A coupling maintenance tool

A technology for maintenance tools and couplings, applied in the direction of couplings, elastic couplings, manufacturing tools, etc., can solve problems such as multiple time delays, impact of steel output, and increased production costs, and achieve time saving and simple structure , to create the effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

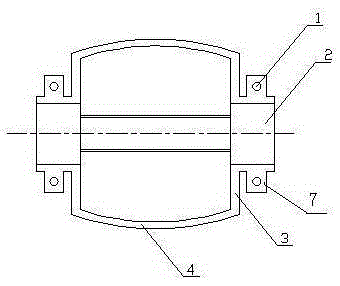

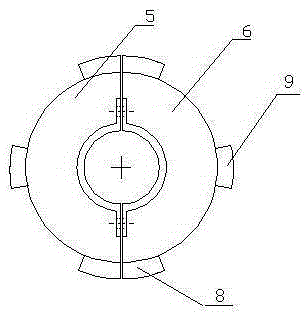

[0016] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0017] It can be seen from the accompanying drawings that the coupling maintenance tool of the present invention is characterized in that it includes part I5 and part II6. Part I5 and part II6 have the same structure and are arranged oppositely. A circular shaft sleeve 2, two ends of the shaft sleeve 2 are provided with connecting protrusions 7, and the connecting protrusions 7 are provided with threaded holes 1, and the parts I5 and II6 are fixedly connected through the threaded holes 1 and bolts. Part I and Part II have the same structure and are connected by bolts. When in use, the device can be installed directly outside the damaged tire coupling very quickly to maintain the normal operation of the coupling, saving time and creating benefits.

[0018] The coupling maintenance too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com