Patents

Literature

36results about How to "Create benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

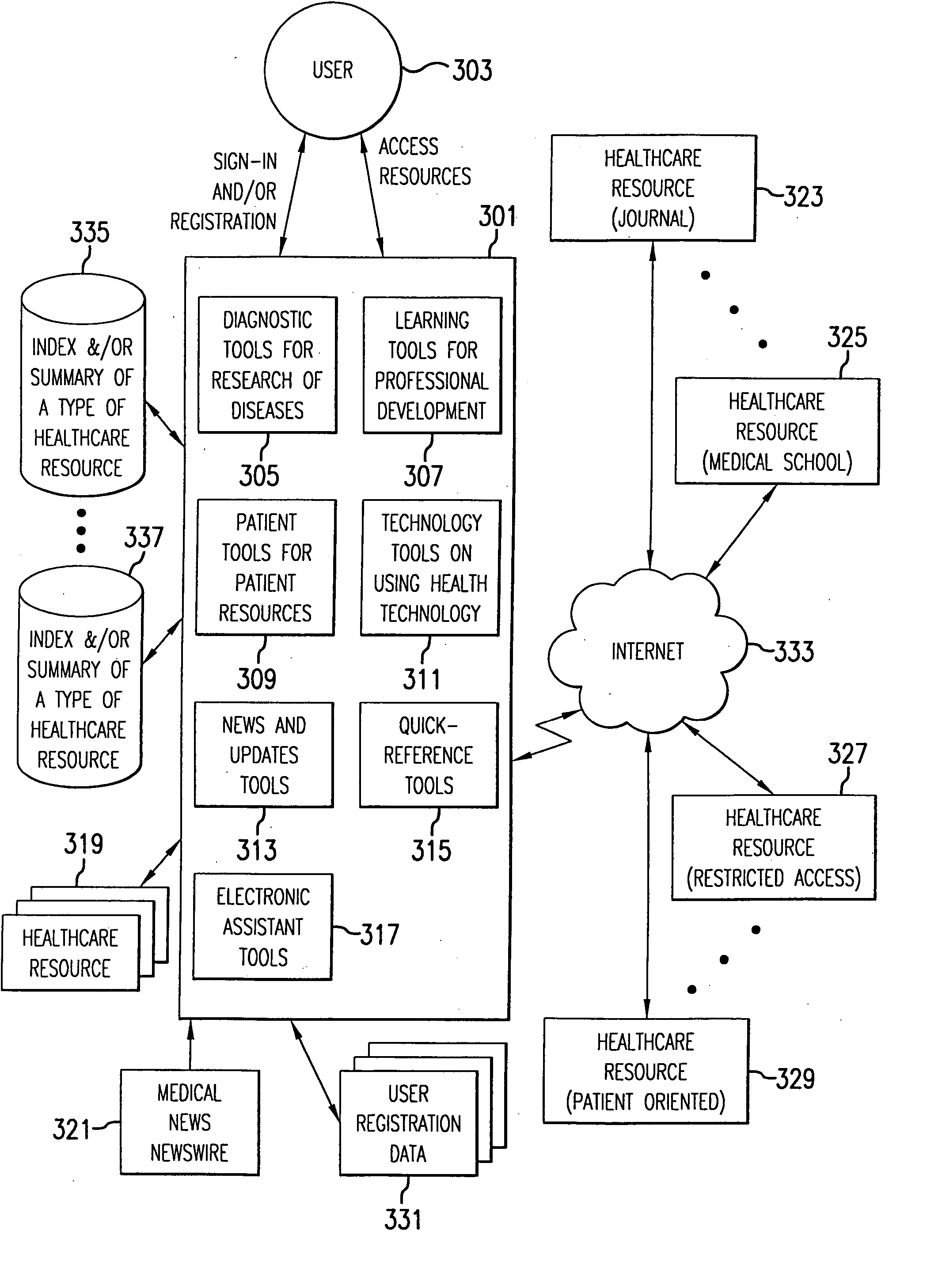

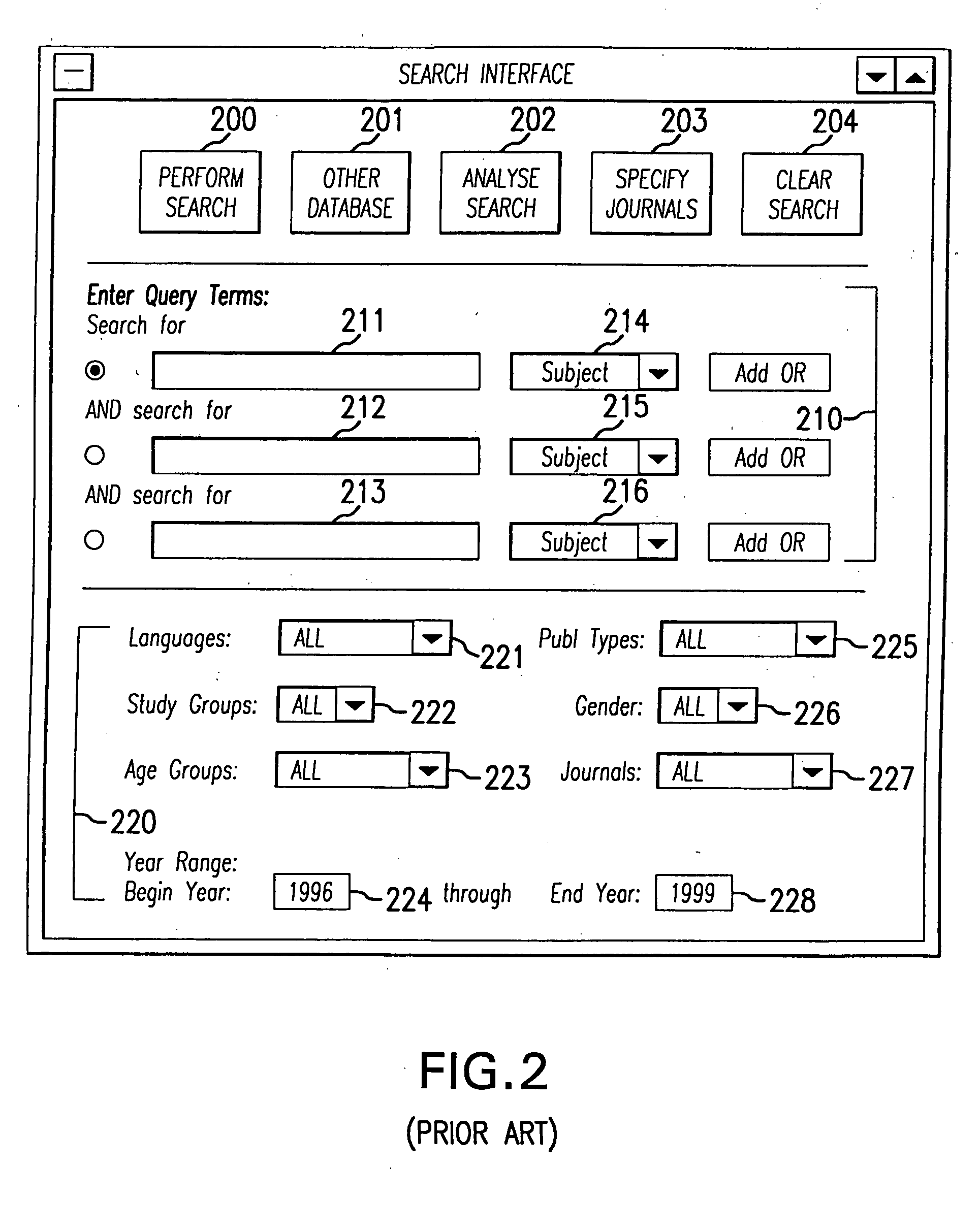

Computer assisted and /or implemented process and system for conducting searches in healthcare provider medical information portals

InactiveUS20050108216A1Alleviate deficiencyMore targetedData processing applicationsCathode-ray tube indicatorsInformation retrievalMouse button

A method, system, and computer program device implements a search in, for example, a healthcare provider medical information portal. For example, instead of having to type or key a search item into an interface, the search may be conducted, automatically, for data records relevant to the item by executing a search query event. More particularly, the search query event identifies the item, which may be displayed in a user interface, to be searched. In addition to identifying the item, the search query event also initiates the search. In one example, the search query event includes positioning a cursor over a phrase, term or other item displayed on a webpage and clicking a mouse button. The present invention requires fewer interactions to execute a search. The search technique may be implemented with any type of portal.

Owner:MERCK & CO INC

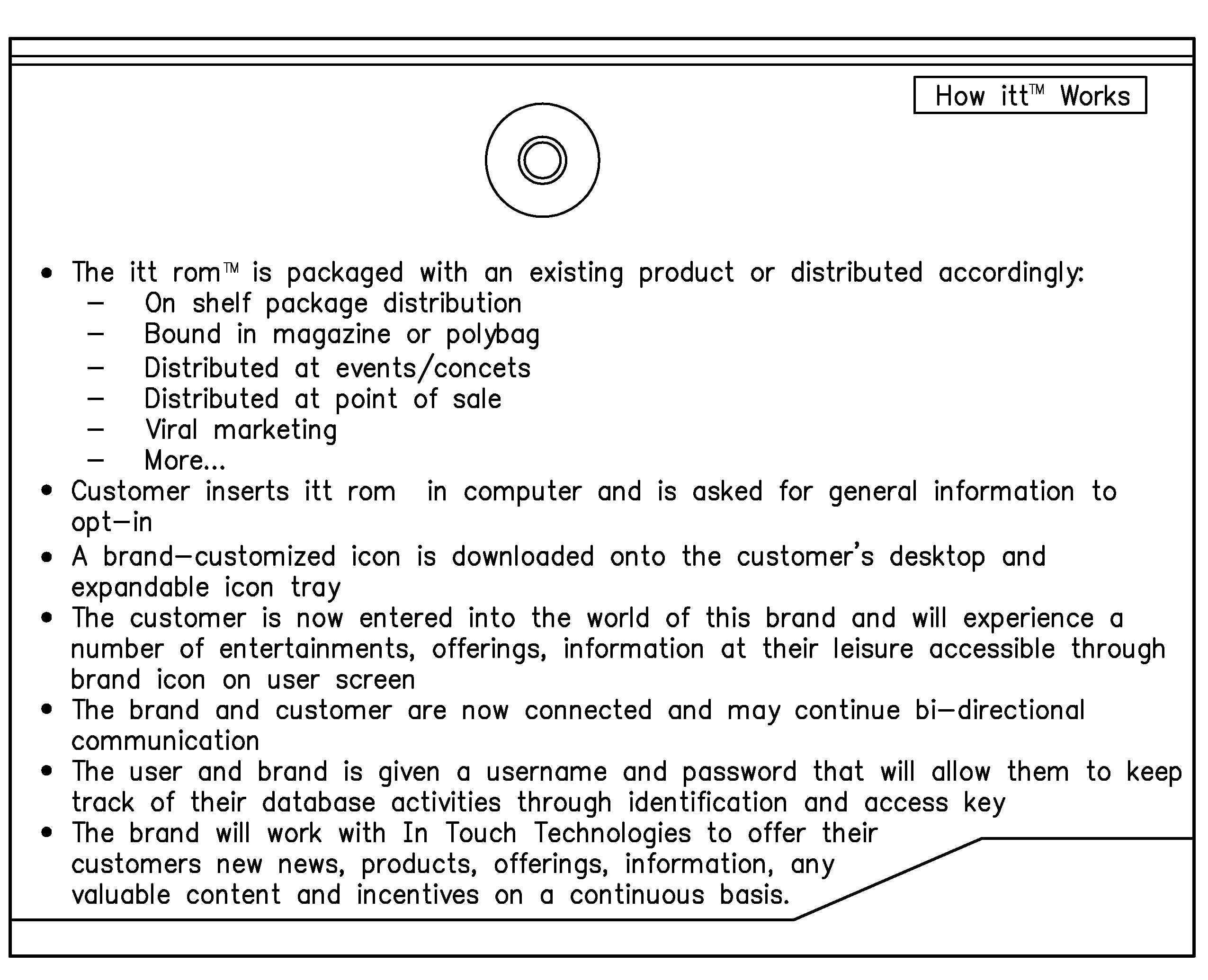

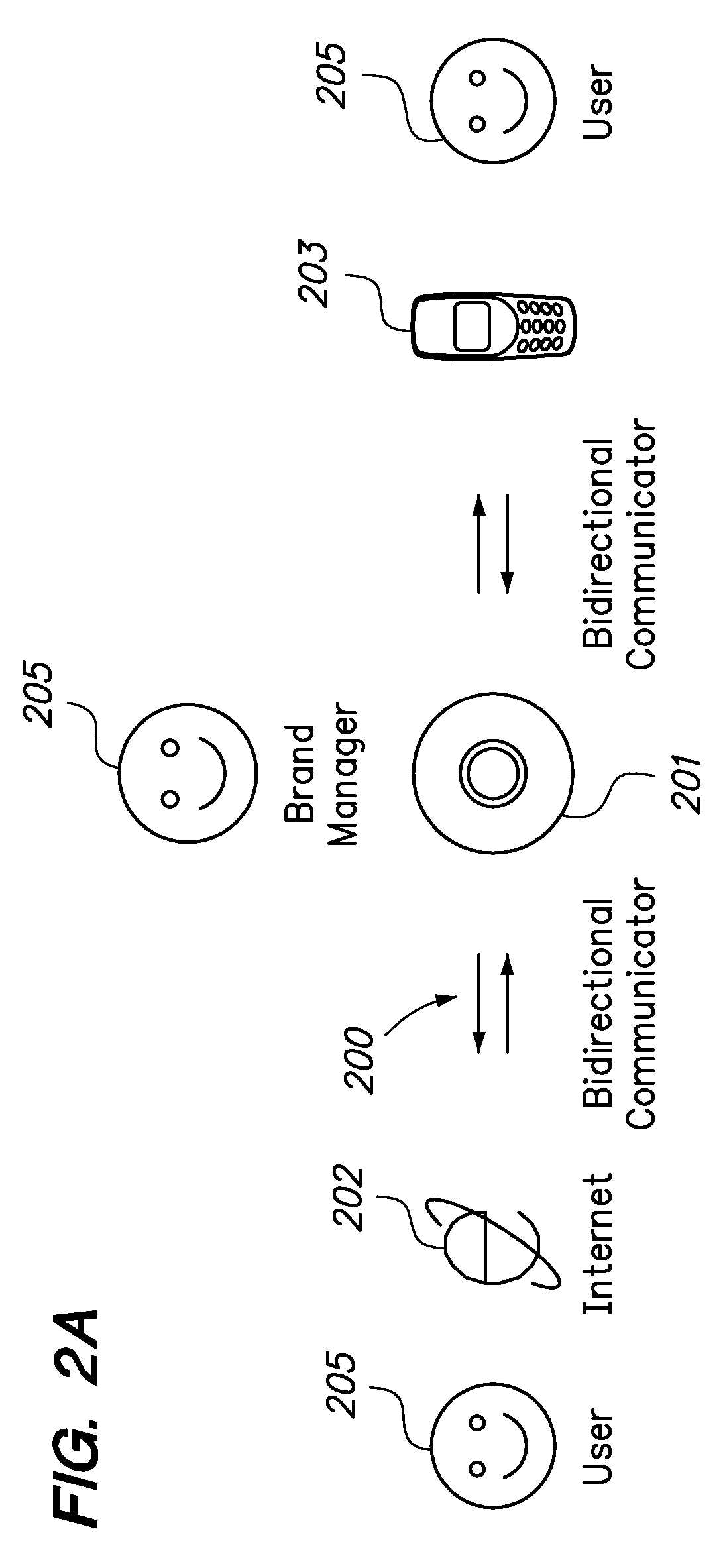

System and Method For Enabling Bi-Directional Communication Between Providers And Consumers of Information In Multi-Level Markets Using A Computer Network

A system and method for enabling continuous bidirectional communication between providers and consumers of information through a computer and telephone network to exchange product and preference information. The system and method of the invention provides a database having accounts for providers and consumers. Each account contains contact, warranty, product, system usage, and billing information for providers, and contact, demographic, product preference, contact permissions, and usage history information for consumers. The invention provides an area for consolidation of all provider access points in a taskbar on the user's computer or communication device. The invention creates an ad reviewing cart that allows users to select providers and content to be received. An information warehouse manager is employed to receive data from providers and users. A commission accounting module calculates commissions.

Owner:QUBEEY INC +1

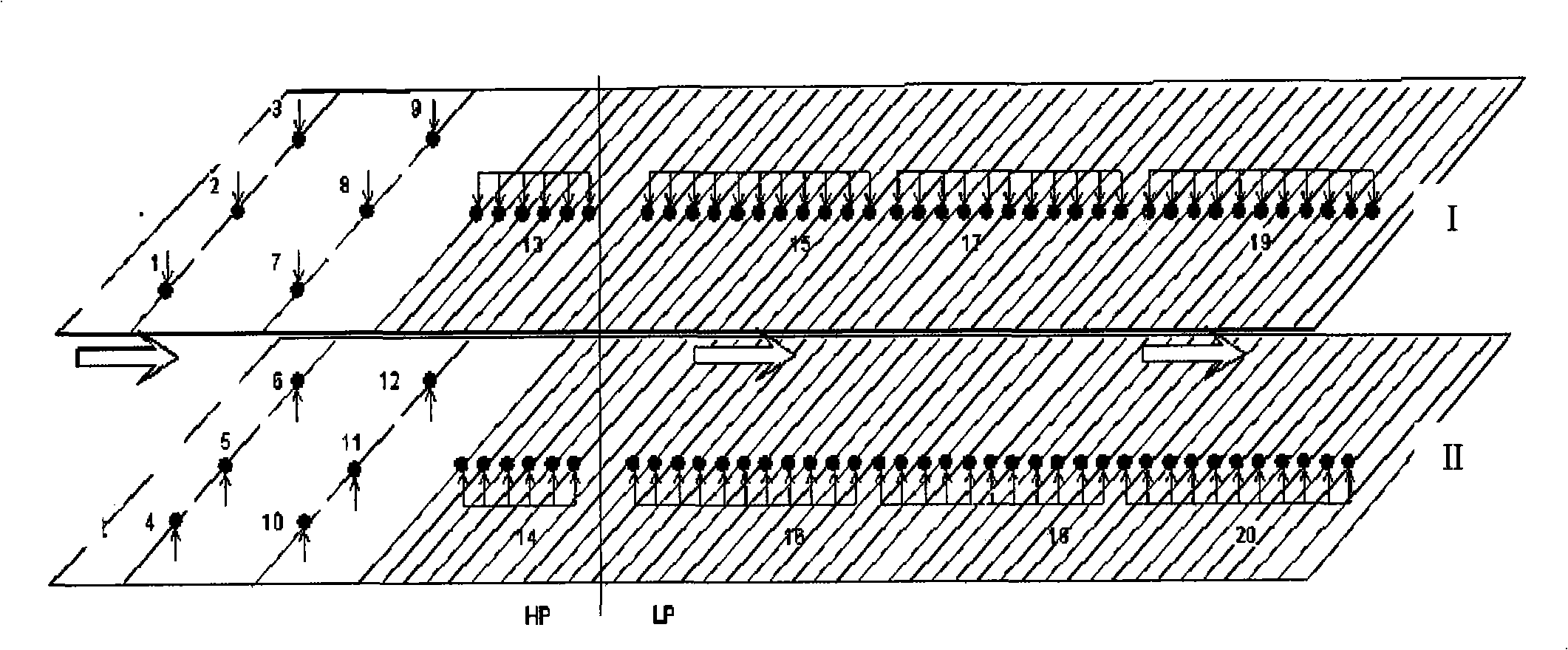

Accelerated cooling process of quenching machine for enhancing intensity of normalized steel plate

ActiveCN101307380AImprove organizationImprove performanceFurnace typesHeat treatment process controlHigh pressureNucleation

The invention discloses a quenching machine accelerated cooling process for improving the strength of a normalized steel plate, which belongs to the medium plate normalization control cooling technical field. After the normalized steel plate is taken out from a quenching furnace, the normalized steel plate enters a quenching machine along with a roll table of the quenching machine for hydrocooling, the speed of the roll table of the quenching machine is controlled to between 10 and 25m / min, and water amount control parameters are as follows: the water amount of district 13 of a high pressure section of the quenching machine is between 2.5 and 3.3m<3> / min; the water amount of district 14 is between 3 and 4m<3> / min; the opening degree of a flow control valve of district 15 of a low pressure section is between 30 and 40 percent; the opening degree of a flow control valve of district 16 is between 35 and 47 percent; and the cooling speed of the steel plate is controlled to between 6 and 8 DEG C / s. The water amount, the opening degree and the speed of the roll table of each district are adjusted according to the specification of the steel plate, so that the steel plate is cooled to between 600 and 650 DEG C; the hydrocooling improves ferrite nucleation rate, inhibits the growth of crystal grains, refines the crystal grains, and improves the strength of the normalized steel plate. The process has the advantages of improving the ferrite nucleation rate, inhibiting the growth of the crystal grains, refining the crystal grains, and improving the strength of the normalized steel plate.

Owner:SHOUGANG CORPORATION

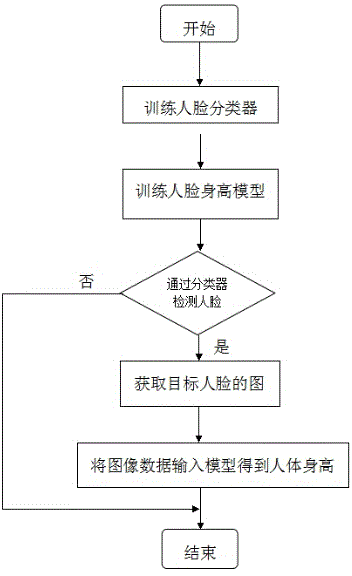

Stature measuring method

ActiveCN104434113AEnsure safetyEasy to operateCharacter and pattern recognitionDiagnostic recording/measuringHuman bodyPattern recognition

A stature measuring method includes the first step of training a human face classifier, the second step of training a human face and stature model, the third step of detecting a human face through the classifier, the fourth step of obtaining image data of the target human face and the fifth step of inputting the image data into the model to obtain the stature of a human body. The stature measuring method is effectively integrated through a machine learning algorithm and a vision algorithm, can be used for measuring stature in a non-contact mode under the circumstance that the distance between a user and a camera is unfixed, and guarantees security of stature data measured on some special occasions. The method breaks through restrictions on a traditional measuring tool, is convenient to operate, capable of effectively saving cost, manpower and material resources and high in transportability, and can be integrated with a variety of intelligent products to create certain economic benefits and practical value.

Owner:JIANGXI HONGDU AVIATION IND GRP

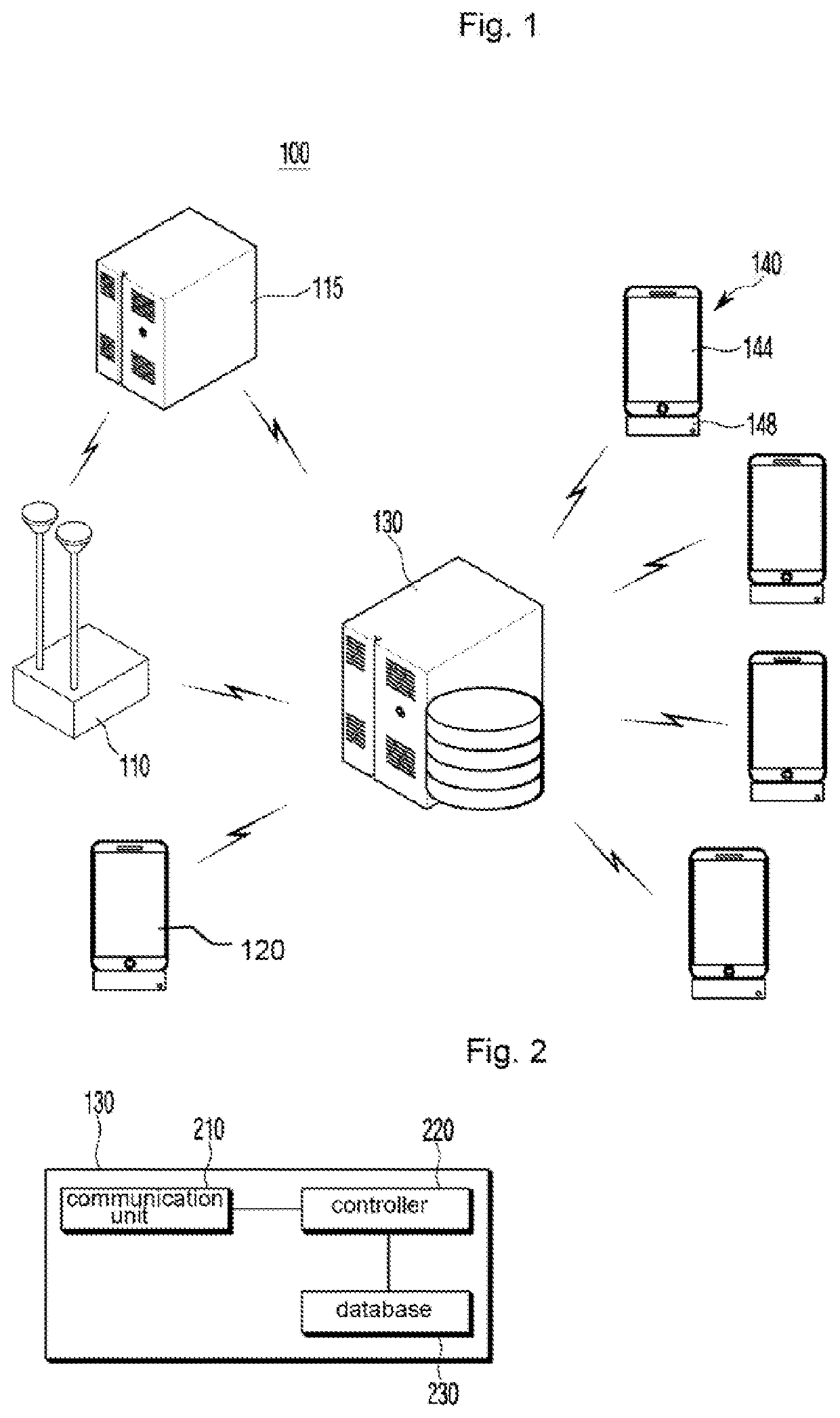

Android platform-based big dipper and GPS dual-mode on-line positioning method

InactiveCN105005058ASolve the problem of difficult transmissionIncrease demandSatellite radio beaconingDual modeThe Internet

The invention relates to an Android platform-based big dipper and GPS dual-mode on-line positioning method, which comprises a mobile positioning terminal capable of receiving the information sent by a satellite, a remote cloud server, a mobile webpage client, and an Android handset client. The mobile positioning terminal is connected with the remote cloud server through the internet. The remote cloud server is respectively connected with the mobile webpage client and the Android handset client through the internet. A mobile platform of the Freescale i.MX 6q series is operated based on the android system, so that the real-time location information of a Big Dipper / GPS dual-mode module can be received in real time. Therefore, problems in the prior art that in some remote areas, corresponding services cannot be supplied to people or enterprise and public institutions in need due to the bare coverage of communication base stations and the large transmission difficulty of information can be solved.

Owner:LIUZHOU BAISIDE INFORMATION TECH CO LTD

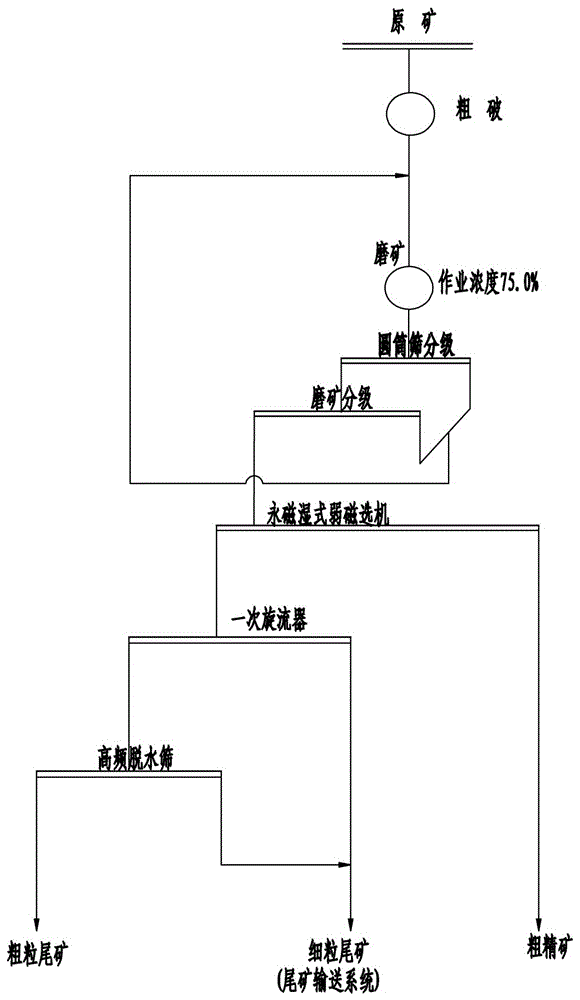

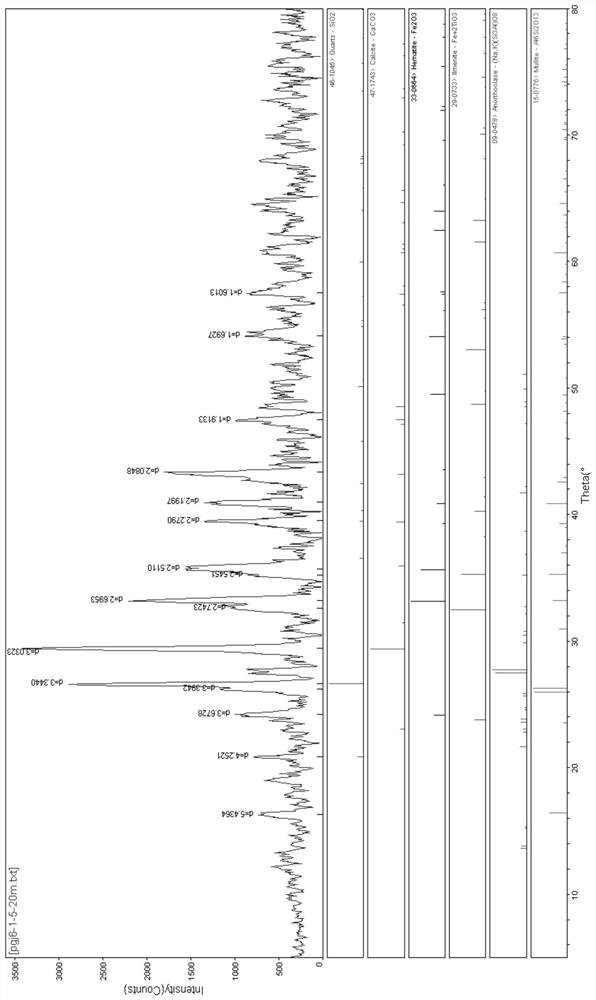

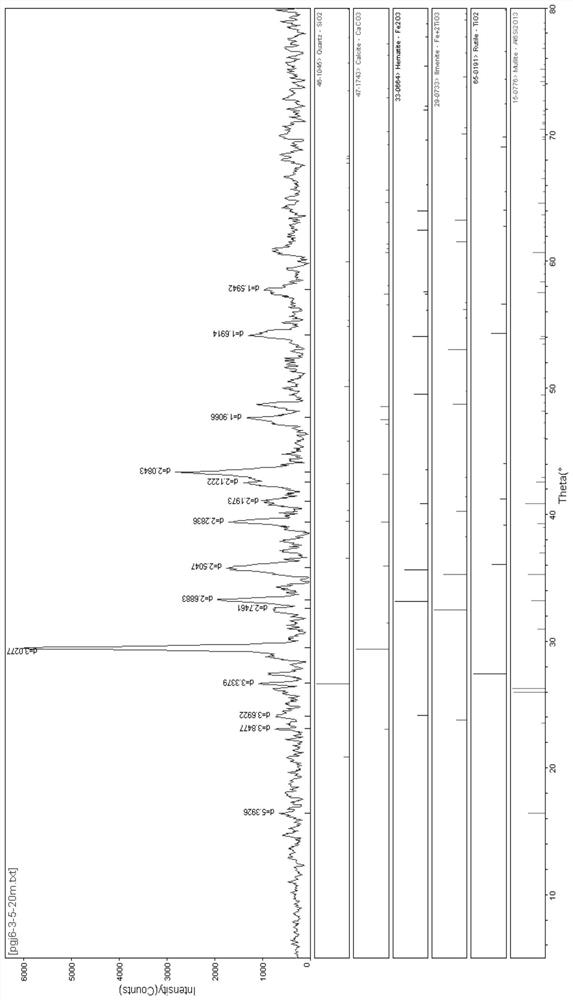

Low-grade Anshan magnetite beneficiation process

InactiveCN106311438ASmall footprintExtended service lifeMagnetic separationGrain treatmentsMagnetic separatorWater content

The invention relates to a low-grade Anshan magnetite beneficiation process. The low-grade Anshan magnetite beneficiation process is characterized by comprising the following steps: ores with a grade of 18.34% are fed in a rough crusher and a wet semi-autogenous mill in sequence; oversize products on a cylinder screen and a linear vibration screen are merged and returned to the wet semi-autogenous mill; undersize products on the linear vibration screen with a particle size of below 3 mm are fed in a weak magnetic separator to separate weak magnetic separator concentrates from weak magnetic separator tailing; rough concentrates of the weak magnetic separator are fed in a next sorting procedure; the weak magnetic separator tailing is fed in a primary concentration cyclone and a high-frequency dehydration screen; overflows of the primary concentration cyclone and undersize products of the high-frequency dehydration screen are combined as fine-particle tailing to feed into a tailing conveying system; and the coarse-grain tailing with a water content of 15-20%, a grade of 6.85% and a particle size of 3-0.3 mm and dehydrated by the high-frequency dehydration screen is used as building sand. The low-grade Anshan magnetite beneficiation process has the following advantages: the same one process can extract both coarse concentrates and the building sand.

Owner:ANSTEEL GRP MINING CO LTD

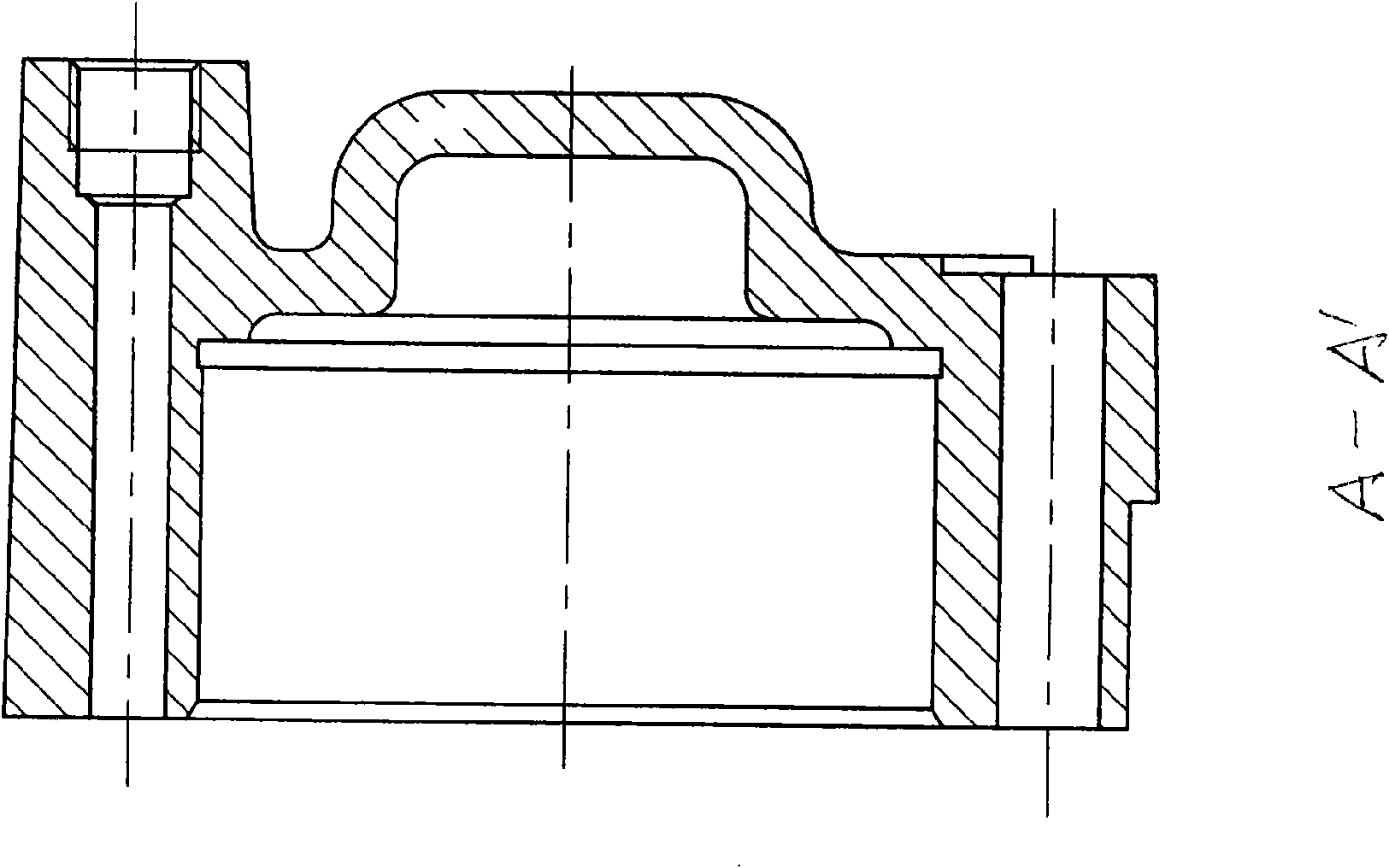

Method for processing range gear air cylinder of automobile parts

The invention provides a method for processing a range gear air cylinder of automobile parts, which comprises the following steps: according to the dimensions required by a drawing, lathing the end face of a left end, an outer circle and a length, boring a big inner hole and a depth, and cutting an inner groove; positioning by using the inner hole in the left end, and drilling four phi11 through holes, two phi8 through holes and a phi16.5 through hole according to the requirements of the drawing; performing milling according the requirements of the drawing; reaming four phi24 counter bores which are two millimeters deep on the four phi11 through holes; reaming two phi12.5 counter bores which are 15 millimeters deep on the two phi8 through holes and chamfering the two counter bores; performing tapping according to the requirements of the drawing; doing tests by using corresponding measuring tools; doing a gas test by mounting a workpiece on a special clamp and fixedly sealing a contact part; and doing a leakage test of the big hole in the left end and the two phi8 holes by applying a pressure of 8 bar and preventing leakage. The method prevents the air leakage of the air cylinder, ensures geometric tolerance and positioning tolerance, greatly improves product quality, creates benefits for enterprises and meets living needs of people.

Owner:鞠小平

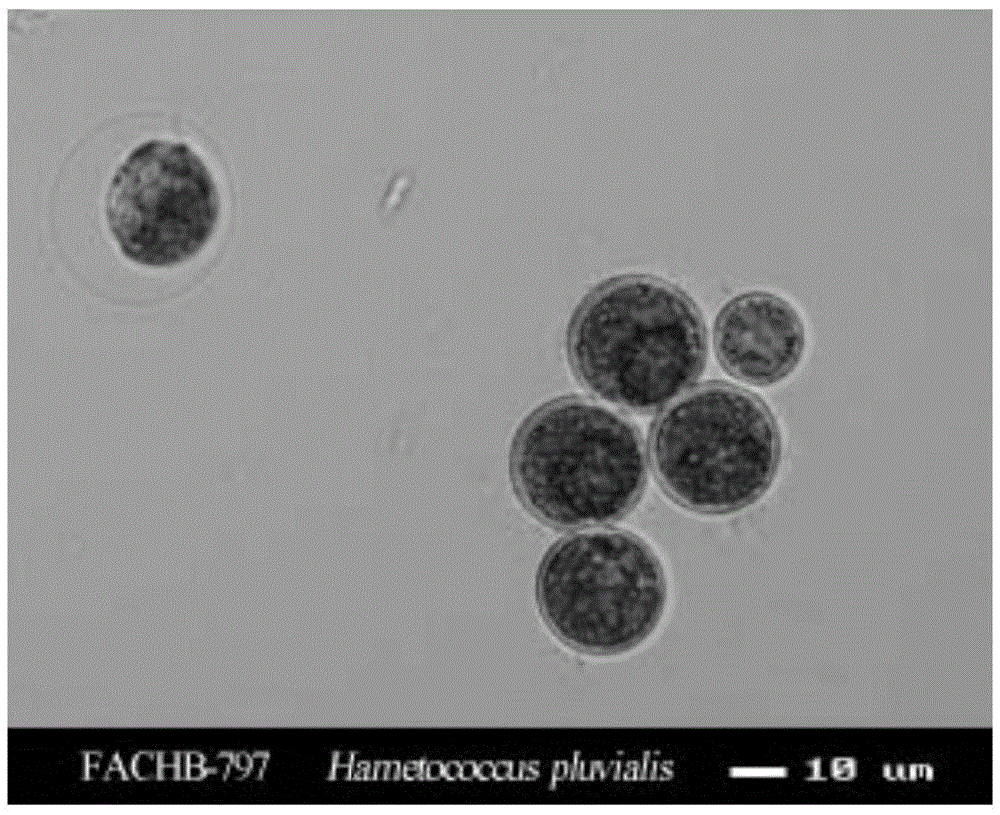

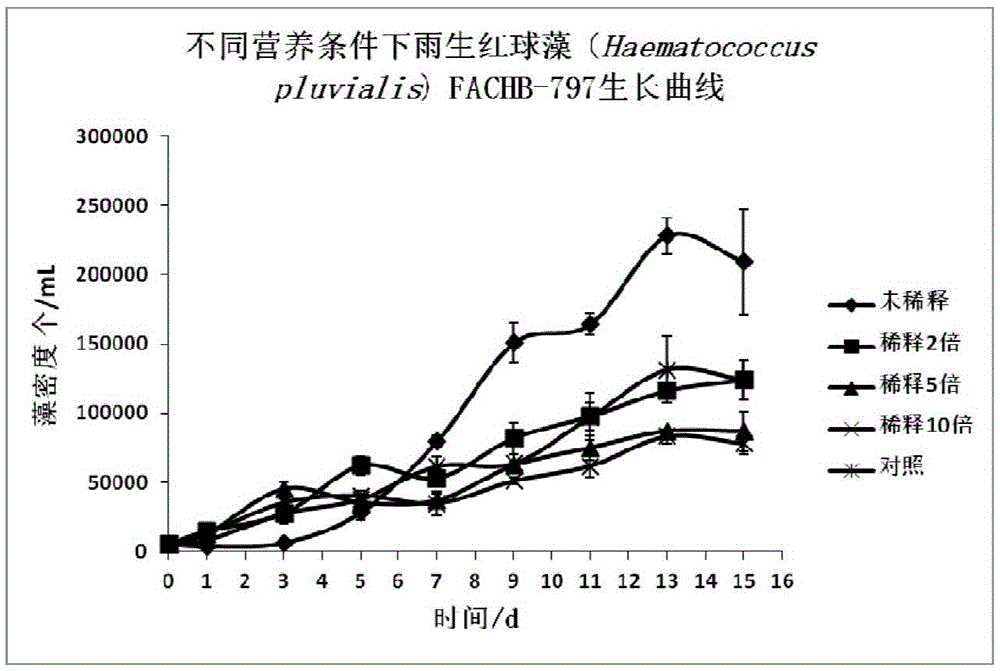

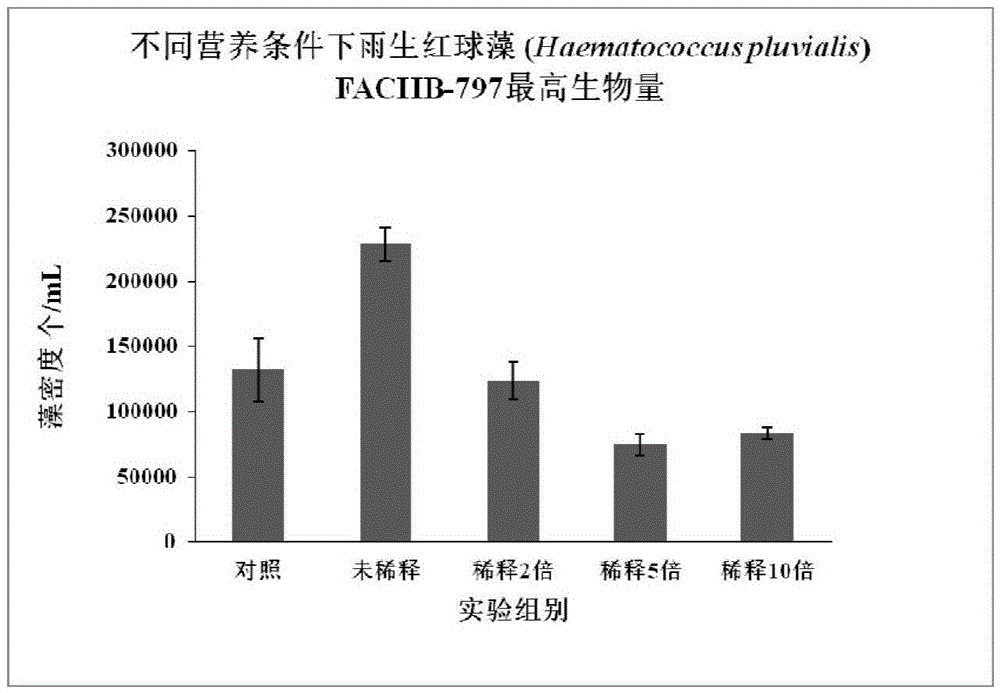

Method for culturing haematococcus pluvialis and application of haematococcus pluvialis

InactiveCN105483016ALow costIncrease biomassUnicellular algaeTreatment involving filtrationEutrophicationBetaxanthins

The invention discloses a method I for culturing haematococcus pluvialis, a method II for improving biomass of haematococcus pluvialis, a method III for producing astaxanthin and a method IV for purifying domestic sewage. Through utilization of the method II, the biomass of haematococcus pluvialis can be greatly increased, haematococcus pluvialis can relatively quickly enter the astaxanthin synthesis period, the astaxanthin synthesis period can be greatly shortened, and good basis can be provided for follow-up increase of metabolite astaxanthin yield. Besides, the content of heavy metal and other pollutants in haematococcus pluvialis obtained by utilizing the method I is not obviously increased, so that the haematococcus pluvialis obtained by utilizing the method I can be used as a safe product for follow-up use. Meanwhile, through utilization of the method IV, the nitrogen content and the phosphorus content in sewage can be obviously reduced, and the sewage eutrophication degree is obviously relieved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Treatment method for waste water of acephate producing process

InactiveCN101143813ASolve environmental problemsPrevent the occurrenceGroup 5/15 element organic compoundsCarboxylic acid salt preparationFiltrationAqueous sodium hydroxide

The invention discloses a method of processing the process wastewater in the production of acephate. The acephate process wastewater is poured into a reaction kettle, thirty percent of sodium hydroxide solution is dripped into the acephate process wastewater at a temperature between 30 DEG C and 40 DEG C, the pH value is contolled in a range of nine to nine point five, and the ammonia gas generated by reaction is absorbed by water, so that ammonia is produced; reaction liquid is desolventized under the conditions of temperature between 80 DEG C and 100 DEG C and vacuum between-0.08 MPa and-0.1 MPa, the desolventizing time is two to four hours, the temperature is then decreased to 18 to 20 DEG C, so that the reaction liquid is crystallized, the crystallizing time is half to five hours, and finally, sodium acetate trihydrate and mother liquid are produced by extraction and filtration. The invention has the advantages of simple technique, safety, low cost, no production of three wastes and environmental protection.

Owner:SHANGHAI TOPCARE MEDICAL SERVICES CO LTD

Corrosion-resisting alloy for immersion piece of hot-dip galvanized pan

The invention relates to metallurgical industry, and provides a corrosion-resisting alloy for an immersion piece of a hot-dip galvanized pan, which comprises the following chemical components in percentage by weight: less than or equal to 0.08 percent of C, less than or equal to 1.50 percent of Si, less than or equal to 1.50 percent of Mn, less than 0.03 percent of P, less than 0.03 percent of S,17.50 to 22.00 percent of Cr, 9.00 to 13.00 percent of Ni, 2.00 to 3.00 percent of Mo, and the balance of Fe and trace impurities. The corrosion-resisting alloy for the immersion piece of the hot-dipgalvanized pan overcomes the disadvantages of susceptibility to corrosion and short service life of the galvanized pan made of the prior common used steel, has the advantages of Ai, Zn and Si alloy solution resistance, strong strength of intermediate temperature, and the like, is mainly used for manufacturing immersion pieces of galvanized pans in thin plate galvanizing production lines or dip Al-Zn-Si production lines such as immersion rollers, stabilizing rollers and supporting arms, as well as spare parts of anti-intermediate temperature corrosion equipment.

Owner:黄石山力大通热工设备有限公司

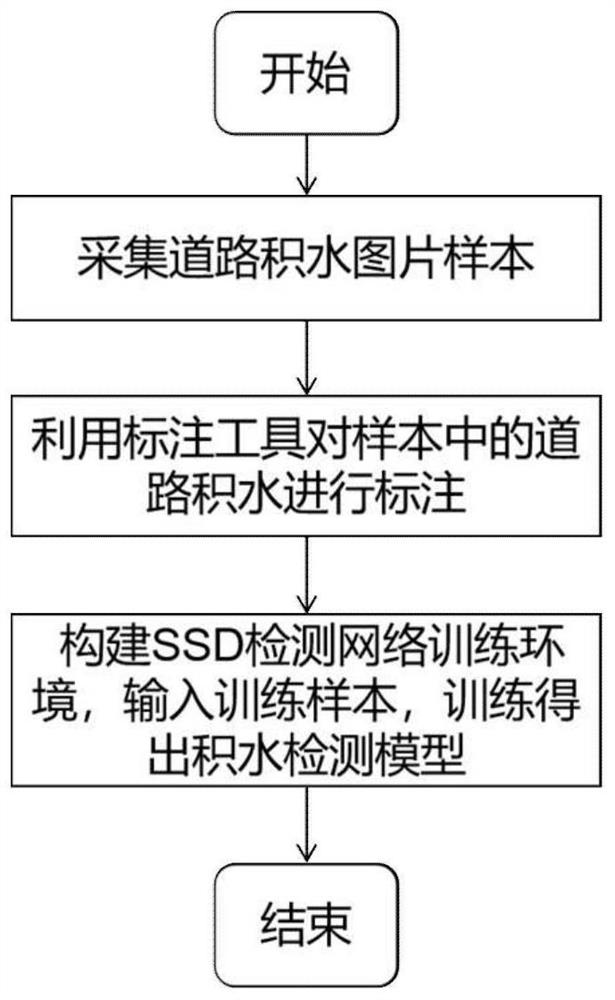

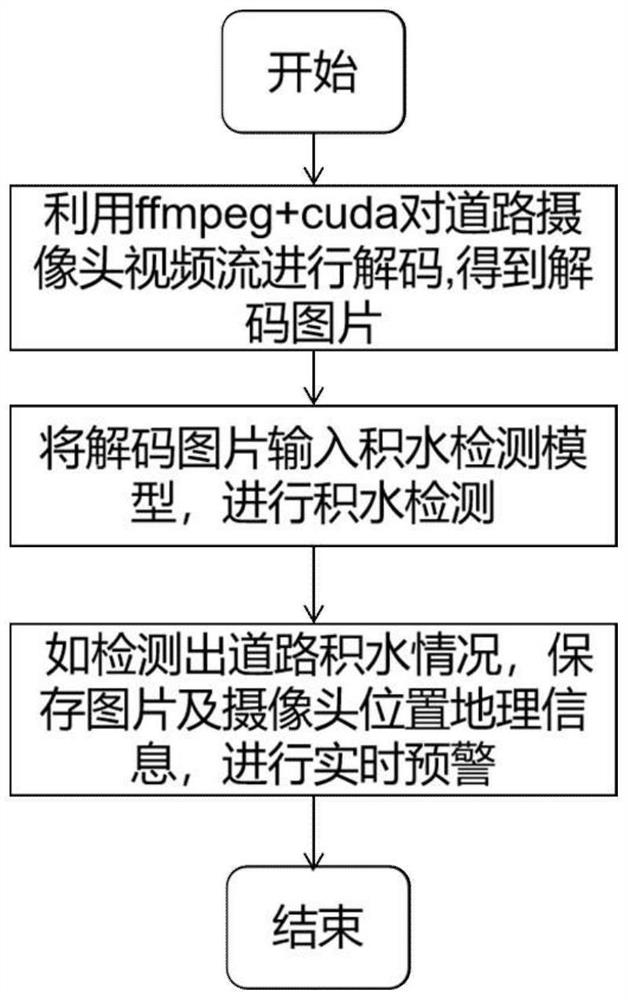

Accumulated water detection method based on video

PendingCN114219788AAccurately identify water accumulation statusAccurate identificationImage enhancementImage analysisVideo monitoringStreaming data

A video-based ponding detection method comprises the steps of firstly collecting a sample picture with a large amount of road ponding, then labeling the sample picture through a labeling tool, training the labeled sample picture based on an SSD target detection algorithm, and constructing a ponding detection model; and finally, acquiring video stream data of the road camera, and performing ponding detection on the acquired video stream data of the road camera by using the constructed ponding detection model. According to the method, sample collection, sample labeling, target detection and deep learning technologies are effectively combined with an actual road scene, the road waterlogging state is accurately recognized, the recognition accuracy is greatly improved, large-scale application can be performed by means of the constructed video monitoring network, and certain economic benefits and use values can be created.

Owner:JIANGXI HONGDU AVIATION IND GRP

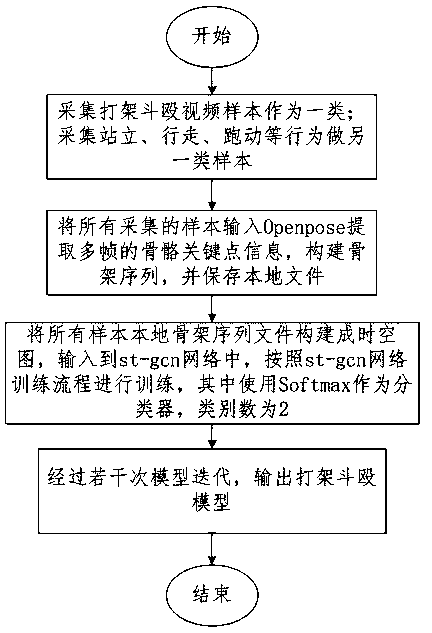

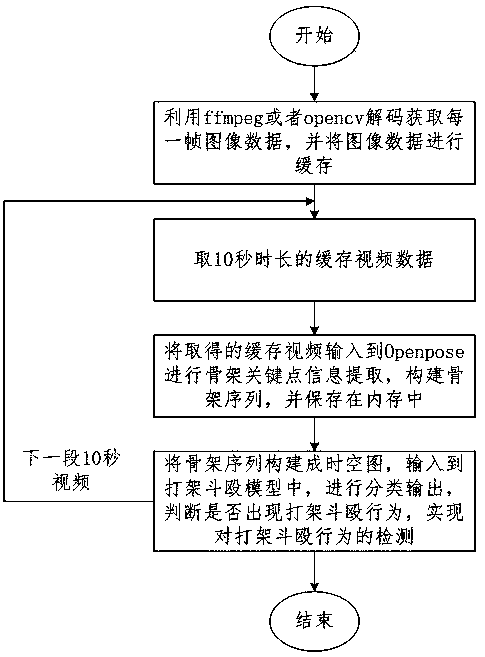

Video-based fighting detection method

InactiveCN111008601AImprove recognition accuracyCreate benefitsCharacter and pattern recognitionHuman bodyPublic place

The invention discloses a fighting detection method based on a video. The method comprises the steps of based on a target detection method, effectively detecting a human body target in a video ; secondly, extracting human body skeleton key point information, including continuous multi-frame skeleton key point 2D coordinate information of each human body; constructing a skeleton sequence, and constructing a space-time convolution graph on the skeleton sequence; and inputting the space-time convolution graph into a trained multilayer space-time convolution network (st-gcn) to perform action recognition. The method can be used to accurately identify fighting and other action behaviors, can be widely applied to stations, airports, supermarkets, commercial streets, playgrounds and other important public places, and realizes real-time early warning.

Owner:JIANGXI HONGDU AVIATION IND GRP

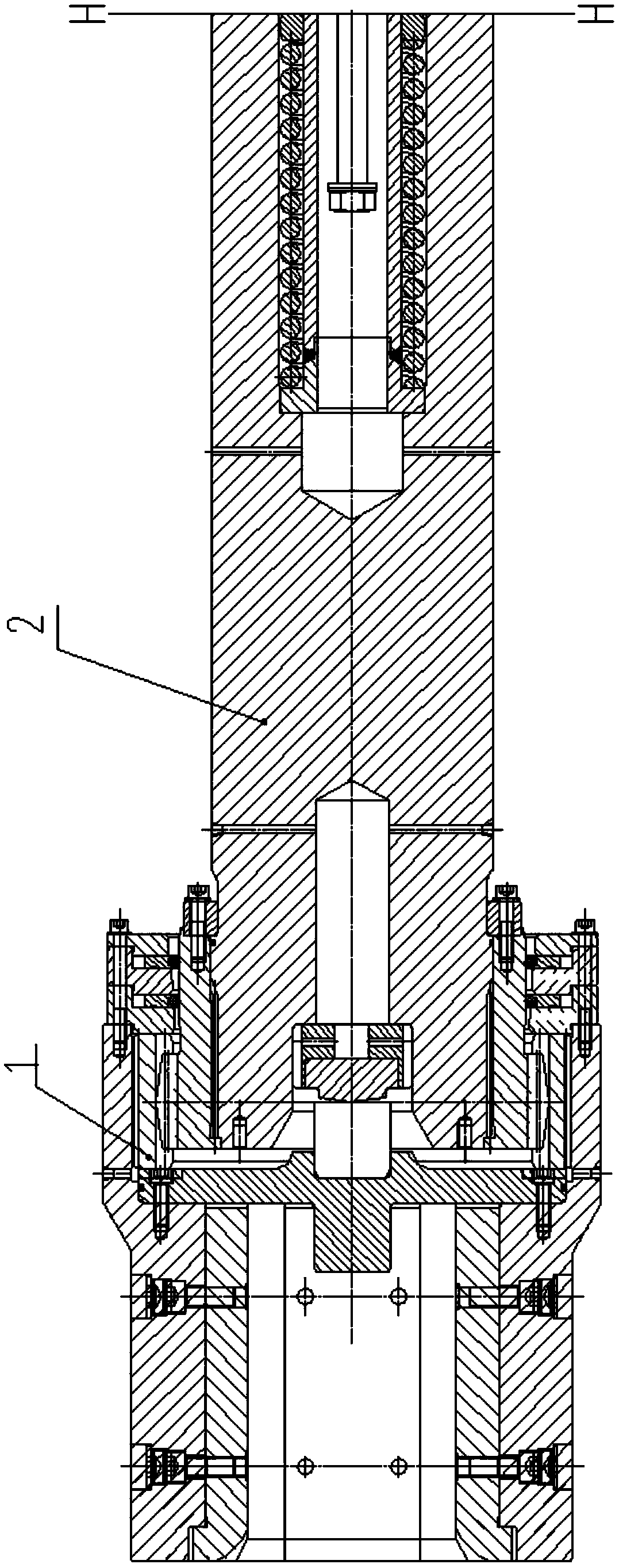

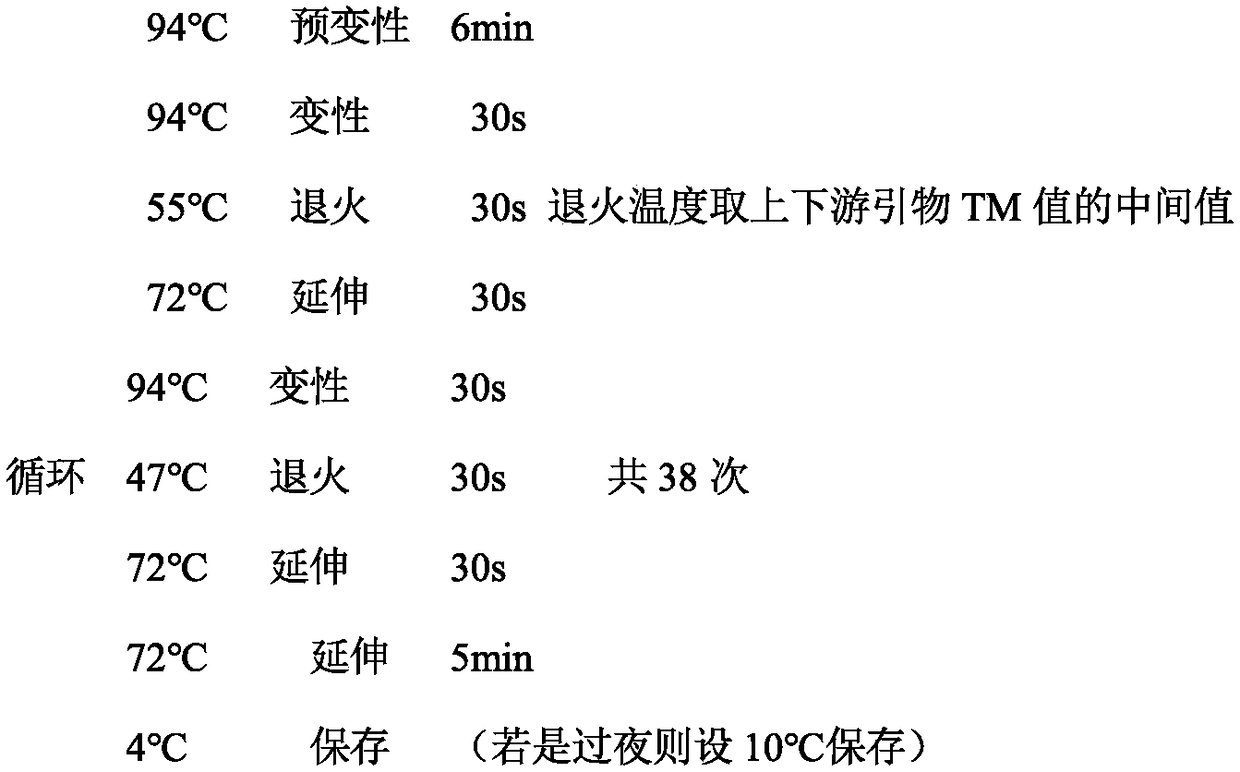

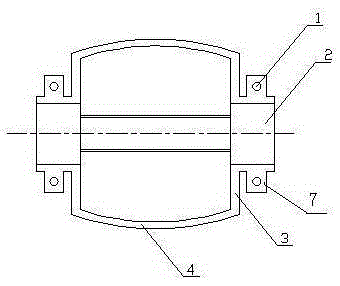

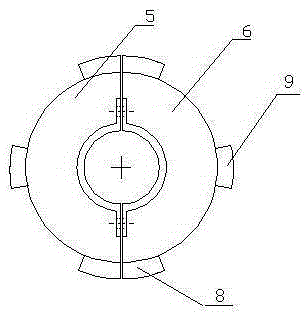

Drum gear coupling for ESP finishing mill

PendingCN109372899AElastic stabilityReset stableYielding couplingRolling mill drivesCouplingAgricultural engineering

The invention discloses a drum gear coupling for an ESP finishing mill. The drum gear coupling comprises a roller-end component, a reducer-end shaft sleeve and a reducer-end transition gear ring, andfurther comprises a spline shaft, a reducer-end external gear shaft sleeve, a protective cover and a reducer-end sealing component, wherein the protective cover is mounted on the spline shaft in a sleeving manner; the left end of the reducer-end external gear shaft sleeve is connected to male splines at the right end of the spline shaft through female splines; the right end of the reducer-end external gear shaft sleeve meshes internal teeth of the reducer-end transition gear ring through external teeth; the protective cover is connected to the reducer-end external gear shaft sleeve; and the reducer-end sealing component is mounted on the reducer-end shaft sleeve through bolts and mounted on the excircle of the reducer-end external gear shaft sleeve in a sleeving manner. Through a novel axial telescopic structure, the problem of a long extension stroke is solved, and meanwhile, the problems that sealing of an original drum gear coupling fails due to frequent sliding, and a gear pair ofthe original drum gear coupling is prone to damage are also solved.

Owner:TAIER HEAVY IND

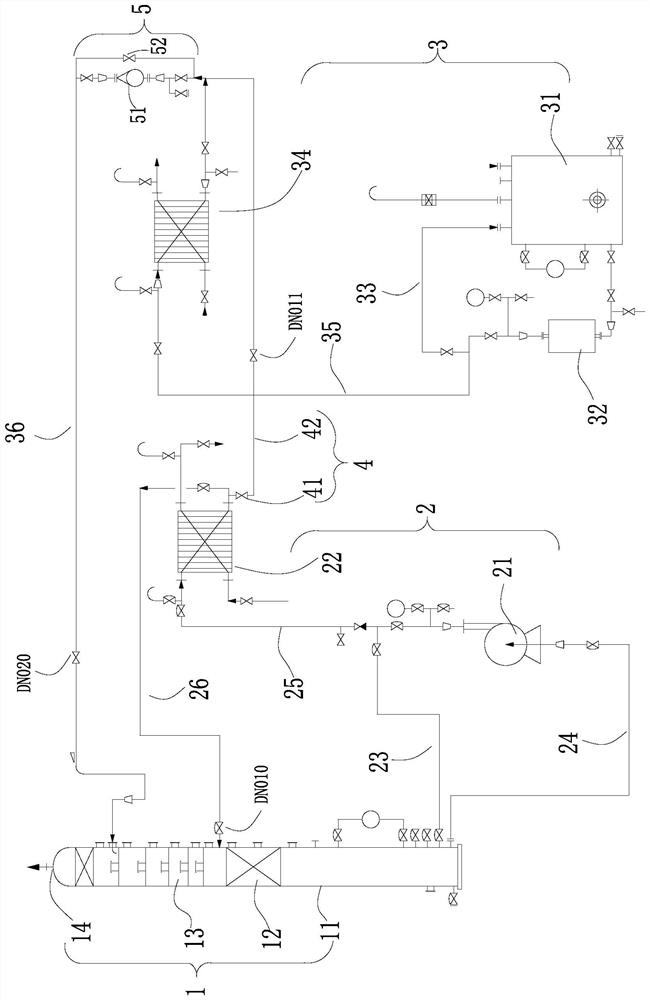

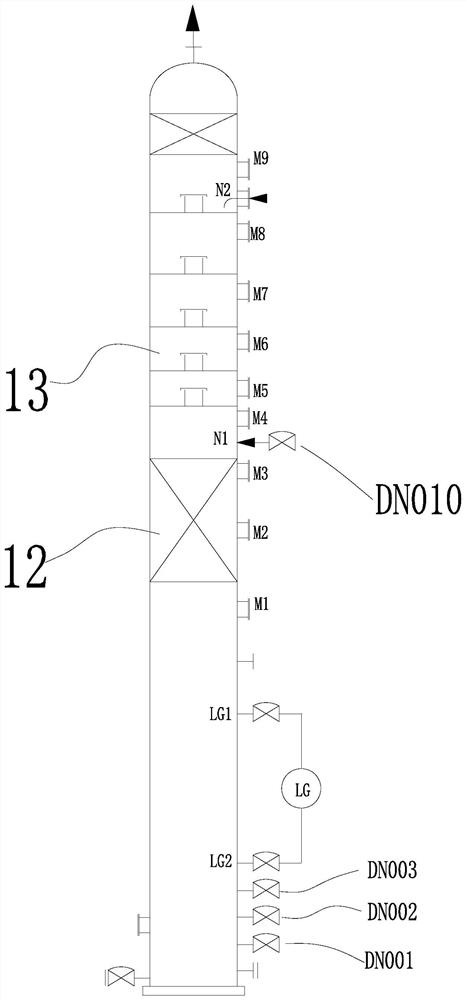

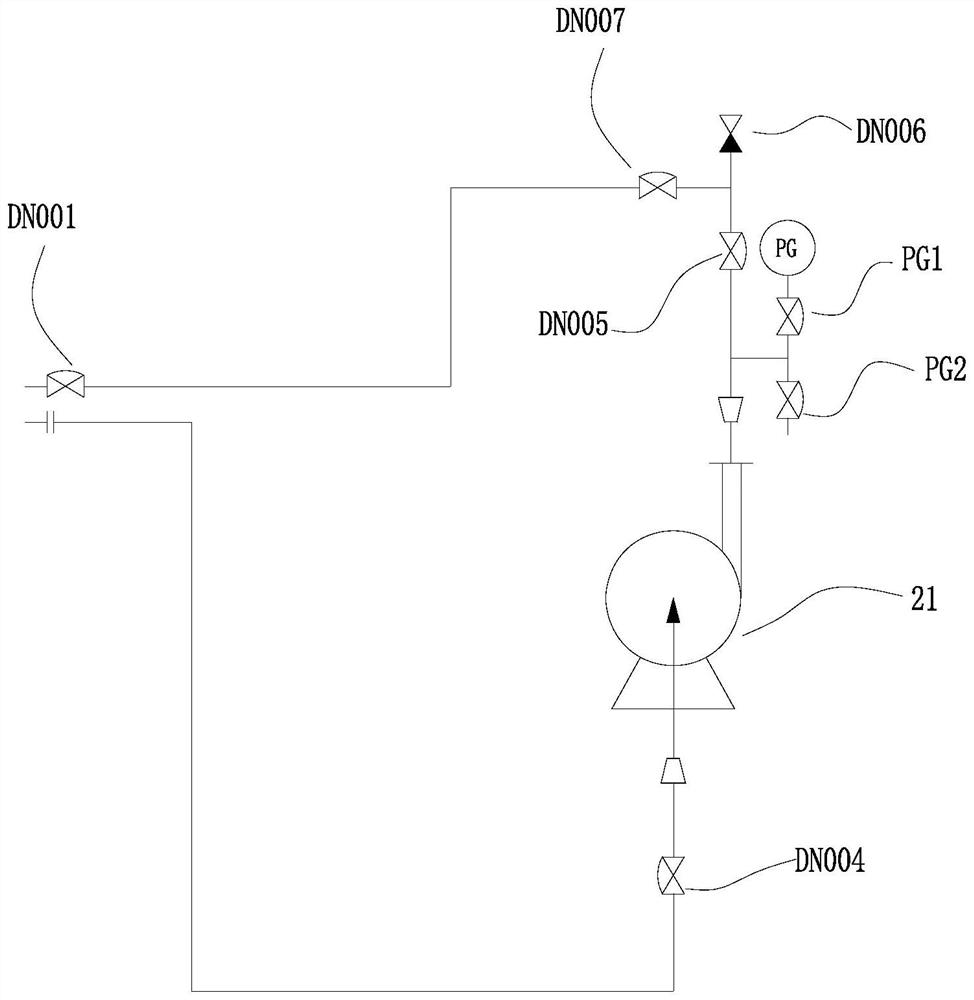

Device and method for drying chlorine gas through bubble cap drying tower

PendingCN114191948AIncrease usageEasy dischargeChlorine/hydrogen-chloride purificationDispersed particle separationProcess engineeringEnvironmental engineering

The invention relates to a device and a method for drying chlorine by a bubble cap drying tower. The device comprises a bubble cap tower, an acid circulation system, a new acid feeding system and an acid circulation branch system, the bubble cap tower comprises a tower body, and a filler layer and a bubble cap layer which are sequentially arranged in the tower body from bottom to top, and a dry chlorine outlet is formed in the top of the tower body; firstly, a new acid feeding system is operated, and sulfuric acid is fed into a bubble cap layer; an acid circulation system is operated, so that sulfuric acid circulates in the filler layer; and finally, opening the acid circulation branch system, adjusting the accumulated sulfuric acid flow entering the bubble cap layer, controlling the flow of the sulfuric acid sent out by the new acid sending system to be less than half of the accumulated sulfuric acid flow, and after stable operation, introducing chlorine to be dried into the tower body, sequentially passing through the filler layer and the bubble cap layer, and discharging through a dry chlorine outlet, thereby completing the drying of the chlorine. The method effectively reduces the generation amount of waste sulfuric acid which is difficult to treat in chlor-alkali production, the minimum amount reaches 13.52 kg / ton, and the method is particularly suitable for the situation that the annual output is not higher than 100,000 tons.

Owner:湖北葛化华祥化学有限公司

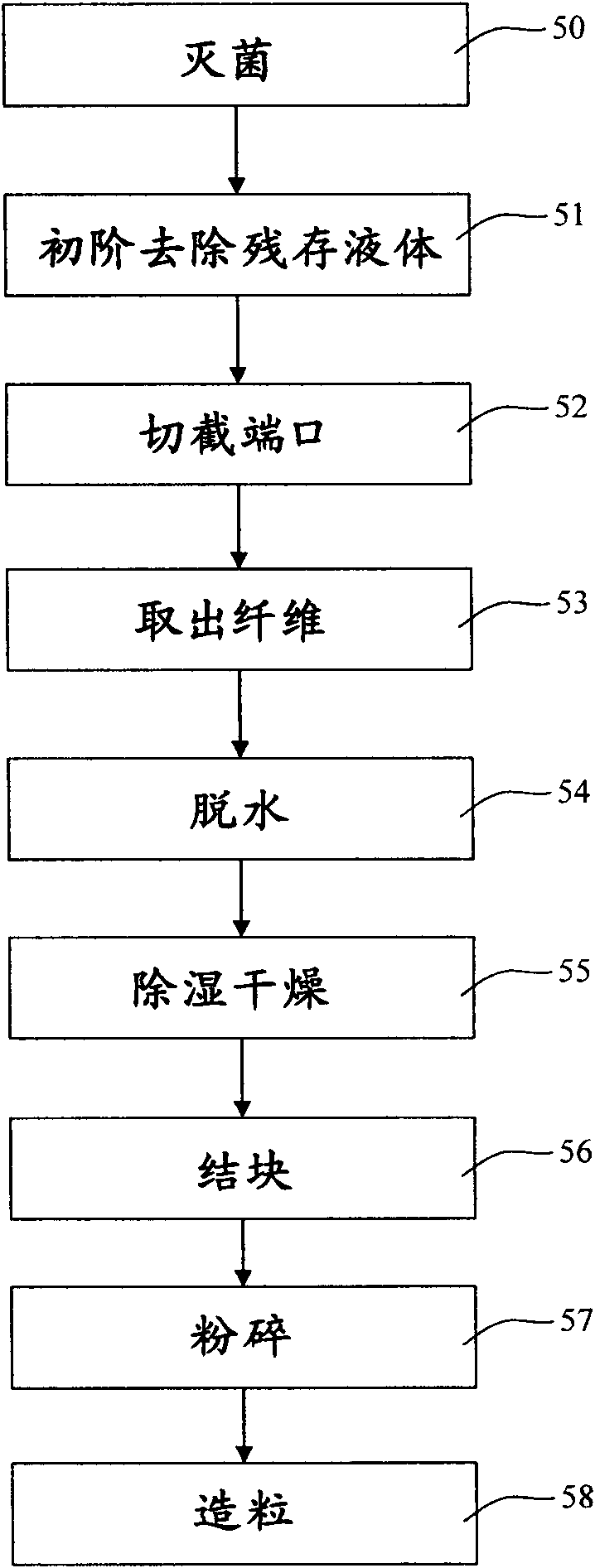

Recycling remanufacture method for hollow fiber material of dialysis tube

ActiveCN102605480BReduce pollutionCreate benefitsTextile disintegration and recoveryFibre disintegrationEnvironmental resistanceFiber

The invention claims a recycling remanufacture method for hollow fiber material of dialysis tube, namely the recycling remanufacture method for hollow fiber material of artificial kidney. The recycling remanufacture method comprising the steps of removing residue liquid, cutting port, taking fiber, dehydrating, dehumidification drying and palletizing, therefore the hollow fiber material discarded by combustion is recycled as polymer raw materials and then the polymer raw materials are recycled to be the production raw materials of other articles to lower the air pollution generated in the combustion process, further create new economic value and benefit and provide alternative materials for related raw material production industries. The recycling remanufacture method for hollow fiber material of dialysis tube not only realizes energy conservation and emissions reduction and reuse of resources and meets the regulations and policies and world trend, but also completely solves the environmental issues such as pollution and waste in the waste combustion process of present technique.

Owner:GSHINE WELLTECH

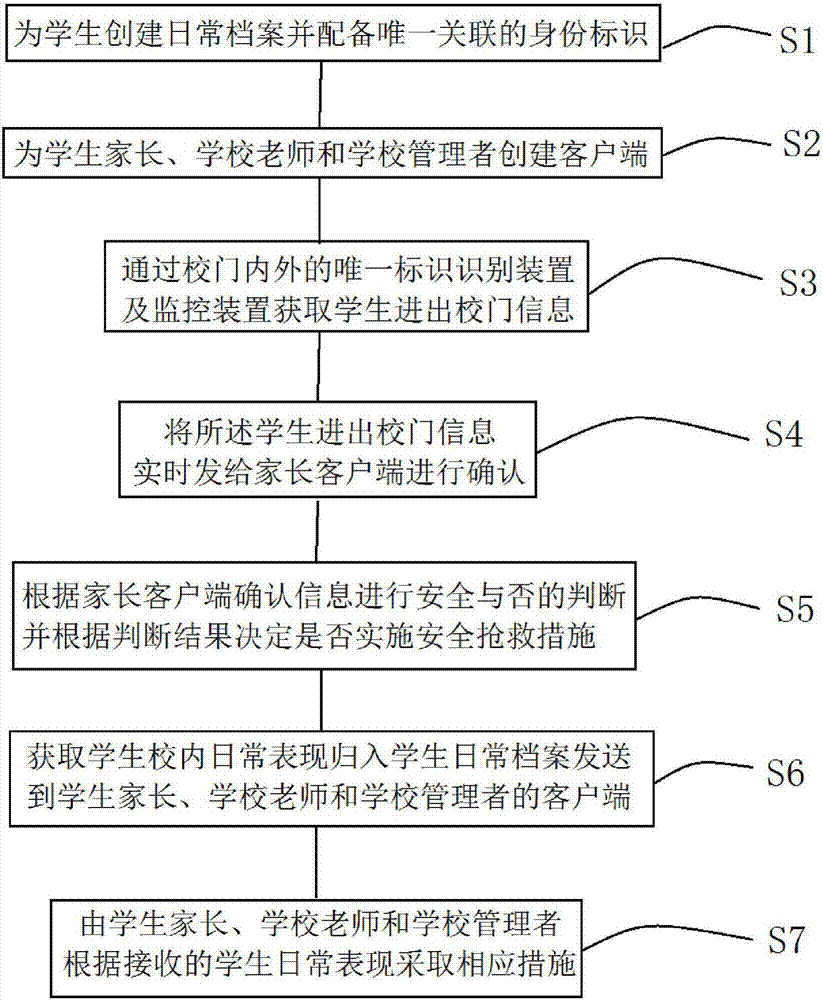

Daily performance and safety management method for primary and secondary school students

InactiveCN107424094APrevent getting lostGuarantee personal safetyData processing applicationsUnique identifierComputer science

The invention discloses a daily performance and safety management method for primary and secondary school students, which solves potential safety hazards in student pickup through a technical scheme of creating a daily file and providing a unique associated identity identifier for each student, creating a client for student parents, school teachers and school administrators, acquiring school gate entering and leaving information of the students through a unique identifier recognition device and a monitoring device inside and outside the school gate, sending the school gate entering and leaving information of the students to the parent clients in real time for confirmation, performing judgment on the safety according to the confirmation information of the parent clients, deciding whether to take a safety rescue measure or not according to a judgment result, acquiring daily performance of the students at school, putting the daily performance into the daily files of the students, sending the daily performance of the students to the clients of the student parents, the school teacher and the school administrators, and adopting corresponding measures by the student parents, the school teachers and the school administrators according to the received daily performance of the students, thereby providing a protective guarantee for the safety of the students, and performing assessment on development conditions of the students at school on various aspects.

Owner:上海万舰信息科技有限公司

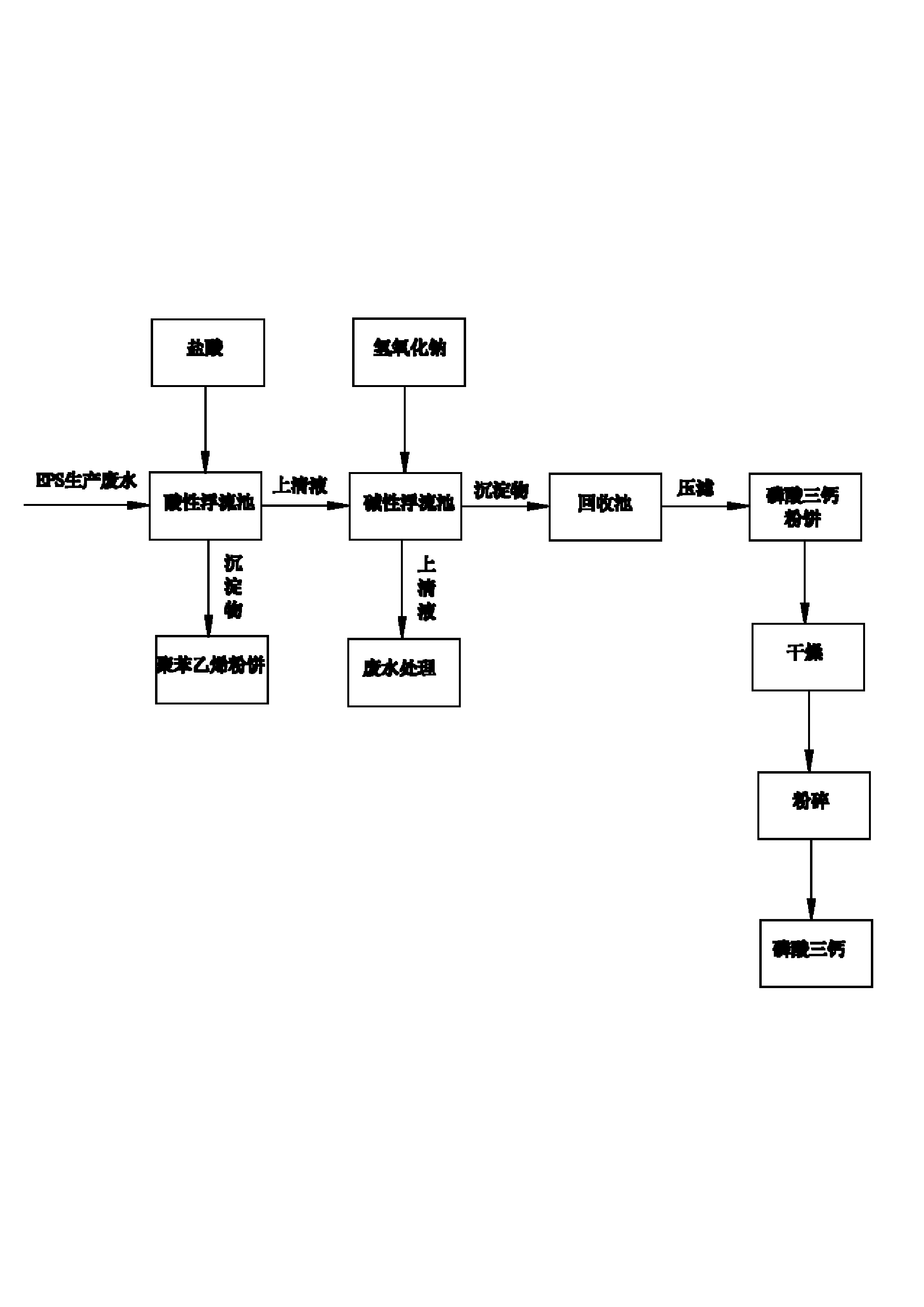

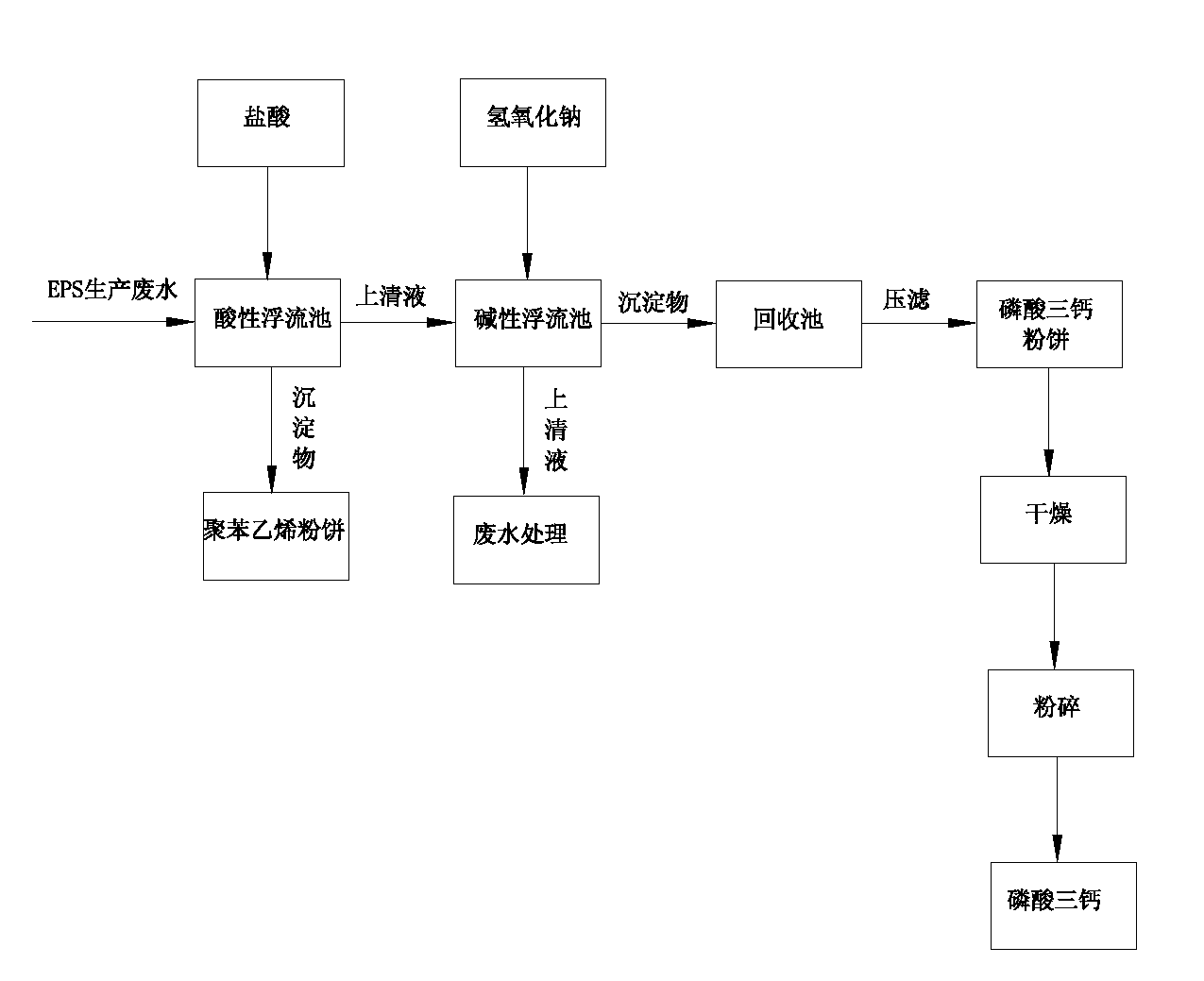

Method for recycling tricalcium phosphate from expandable polystyrene industrial wastewater

ActiveCN102849705AReduce processingReduce dosageMultistage water/sewage treatmentNature of treatment waterPolystyreneWastewater

The invention relates to the technical field of recycle of tricalcium phosphate, in particular to a method for recycling tricalcium phosphate from expandable polystyrene industrial wastewater. According to the method provided by the invention, tricalcium phosphate in the expandable polystyrene industrial wastewater can be recycled before materialization and biochemical treatment of wastewater, and the recovery of tricalcium phosphate reaches 85% so that the use level of tricalcium phosphate needed by producing the expandable polystyrene is greatly reduced, the production cost is lowered, and the content of inorganic phosphorus in the wastewater is decreased quickly to the benefit of environmental protection, and therefore the environmental and economical benefits can be realized.

Owner:见龙国际贸易有限公司

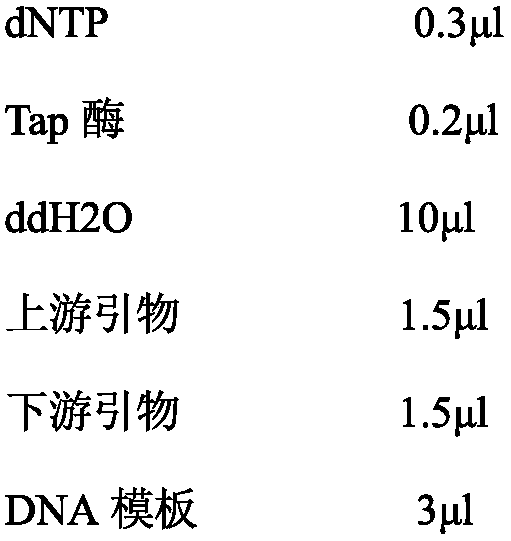

Sterile line mutant acquisition method

InactiveCN108967180AImprove acquisition efficiencyAvoid uncertaintyPlant genotype modificationAgricultural scienceBackcrossing

The invention discloses a sterile line mutant acquisition method which is characterized in that the existing mutant is utilized to be hybridized to other varieties, progeny screening is performed by taking a sterile gene as a marker, and progenies perform backcrossing at the same time; and each backcrossing is subjected to detection with the sterile gene. The method provided by the invention solves the limitation that fertility mutants are long in discovery period and cannot be acquired in batch, and various mutants in different variety types cannot be acquired at the same time when the fertility mutants are acquired before. The method provided by the invention is simple, is liable to operate, avoids the indetermination of EMS mutation, omits the tediousness of a gene editing process, canperform backcross transformation on multiple rice varieties at the same time, greatly improves the acquisition efficiency of the fertility mutants, is beneficial to discovering a third generation intelligent sterile line and accelerates application of a third generation hybrid rice breeding.

Owner:QINGDAO YUANCE GRP CO LTD

A kind of protective separation agent for stack rolling of high nickel steel wide thin plate and stack rolling method

ActiveCN109365553BNot oxidizedStacking is easyAuxillary arrangementsWork lubrication devicesAdhesiveAluminum silicate

The invention relates to a protective separating agent for high-nickel steel wide sheet rolling and a rolling method. The protective separating agent is formed by mixing a protective separating agentadhesive and a protective separating agent powder, wherein the protective separating agent adhesive is composed of silicon dioxide and ionized water, and the protective separating agent powder is composed of nano silicon dioxide, silicon nitride, zirconium dioxide and aluminum silicate. The process route of the high-nickel steel wide sheet rolling comprises the following steps of selecting materials, normalizing, cutting, beveling, edge milling, cleaning, preparing a protective separating agent, spraying the protective separating agent, assembling, presetting air holes, welding, spraying a high-temperature anti-oxidation paint, heating, rolling, separating and measuring thickness. The protective separating agent can play a role in preventing the rolled steel plate from being oxidized in ahigh-temperature process, and the effect that the steel plates are easy to separate after rolling is ensured; and the protective separating agent can be applied to the high-nickel steel wide sheet rolling, the rolling difficulty can be reduced, the flatness of the steel plate is improved, the rolling success rate is improved, and the yield is improved.

Owner:ANGANG STEEL CO LTD

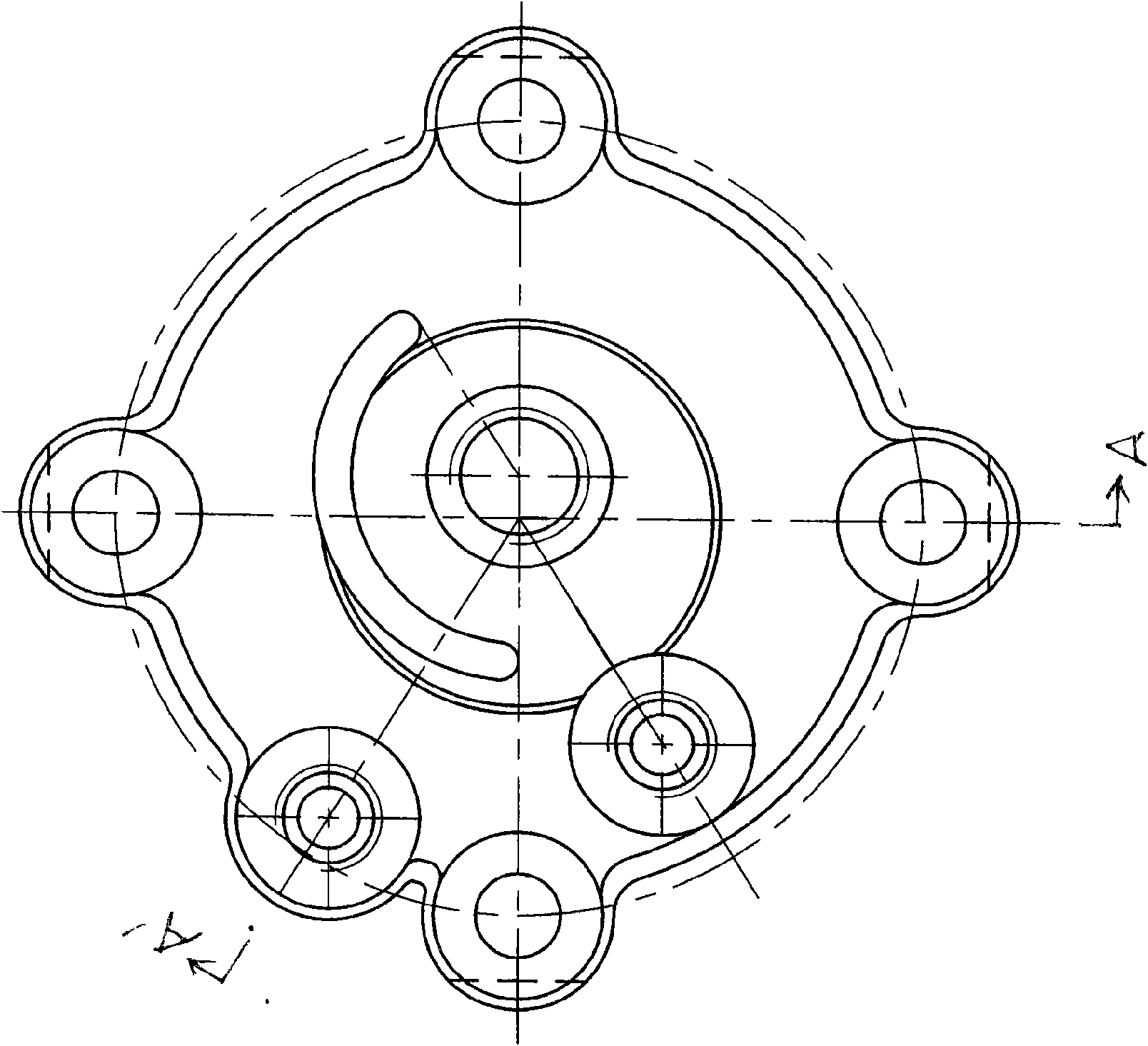

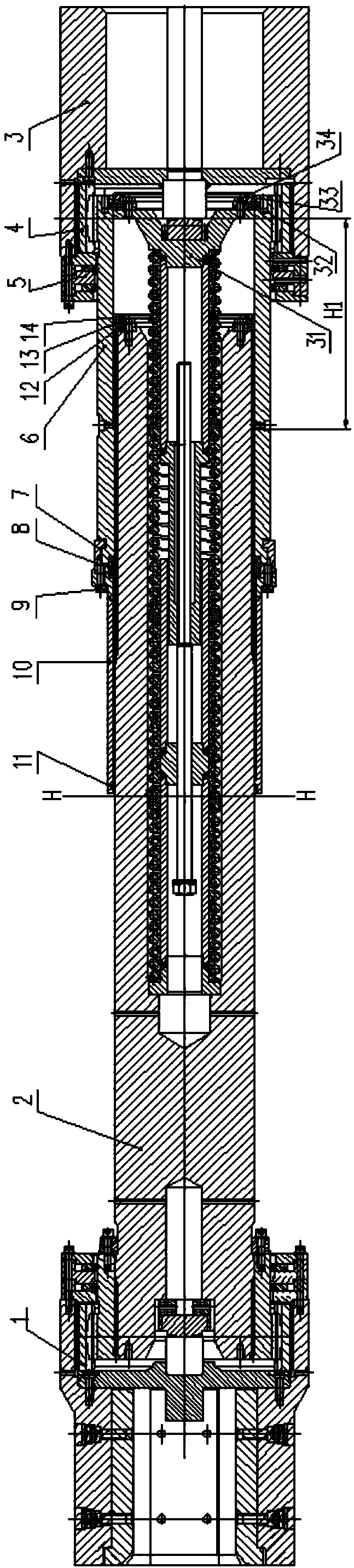

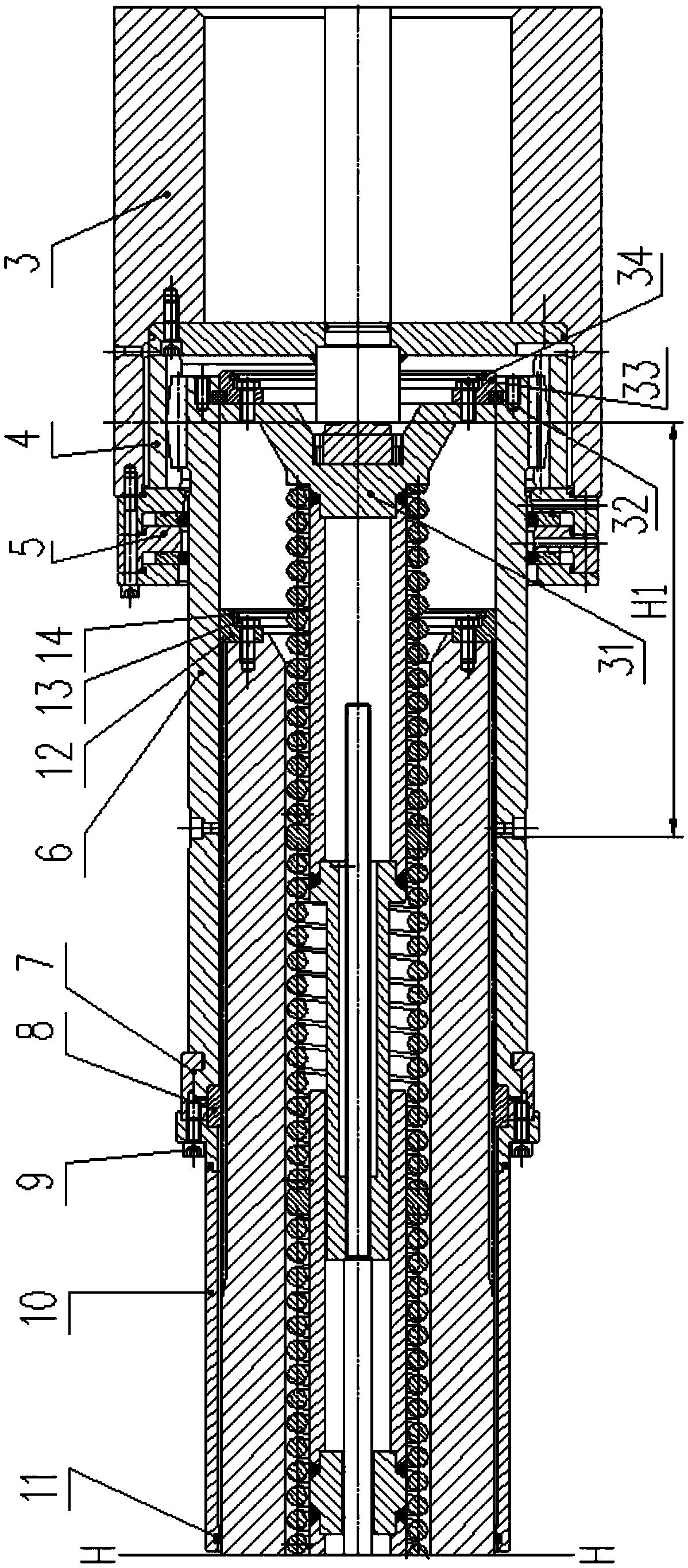

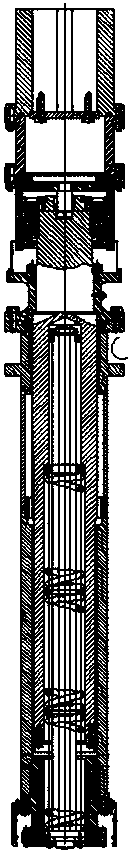

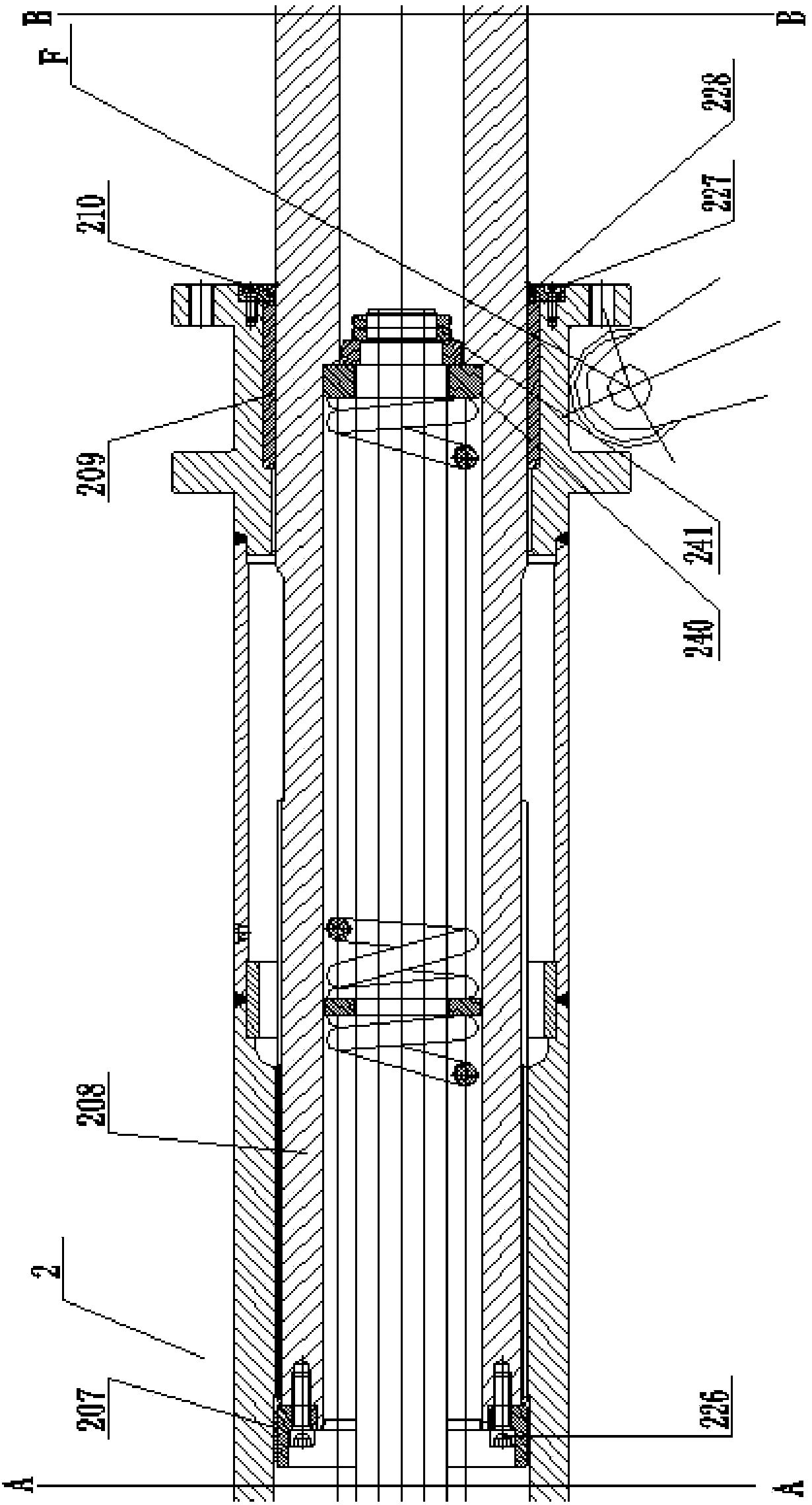

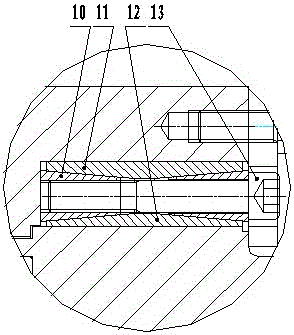

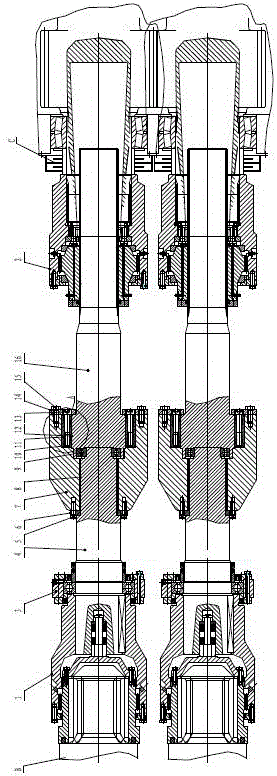

A kind of pqf continuous rolling mill connecting shaft and its roll changing method

ActiveCN105583234BReset balanceReset stableMetal rolling stand detailsRolling mill drivesRing deviceGear wheel

The invention discloses a method for connecting shafts and changing rolls of a PQF continuous rolling mill. The PQF continuous rolling mill connecting shaft of the present invention includes a roll end assembly and a tooth end assembly, and it also includes a shaft assembly. The left end of the shaft assembly is connected with the roll end assembly through a gear pair, and its right end is connected with the tooth end assembly through a fastener; The end assembly includes the inner ring gear at the roller end, the large connecting plate, the tensioning ring device, and the large mandrel; the shaft assembly includes the left top block, split gland, large external gear sleeve, spline sleeve, spline shaft, spacer sleeve, Locate the snap ring device, spring assembly, shaft end assembly, and right top block. The invention relates to a connecting shaft of a PQF continuous rolling mill, which can realize large-displacement expansion and contraction, and can realize rapid reset, thereby ensuring high production efficiency. At the same time, it can meet the requirements of on-site production of high-precision and high-quality seamless steel pipes.

Owner:TAIER HEAVY IND

A kind of red mud silicon calcium potassium fertilizer and preparation method thereof

ActiveCN109134154BLow costLow fine grinding abilityCalcareous fertilisersPotassium fertilisersSoil sciencePotassium hydroxide

The invention discloses a red mud silicon calcium potassium fertilizer and a preparation method thereof. The preparation method of the red mud silicon calcium potassium fertilizer comprises the following steps: 1) weighing 20% to 50% of red mud, 30% to 60% of fly ash and 5% to 30% of desulfurization residue , and mix uniformly to obtain a mixture; 2) Weigh potassium hydroxide equivalent to 2% to 30% of the mixture mass, make a solution with water as a solvent, add it to the obtained mixture, mix uniformly, and granulate the obtained material , to obtain the granular material; 3) the gained granular material is placed in the dry powder and the granular material is fully contacted with the dry powder, so that the surface of the granular material is wrapped with a layer of dry powder to obtain the granular material after the powder makeup; 4) the granular material after the gained powder makeup is placed in Calcined under the condition of ≥450℃, after the calcination is completed, cool to obtain. The method of the invention is simple and easy to control, has low cost, and the prepared red mud silicon calcium potassium fertilizer has low content of free sodium and high content of soluble silicon.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

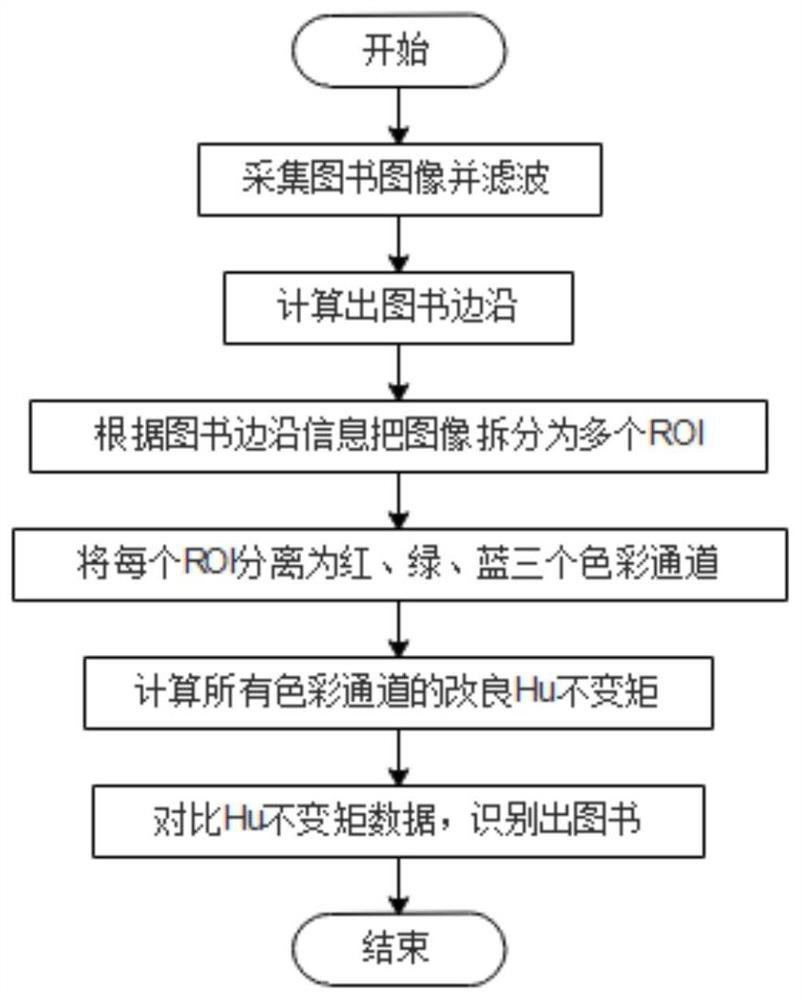

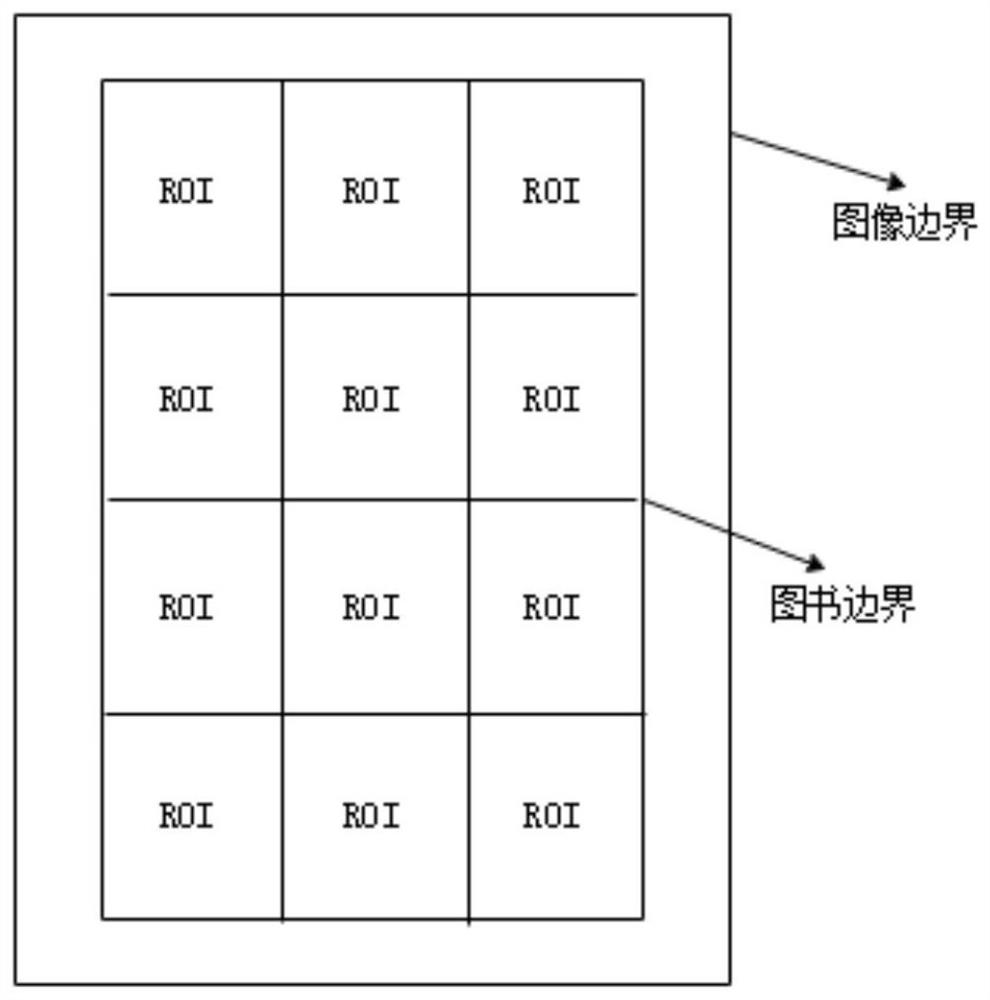

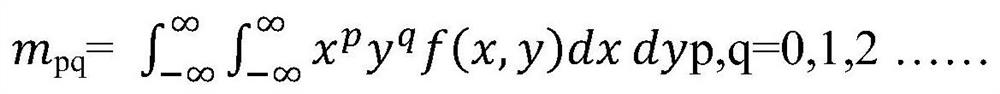

A Book Recognition Method Based on Improved Hu Invariant Moment Algorithm

InactiveCN109934225BReduce the amount of operationAvoid designCharacter and pattern recognitionPattern recognitionColor image

The invention proposes a book recognition method based on the Hu invariant moment improved algorithm. The method includes the following steps: (1) collect the color image of the book and filter it; (2) use the minimum enclosing rectangle algorithm to determine the edge of the book according to the filtered image; (3) process the book image inside the edge of the book into a fixed pixel size, and disassemble it. Divided into multiple ROIs; (4) Separate the channels of each ROI in turn, and separate them into three color channels of red, green, and blue; (5) Use the improved Hu invariant moment algorithm to calculate the The improved invariant moment of the color channel; (6) analyzing and comparing all the improved Hu invariant moment data of each book image for book recognition. Using this method greatly reduces the amount of human operations, and avoids the barcode design and pasting of books in the early stage, effectively saving manpower and material costs, accurate recognition, strong portability, and significantly improved standards. The moment algorithm has the disadvantage of poor robustness when the external light source is color cast or the brightness changes significantly.

Owner:DALIAN UNIV OF TECH

Method for recycling tricalcium phosphate from expandable polystyrene industrial wastewater

ActiveCN102849705BReduce processingReduce dosageMultistage water/sewage treatmentWater/sewage treatment by neutralisationPolystyreneWastewater

The present invention relates to the technical field of recovery and utilization of tricalcium phosphate, in particular to a method for reclaiming tricalcium phosphate from waste water produced by expandable polystyrene. The recovery rate of tricalcium phosphate reaches 85% after physical and biochemical treatment of wastewater, which greatly reduces the amount of tricalcium phosphate required for the production of expandable polystyrene, reduces production costs, and makes waste water inorganic The rapid reduction of phosphorus content is beneficial to environmental protection and achieves double benefits of environment and economy.

Owner:见龙国际贸易有限公司

A coupling maintenance tool

InactiveCN103878581BShorten the timeCreate benefitsYielding couplingMetal working apparatusEngineeringCoupling

Owner:JIGANG GRP

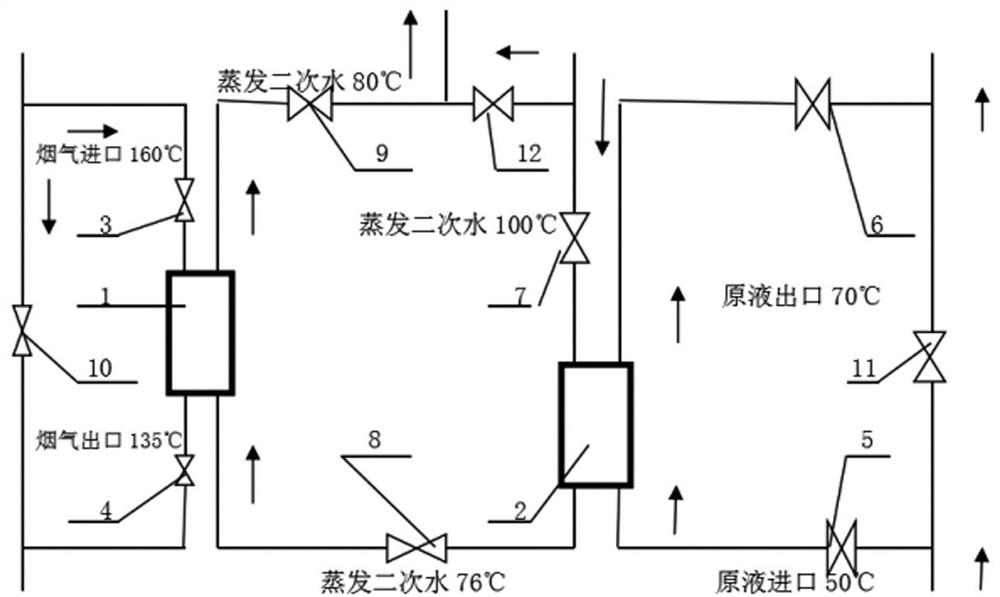

Flue gas waste heat recovery system of Bayer process aluminum oxide production roasting furnace

PendingCN112113439ACreate economic benefits and environmental effectsRun smoothlyIncreasing energy efficiencyStationary plate conduit assembliesChemistryProcess engineering

The invention relates to the field of aluminum oxide roasting, in particular to a flue gas waste heat recovery system of a Bayer process aluminum oxide production roasting furnace. The flue gas wasteheat recovery system is provided with a flue gas heat exchanger and an evaporation stock solution heat exchanger, evaporated secondary water sequentially enters the evaporation stock solution heat exchanger and the flue gas heat exchanger to separately exchange heat with evaporation stock solution and flue gas, recovery of flue gas waste heat in a Bayer process aluminum oxide production system isrealized, and economic benefits and environmental protection effects are created; and operation is stable, the equipment failure rate is low, the operation rate is high, and frequent cleaning is not needed.

Owner:山西复晟铝业有限公司

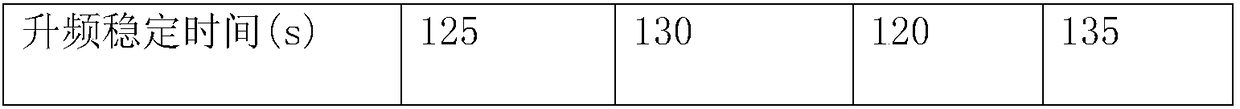

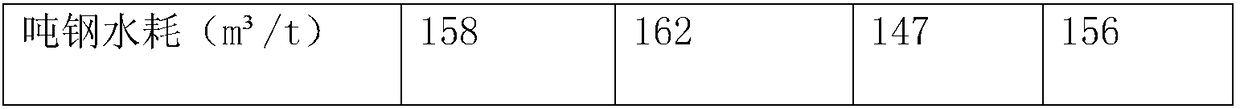

Frequency rising method for magnetic valve of quenching machine

InactiveCN108060294AUpscaling speed is slowIncrease clock speedHeat treatment process controlQuenching devicesStable stateMagnetic valve

The invention relates to a frequency rising method for a magnetic valve of a quenching machine. According to the method, the interface of the quenching machine is clicked for frequency rising in the tapping process of a next steel plate, the electromagnetic valve is quickly opened to the opening degree under the stable state of a previous steel plate, and then fine adjustment is carried out. The method is mainly applied to the roller type quenching machine with low frequency rising speed, the frequency rising speed can be increased, the problems that the tapping rhythm is limited and the energy consumption is wasted due to the fact that the water yield stabilizing time is long can be solved, and the method is fast, effective and simple. The method has the advantages that the stabilizing time for frequency rising of the quenching machine can be greatly shortened, meanwhile, the tapping rhythm can be accelerated, the benefits can be created, the energy consumption utilization rate can beincreased, and no cost is needed.

Owner:NANJING IRON & STEEL CO LTD

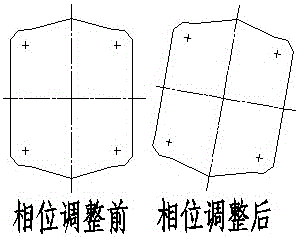

A New Type of Adjustable Phase Coupling

ActiveCN104728283BReduce phase downtimeMeet the requirements of job characteristicsYielding couplingPhase couplingTransmission equipment

The invention discloses a new type adjustable phase coupling, which includes a roller end assembly, a tooth end assembly, a support frame assembly, a first spline shaft, a second spline shaft, an adjustable phase assembly; the adjustable phase assembly Including snap ring, connecting sleeve, pressure plate, and transmission parts; the first spline shaft is connected with the inner spline of the connecting sleeve through the outer spline at the right end to form a spline pair; the snap ring is sleeved on the first spline shaft, and its left and right The end faces are respectively in contact with the step surface of the first spline shaft and the left end face of the connecting sleeve, and are connected with the connecting sleeve through connecting screws; a transmission part is arranged between the inner hole at the right end of the connecting sleeve and the journal at the left end of the second spline shaft , the pressure plate is set outside the second spline shaft, and is pressed tightly on the right end surface of the connecting sleeve through screws, and at the same time, the transmission parts are pressed. The invention makes the phase adjustment of the transmission equipment convenient and fast, can effectively shorten the downtime for adjusting the phase of the shaft coupling, reduces labor intensity, and meets the requirements of the working characteristics of the continuous rolling mill.

Owner:TAIER HEAVY IND

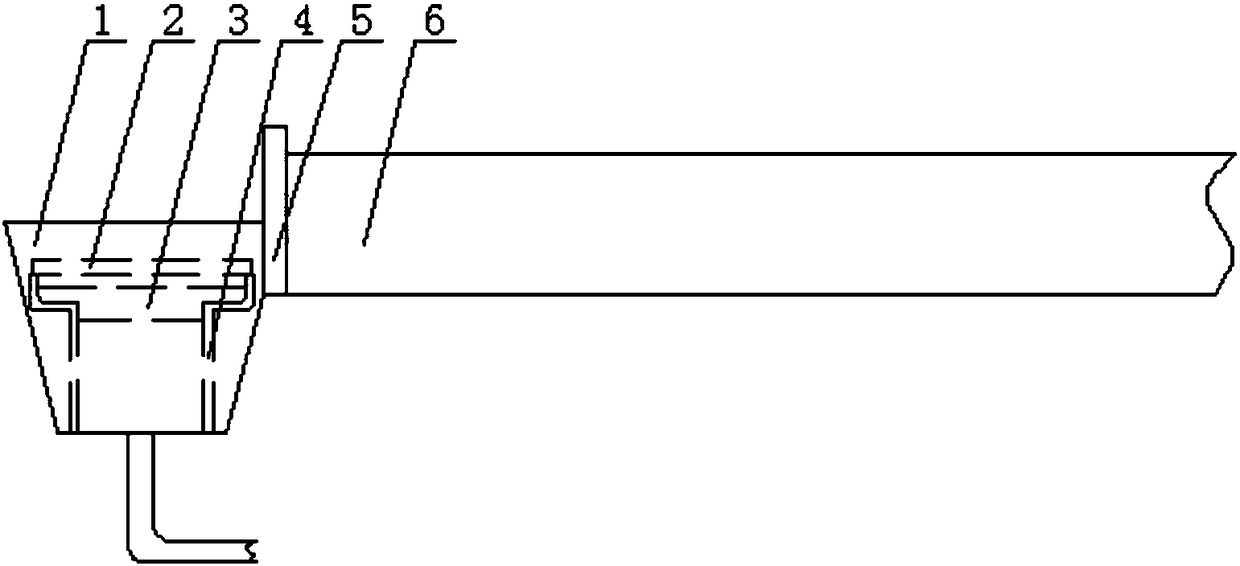

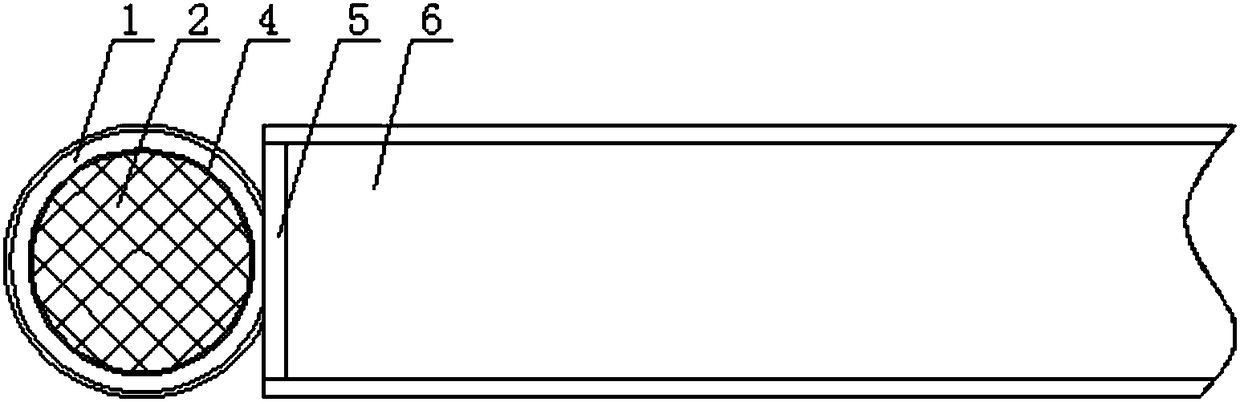

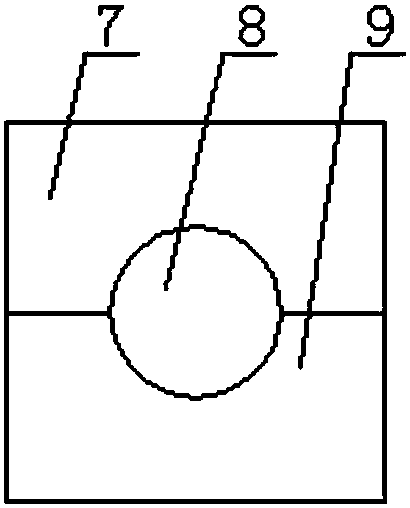

Splash-proof sink for 50-bundle tube production equipment line

The invention relates to an anti-splashing water tank for 50 beam tube production equipment. The anti-splashing water tank comprises a funnel, a baffle and a tank body. The rear end of the funnel is connected with the tank body. The vertical baffle is arranged at the joint of the tank body and the funnel. A through hole allowing a beam tube to penetrate is formed in the center of the baffle. An anti-splashing device is mounted in the funnel and comprises a support, a stainless steel net and a soft sponge mat. The support is mounted in the funnel. The stainless steel net is mounted on the upper portion of the support. The soft sponge mat is mounted on the lower portion of the support. The soft sponge mat is located below the stainless steel net, and a clearance exists between the soft sponge mat and the stainless steel net. The anti-splashing water tank is low in improvement cost, and operation is simple and easy to understand; the situation that spray splashes to fly onto the surface of the beam tube to form bumps can be effectively avoided, and accidents of the bumps of the beam tube are reduced to the maximum extent; and product quality and production efficiency are greatly improved.

Owner:天津立孚光电科技股份有限公司

Method for shortening interval rolling time of steel plates and steel coils

PendingCN111633035AShorter rolling intervalsIncrease productivityRoll mill control devicesMetal rolling arrangementsHeating furnaceMaterials science

The invention discloses a method for shortening the interval rolling time of steel plates and steel coils and relates to the technical field of steel and iron smelting. The method comprises the stepsof S1, dividing production modes into a steel plate mode and a steel coil mode according to finished products; S2, dividing the area from a heating furnace steel tapping rejection roller bed to an underground coiling machine into two logic control areas, namely, the rolling mill area and the underground coiling machine area; S3, determining the working mode of the area where steel is located currently according to information of the steel and the actual position of the steel; and S4, controlling related equipment to operate in the steel plate production mode or in the steel coil production mode through the underground coiling machine according to the working mode of the underground coiling machine area. Through the method provided by the invention, the interval rolling time of two kinds ofplates is greatly shortened, the production efficiency is improved, and extra benefits are created.

Owner:NANJING IRON & STEEL CO LTD

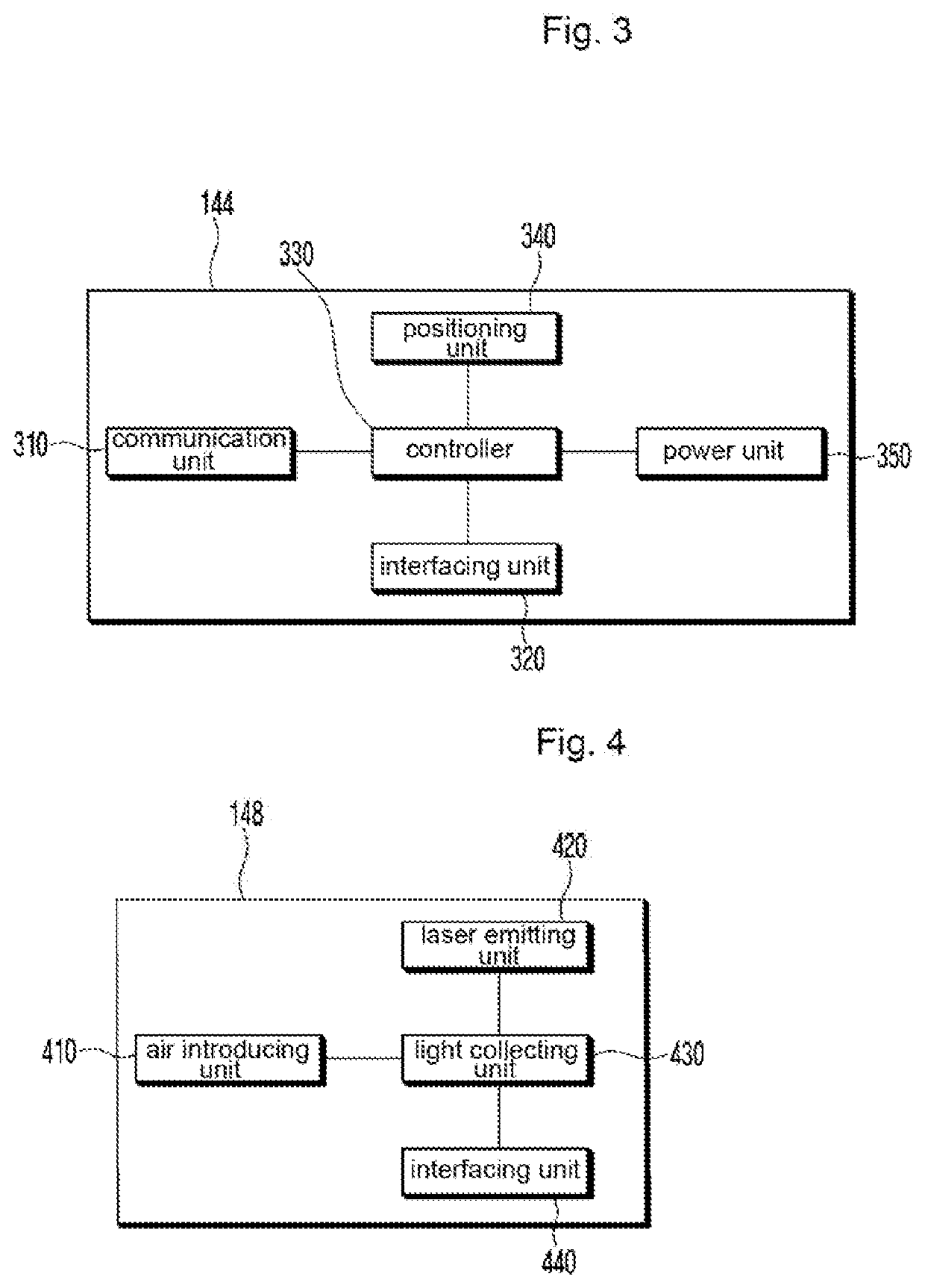

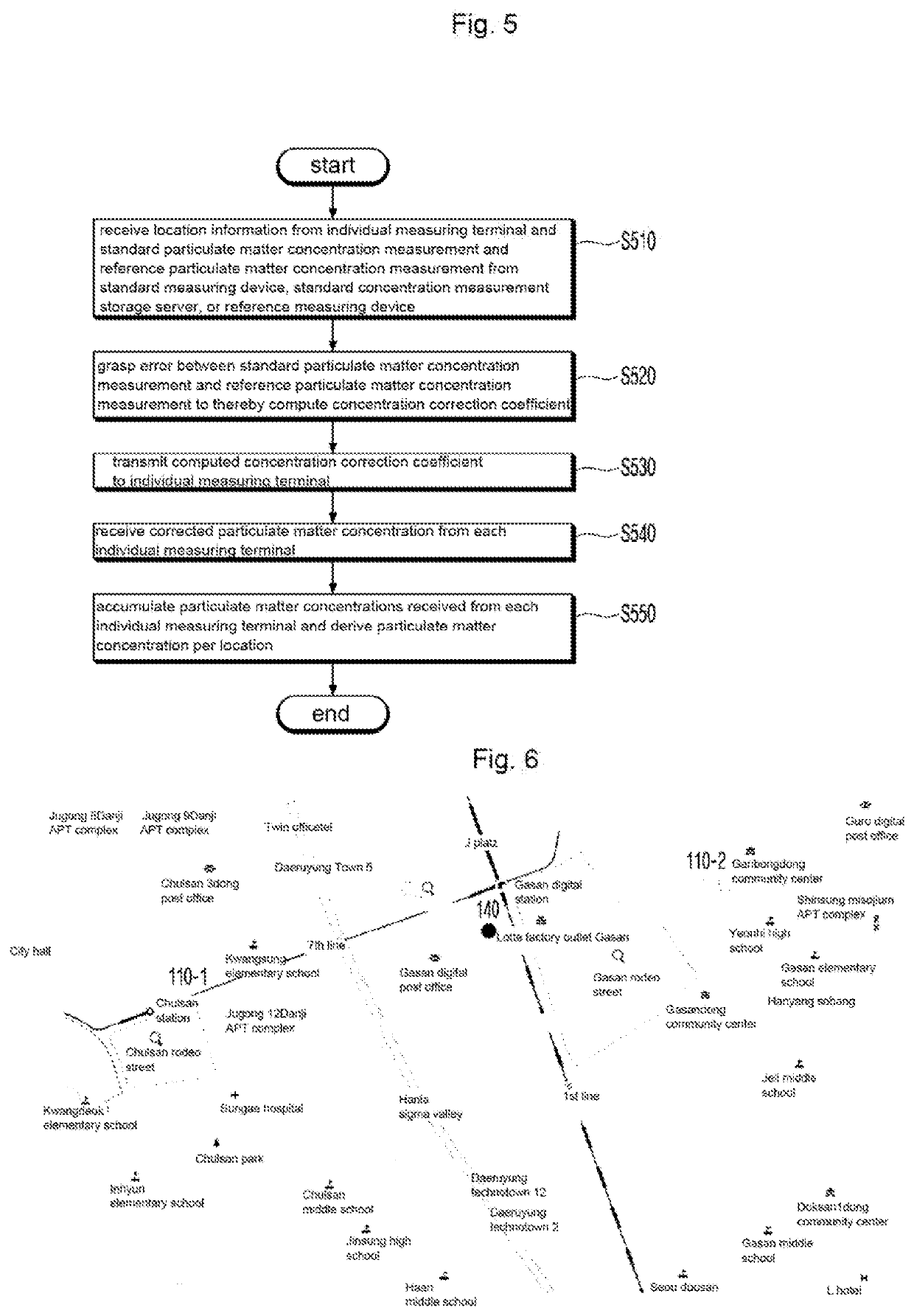

Particulate matter concentration calculating device and method

InactiveUS20200333239A1Accurate particulate matter concentrationAccurate predictionData processing applicationsOptically investigating flaws/contaminationPhysical chemistryLight scattering

A particulate matter concentration calculating device and method is disclosed. An objective of an embodiment of the present invention is to provide a particulate matter concentration calculating device and method which, in order to allow individual measurement terminals employing a light scattering method to accurately measure particulate matter concentration, calculates a constant or constants required for correction of a concentration value measured by each of the measurement terminals, by using a standard particulate matter measurement device and a reference particulate matter measurement device.

Owner:XL PHOTONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com