Automobile oil filler cap hinge module

A technology of fuel filler cap and hinge assembly, which is applied to vehicle parts, hinges with pins, door/window accessories, etc., can solve the problems of manual correction, low production efficiency, and difficulty in wearing sleeves at the same time, so as to achieve easy adjustment and consistency, improve Production efficiency, ensure the effect of appearance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

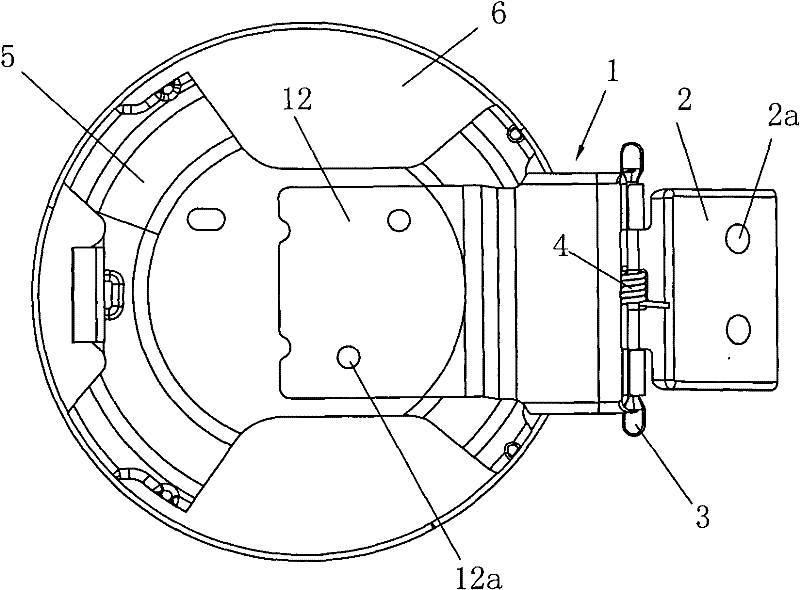

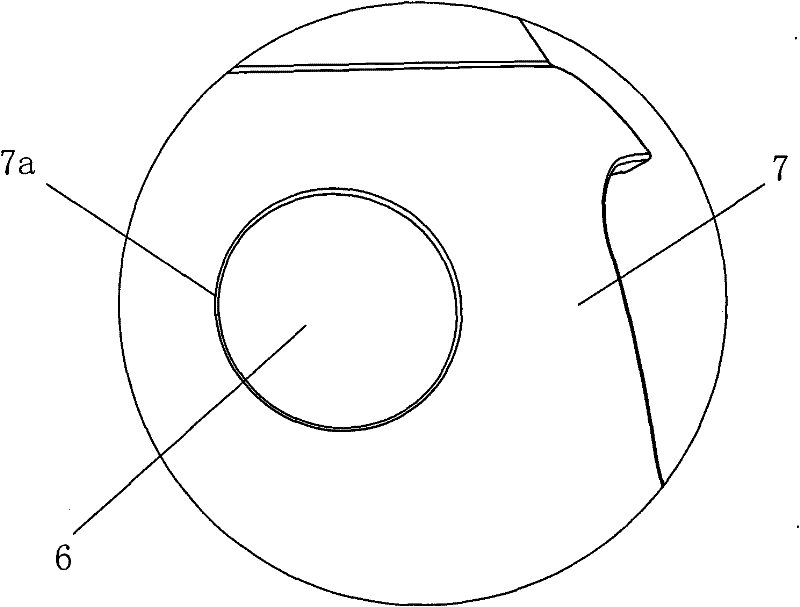

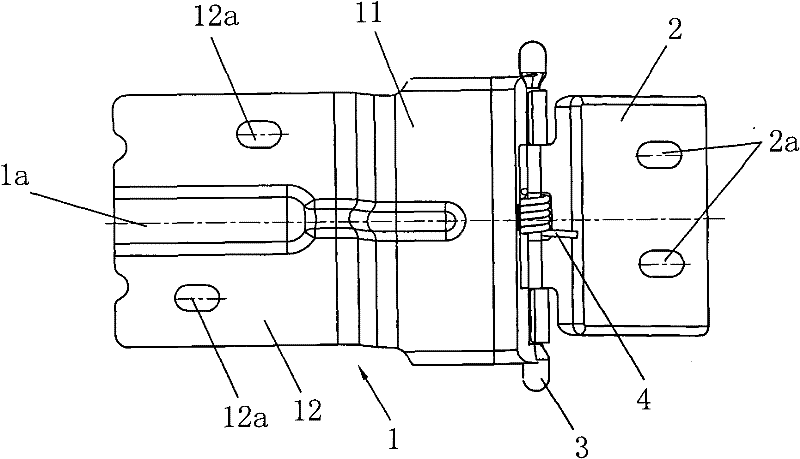

[0024] Such as image 3 with Image 6 As shown, the present invention is an automobile fuel filler cap hinge assembly, which is composed of a fuel filler cap hinge 1, a hinge seat 2, a rotating shaft 3 and a hinge spring 4, wherein the fuel filler cap hinge 1 and the hinge seat 2 are metal stamping parts, The fuel filler cap hinge 1 is hinged to the hinge seat 2 through the rotating shaft 3 .

[0025] Such as image 3 , Figure 5 with Image 6 As shown, the fuel filler cap hinge 1 includes a U-shaped bending part 11 and a horizontal mounting plate 12, one side of the opening end of the U-shaped bending part 11 is hinged with the hinge seat 2, and the other side is connected with the horizontal mounting plate 12. Both ends of the hinged end of the U-shaped bent portion 11 of the lid hinge 1 are curled outward to form two sections of hinge shaft holes 11a....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com