Riveting clamp for assembling plates of radiator

A technology for riveting fixtures and mounting plates, applied in the field of fixtures for riveting radiator mounting plates and process equipment, can solve the problems of deformation of the mounting plate and the core, easy loosening of the mounting plate, and easy damage to the heat dissipation belt, so as to avoid lodging and riveting. Robust and reliable, reducing the effect of manual finishing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

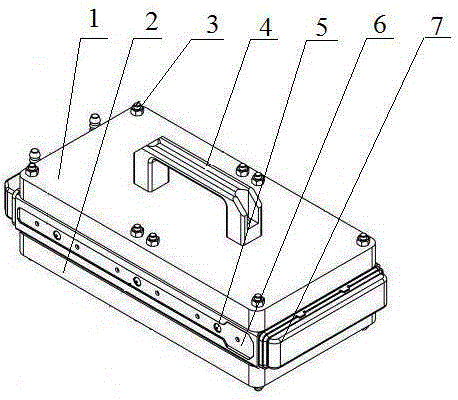

[0010] Such as figure 1 Shown: In order to fix securely and position accurately, the number of upper limit screws 3 on the upper base plate 1 and lower base plate 2 is the same as the number of mounting holes on the riveted mounting plate 6, and their positions correspond to the positions of the mounting holes.

[0011] In the riveting process, the left and right mounting plates are first assembled to the designated positions of the heat dissipation core assembly 7, and then the upper substrate 1 and the lower substrate 2 are buckled on the heat dissipation core assembly 7, wherein the upper substrate 1 and the lower substrate 2 The upper limit screw 3 is assembled into the corresponding mounting hole of the mounting plate 6 for positioning, and at the same time, the limit cavity part of the upper base plate 1 and the lower base plate 2 limits the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com