Method for processing range gear air cylinder of automobile parts

A technology of auto parts and processing methods, applied in the field of auto parts, can solve the problems of enterprise loss, low work efficiency, poor product quality, etc., and achieve the effect of meeting the needs of life, improving product quality, and ensuring positional tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

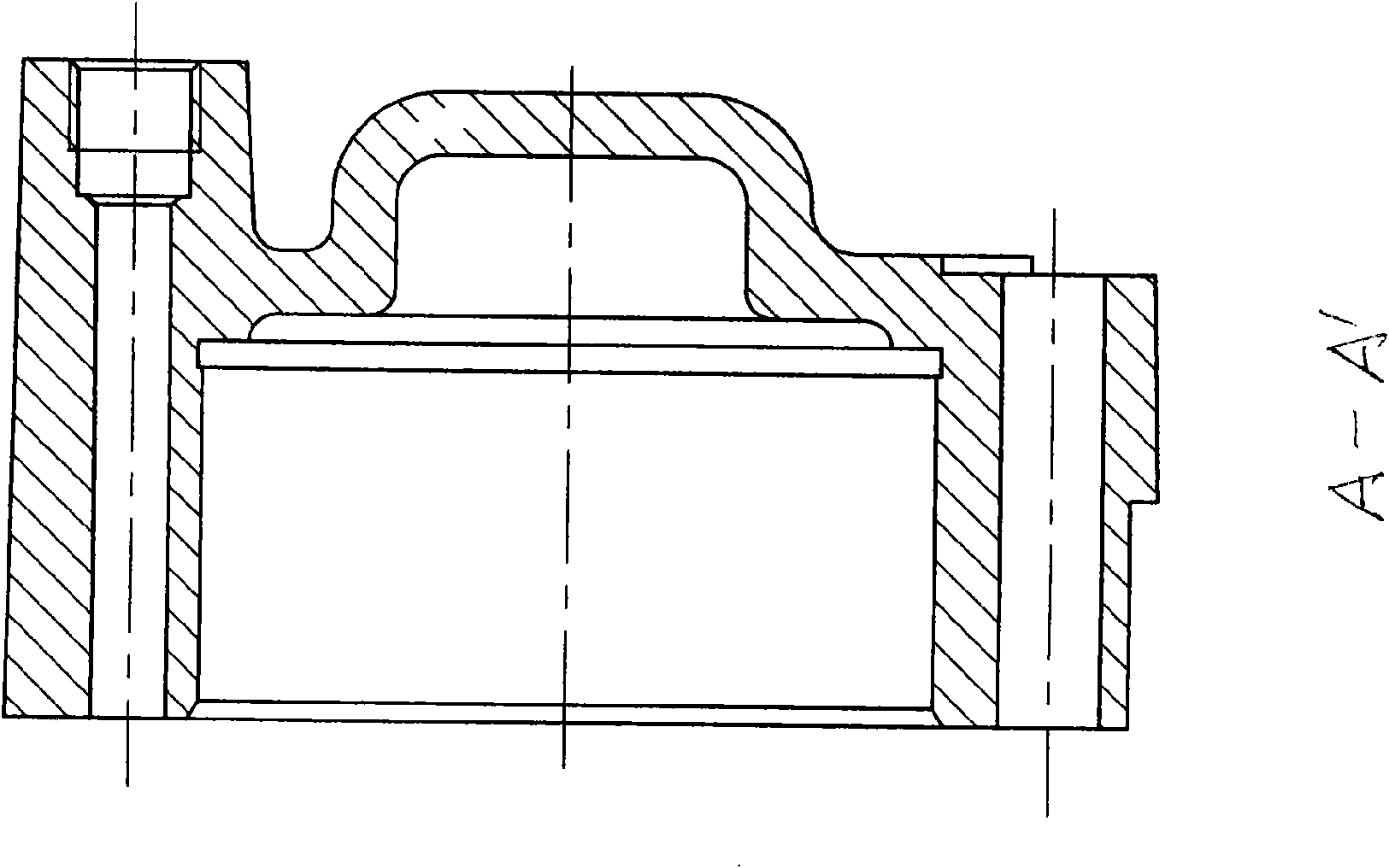

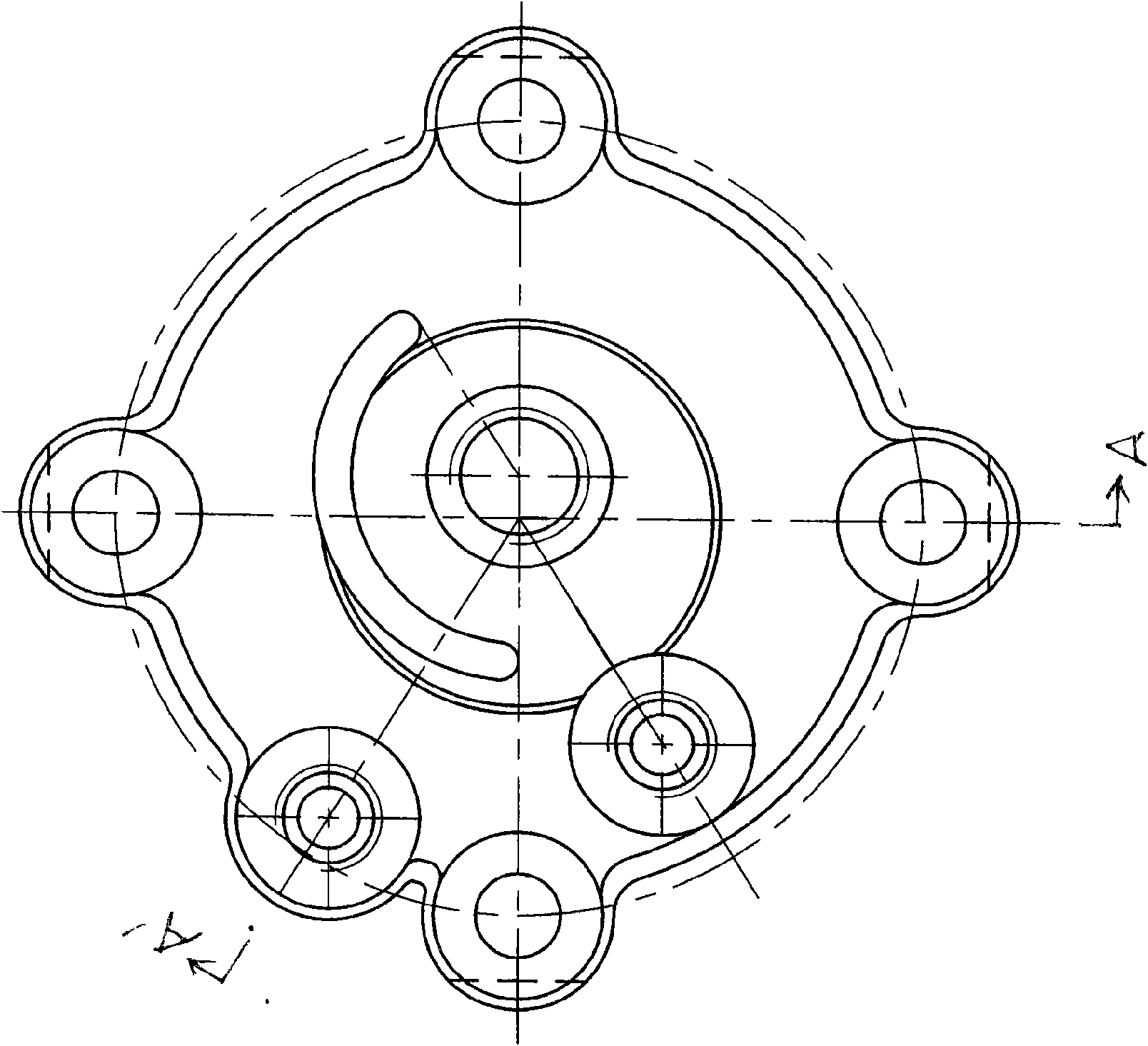

[0007] Below in conjunction with accompanying drawing, the present invention will be further described;

[0008] In the figure, the processing method of the range gear cylinder of auto parts is characterized in that: turning: clamping the right end, positioning with the outer circle of the blank, turning the end surface and outer circle of the left end, the length to the size shown in the figure, boring the large and small inner holes and the depth to For the size shown in the picture, cut the inner groove on the size shown in the picture; Drilling: upper drilling mold, position with the inner hole at the left end, and drill through holes evenly on the center line of the picture 4- 11. Ensure the position 0.5; Drill 2- on the centerline and angle of the diagram 8 through holes, through holes drilled on the center eccentric line 16.5; milling: upper milling clamp, milling according to the requirements of the drawing; spot facing; pressing the workpiece, 4- 11 through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com