Metal coiled material color-coating production method and production apparatus thereof

A technology of metal coils and production methods, applied in lamination devices, chemical instruments and methods, layered products, etc., to achieve the effects of reducing investment costs, avoiding bending, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

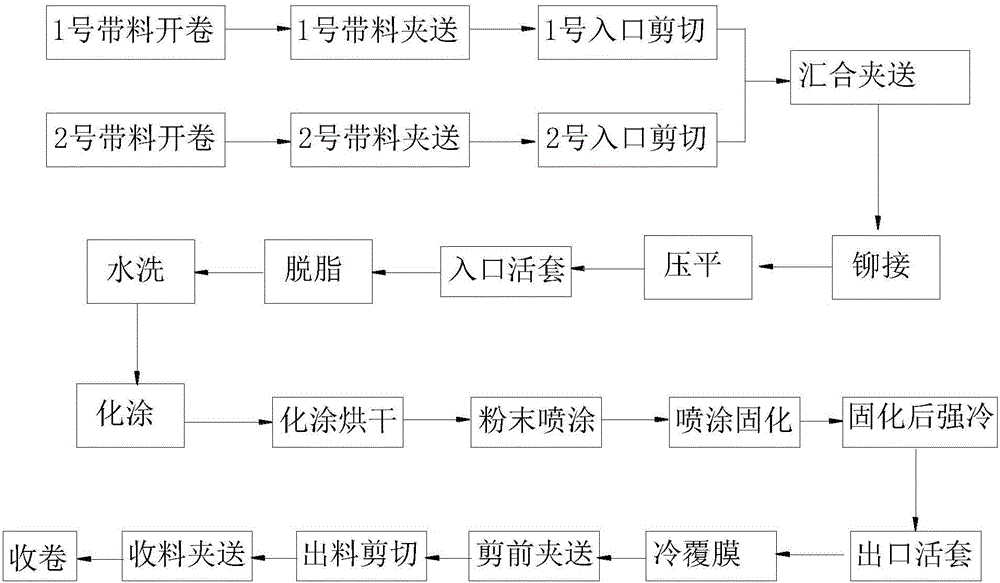

[0042] Such as figure 1 As shown, the present invention provides a kind of metal coil color coating production method, described metal coil color coating production method mainly comprises the following production steps: (1a) No. The material roll is gradually unrolled; (2a) No. 1 strip is pinched, and the No. 1 metal coil is conveyed downstream by a pinch device; (3a) No. 1 strip is cut at the entrance; (1b) No. 2 strip is uncoiled, and the No. Uncoiler, gradually unfolding the No. 2 metal coil material; (2b) No. 2 strip material pinching, using the pinch mechanism to transport the No. 2 metal coil material downstream; (3b) No. 2 strip material entrance shearing; (4 ) converging and pinching, the No. 1 and No. 2 strips are jointly conveyed downstream; (5) riveting, using a riveting welding machine to combine the No. 1 and No. 2 strips together, so that the No. 1 strip will be (6) flattening, using a roller press mechanism to press the No. 1 and No. 2 strips together; (7) Inl...

Embodiment 2

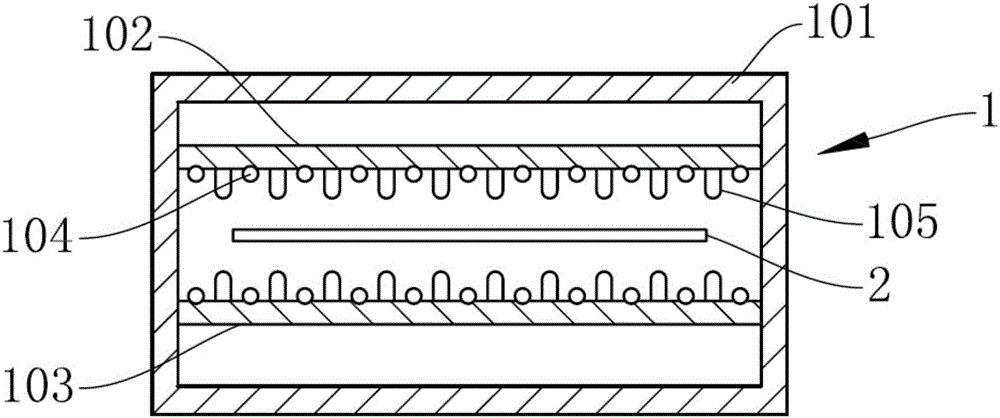

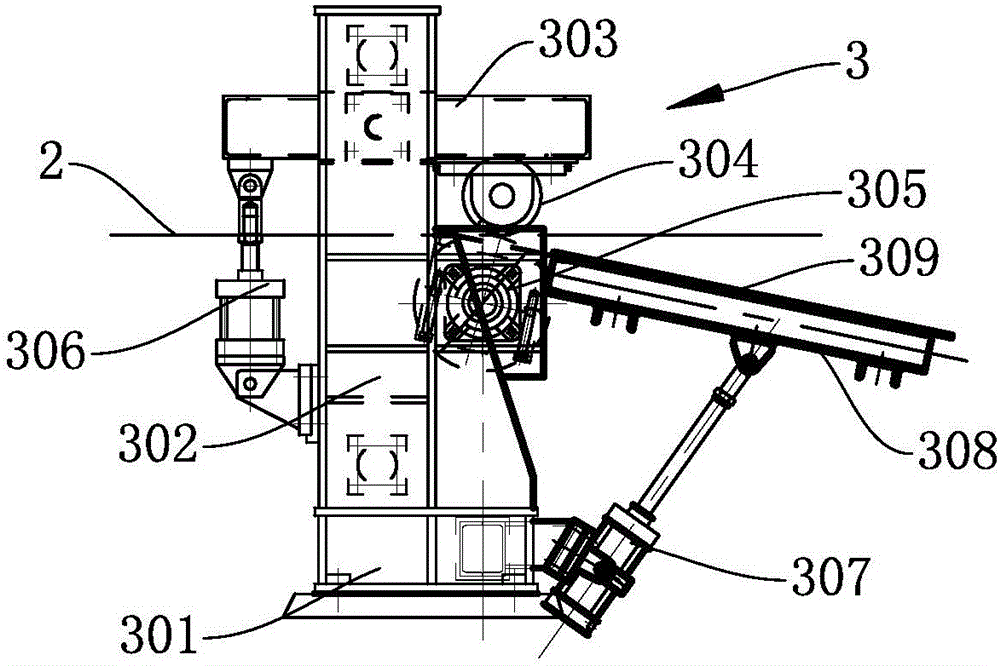

[0049] Such as Figure 1 to Figure 5 Commonly shown, the present invention also provides a metal coil color coating production device, the metal coil color coating production device mainly includes No. 1 strip uncoiling device, No. 1 strip pinch device, 1 No. strip material inlet shearing device, converging pinch device, riveting device, flattening device, inlet looper device, degreasing device, water washing device, chemical coating machine, chemical coating drying device, spraying device, curing furnace, after curing Cold device 5, export looper device, cold lamination device, pre-shear pinch device, discharge shear device, receiving pinch device and winding device.

[0050] Wherein, in parallel with the No. 1 strip material uncoiling device, No. 1 strip material pinch device and No. 1 strip material inlet shearing device, No. 2 strip material uncoiler device, No. 2 strip material pinch device and No. 2 strip material The material entrance shearing device, the No. 1 strip m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com