Automatic black glue dispensing technique and automatic glue dispensing device

An automatic dispensing and dispensing device technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of poor product appearance consistency, high personnel costs, and affecting product quality, so as to ensure product appearance Requirements, saving costs and resources, and the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

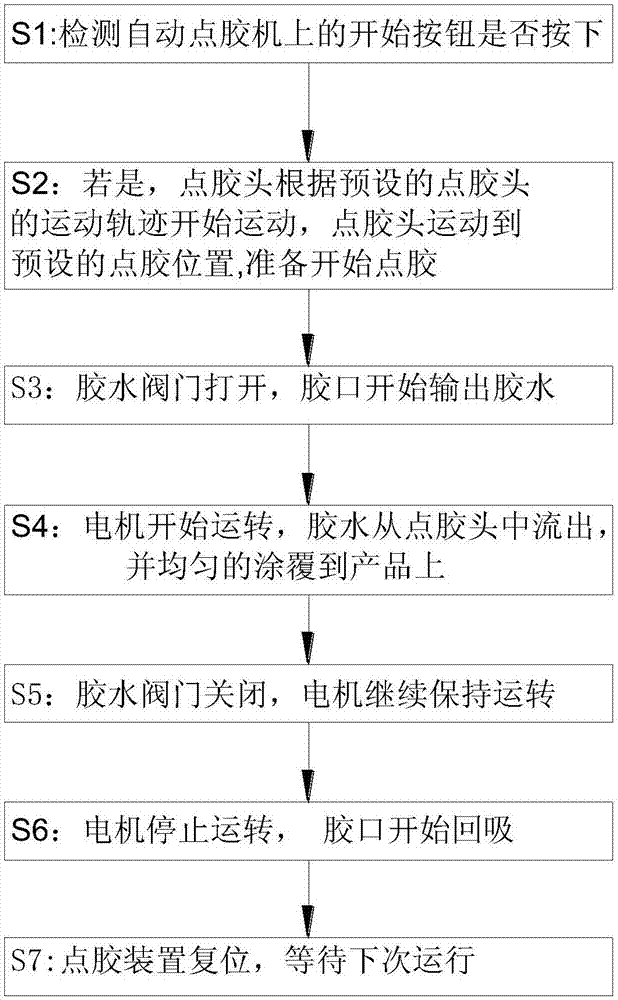

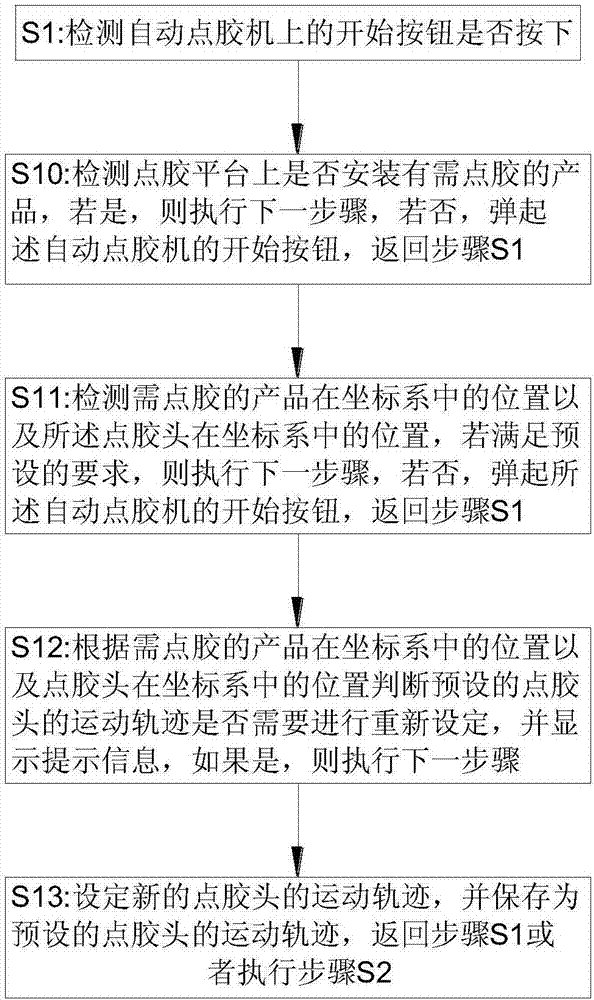

[0047] like figure 1 As shown, the invention is realized in this way: an automatic dispensing process for black glue is applied to an automatic dispensing machine 1, the automatic dispensing machine 1 includes a dispensing device, a dispensing platform, and the dispensing device includes a dispensing head, a glue valve, The glue port, the motor, and the process include the following steps:

[0048] S1: detect whether the start button on the automatic glue dispenser 1 is pressed;

[0049] S2: If yes, the dispensing head starts to move according to the preset trajectory of the dispensing head, and the dispensing head moves to the preset dispensing position, ready to start dispensing;

[0050] S3: The glue valve is opened, and the glue port starts to output glue;

[0051] S4: The motor starts to run, the glue flows out from the dispensing head, and is evenly coated on the product;

[0052] S5: The glue valve is closed, and the motor continues to run;

[0053] S6: The motor st...

Embodiment 2

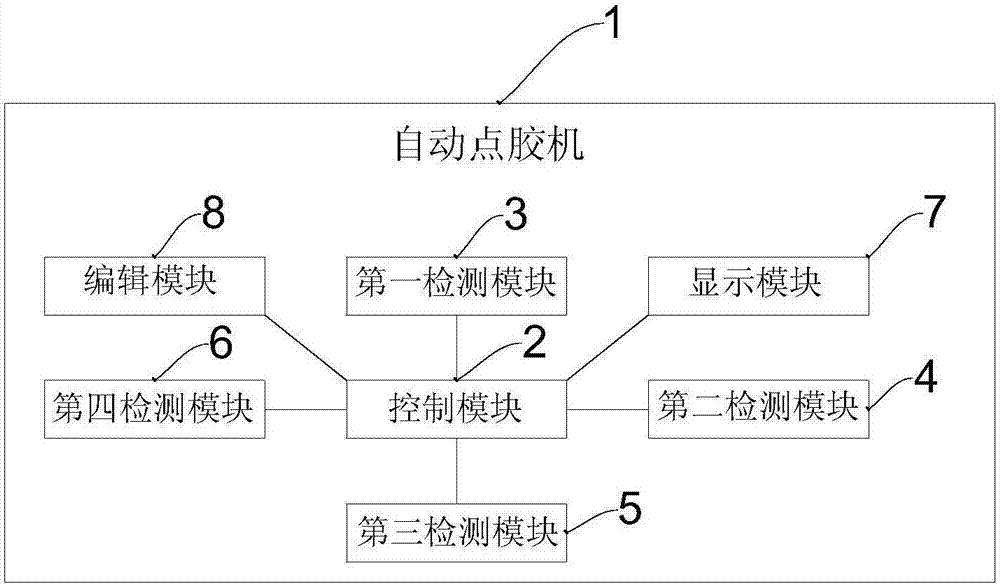

[0074] At the same time, if image 3 Shown the present invention also provides a kind of automatic dispensing device, comprises automatic dispensing machine 1, and automatic dispensing machine 1 comprises dispensing device, dispensing platform, and dispensing device comprises dispensing head, glue valve, glue port, motor , characterized in that the device also includes:

[0075] The first detection module 3 is used to detect whether the start button of the automatic glue dispenser 1 is pressed;

[0076] The control module 2 is used to control the movement of the dispensing head, control the opening and closing of the glue valve, control the operation of the motor, and control the suction back of the glue port.

[0077] like image 3 As shown, the device is based on the automatic glue dispenser 1, and all modules are installed on the automatic glue dispenser 1 or are obtained by using the original devices in the automatic glue dispenser 1 and improving it.

[0078] As can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com