A polishing method for small ceramic products

A technology for ceramics and products, applied in the polishing field of small ceramic products, can solve the problems of poor uniformity and consistency of size of ceramic products, inability to adapt to polishing, inability to adapt, etc., to ensure smoothness and appearance requirements, and improve polishing efficiency. , The effect of reducing the shape and structure requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the specific implementation manner of this patent is described in further detail.

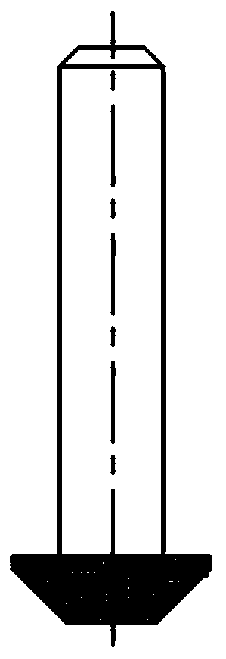

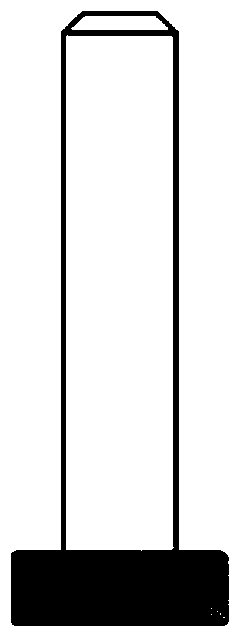

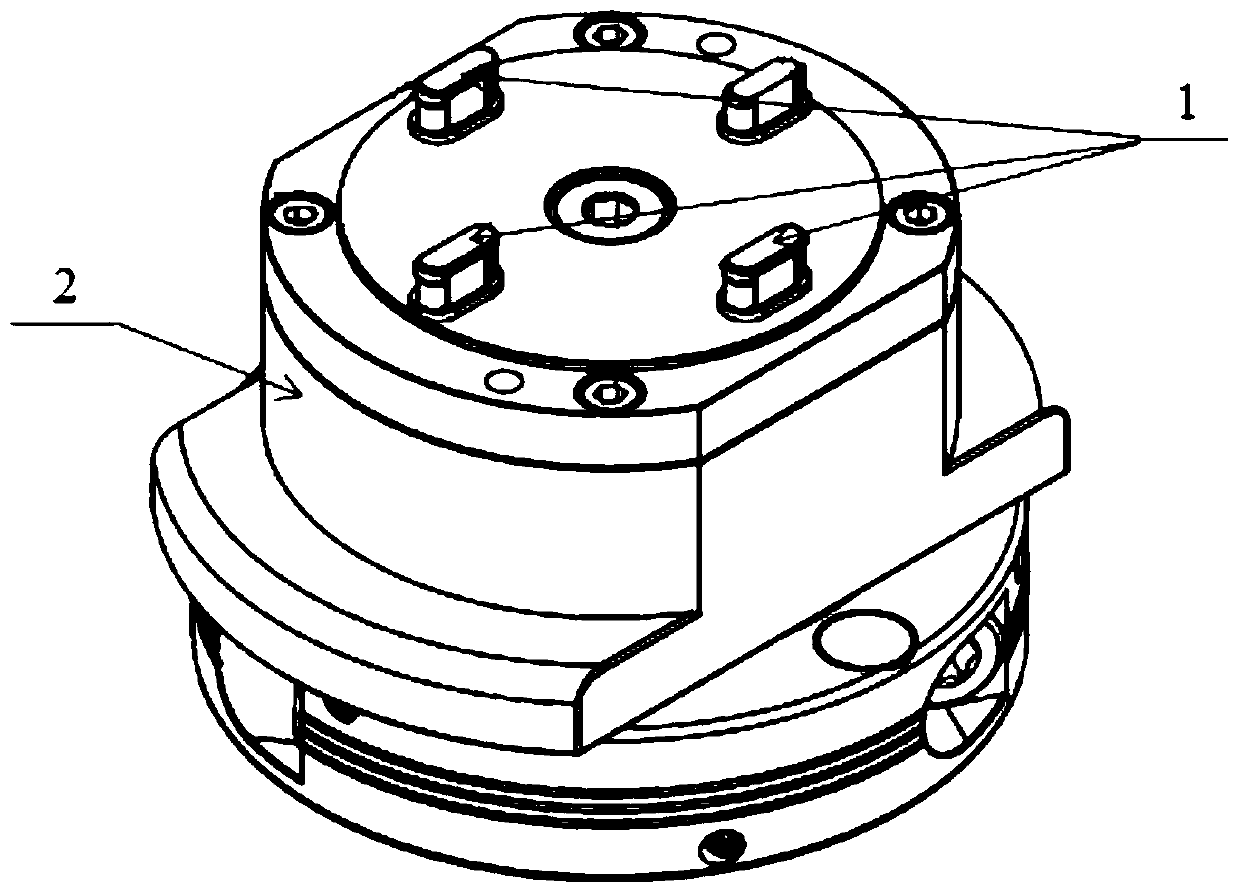

[0029] In the present invention, CNC is equipped with JDJK-500E CNC engraving machine, image 3 There are four clamping positions on the jig shown, and the four pieces of ceramic products placed respectively are polished sequentially one by one, so the polishing efficiency of the method provided by the present invention is slightly lower than other methods, so for large and regular shaped Ceramic products are suitable for polishing by other conventional polishing methods.

[0030] image 3 The small pieces of ceramic products are roughly in the shape of a cuboid, and the clamp clamps the lower half of each product. Generally, the length of the small piece of ceramic products to be polished is less than 15 mm, the width is less than 10 mm, and the height is less than 5 mm. The exposed part includes four sides, that is, the shape, and the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com