Concrete crack surface cut groove sealing and blocking structure and method

A technology of concrete and grooving, which is applied in the direction of building structure, construction, and building material processing, etc. It can solve the problems of inapplicability of thin-walled structures, large chisel removal volume, and increased engineering cost, so as to achieve firm and reliable plugging quality, Reduction of engineering costs and remarkable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

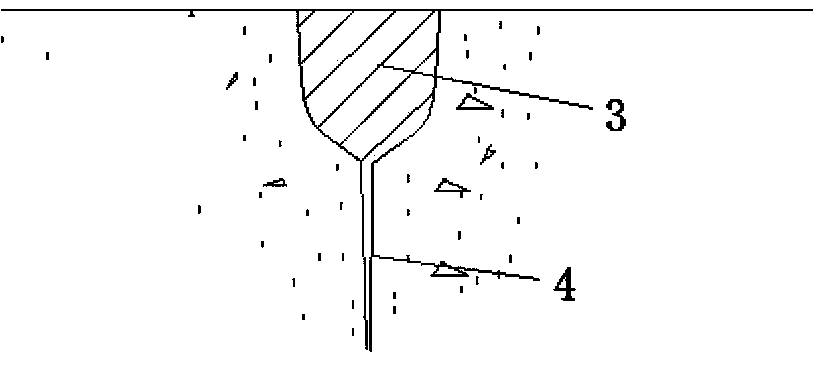

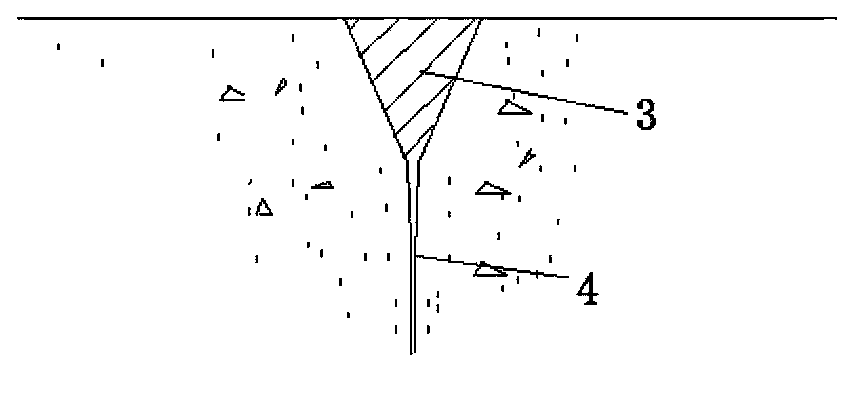

[0029] figure 1 and figure 2 It is a schematic diagram of two cutting groove shapes during construction at present, and the concrete crack 4 is sealed by using the cementitious material 3 .

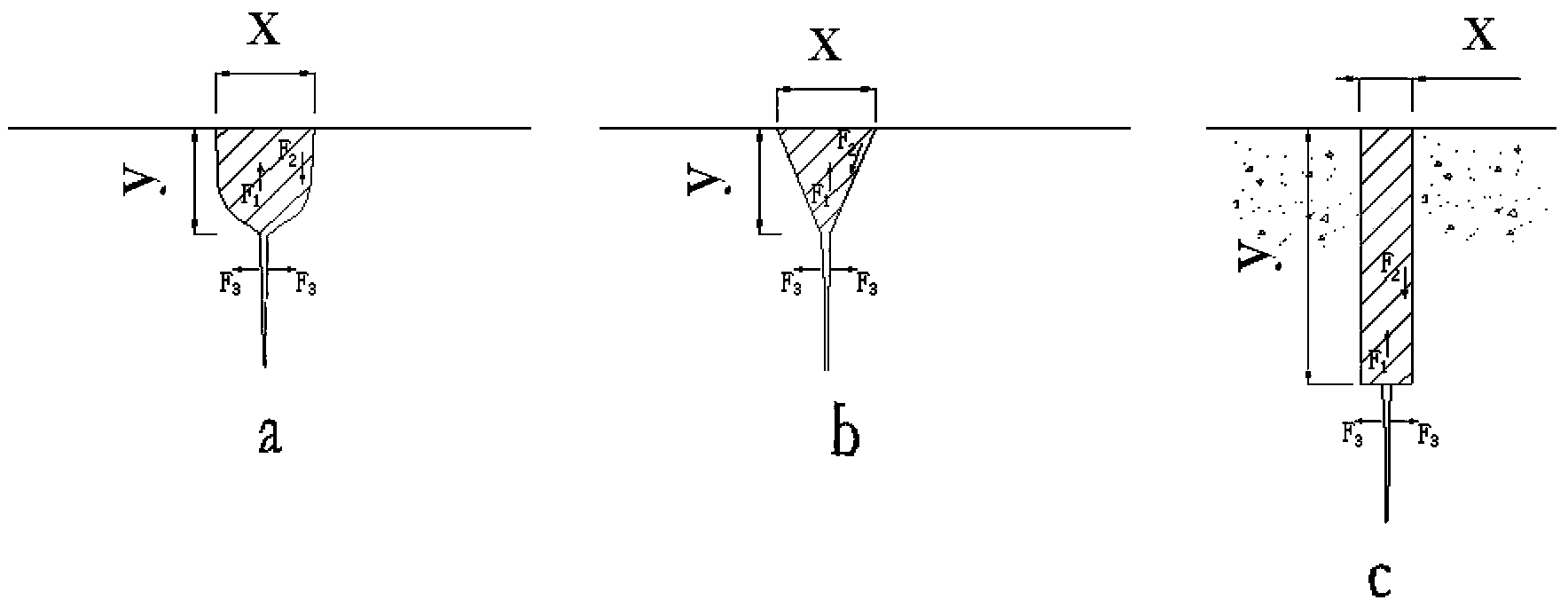

[0030] like image 3 As shown, a is the use of "U"-shaped grooves, b is the use of "V"-shaped grooves, c is the use of the groove structure provided by the present invention, the groove structure adopts the width and depth of the section along the crack direction than a small rectangular structure.

[0031] Analyzing the structure of traditional V-shaped or U-shaped grooves, it is not difficult to find that during the grouting process, the grout in the gap has an outward force F1 to push the filling gel material outwards. Whether the material is pushed out depends on the material. In addition to the size of the bonding force F2 on the edge of the groove, it is also related to the length y of the edge of the groove. Obviously, when the bonding force between the cementitious material an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com