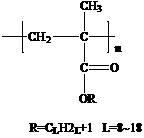

Preparation method for polymethacrylate pour point depressant

A technology of polymethacrylate and polymethacrylate higher alcohol ester is applied in the petroleum industry, lubricating composition and other directions, which can solve the problems of easy explosion, environmental pollution, inflammability and explosion, and eliminate the source of explosion. , the effect of reducing costs and shortening the response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

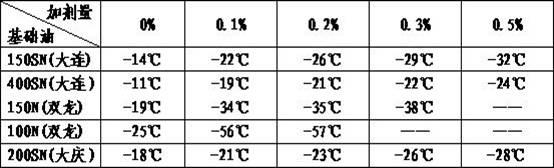

Examples

example 1

[0024] Example 1: In a 1000 mL three-necked flask equipped with a distillation head, add single C 14 428g (2mol) of fatty alcohol, 2.2mol of methacrylic acid, 2g of hydroquinone as a polymerization inhibitor, and 6.2g of sulfuric acid as a catalyst. Slowly raise the temperature. When the temperature reaches 60°C, turn on the vacuum pump to a vacuum degree of -0.1mpa for vacuum dehydration. Continue to raise the temperature and perform esterification at 95-100°C. After about 5 hours, the quality in the recovery bottle does not change, and the reaction is stopped to obtain crude tetradecyl methacrylate. After neutralizing the obtained crude product with aqueous sodium hydroxide solution to pH = 7, the organic layer was separated, washed with water and saturated brine, and dehydrated under reduced pressure by turning on the vacuum pump to obtain myristyl methacrylate with a conversion rate of 97.5%.

example 2

[0025] Example 2: In a 1000 mL three-necked flask equipped with a distillation head, add C 8 -C 18 Mixed fatty alcohol 417g (2mol), average molecular weight 208.68, 2.2mol methacrylic acid, polymerization inhibitor hydroquinone 2g, catalyst sulfuric acid 6.0g, heat up slowly, when the temperature reaches 60°C, turn on the vacuum pump to vacuum degree -0.1mpa , vacuum dehydration. Continue to raise the temperature and esterify at 95-100°C. After about 5 hours, the quality in the recovery bottle does not change, and the reaction is stopped to obtain the crude mixed higher alcohol methacrylate. After neutralizing the obtained crude product with aqueous sodium hydroxide solution to pH = 7, separate the organic layer, wash the organic layer with water, and wash with saturated brine, then turn on the vacuum pump for dehydration under reduced pressure to obtain mixed higher alcohol methacrylate with a conversion rate of 96.8% .

example 3

[0026] Example 3: Replace the sulfuric acid in Example 2 with 6.0 g of p-toluenesulfonic acid to obtain mixed higher alcohol methacrylate with a conversion rate of 96.5%.

[0027] 2. Distillation and purification

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com