Low-grade Anshan magnetite beneficiation process

An Anshan-type, magnetite technology, applied in the field of low-grade Anshan-type magnetite beneficiation process, can solve the problems of long investment recovery period, destroying the balance of tailings treatment, and building river sand tailings, etc., to achieve economical Remarkable benefits, full utilization of resources and environmental protection, the effect of improving comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

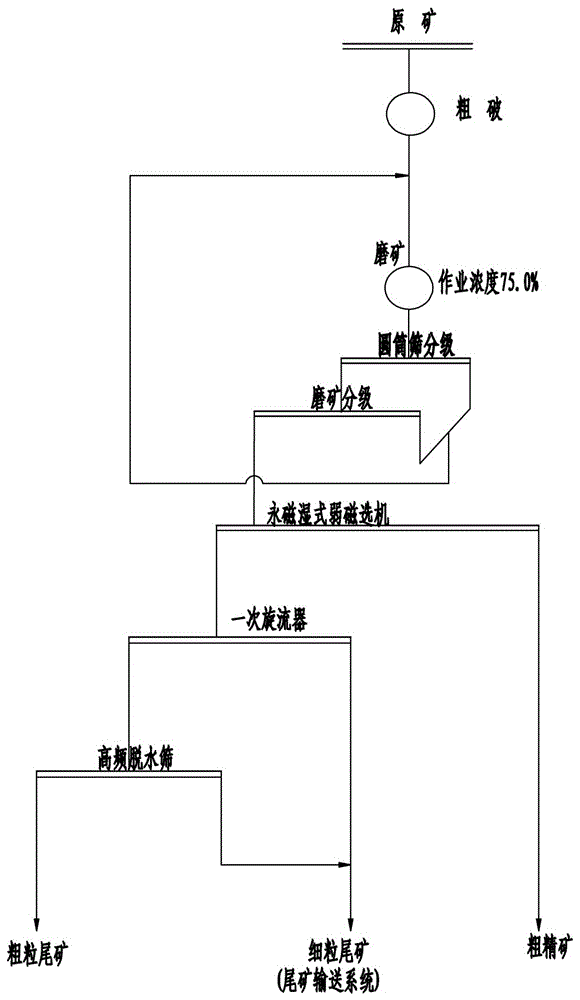

[0026] Such as figure 1 Shown, a kind of low-grade Anshan type magnetite mineral processing technology of the present invention is characterized in that comprising the following steps:

[0027] a. Feed the ore with a grade of 18.34% into the coarse crusher, and feed the ore with a particle size of 300mm-0 into the wet semi-autogenous mill; the wet semi-autogenous mill is selected from Φ9.15×5.03m mill;

[0028] b. The discharge of the wet semi-autogenous mill is fed into the cylindrical sieve for grading operations, and the products with a particle size of the cylindrical sieve below 8mm are automatically fed into the linear vibrating screen for grading operations, and the products on the cylindrical sieve and linear vibrating screen are combined Return to the wet semi-autogenous mill; the linear vibrating screen uses a ZKR3070 linear vibrating screen for linear vibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com