Production method and products of metal exposed terminals

A production method and leakage terminal technology, applied in electrical components, circuits, connections, etc., can solve the problems of low product production efficiency, high labor costs, waste of precious metal Au, etc., to achieve enhanced soldering effect, improve production efficiency, and create benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

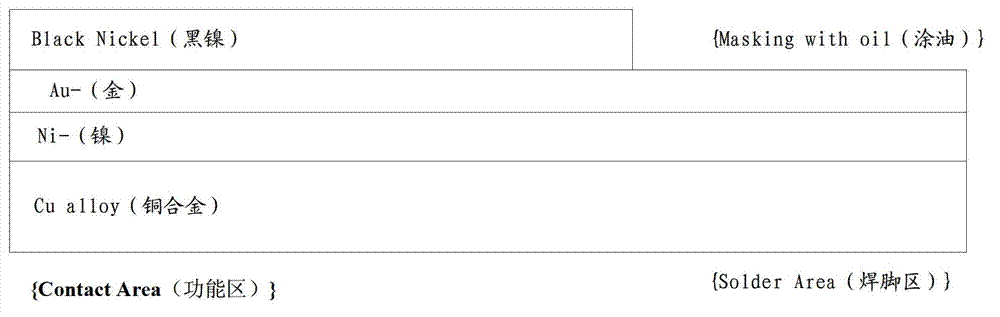

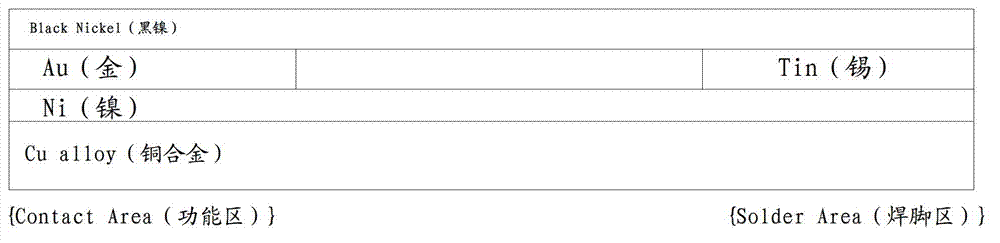

[0026] In view of the defects of high material cost caused by continuous plating of precious metal gold in the prior art and high labor cost when manually oiling the solder leg, in the embodiment of the present invention, the structure of the metal leakage terminal is redesigned and a different process is adopted Process production, specifically, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

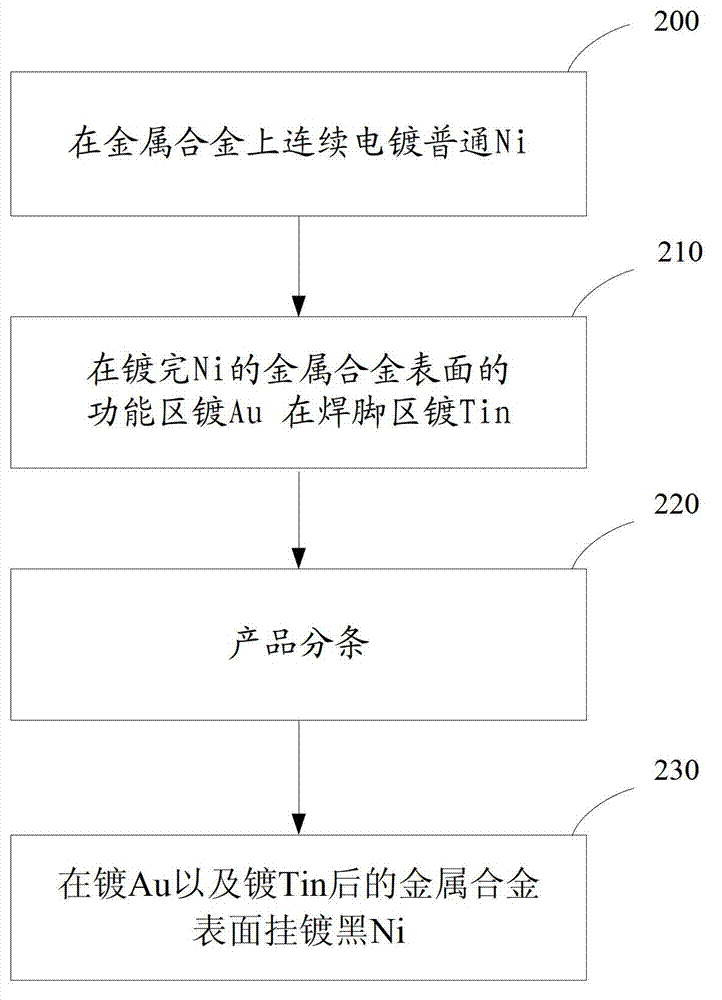

[0027] refer to figure 2 As shown, in the embodiment of the present invention, the detailed process of manufacturing the metal leakage terminal is as follows:

[0028] Step 200: Continuous electroplating of common Ni on the metal alloy.

[0029] In the embodiment of the present invention, preferably, the metal alloy may be Cu alloy.

[0030] Step 210 : plating Au on the functional area of the Ni-plated metal alloy surface, and plating Tin (tin) on the solder leg area.

[0031] In the embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com