Preparation method of solderable silver-coated nickel conductive layer and automatic screen printing silver-coated device

A conductive layer, silver-nickel technology, applied in screen printing, screen printing machine, printing and other directions, to achieve the effect of simple and convenient operation, low cost, good consistency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of a solderable silver-coated nickel conductive layer, specifically comprising the following steps:

[0035] (1) Nano-Ni-B powder is used, mixed with glass powder, ethyl cellulose, and terpineol in proportion, and rolled with a three-roll mill to prepare the corresponding nickel paste.

[0036] (2) Mix silver particles of 20-50nm with glass powder, ethylene glycol, and ethyl cellulose in proportion, and ultrasonically treat them in an ultrasonic tank for 30-80 minutes to prepare nano-silver paste.

[0037] (3) Using automatic screen printing silver coating equipment, the nickel paste prepared above is first screen printed on the processed alumina ceramic substrate through an automatic screen printing machine, and then the screen printed alumina ceramic substrate is transferred to the automatic On the working table of the drip silver paste machine, drip low-viscosity nano-silver paste on the surface of the nickel paste to be welded.

[0038] (4) Sen...

Embodiment 1

[0045] 1. Mix nano-Ni-B powder with glass powder, ethyl cellulose, and terpineol in proportion, and roll it with a three-roll mill to prepare the corresponding nickel paste.

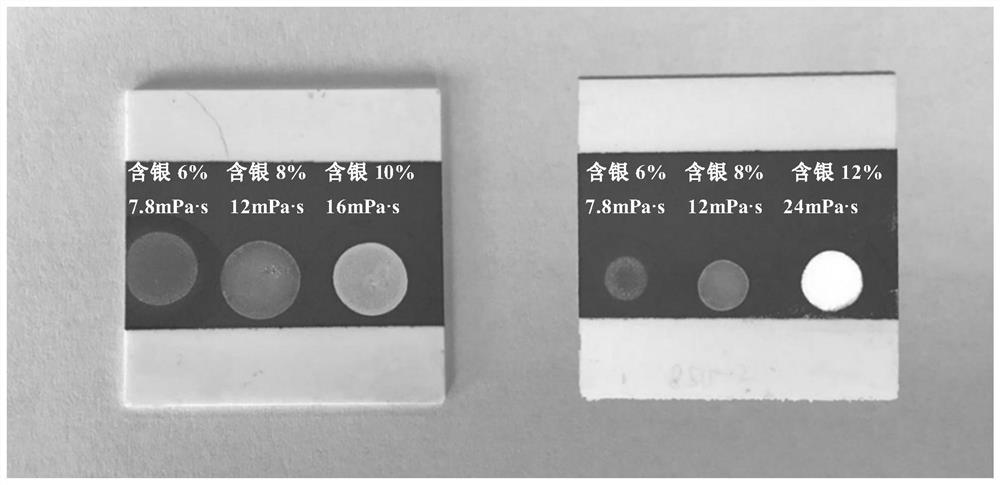

[0046] 2. Mix silver particles with an average particle size of 25nm with glass powder, ethylene glycol, and ethyl cellulose in proportion, and ultrasonically treat them in an ultrasonic tank for 70 minutes to obtain a glass phase with a silver content of 10%. Nano-silver paste with a content of 0.8% and a viscosity of 16mPa·s.

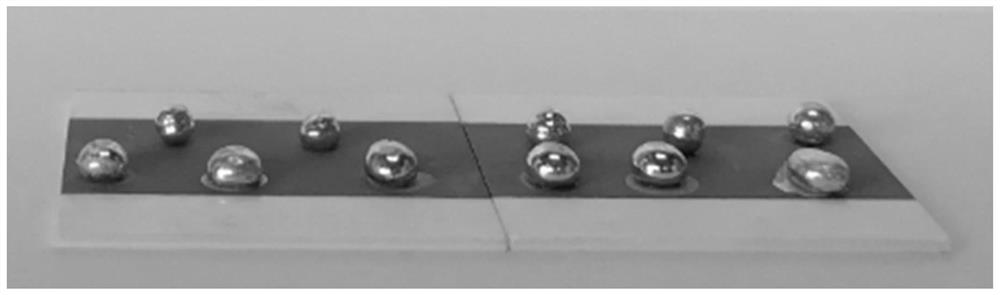

[0047] 3. Using automatic screen printing silver coating equipment, the nickel paste prepared above is first screen printed on the processed alumina ceramic substrate through the automatic screen printing machine, and then the screen printed alumina ceramic substrate is transferred to the automatic drop by the robot. On the workbench of the silver paste machine, drop 0.3g of nano-silver paste on the surface of the nickel paste to be welded.

[0048] 4. Send the ceramic sheets d...

Embodiment 2

[0053] 1. Mix Ni-B powder with glass powder, ethyl cellulose, and terpineol in proportion, and roll it with a three-roll mill to prepare the corresponding nickel paste.

[0054] 2. Mix silver particles with an average particle size of 47nm with glass powder, ethylene glycol, and ethyl cellulose in proportion, and ultrasonically treat them in an ultrasonic tank for 35 minutes to obtain a glass phase with a silver content of 12%. Nano-silver paste with a content of 1.2% and a viscosity of 24mPa·s.

[0055] 3. Using automatic screen printing silver coating equipment, the nickel paste prepared above is first screen printed on the processed alumina ceramic substrate through the automatic screen printing machine, and then the screen printed alumina ceramic substrate is transferred to the automatic drop by the robot. On the workbench of the silver paste machine, drop 0.8g of nano-silver paste on the surface of the nickel paste to be welded.

[0056] 4. Send the ceramic sheets drippe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com