Fiber sheet tensioning device and its tensioning method

A tensioning device and plate technology, which is applied in building maintenance, bridge maintenance, and building material processing, can solve problems such as low bonding strength, sheet warping, and reduced sheet use efficiency, so as to improve bonding performance and enhance Reinforcement effect, effect of improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

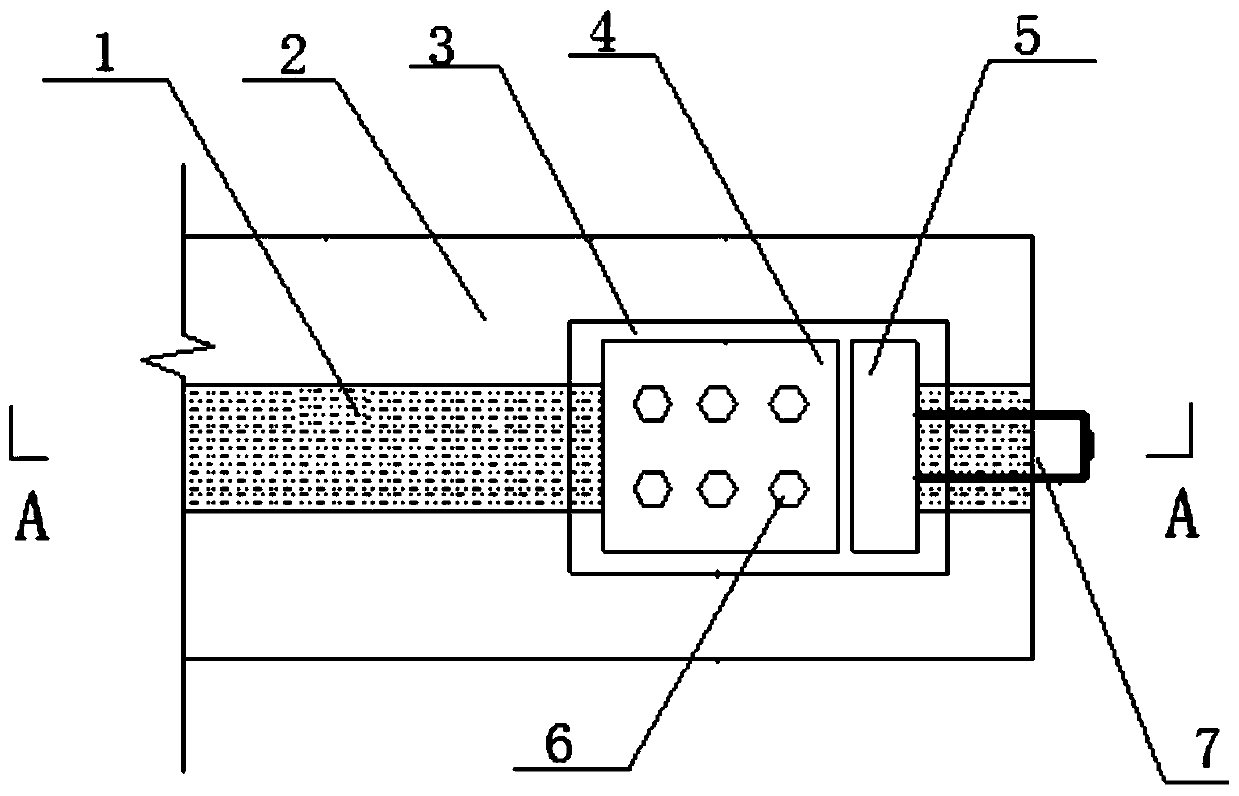

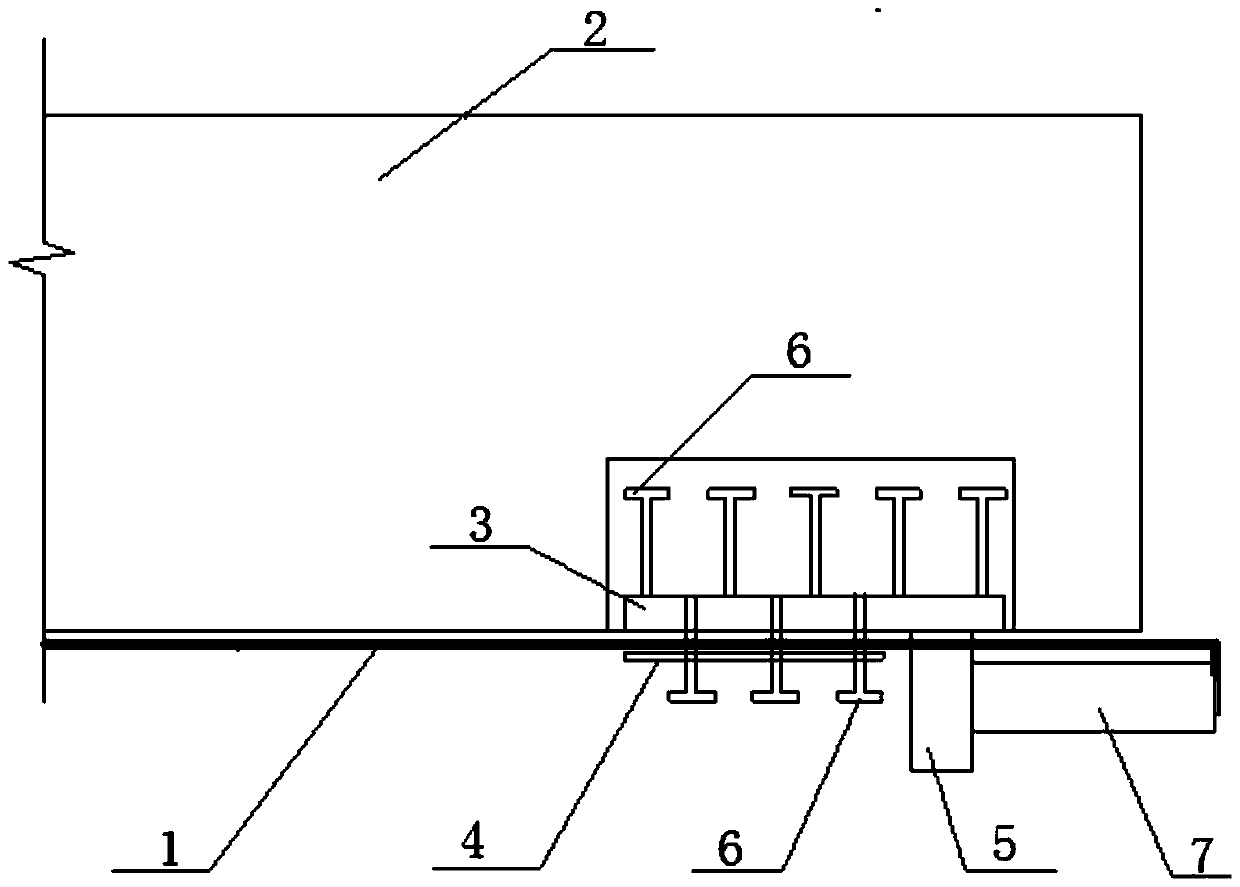

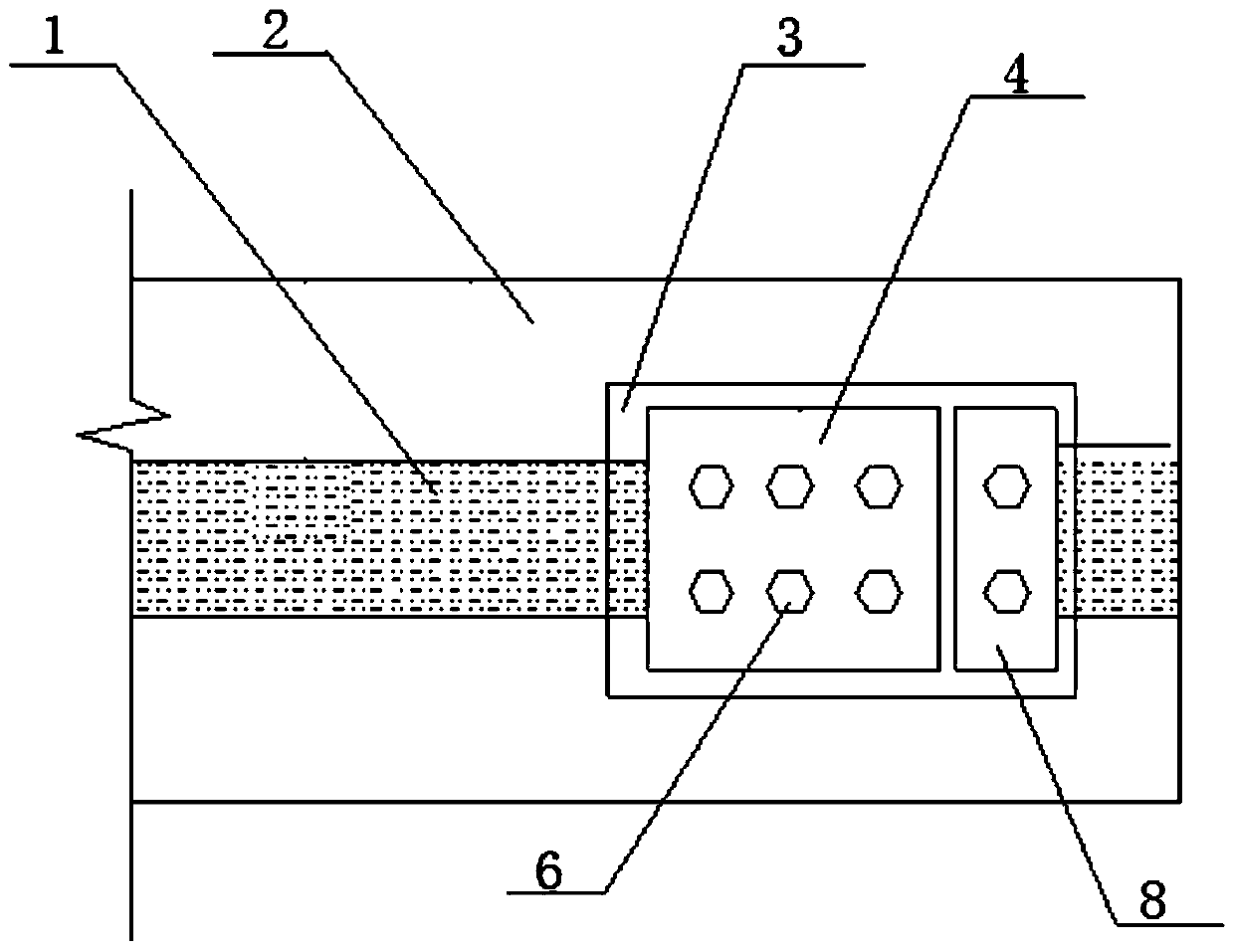

[0033] Such as Figure 1~6 The schematic structural diagram of the fiber sheet tensioning device of the present invention is shown, including a fiber sheet 1, a beam plate 2, a fixed steel plate 3, a first anchor steel plate 4, a counter force device 5, a bolt 6, a jack 7 and a second anchor steel plate 8.

[0034] One end of the surface reinforcement position of the beam plate 2 is grooved, and a fixed steel plate 3 is arranged in the groove. The outer surface of the fixed steel plate 3 is set flush with the surface of the beam plate 2. The other end is fixed to the fixed steel plate 3; the fiber plate 1 and the fixed steel plate 3 are fixed by the first anchor steel plate 4 and the second anchor steel plate 8, and the first anchor steel plate 4 is arranged at one end of the fixed steel plate 3 in the longitudinal direction , the second anchoring steel plate 8 is arranged on the other end of the fixed steel plate 3 in the length direction; the inside of the beam plate 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com