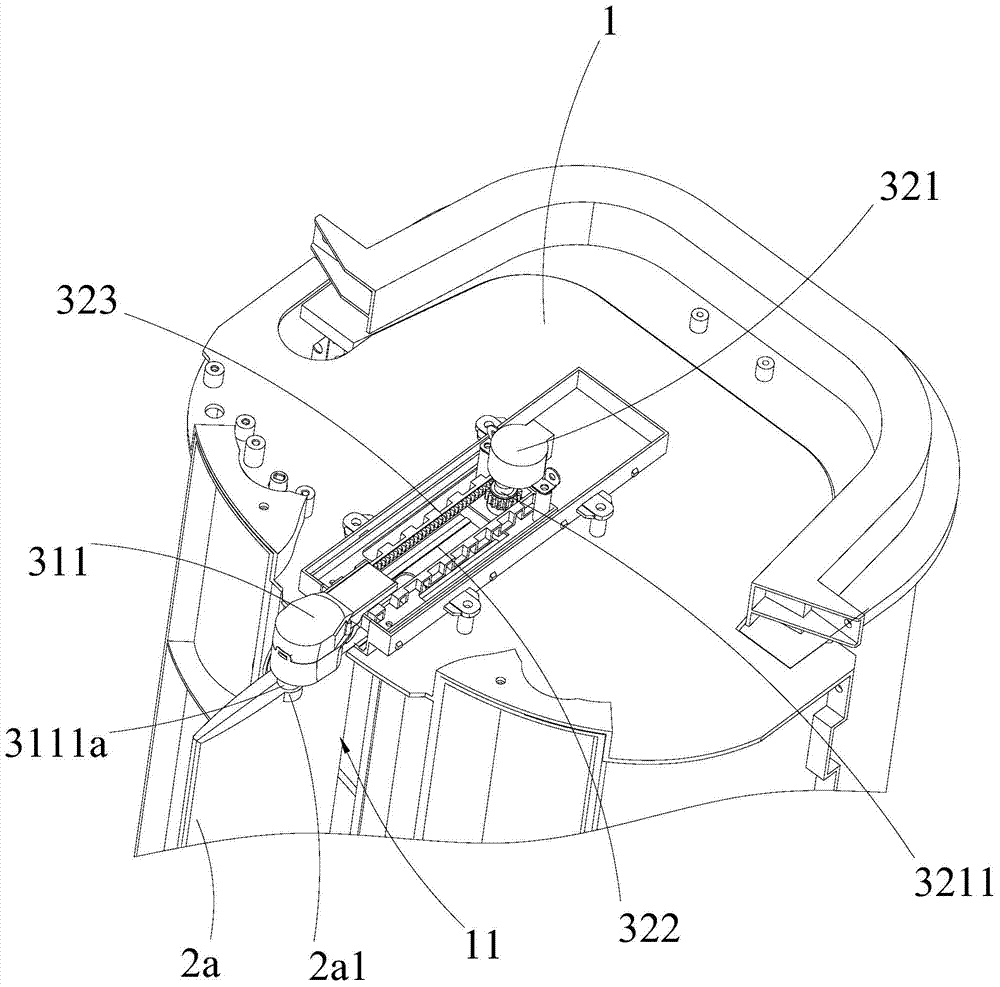

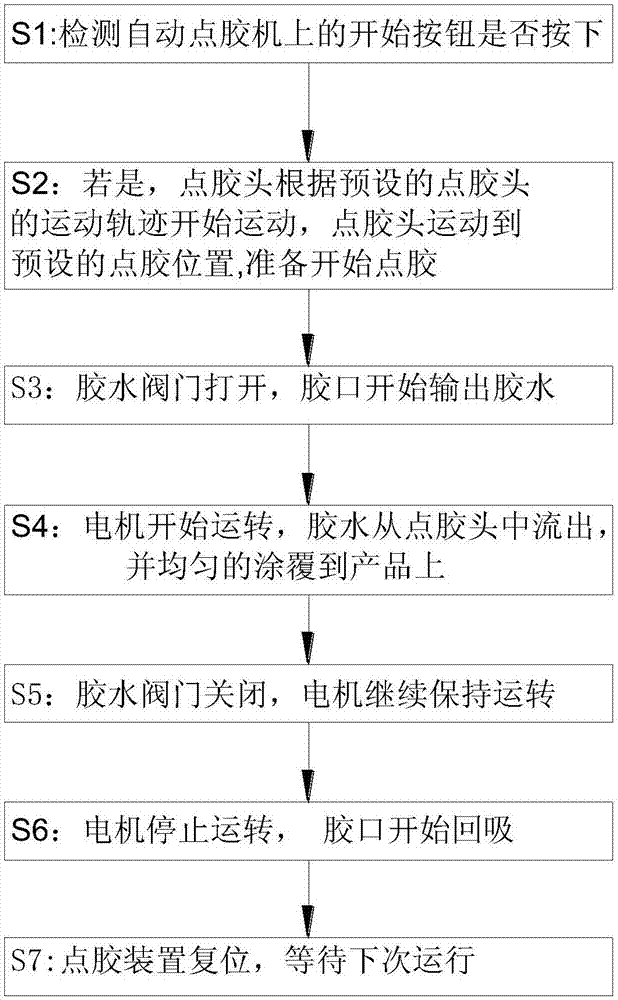

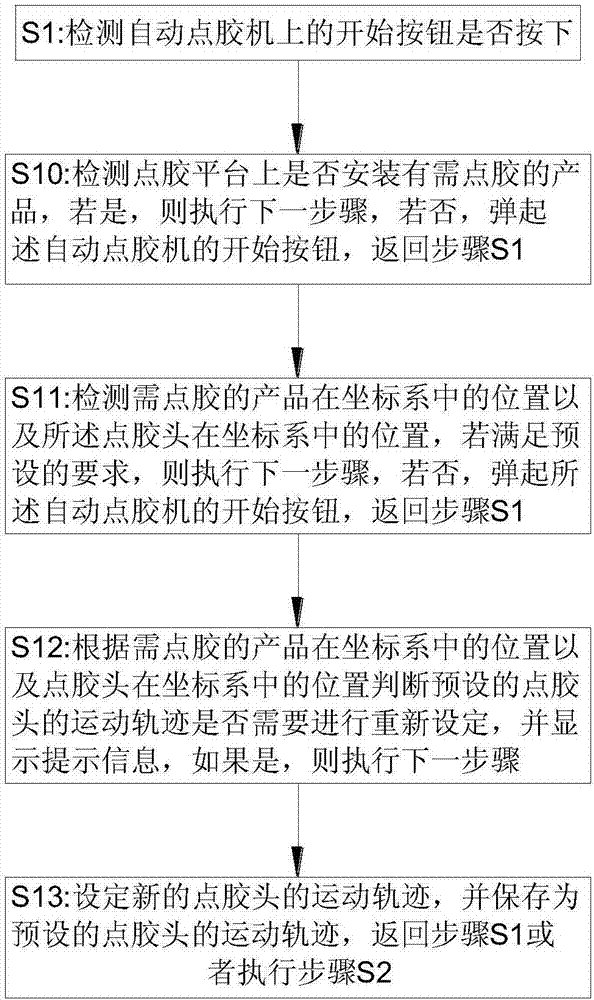

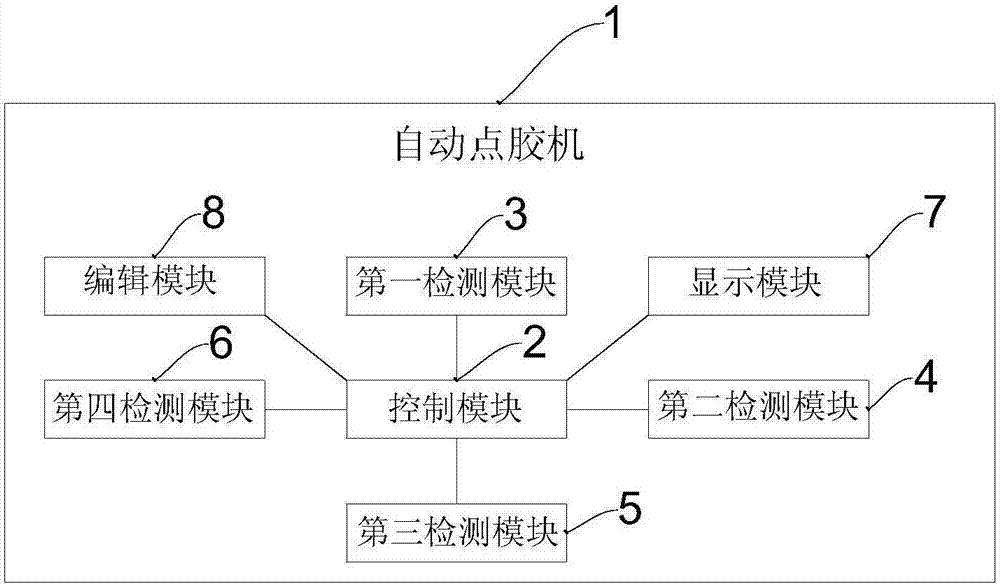

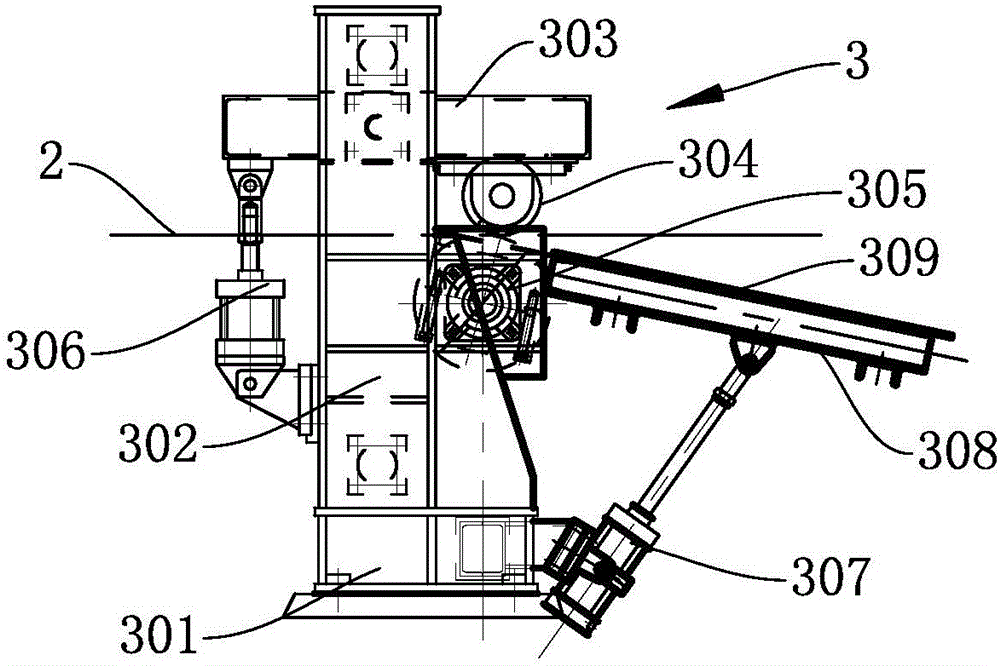

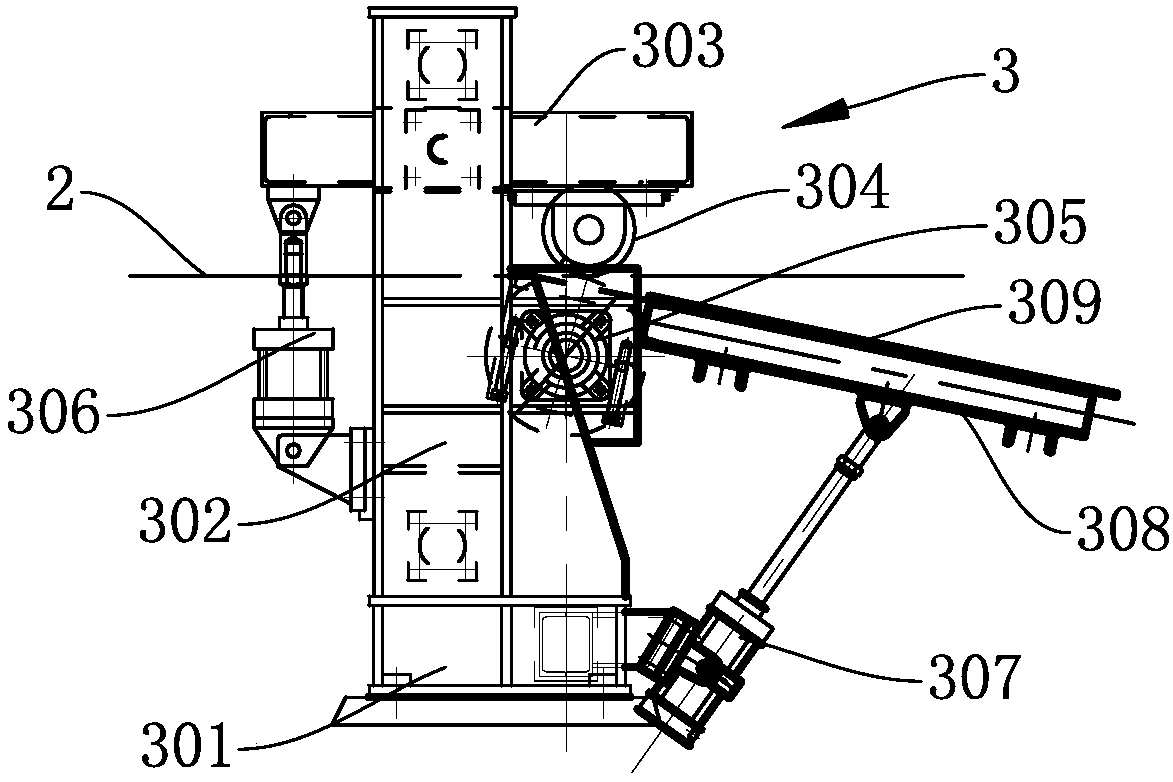

Automatic black glue dispensing technique and automatic glue dispensing device

InactiveCN107008616ASimple processQuality assuranceLiquid surface applicatorsCoatingsFluid controlEngineering

The invention belongs to the technical field of fluid control, and particularly relates to an automatic black glue dispensing technique and an automatic glue dispensing device. The automatic black glue dispensing technique is applied to the automatic glue dispensing machine which comprises a glue dispensing platform, a glue dispensing head, a glue valve, a glue port and a motor. The automatic black glue dispensing technique comprises the following steps that S1, whether a starting button on the automatic glue dispensing machine is pressed or not is detected; S2, if yes, the glue dispensing head starts to move according to a preset motion curve and moves to a preset glue dispensing positions; S3, the glue valve is opened, and glue starts to be output of the glue port; S4, the motor starts to operate, and a product is evenly coated with glue; S5, the glue valve is closed, and the motor continues to keep operating; S6, the motor stops operating, and the glue port starts to suck the glue backwards; and S7, the glue dispensing device is reset. According to the automatic black glue dispensing technique provided by the invention, black glue dispensing can be completed efficiently with high quality, the production efficiency can be improved substantially, production cost is reduced, and the practicability is high.

Owner:APAT OPTOELECTRONICS COMPONENTS

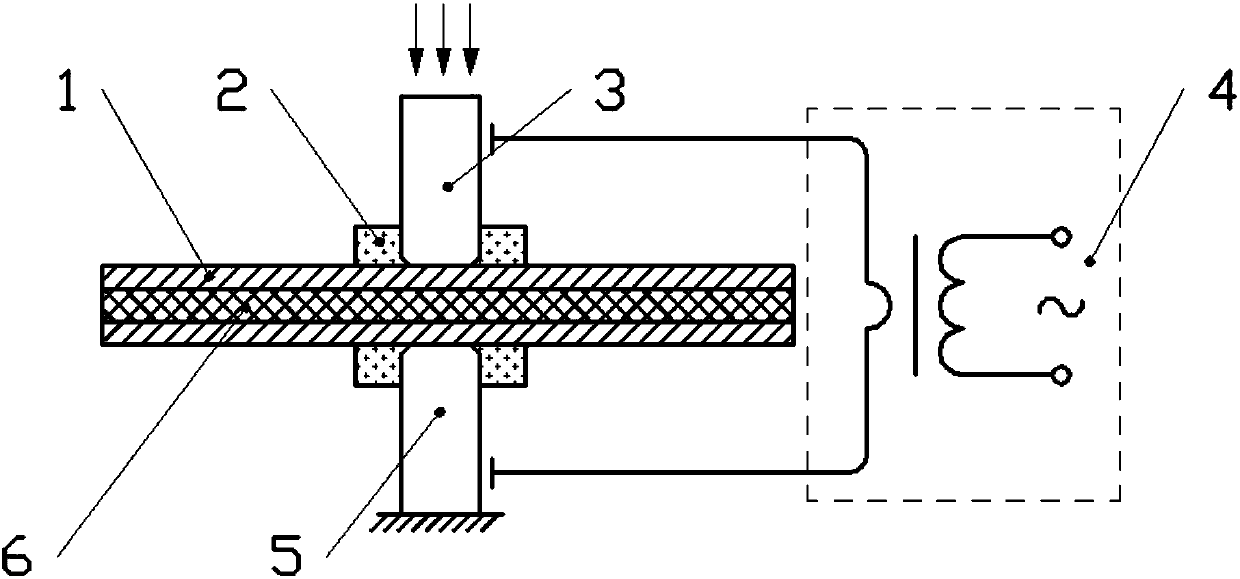

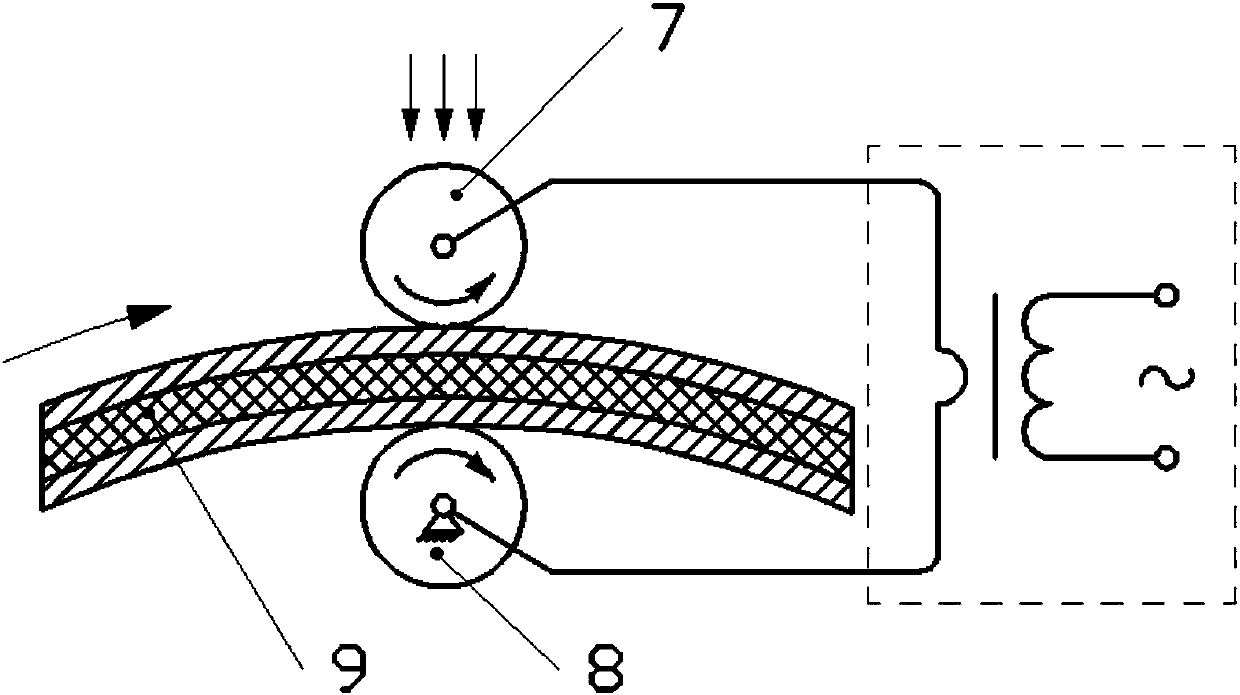

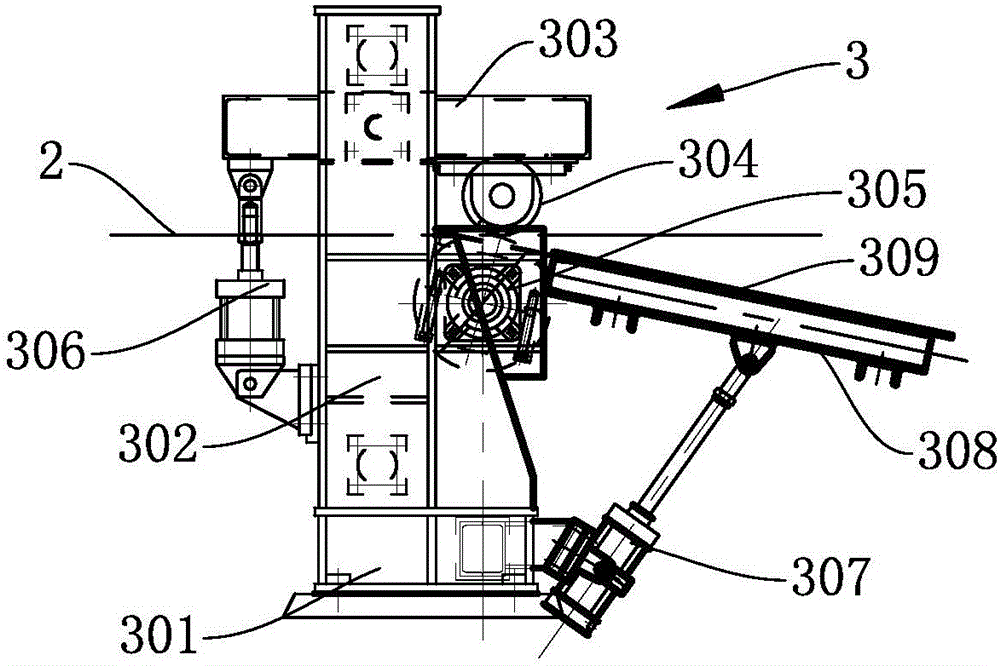

Damage repair process and device for carbon-fiber-enhanced thermoplastic super-hybrid composite laminates

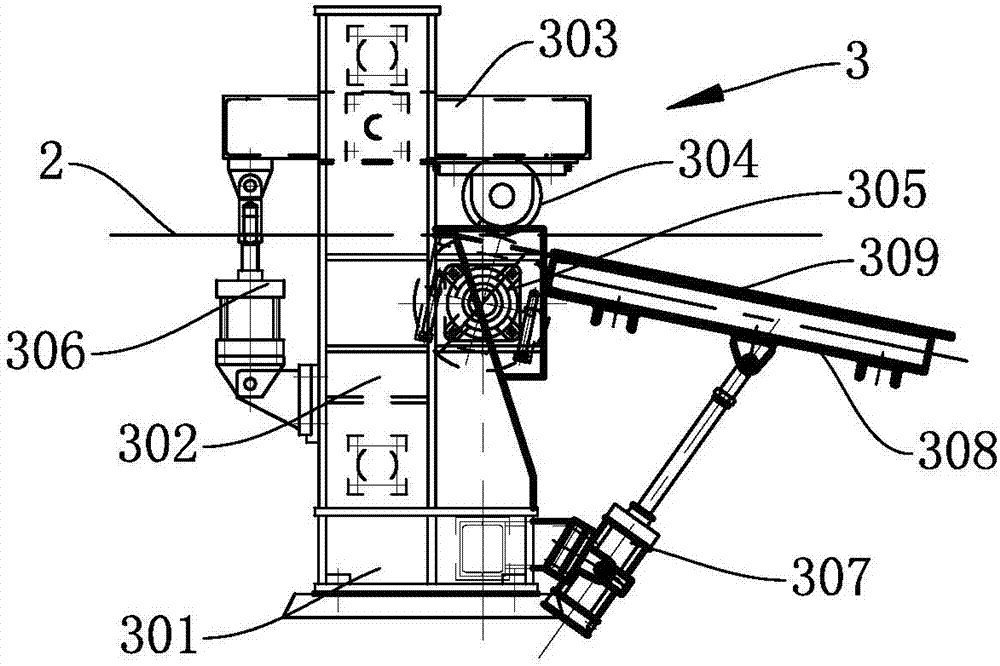

The invention relates to a damage repair device for carbon-fiber-enhanced thermoplastic super-hybrid composite laminates. The damage repair device comprises an electrode, a pressure giving assembly and a power supply assembly. The electrode comprises a vertical type point pressure upper electrode body, a vertical type point pressure lower electrode body, a horizontal rolling pressure upper electrode body and a horizontal rolling pressure lower electrode body. The portions, in contact with a component, of the vertical type point pressure upper electrode body and the vertical type point pressurelower electrode body are sleeved with ceramic pressure rings. The lower electrode bodies are fixed, and the pressure giving assembly drives the upper electrode bodies to move downwardly to give the constant pressure to the component. The horizontal rolling pressure upper electrode body and the horizontal rolling pressure lower electrode body rotate at the same angular speed in opposite directions. Rolling friction with the component is generated when the horizontal rolling pressure upper electrode body rolls along the upper surface of the component and the horizontal rolling pressure lower electrode body rolls along the lower surface of the component. The power supply assembly can adjust the current under the synergistic effect of a built-in power source and a transformer, and the currentparameter changes according to the super-hybrid composite laminates with different sizes and made of different materials. The damage repair device and method have beneficial effects that the energy consumption is low, the method is simple and easy to implement, the repair cycle is short, and the repair cost of composites is reduced greatly.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

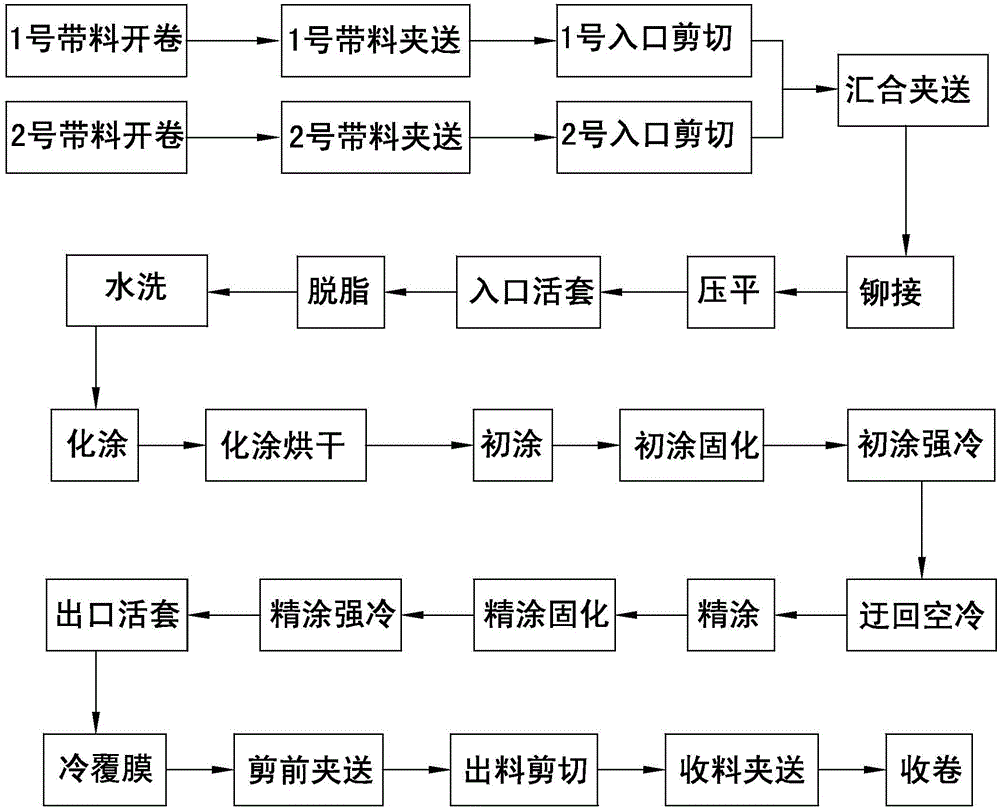

Color coating production method and production device for steel plates

ActiveCN105881032AOvercoming technical deficienciesQuick transitionLiquid surface applicatorsOther manufacturing equipments/toolsSheet steelMethods of production

The invention discloses a color coating production method for steel plates. The method comprises the steps of (1a), No.1 belt material unwinding; (2a), No.1 belt material clamping feeding; (3a), No.1 belt material inlet shearing; (4) integral clamping feeding; (5) riveting; (6) flattening; (7) inlet looping; (8) degreasing; (9) water washing; (10) chemical coating; (11) chemical coating drying; (12) primary coating; (13) primary coating curing; (14) primary coating forced cooling; (15) roundabout air cooling; (16) finish coating; (17) finish coating curing; (18) finished coating forced cooling; (19) outlet looping; (20) cold film coating; (21) clamping feeding before shearing; (22) discharge shearing; (23) collection clamping feeding; and (24) winding. The invention further provides a production device for implementing the method. Through utilizing the method and the device, the coating technology of replacing paint through powder can be achieved, the environment is improved, the production efficiency of colored steel is improved, and the method and the device can be widely applied to color coating of steel plates and have good industrial production prospect and application potential.

Owner:赛高粉末技术(滨州)有限公司

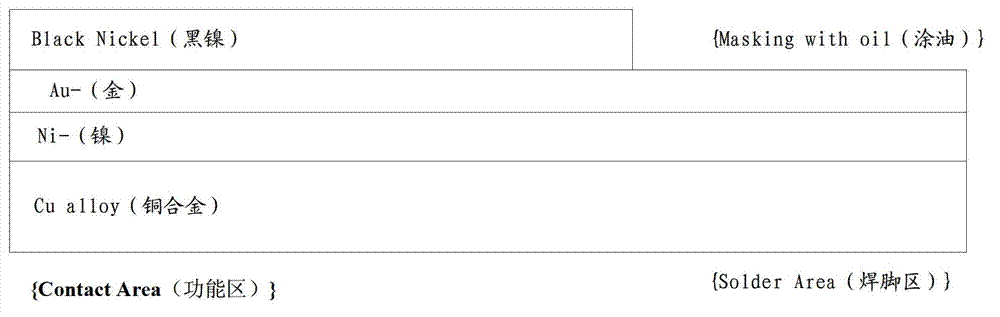

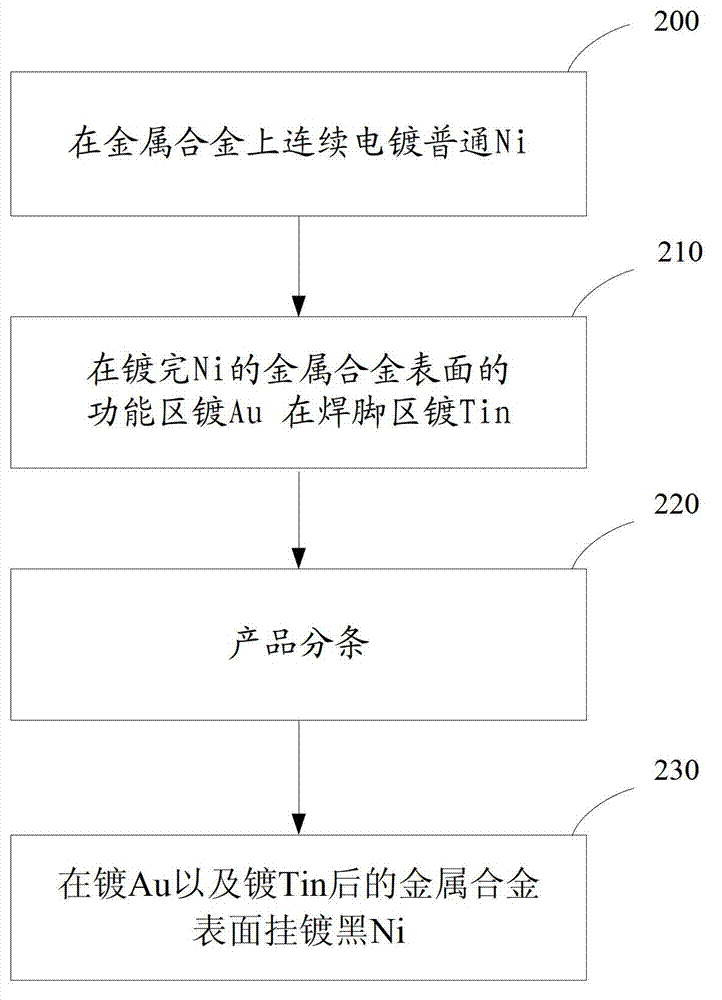

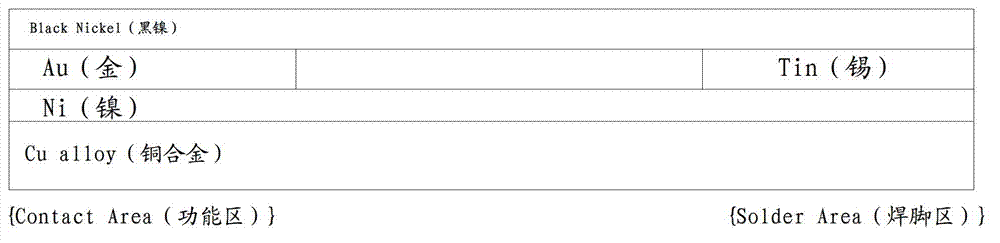

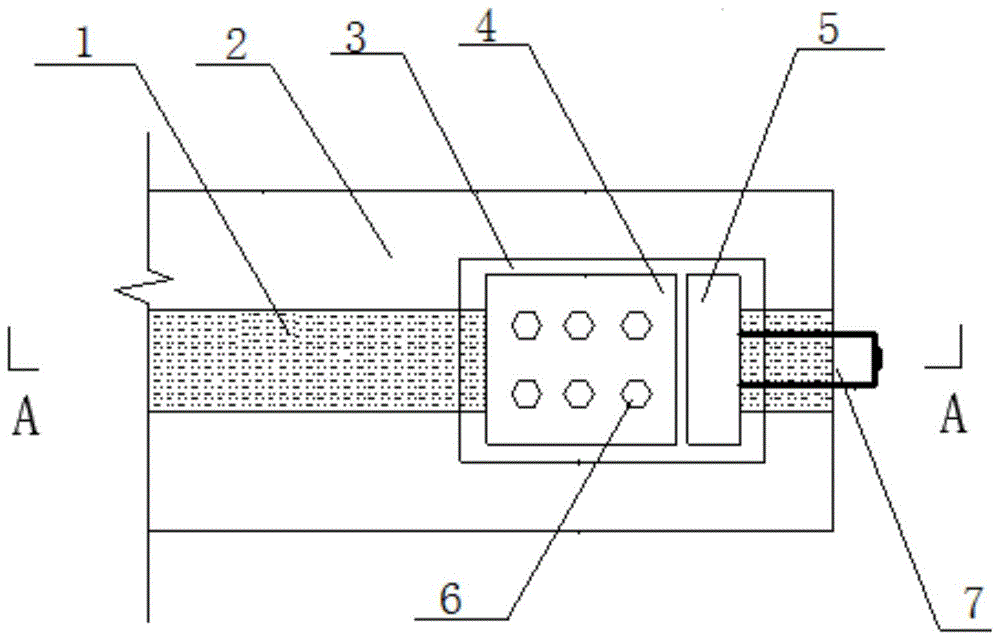

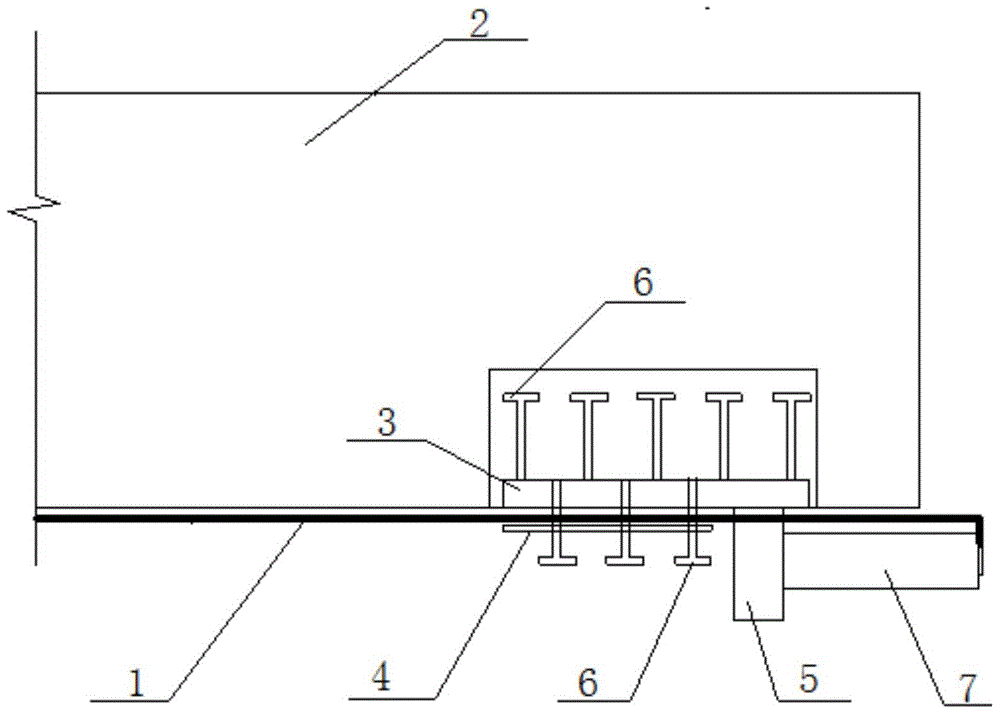

Production method and products of metal exposed terminals

ActiveCN102851714AImprove soldering effectLow priceElectrically conductive connectionsNickelMetal alloy

The invention discloses a production method and products of metal exposed terminals. The production method includes: making the metal exposed terminals by new manufacturing process, namely plating a functional area of metal alloy with Au, plating a weld leg area with metal for enhancing solderability. In other words, the metal for enhancing solderability replaces part of plated Au, and a layer of black Ni is plated on the surface of the metal alloy plated with the Au and the metal for enhancing solderability by rack plating. Therefore the function and appearance requirements of the metal exposed terminals are met, production efficiency of the metal exposed terminals is improved, the cost is lowered, and benefit is created. According to related production and applications, the treatment cost of the metal exposed terminals can be reduced by about 50% by improving the production efficiency and saving precious metals.

Owner:XIAOMI INC

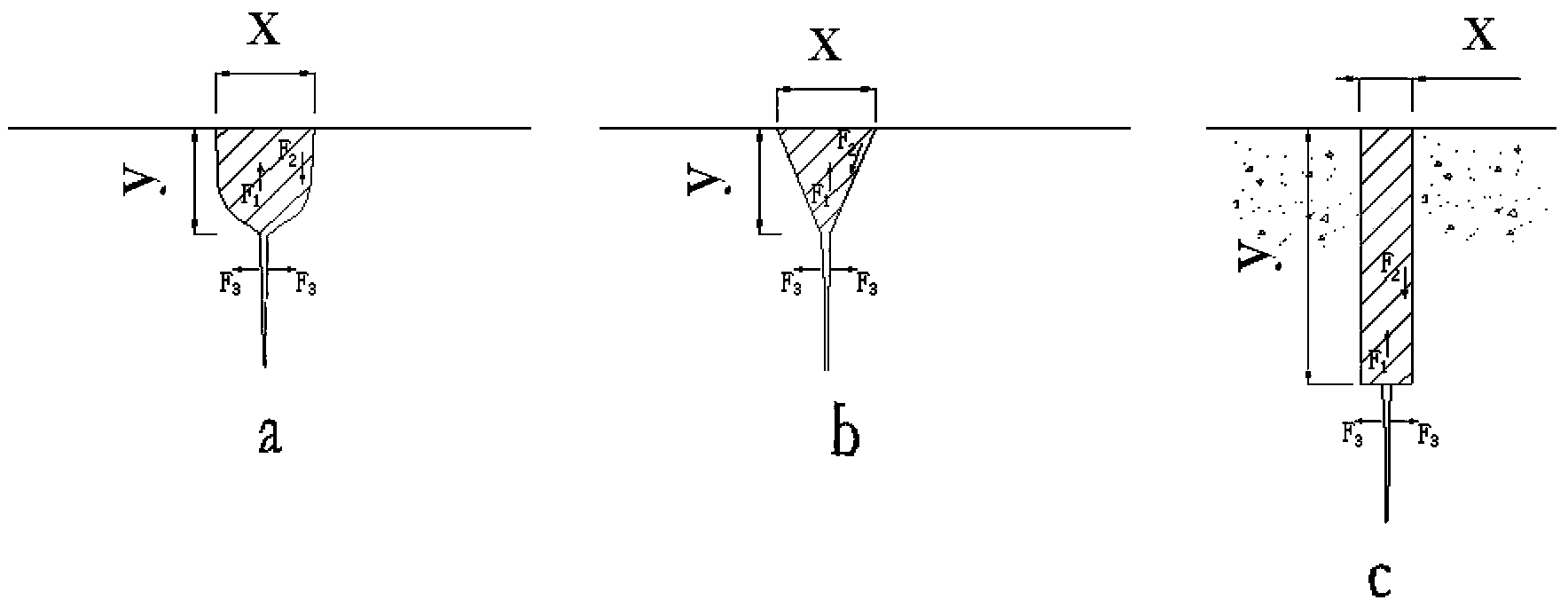

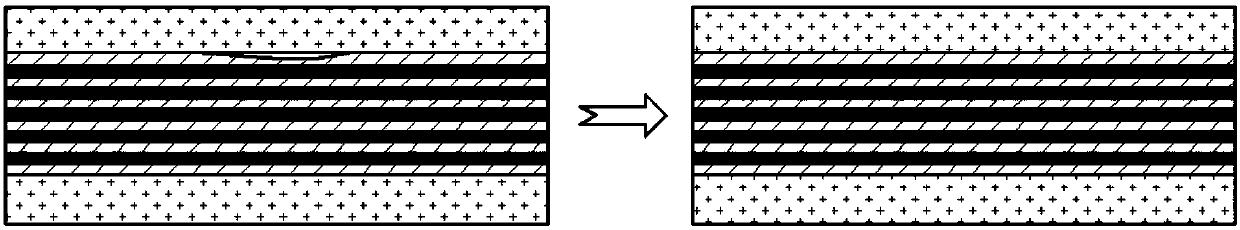

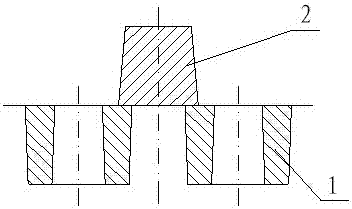

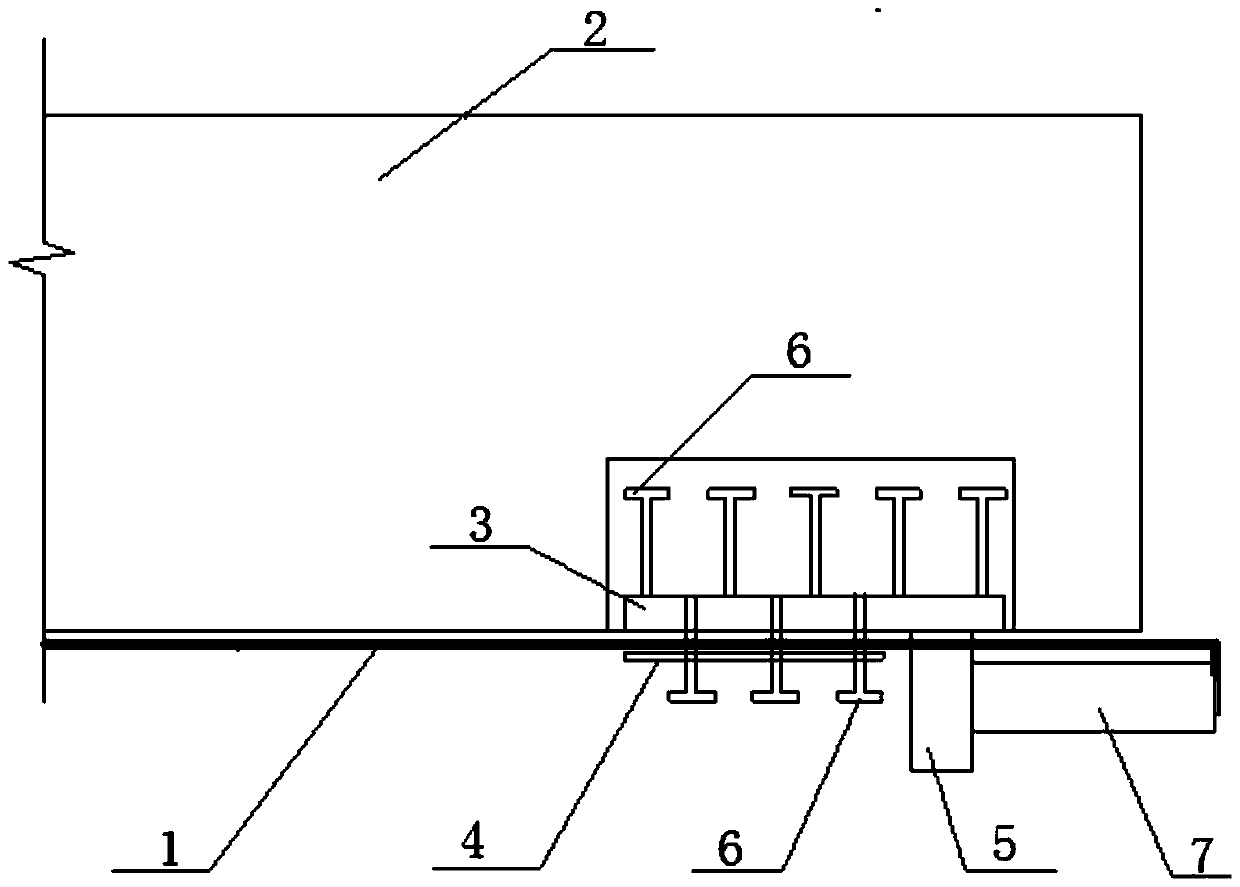

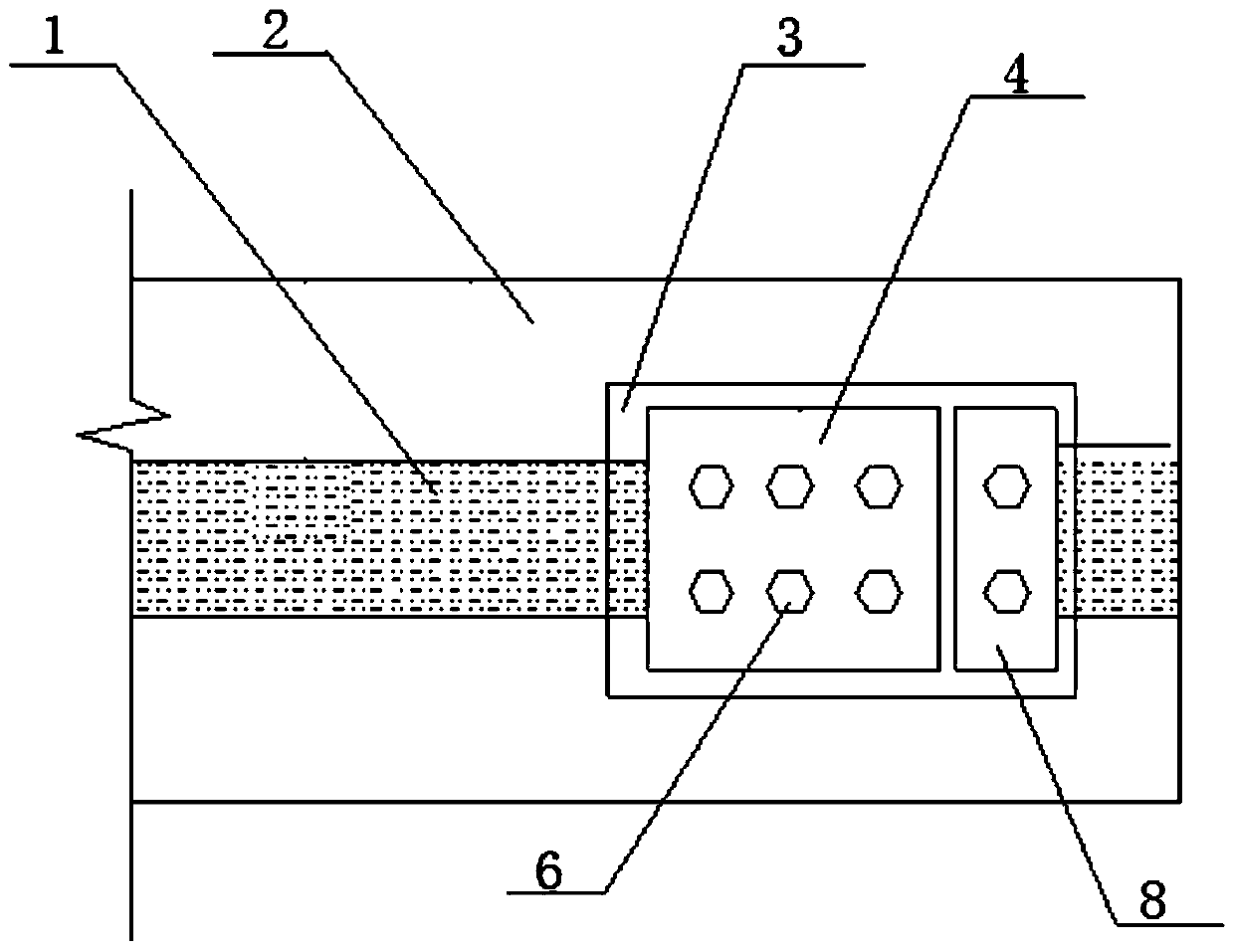

Fiber board tensioning device and fiber board tensioning method

ActiveCN104818677AImprove efficiencyImprove adhesionBuilding repairsBridge erection/assemblyFiberConcrete beams

The invention discloses a prestressed fiber board tensioning device. A groove(s) is / are formed in one end / two ends of the reinforced position of the surface of a beam plank; a fixing steel plate is arranged in the groove; a fiber board is fixed to the reinforced position, one end of the fiber board is fixed to the beam plank / the fixing steel plate, and the other end of the fiber board is fixed to the fixing steel plate; the fiber board and the fixing steel plate are fixed by a first anchoring steel plate and a second anchoring steel plate; the first anchoring steel plate is arranged at the end of the fixing steel plate in the length direction, and the second anchoring steel plate is arranged at the other end of the fixing steel plate in the length direction. According to the invention, the bonding performance of the fiber board and a concrete beam can be obviously improved, a reinforcement material, such as the fiber board, is fully bonded to the reinforced beam plank, the use efficiency of the material is improved, anchorage segments are effectively prevented from tilting, and the reinforcement effect is enhanced.

Owner:JSTI GRP CO LTD +1

Metal coiled material color-coating production method and production apparatus thereof

ActiveCN106671563AOvercoming technical deficienciesQuick transitionLamination plant layoutLamination ancillary operationsSheet steelMethods of production

The invention discloses a metal coiled material color-coating production method and a production apparatus thereof. The method comprises the following steps: (1a) No.1 belt material unwinding, an uncoiler is used for gradually expanding the steel belt material coil to obtain the No.1 belt material; (2a), No.1 belt material clamping feeding; (3a), No.1 belt material inlet shearing;) (4) integral clamping feeding; (5) riveting; (6) flattening; (7) inlet looping; (8) degreasing; (9) water washing; (10) chemical coating; (11) chemical coating drying; (12) powder spraying; (13) primary coating curing, powder coating solidification treatment is carried out in a spraying curing furnace; (14) spraying forced cooling; (15) outlet looping; (16) cold film coating; (17) clamping feeding before shearing; (18) discharge shearing; (19) collection clamping feeding; and (20) winding. The invention further provides the production apparatus for implementing the method. Through utilizing the method and the production apparatus, the coating technology of replacing paint through powder can be achieved, the environment is improved, the production efficiency of colored steel is improved, and the method and the apparatus can be widely applied to color coating of steel plates and have good industrial production prospect and application potential.

Owner:赛高粉末技术(滨州)有限公司

Polishing method of small ceramic product

ActiveCN107150283AImprove polishing efficiencyLow structural requirementsPolishing machinesVertical planeMetallurgy

The invention provides a polishing method of a small ceramic product. The polishing method comprises the steps of polishing the ceramic product through CNC in combination with a grinding wheel rod, the ceramic product is immovable during polishing, and the grinding wheel rod is controlled by the CNC to rotate and move in the wave line form for polishing the ceramic product. In one embodiment, the grinding wheel rod is controlled by the CNC to move in the wave line form on a vertical plane. The polishing method provided by the invention is simple and easy, and the polishing efficiency of the irregular ceramic product is improved; according to the polishing method, not only the degree of finish and appearance requirements can be ensured, but also the requirements for the appearance and structure of the ceramic product can be reduced.

Owner:LENS TECH CHANGSHA

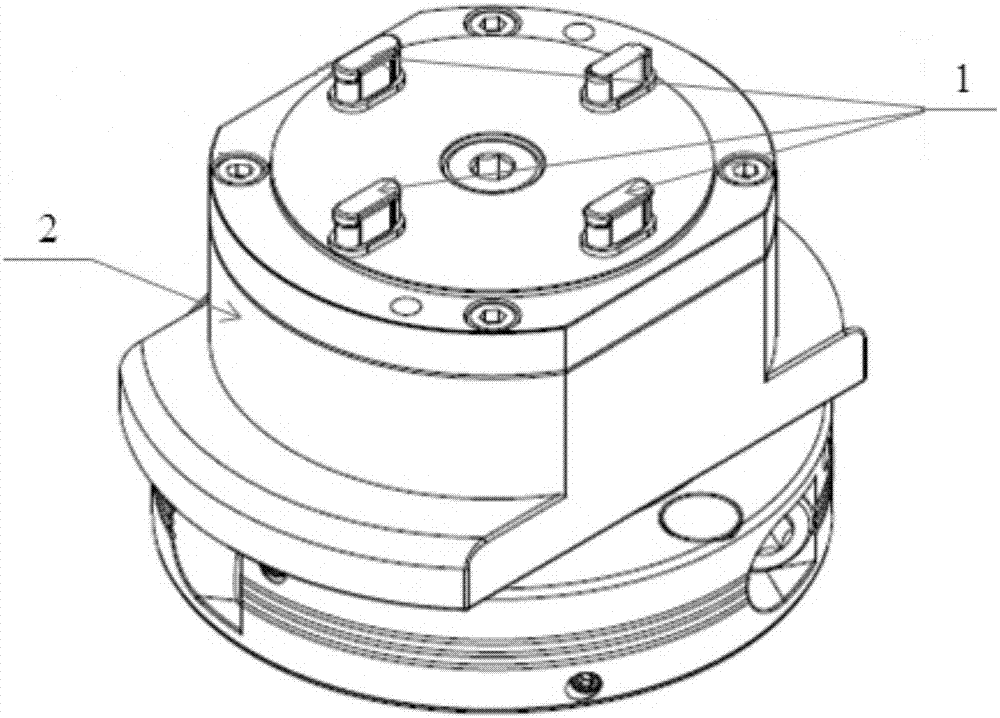

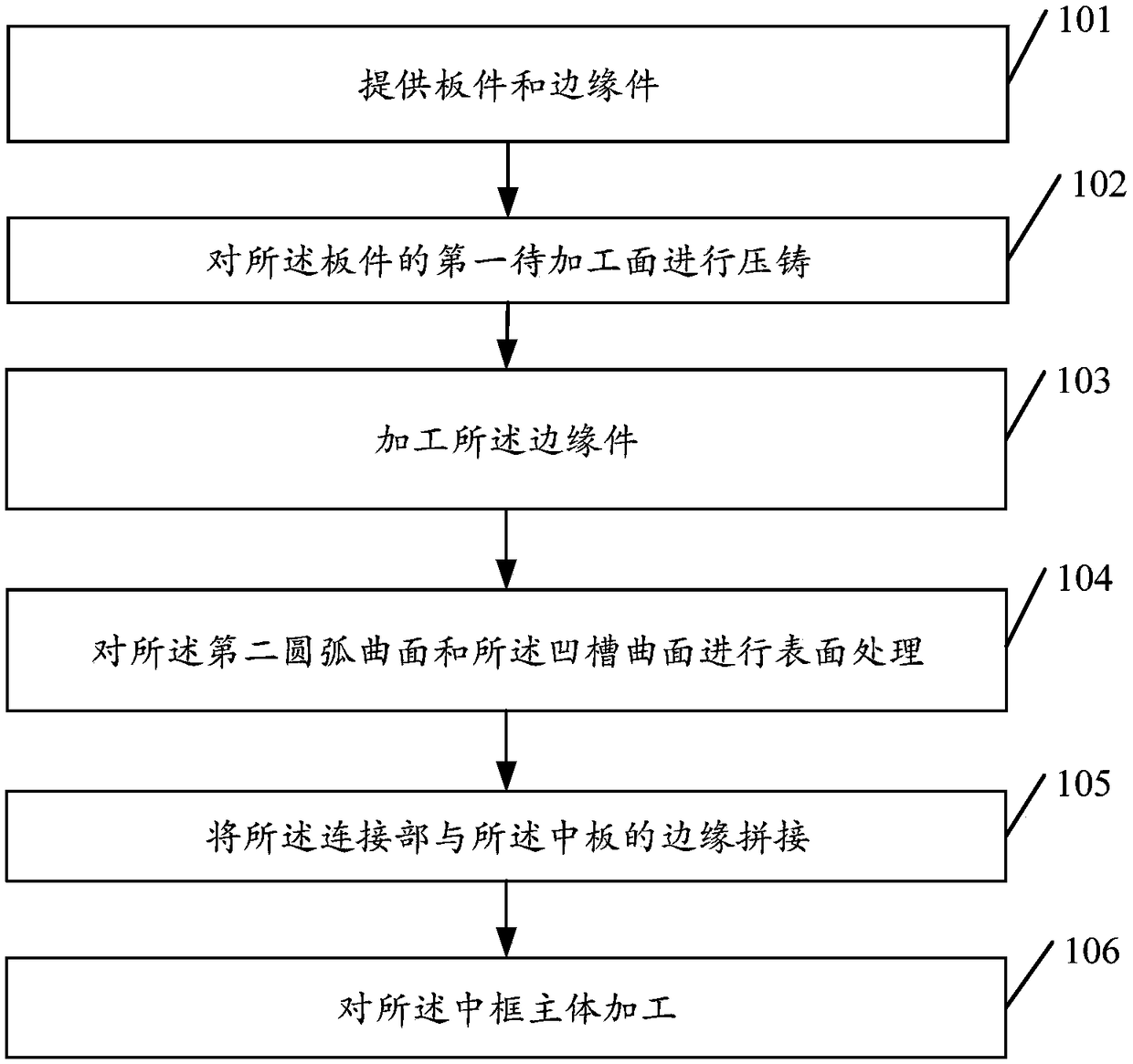

Middle frame manufacturing method, middle frame and electronic device

InactiveCN108513469AGuaranteed Appearance RequirementsEffortless to obtainCasings/cabinets/drawers detailsNumerical controlPressure casting

The present invention provides a middle frame manufacturing method, a middle frame and an electronic device. The method comprises the steps of: providing a plate piece and an edge piece, wherein the plate piece has a first surface to be processed, and the edge piece has an outer surface to be processed; performing pressure casting of the first surface to be processed of the plate piece to obtain amiddle frame, wherein the middle frame has a first forming portion; processing the edge piece to obtain a frame piece, wherein the outer surface to be processed is subjected to numerical control milling to form an appearance portion, and the frame piece further has a connection portion opposite to the appearance portion; splicing the connection portion and the edge of the middle plate to obtain the middle frame main body; and processing the middle frame main body to obtain a middle frame. The middle frame only need to perform numerical control milling of the outer surface of the middle frameto reduce the processing time, reduce the processing cost, ensure the appearance requirement of the middle frame and allow the manufacturing method of the middle frame to greatly reduce the manufacturing cost.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

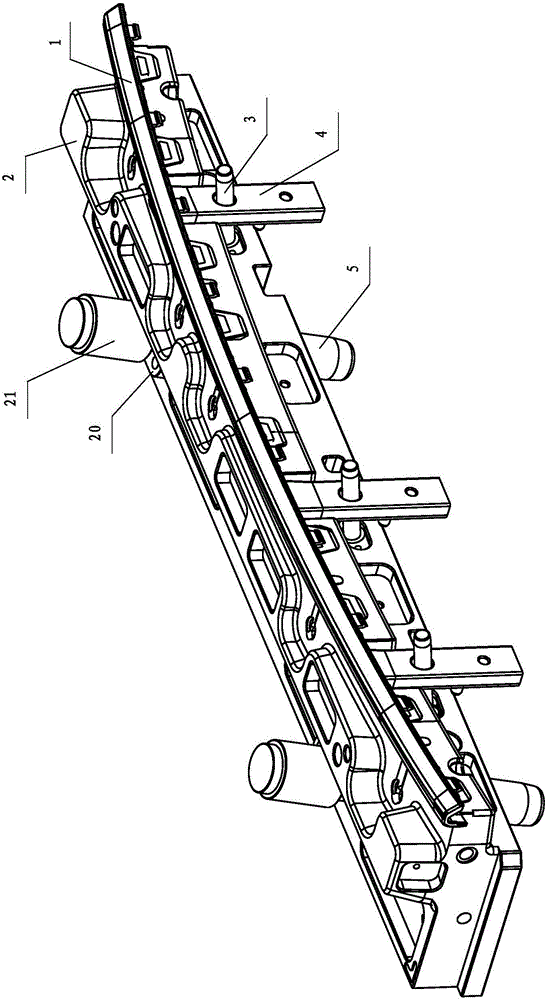

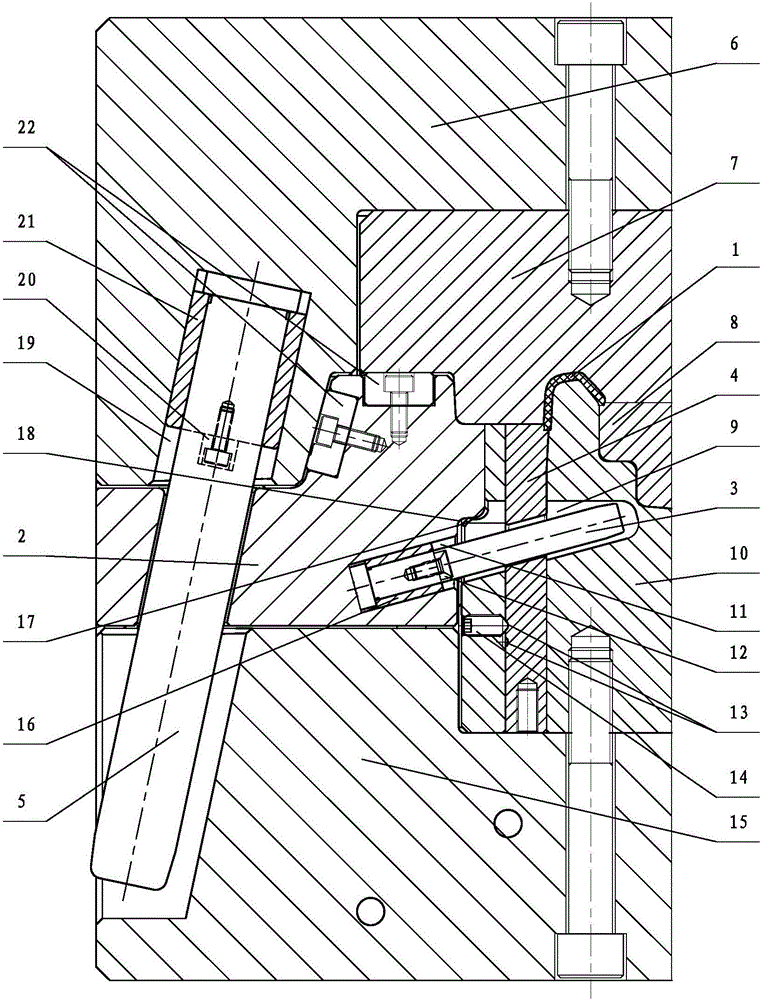

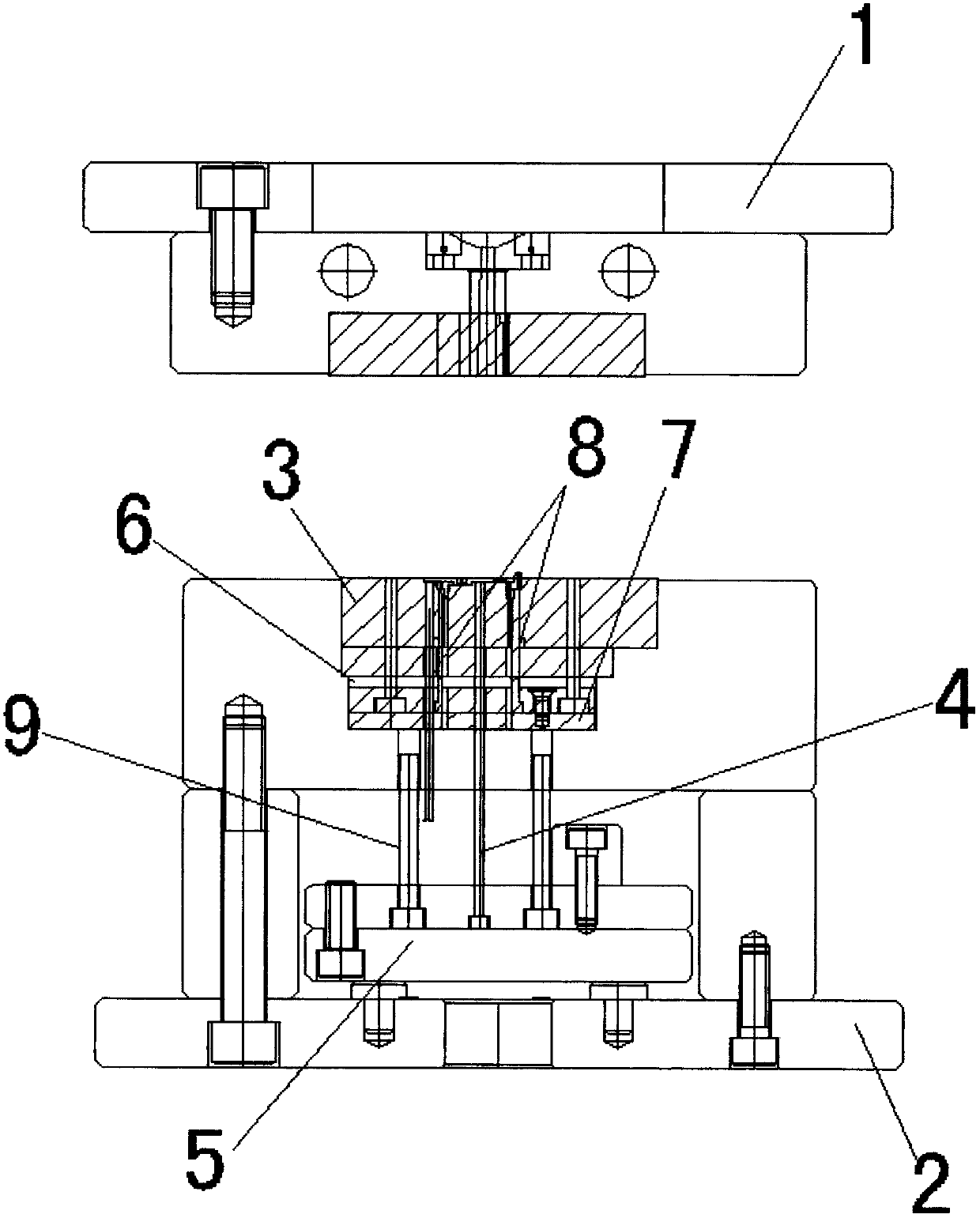

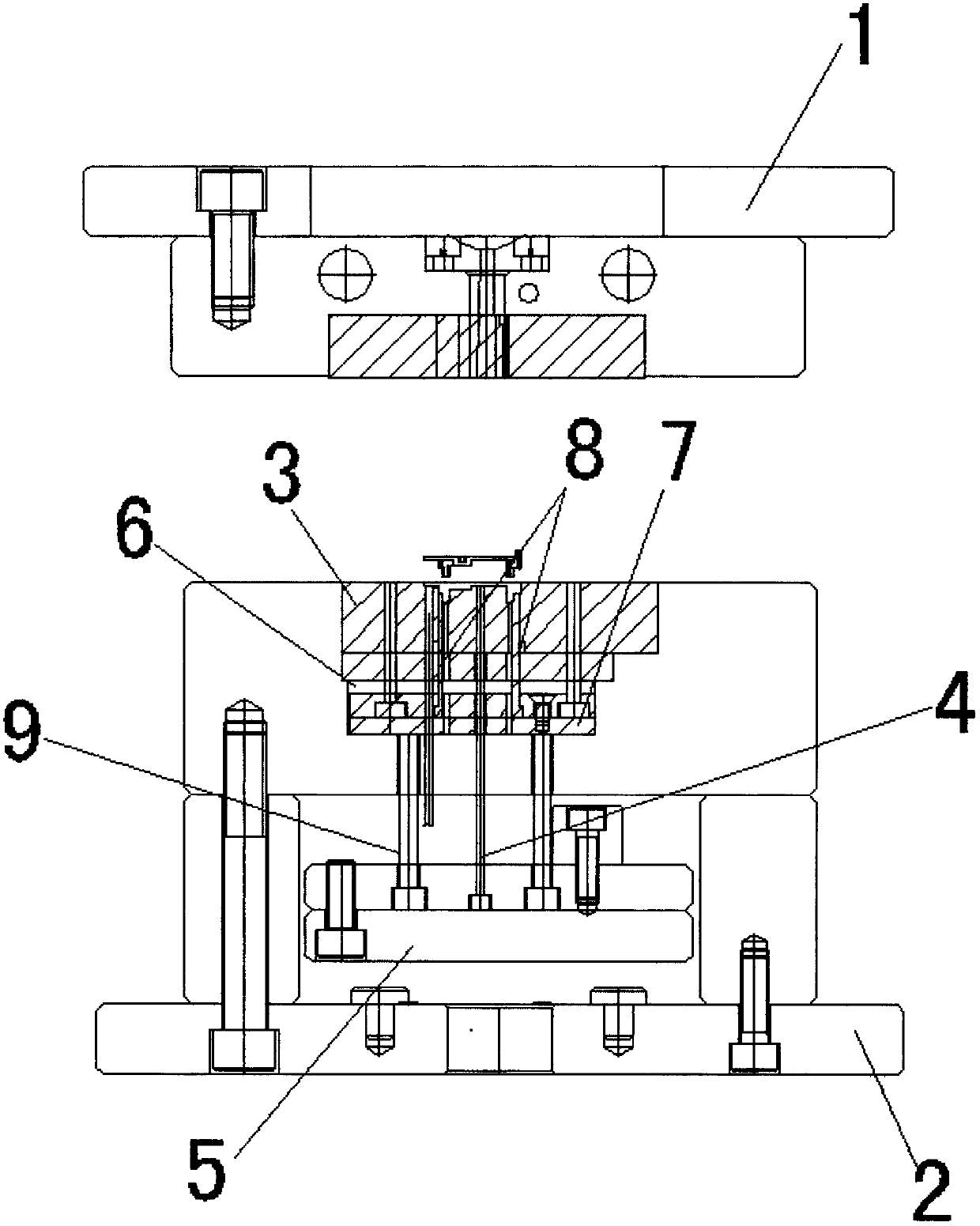

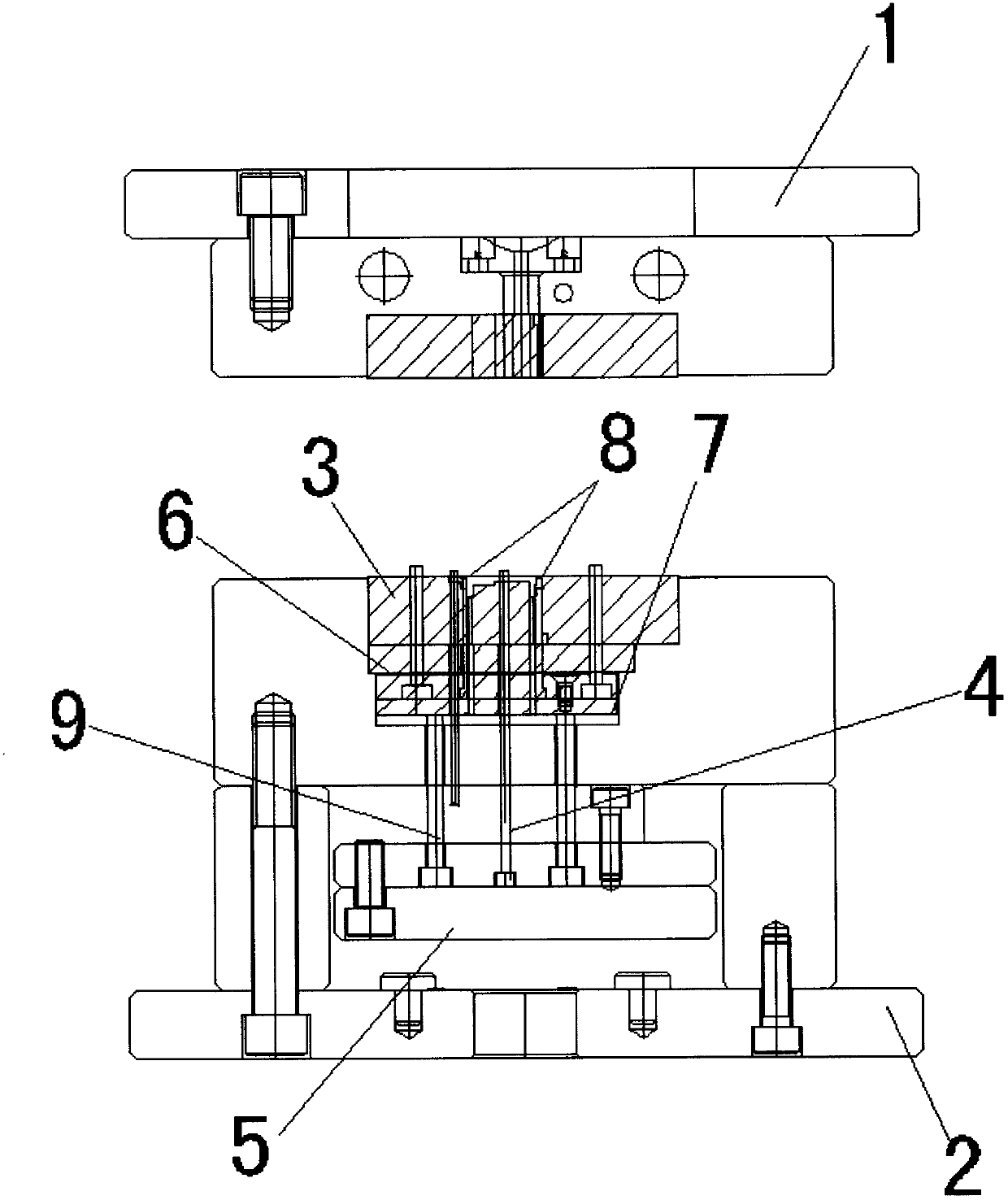

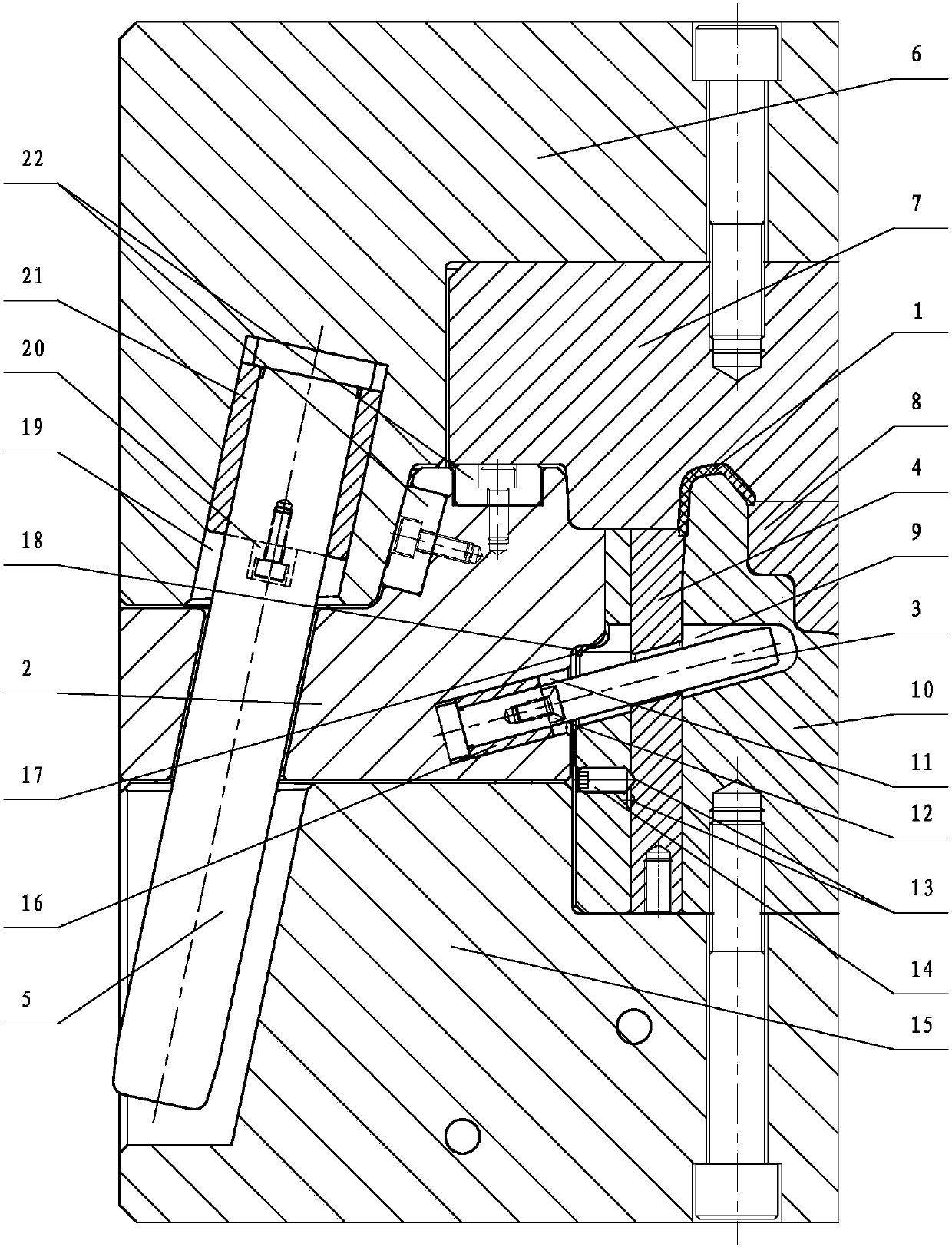

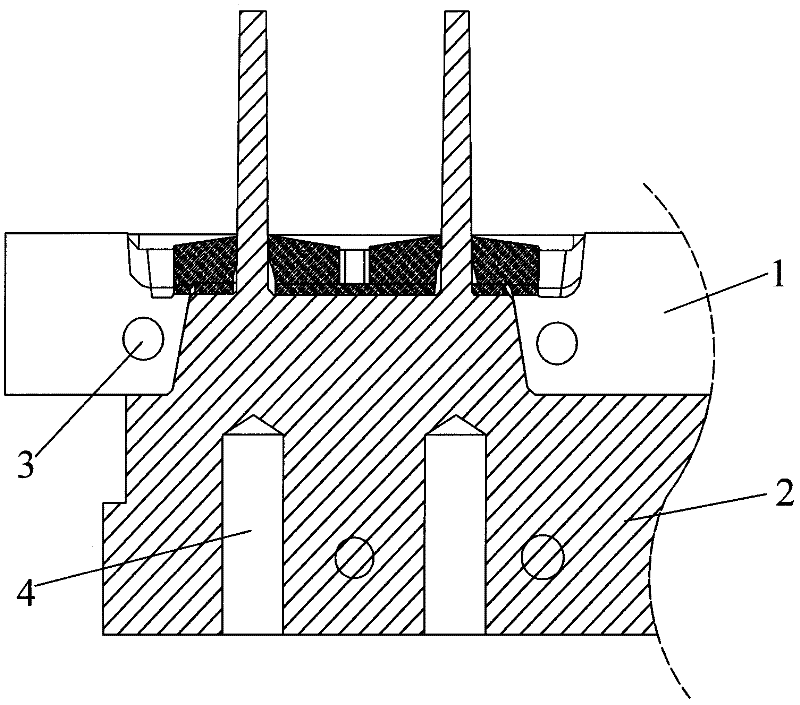

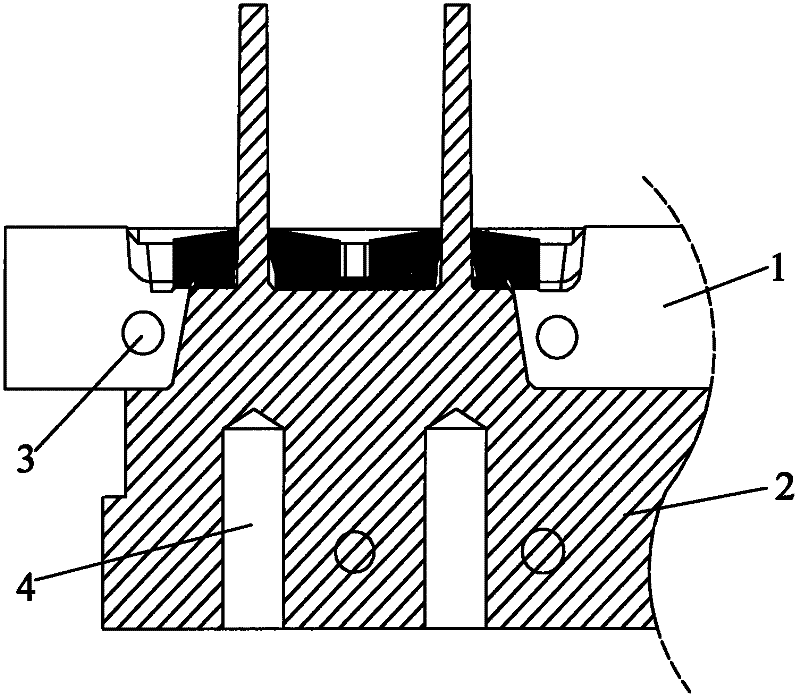

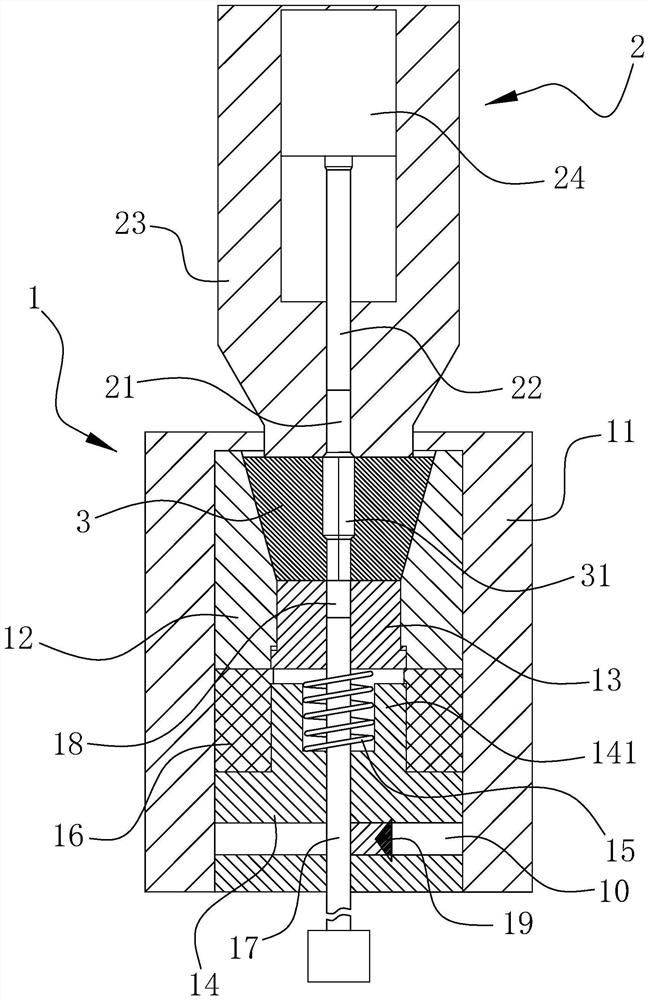

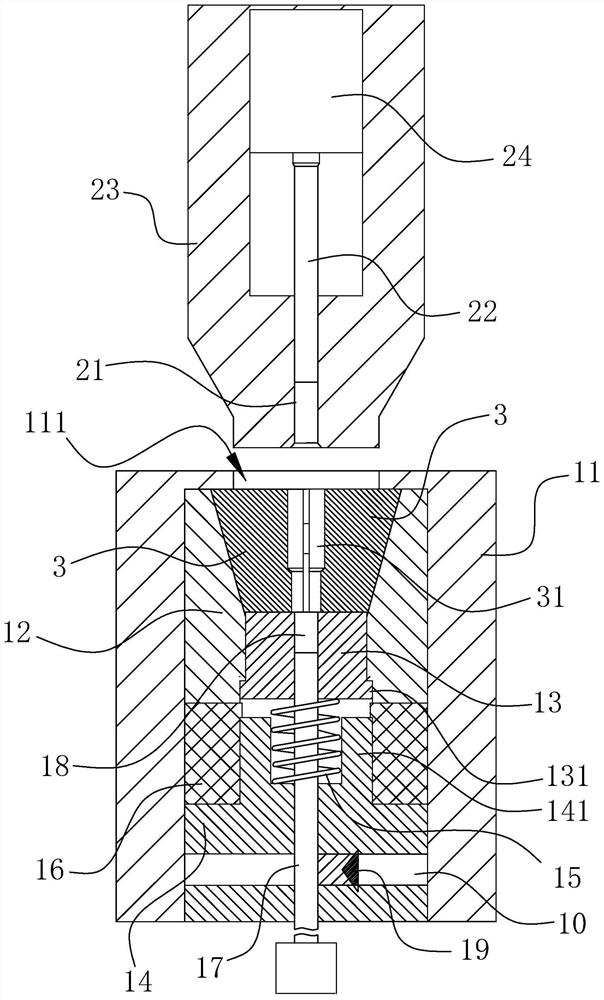

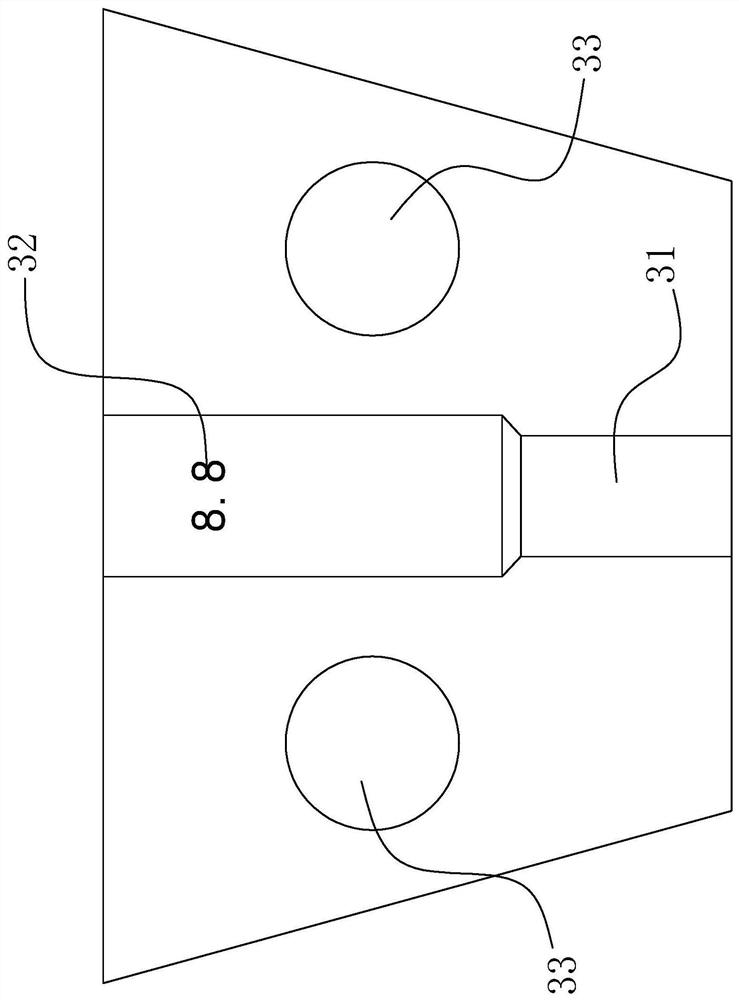

Ejection mechanism for injection mold for electroplated parts

ActiveCN105965804AReduce contact areaGuaranteed Appearance RequirementsMechanical engineeringElectroplating

The invention discloses an ejection mechanism for an injection mold for electroplated parts. The ejection mechanism comprises ejection blocks (4) and a driving mechanism used for driving the ejection blocks (4) to vertically move for being released from the mold; the ejection blocks (4) are connected inside a lower mold assembly of the injection mold in a sliding mode in the vertical direction; the driving mechanism comprises a sliding block (2), sliding block inclination guide columns (5) and ejection block inclination guide columns (3), wherein the sliding block (2) is connected to the lower mold assembly in a sliding mode in the horizontal direction, the upper ends of the sliding block inclination guide columns (5) are fixedly connected to an upper mold assembly, the lower ends of the sliding block inclination guide columns (5) are connected to the sliding block (2) in a sliding mode and drive the sliding block (2) to slide towards the outer side of the injection mold in the mold opening process, one ends of the ejection block inclination guide columns (3) are fixedly connected inside the sliding block (2), and the other ends of the ejection block inclination guide columns (3) are connected to the ejection blocks (4) in a sliding mode and drive the ejection blocks (4) to slide upwards for ejecting products in the mold opening process. According to the structure, ejection marks are prevented from being left on surfaces of the products, the appearance requirement of subsequent electroplating is met, and the quality requirement of the products is met.

Owner:NINGBO FANGZHENG TOOL

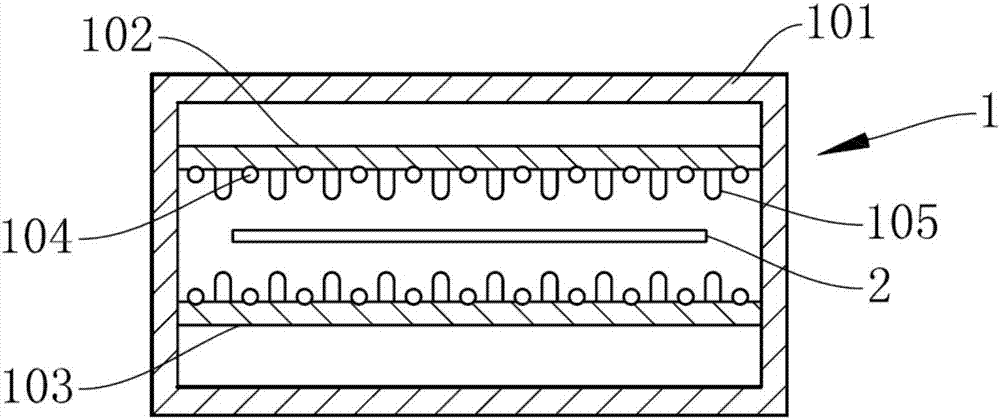

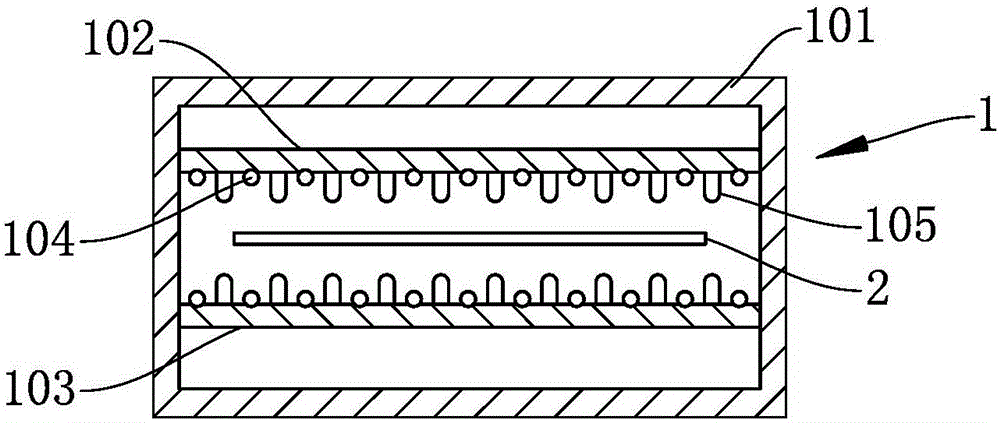

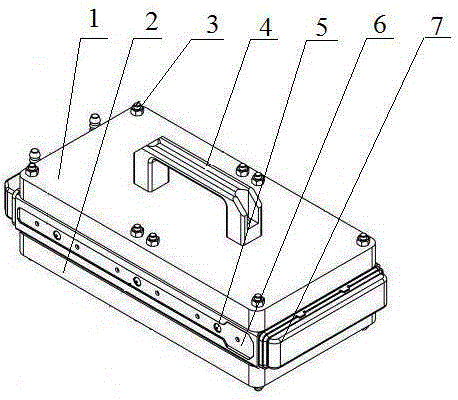

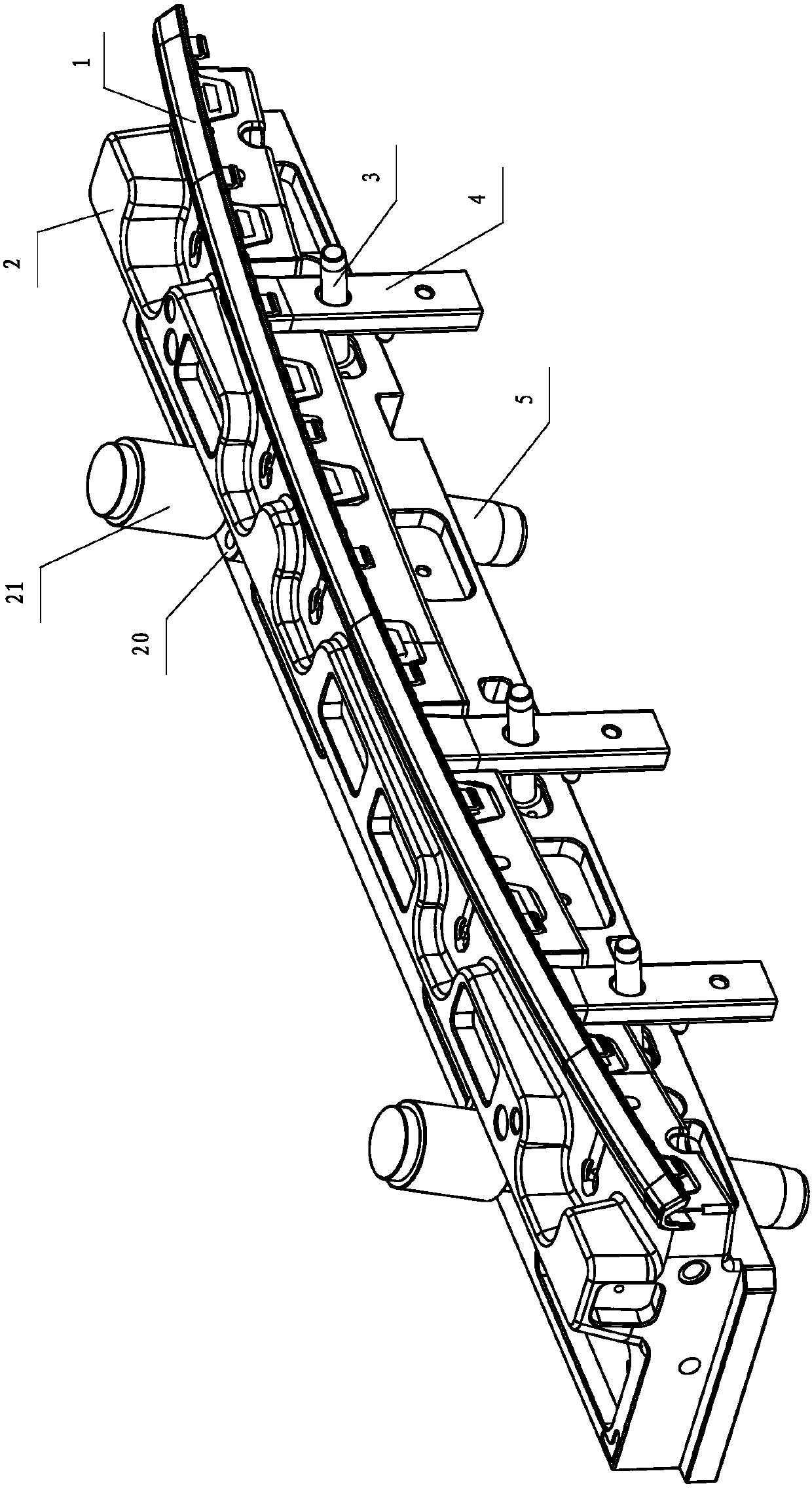

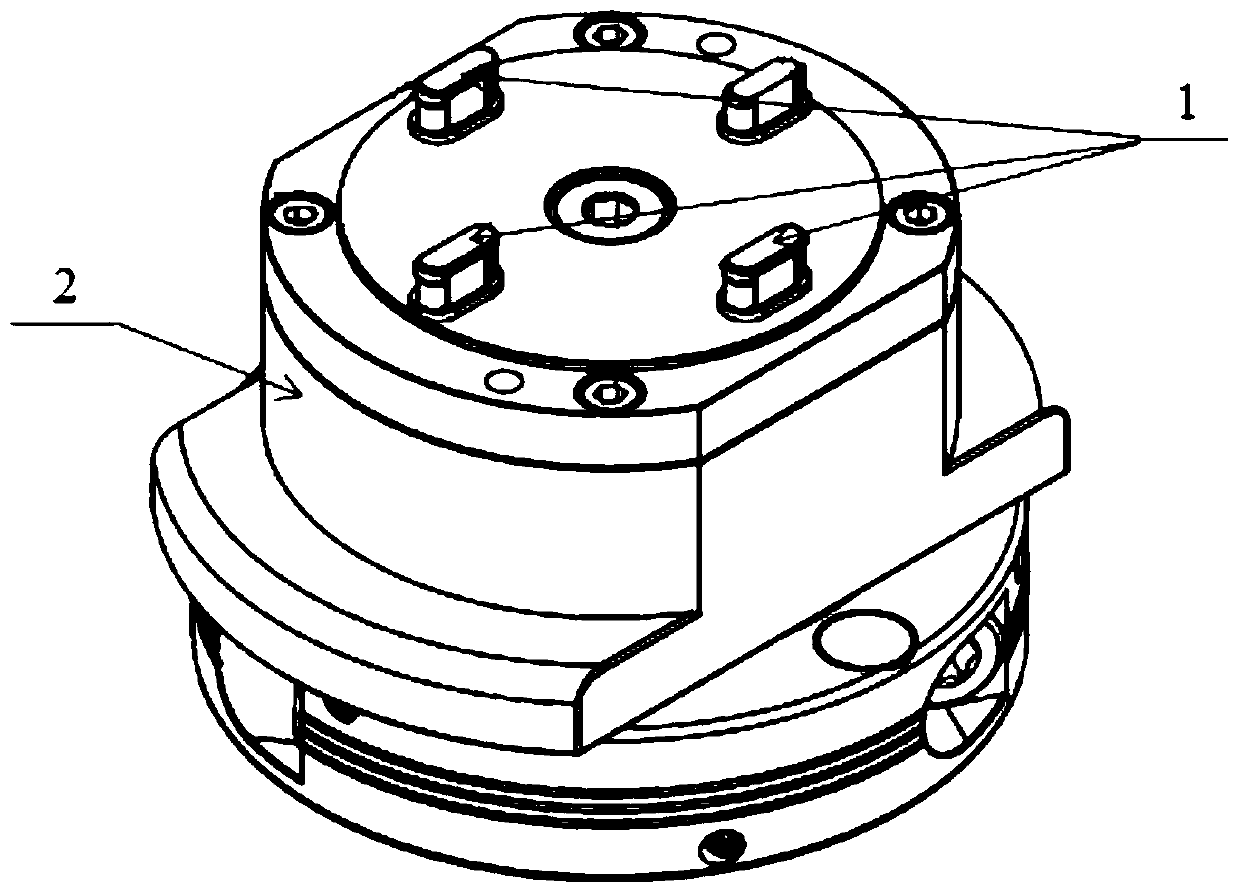

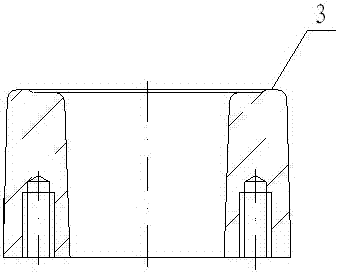

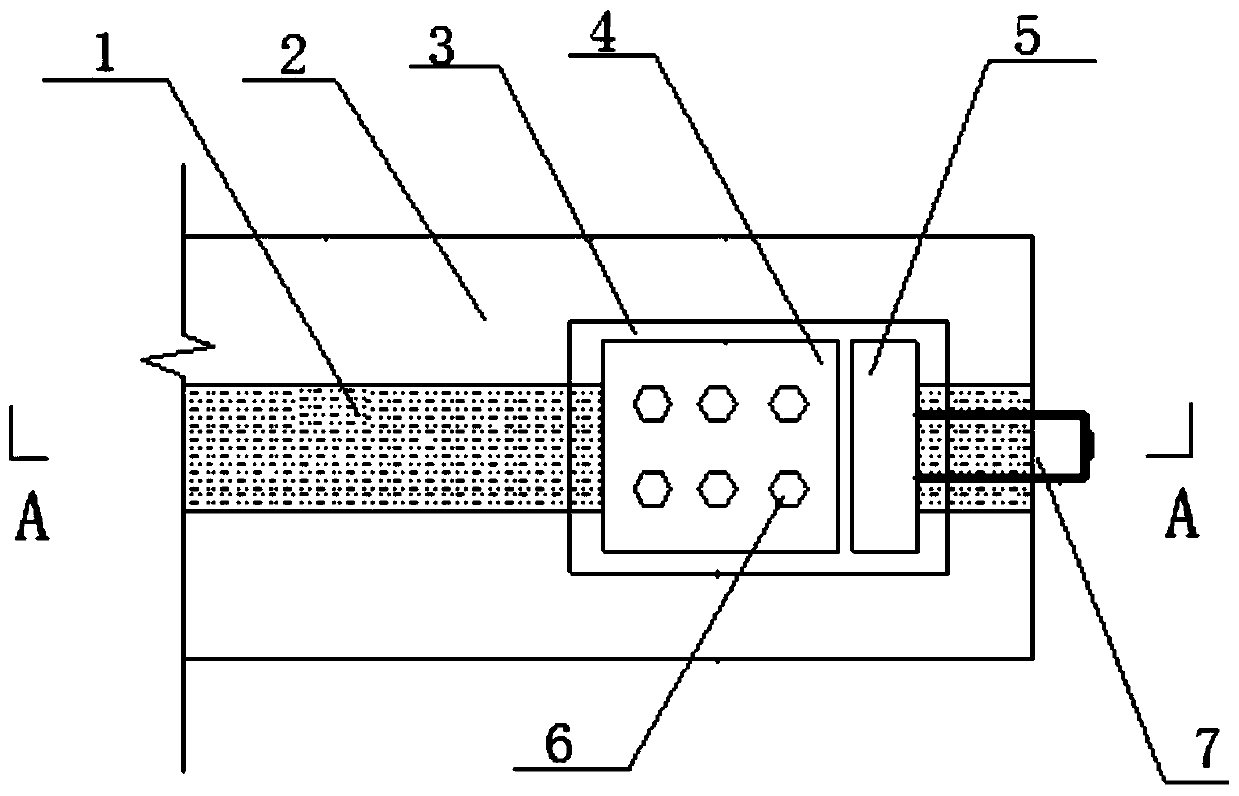

Riveting clamp for assembling plates of radiator

The invention discloses a riveting clamp for assembling plates of a radiator, belonging to technological equipment; and the invention aims to provide the riveting clamp which is simple in structure, convenient for operation, stable and reliable for riveting and high in riveting efficiency. The riveting clamp comprises an upper base plate (1) buckled on the upper bottom surface of the radiator and a lower base plate (2) buckled on the lower bottom surface of the radiator; and limiting screws (3) are arranged at corresponding positions on the surfaces of the upper base plate (1) and the lower base plate (2). A handle (4) is fixedly arranged on the upper base plate (1) or the lower base plate (2); and the number of the limiting screws (3) is identical with the number of assembling holes in the riveted assembling plates, and the positions of the limiting screws correspond to the positions of the assembling holes. By adopting the riveting clamp disclosed by the invention, the deformation of a radiating core caused by brazing can be corrected, and the deformation of the radiating core caused by the pneumatic external force of a riveter can also be reduced; the riveting is stable and reliable and is high in efficiency; and falling-down of radiating belts caused by external force can also be avoided, and manual finishing work in post-working processes is greatly reduced.

Owner:GUIZHOU GUIHANG AUTOMOTIVE COMPONENTS

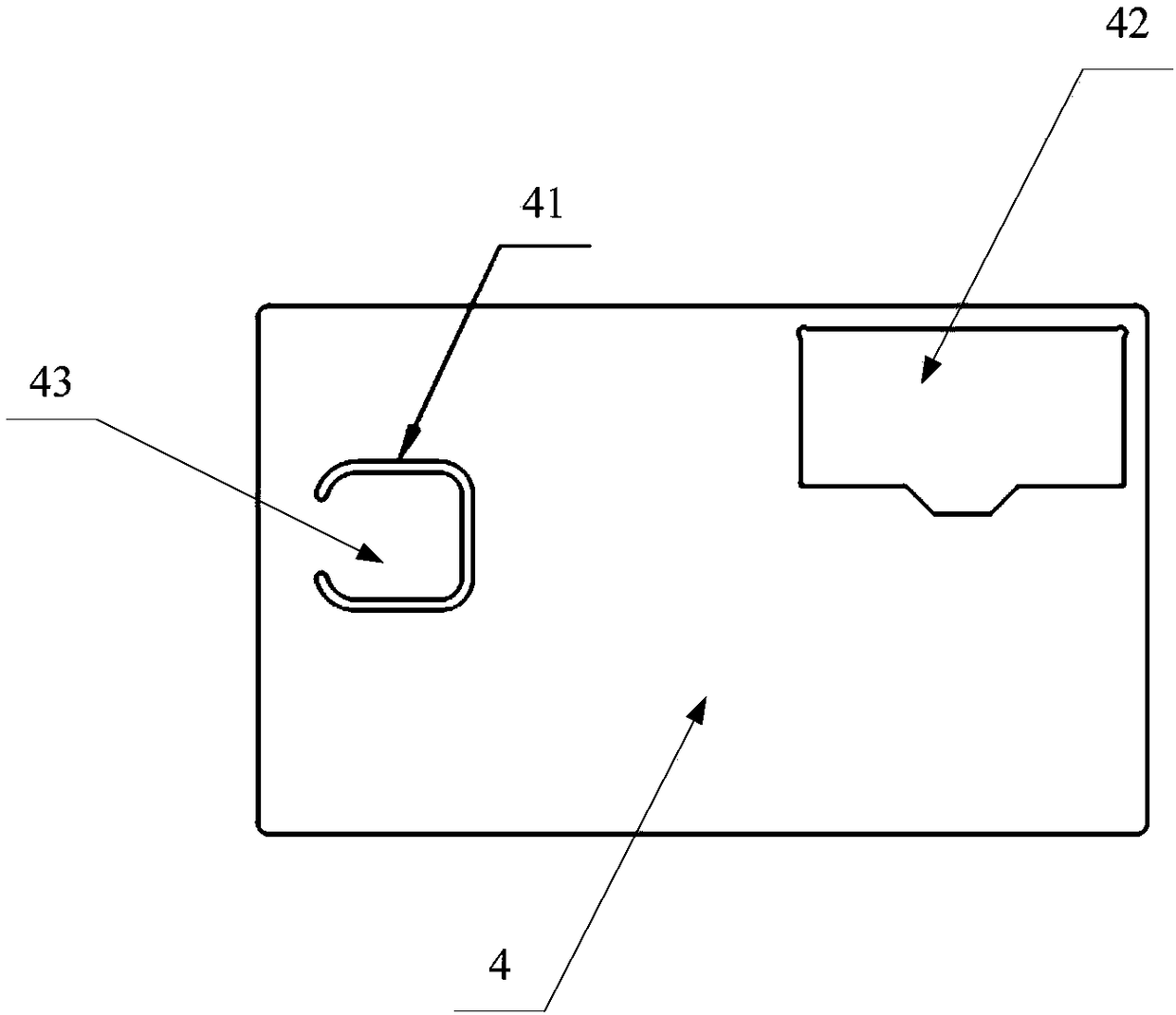

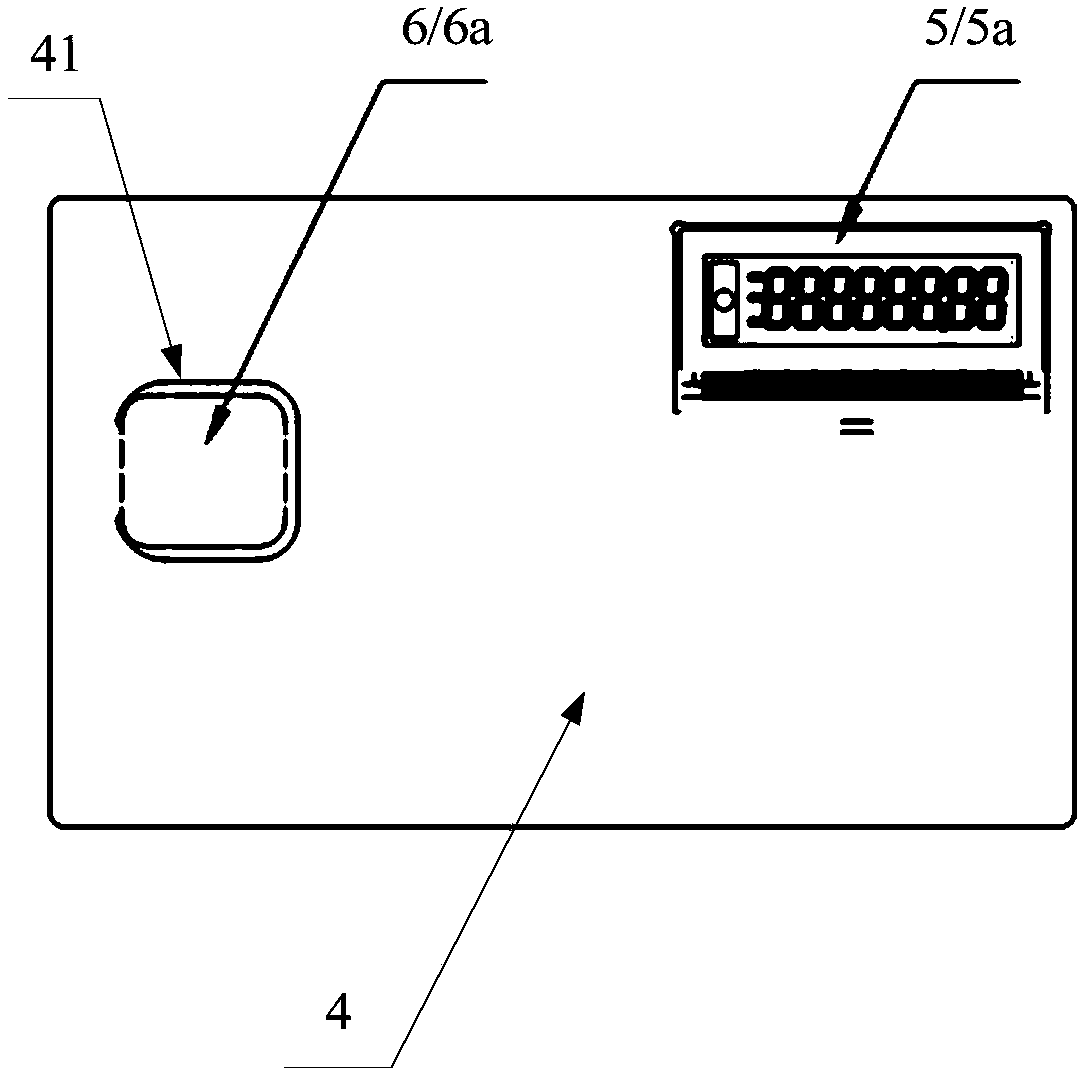

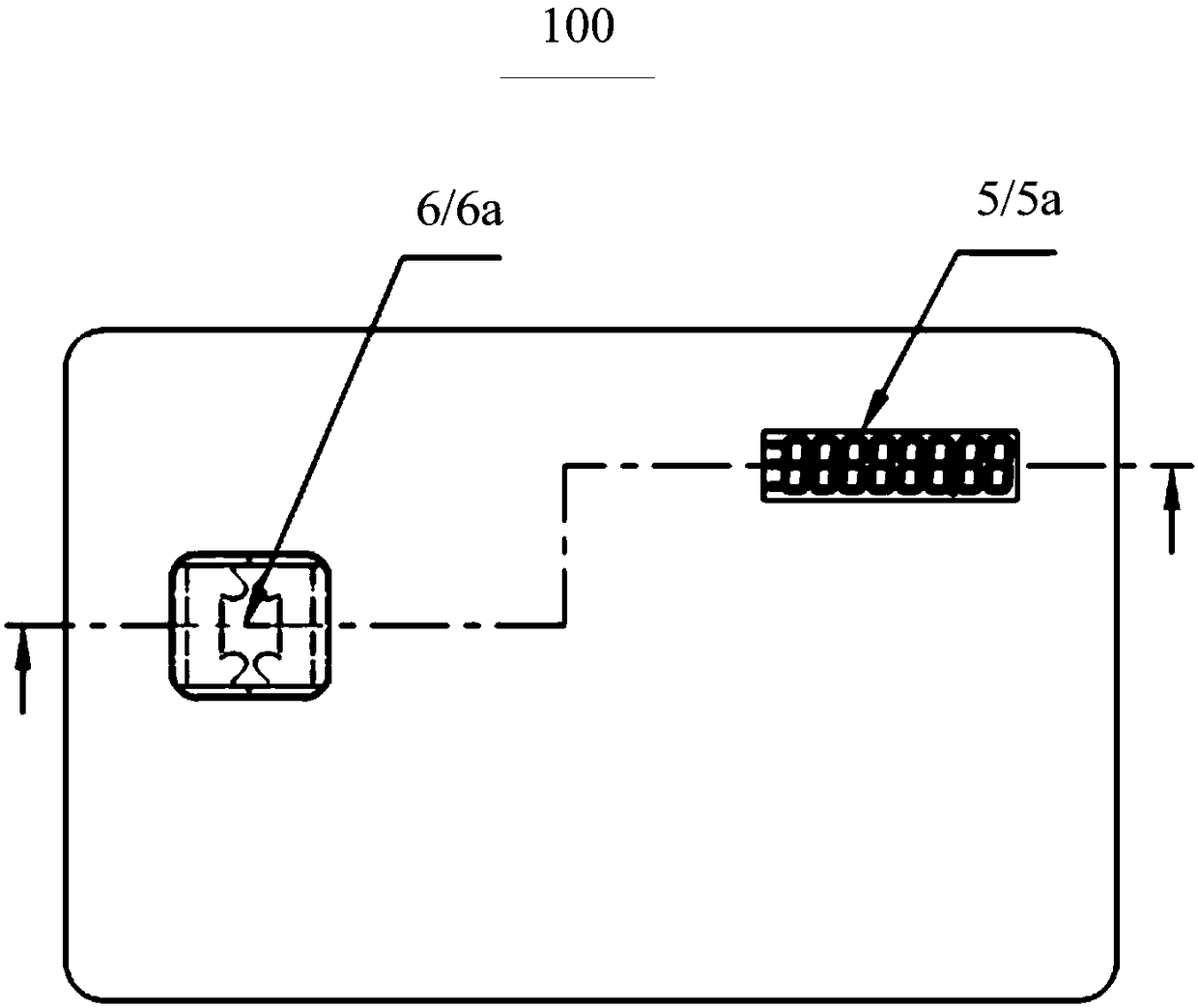

FPCB (flexible printed circuit board) board, smart card and packaging method thereof

PendingCN108282958AGuaranteed Appearance RequirementsGuaranteed Functional RequirementsFinal product manufacturePrinted circuit aspectsProcess errorEngineering

The invention discloses an FPCB (flexible printed circuit board) board, a smart card and a packaging method thereof. The FPCB board is provided with a first component and a second component, the FPCBboard is provided with a through groove at the position of the second component, and the through groove is used for providing a deformation space for the FPCB board when the second component and the first component are positioned on the smart card, so that processing errors of the two components can be adjusted through the deformation, the two components on the FPCB board can be fixedly positionedat correct positions of the smart card, and poor appearance or poor functions of the smart card due to deflection, caused by production and processing errors, of the two components can be avoided. Inaddition, appearance and functional requirements of the components on the smart card are guaranteed, and smart card production yield is increased.

Owner:SHENZHEN EXCELSECU DATA TECH

Mold insert motion structure

The invention discloses a mold insert motion structure which comprises an upper mold, a lower mold, a mold core and a mold core ejection mechanism; the ejection mechanism comprises an ejection needle and an ejection needle plate; the lower end of the mold core is provided with an empty cavity; the empty cavity is internally provided with a slide block vertically sliding up and down; the side edge of a mold cavity of the mold core is provided with a plurality of inserts; the lower ends of the inserts are fixed on the slide block; the ejection needle plate is also provided with a plurality of ejection rods; a clearance is formed between the upper end of each ejection rod and the slide block; and the lower ends of the ejection rods are fixed in the ejection needle plate. The general inserts are combined with the ejection rods so as to form a novel insert motion mechanism, and a novel mode for solving air trapping is formed, and the appearance requirement of the product surface can be ensured, and the product reject ratio also can be lowered. In the prior art, the ejection needle or a flat ejector is used for exhausting air, compared with the existing ejection needle air exhaust structure, the mold insert motion structure can be used for enabling the inserts not to be difficult to damage; and the mold insert motion structure can exhaust the air fully, runs reliably, is low in cost, is convenient to form, and reduces the unhealthy phenomena in forming.

Owner:KENTA ELECTRONIC MFG KUNSHAN CO LTD

Injection mold ejection mechanism for electroplated parts

ActiveCN105965804BReduce contact areaGuaranteed Appearance RequirementsEngineeringMechanical engineering

The invention discloses an ejection mechanism for an injection mold for electroplated parts. The ejection mechanism comprises ejection blocks (4) and a driving mechanism used for driving the ejection blocks (4) to vertically move for being released from the mold; the ejection blocks (4) are connected inside a lower mold assembly of the injection mold in a sliding mode in the vertical direction; the driving mechanism comprises a sliding block (2), sliding block inclination guide columns (5) and ejection block inclination guide columns (3), wherein the sliding block (2) is connected to the lower mold assembly in a sliding mode in the horizontal direction, the upper ends of the sliding block inclination guide columns (5) are fixedly connected to an upper mold assembly, the lower ends of the sliding block inclination guide columns (5) are connected to the sliding block (2) in a sliding mode and drive the sliding block (2) to slide towards the outer side of the injection mold in the mold opening process, one ends of the ejection block inclination guide columns (3) are fixedly connected inside the sliding block (2), and the other ends of the ejection block inclination guide columns (3) are connected to the ejection blocks (4) in a sliding mode and drive the ejection blocks (4) to slide upwards for ejecting products in the mold opening process. According to the structure, ejection marks are prevented from being left on surfaces of the products, the appearance requirement of subsequent electroplating is met, and the quality requirement of the products is met.

Owner:NINGBO FANGZHENG TOOL

A polishing method for small ceramic products

ActiveCN107150283BImprove polishing efficiencyLow structural requirementsPolishing machinesVertical planePolishing

Owner:LENS TECH CHANGSHA

Metal terminal back cover and terminal

ActiveCN105655706BGuaranteed Appearance RequirementsReduce the proportionSimultaneous aerial operationsDigital data processing detailsEngineeringRadio frequency

The present invention discloses a metal terminal back cover and a terminal, the metal terminal back cover comprises a base plate, the base plate is provided with at least one micro-seam tape, the micro-seam tape is provided with a plurality of micro-seams, the at least one micro-seam tape separates the base plate from at least two radiation parts, the at least two radiation parts wherein at least one for access to the matching circuit, and emit electromagnetic waves. The use of the micro-slit tape is provided with a plurality of micro-slits, thereby reducing the proportion of the non-metallic part of the metal terminal cover; And the use of at least one radiation portion connected to the matching circuit to achieve radiated electromagnetic waves; Thus the metal terminal cover itself to achieve antenna RF, thereby improving the antenna RF efficiency, and then in order to ensure the overall appearance of the terminal requirements, but also improve the antenna RF efficiency, to achieve the effect of improving the user experience.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Stripper ejector mechanism

Owner:苏州川鹏塑料有限公司

Piston casting method and casting mold thereof

InactiveCN107537976AThe uniformity of as-cast hardness is improvedThe method steps are simpleFoundry mouldsFoundry coresPistonMaterials science

The invention discloses a piston casting method and a casting mold thereof. A plurality of casting patterns are distributed on a single layer and arrayed orderly; a running gate is arranged in the center of the casting patterns; the running gate and the casting patterns are connected through a plurality of pouring gates; each casting pattern is prevented from shrinkage depression by a blank pressing and shrinkage feeding method, and the blank pressing and shrinkage feeding method means that a riser is arranged between every two adjacent casting patterns for shrinkage feeding; the end faces ofthe casting patterns are provided with annular protrusions used for distinguishing the product specifications; and the upper surface of the risers are provided with strip-shaped protrusions used for distinguishing the product specifications. The piston casting method and the casting mold thereof have the beneficial effects that the production method is simple and high in production efficiency; thecooling speed of castings is even, the hardness uniformity of the castings is high, the protrusions are arranged on the casting patterns and the risers so that the product specifications can be easily distinguished, and management of foundry returns is convenient.

Owner:上海兆丰制冷配件有限公司

Fiber sheet tensioning device and its tensioning method

ActiveCN104818677BImprove efficiencyImprove adhesionBuilding repairsBridge erection/assemblyFiberConcrete beams

The invention discloses a prestressed fiber board tensioning device. A groove(s) is / are formed in one end / two ends of the reinforced position of the surface of a beam plank; a fixing steel plate is arranged in the groove; a fiber board is fixed to the reinforced position, one end of the fiber board is fixed to the beam plank / the fixing steel plate, and the other end of the fiber board is fixed to the fixing steel plate; the fiber board and the fixing steel plate are fixed by a first anchoring steel plate and a second anchoring steel plate; the first anchoring steel plate is arranged at the end of the fixing steel plate in the length direction, and the second anchoring steel plate is arranged at the other end of the fixing steel plate in the length direction. According to the invention, the bonding performance of the fiber board and a concrete beam can be obviously improved, a reinforcement material, such as the fiber board, is fully bonded to the reinforced beam plank, the use efficiency of the material is improved, anchorage segments are effectively prevented from tilting, and the reinforcement effect is enhanced.

Owner:JSTI GRP CO LTD +1

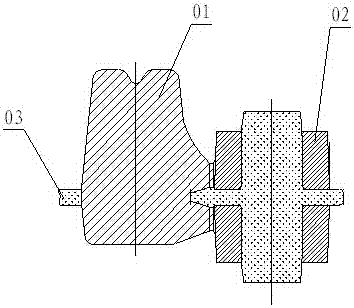

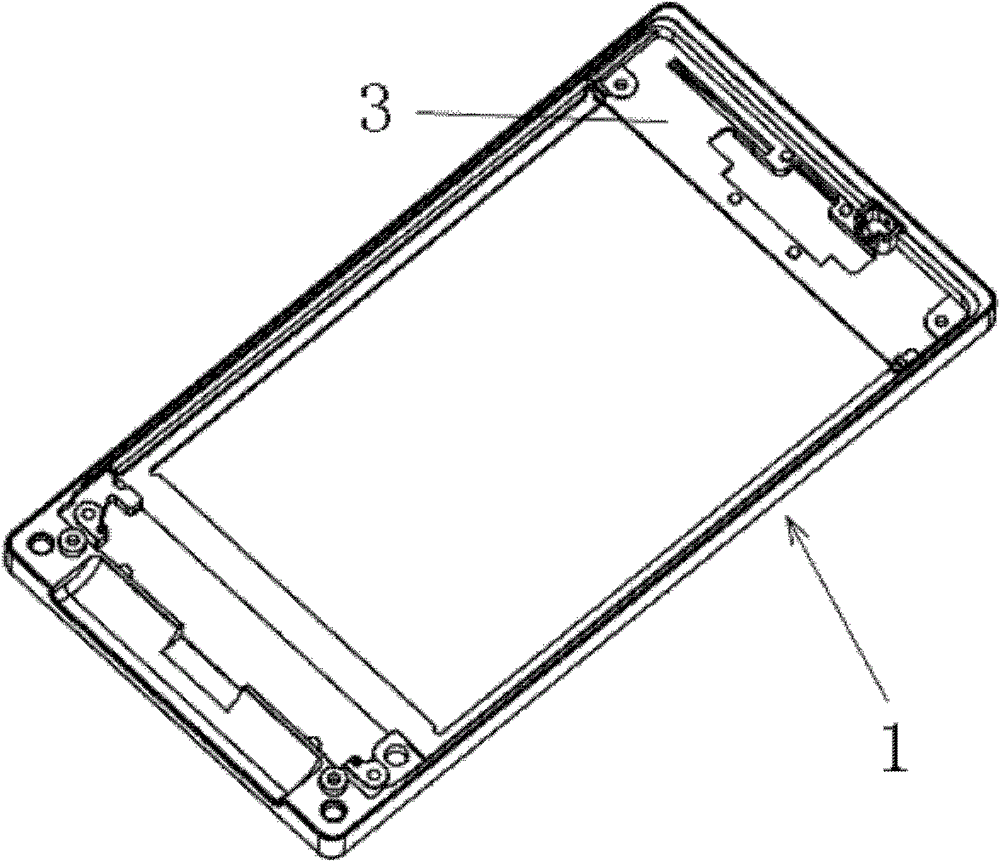

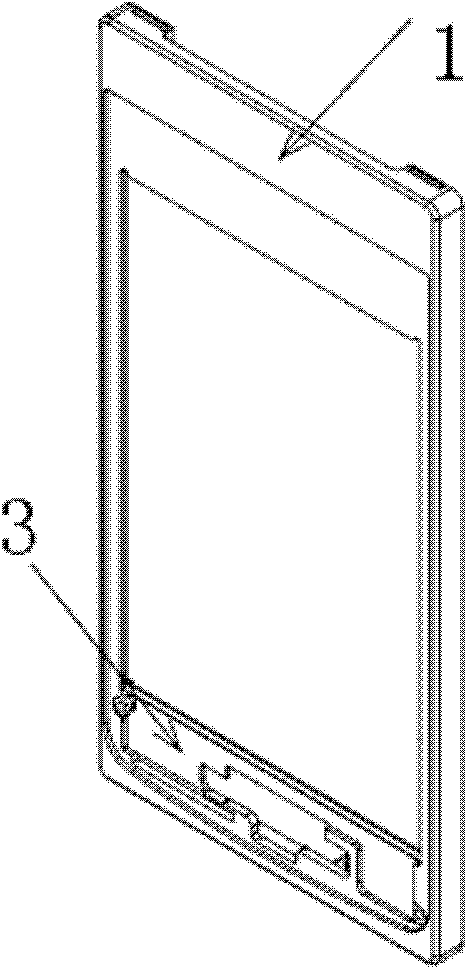

Mobile phone shell and machining method thereof

InactiveCN102811264BGuaranteed Appearance RequirementsLow costTelephone set constructionsMetal layered productsPunchingPressure casting

A mobile phone shell and its processing method are provided. The mobile phone shell comprises an outer shell (1) formed by metal punching, forging or injection molding, and inserts (21,22) are welded or concave structures are formed on the inner side of the outer shell. The mobile phone shell also comprises an inner shell (3) molded on the inner side of the outer shell by metal pressure casting, and the inner shell surrounds the inserts or fills into the concave structures so as to combine the outer shell with the inner shell. The processing method includes following steps: forming the outer shell by metal punching, forging or injection molding; soldering the inserts or forming the concave structures on the inner side of the outer shell; putting the outer shell into a mould and pressure casting the inner shell in the inner side of the outer shell. The method ensures the appearance requirement of the mobile phone shell, as well as reduces processing amount of cutting process, which reduces the cost of mobile phone shell largely.

Owner:李树忠 +1

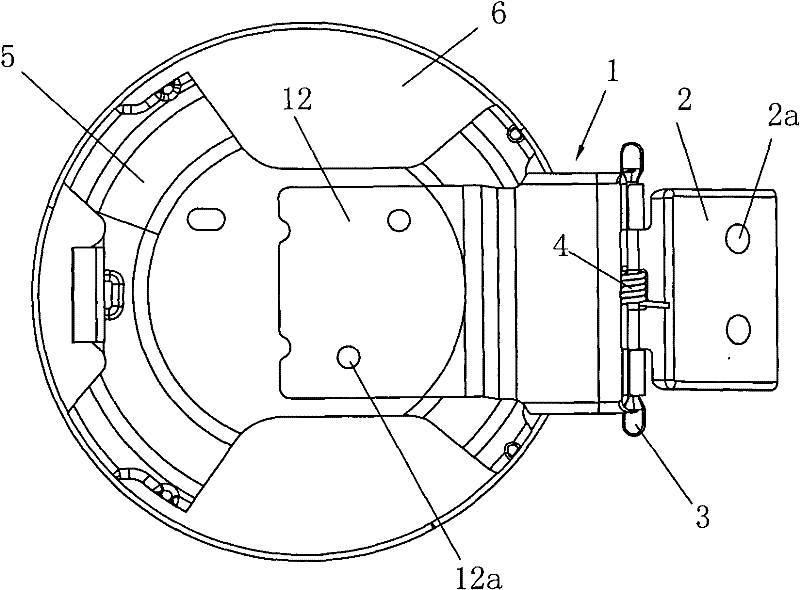

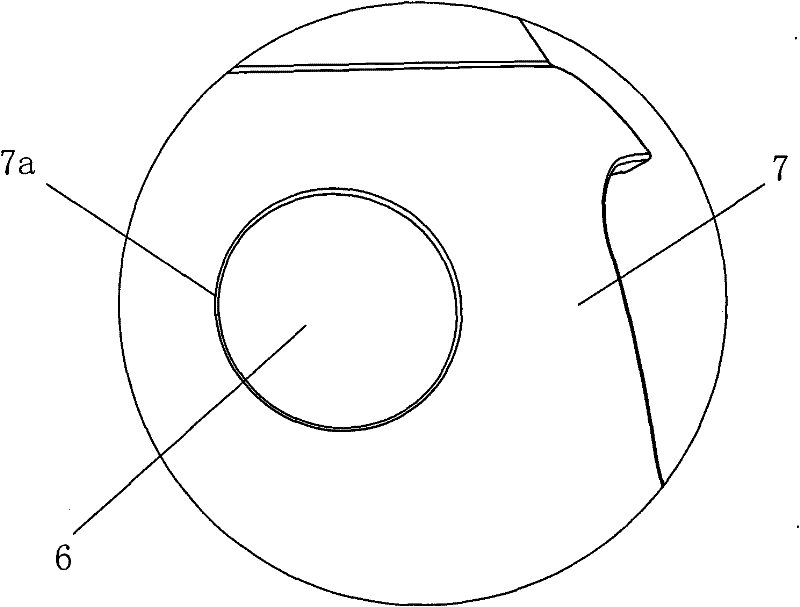

Automobile oil filler cap hinge module

InactiveCN101666193BGuaranteed Appearance RequirementsEasy to adjustSuperstructure subunitsPin hingesPetroleum engineering

The invention discloses an automobile oil filler cap hinge module which comprises an oil filler cap hinge (1), a hinge seat (2), a rotating shaft (3) and a hinge spring (4), wherein the oil filler cap hinge (1) is articulated with the hinge seat (2) by the rotating shaft (3) which is penetrated with the hinge spring (4); and a welding locating hole (12a) is welded on the oil filler cap hinge (1).The automobile oil filler cap hinge module is characterized in that mounting holes (2a) on the hinge seat (2) are strip-shaped; at least one of the welding locating holes (12a) on the oil filler cap hinge (1) is strip-shaped; and the axes in length direction of the strip-shaped holes are all parallel to the axis of the oil filler cap hinge (1). The automobile oil filler cap hinge module can conveniently adjust the matching clearance difference of an oil filler cap assembly and a side-wall shell plate hole, is convenient for adjusting the surface difference of an oil filler cap and a side-wallshell plate, improves production efficiency, and is easy to ensure the appearance of the automobile body at the oil filler.

Owner:力帆科技(集团)股份有限公司

A kind of steel plate color coating production method and production device

ActiveCN105881032BGuaranteed Appearance RequirementsGuarantee quality requirementsLiquid surface applicatorsOther manufacturing equipments/toolsSheet steelFilm-coated tablet

The invention discloses a color coating production method for steel plates. The method comprises the steps of (1a), No.1 belt material unwinding; (2a), No.1 belt material clamping feeding; (3a), No.1 belt material inlet shearing; (4) integral clamping feeding; (5) riveting; (6) flattening; (7) inlet looping; (8) degreasing; (9) water washing; (10) chemical coating; (11) chemical coating drying; (12) primary coating; (13) primary coating curing; (14) primary coating forced cooling; (15) roundabout air cooling; (16) finish coating; (17) finish coating curing; (18) finished coating forced cooling; (19) outlet looping; (20) cold film coating; (21) clamping feeding before shearing; (22) discharge shearing; (23) collection clamping feeding; and (24) winding. The invention further provides a production device for implementing the method. Through utilizing the method and the device, the coating technology of replacing paint through powder can be achieved, the environment is improved, the production efficiency of colored steel is improved, and the method and the device can be widely applied to color coating of steel plates and have good industrial production prospect and application potential.

Owner:赛高粉末技术(滨州)有限公司

A kind of manufacturing method of fastener radial marking

ActiveCN112222344BMeet the appearanceIncrease productivityForging/hammering/pressing machinesPhysicsFastener

A method for manufacturing a radial identification of a fastener, comprising the steps of vertically extending the fastener into a movable mold cavity of a lower mold of a processing device, so that the lower end of the fastener is connected in the fastener installation cavity; The upper mold moves downward relative to the lower mold, and the upper mold cavity of the upper mold is combined with the lower mold cavity to form a fastener forming cavity that matches the shape of the fastener; the raised part on the side wall of the movable mold cavity follows the movement The side wall of the mold cavity moves toward the fastener and presses radial marks on the side wall of the fastener; the upper mold moves upward, and the reset mechanism drives the movable mold body to move to the upper cavity of the limit cavity, and the side of the movable mold cavity Wall separates from fastener; remove fastener from movable cavity. The advantage of the present invention is that radial marks are processed on the side walls of the fasteners by the movable module clamping, which overcomes the technical problem that the upper and lower mould structures can only process marks on the top and bottom of the parts, and the diameter is processed through the upper and lower mould structures. to the identification.

Owner:ZHOUSHAN 7412 FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com