A kind of pqf continuous rolling mill connecting shaft and its roll changing method

A technology for continuous rolling mills and rolls, applied to metal rolling stands, metal rolling mill stands, and driving devices for metal rolling mills, can solve problems such as low efficiency, slow speed, shaking, etc. Improved product quality and reduced downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

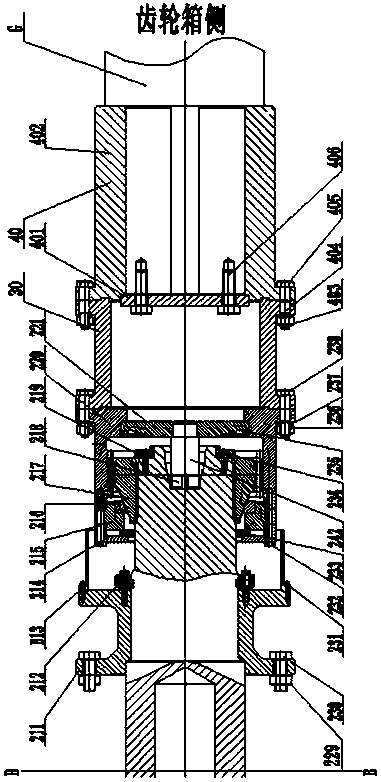

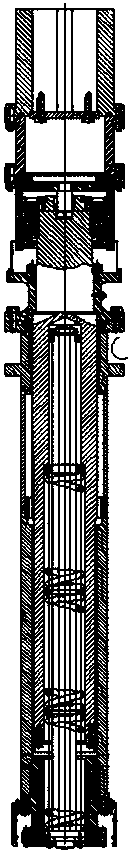

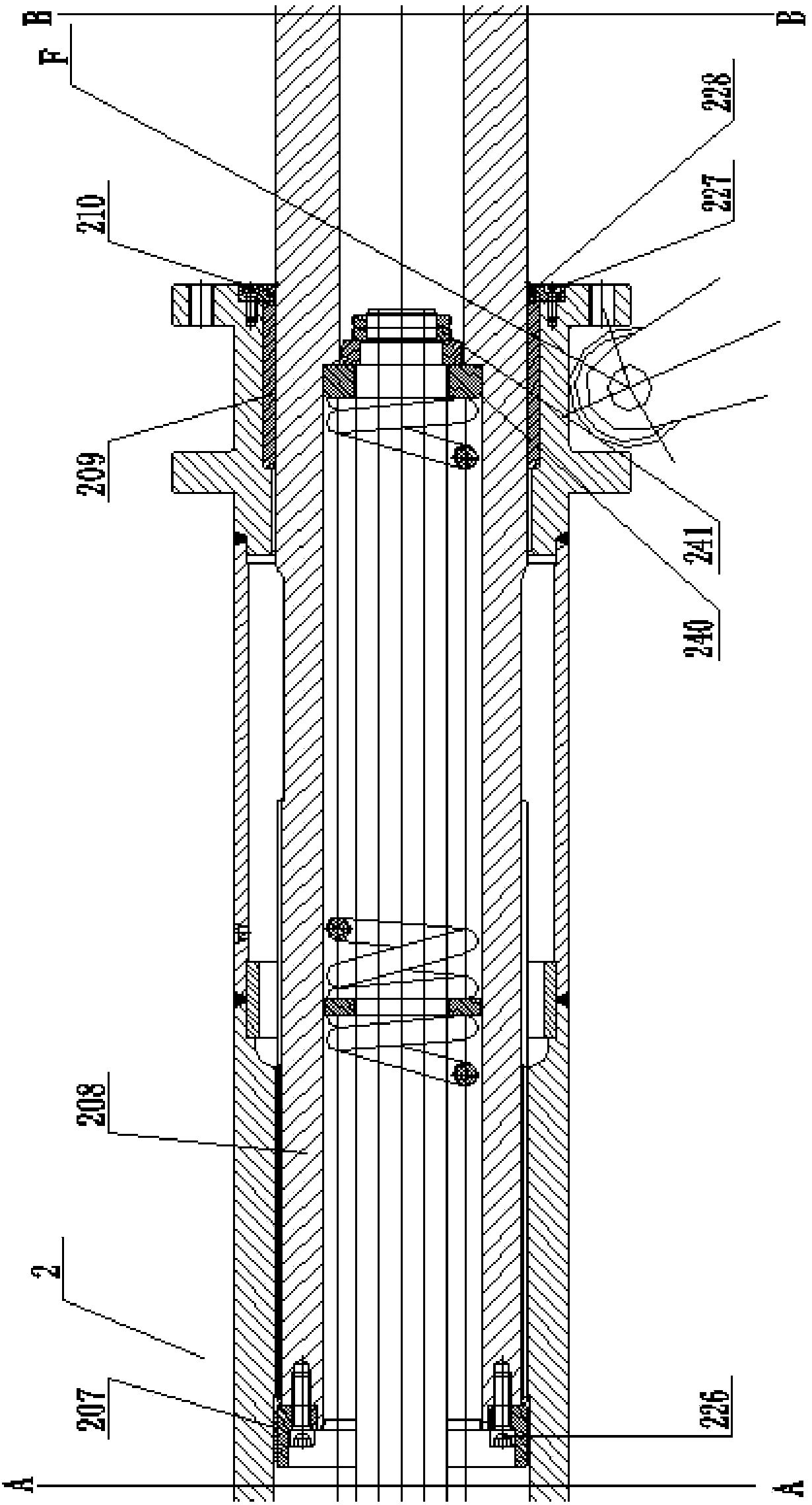

[0016] As can be seen from the drawings, the present invention is a PQF continuous rolling shaft, which includes a roll end assembly 10, a tooth end assembly 40, and a shaft assembly 20; the left end of the shaft assembly is connected with the roll end assembly 10 through a gear pair, and its right end is The firmware is connected to the tooth end assembly 40 . The specific structure is as follows:

[0017] (1) The roll end assembly 10 includes a roll end internal gear ring, a large connecting disc 103, a tensioning ring device 104, and a large mandrel 105; the roll end internal gear ring is sleeved on the roll E, and the large connecting disc 103 is fixed on the Inside the inner ring gear at the roll end, and fastened to the right end surface of the roll E by connecting bolts 107, a large mandrel 105 is arranged on the large connecting plate 103;

[0018] (2) The shaft assembly 20 includes a left top block 201, a split gland 203, a large external gear sleeve 204, a spline sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com