A conductive copper paste and its preparation method

A technology of copper paste and silver-coated copper powder, which is applied in the direction of cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. Long and other problems, to achieve the effect of good product quality, high production efficiency, and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

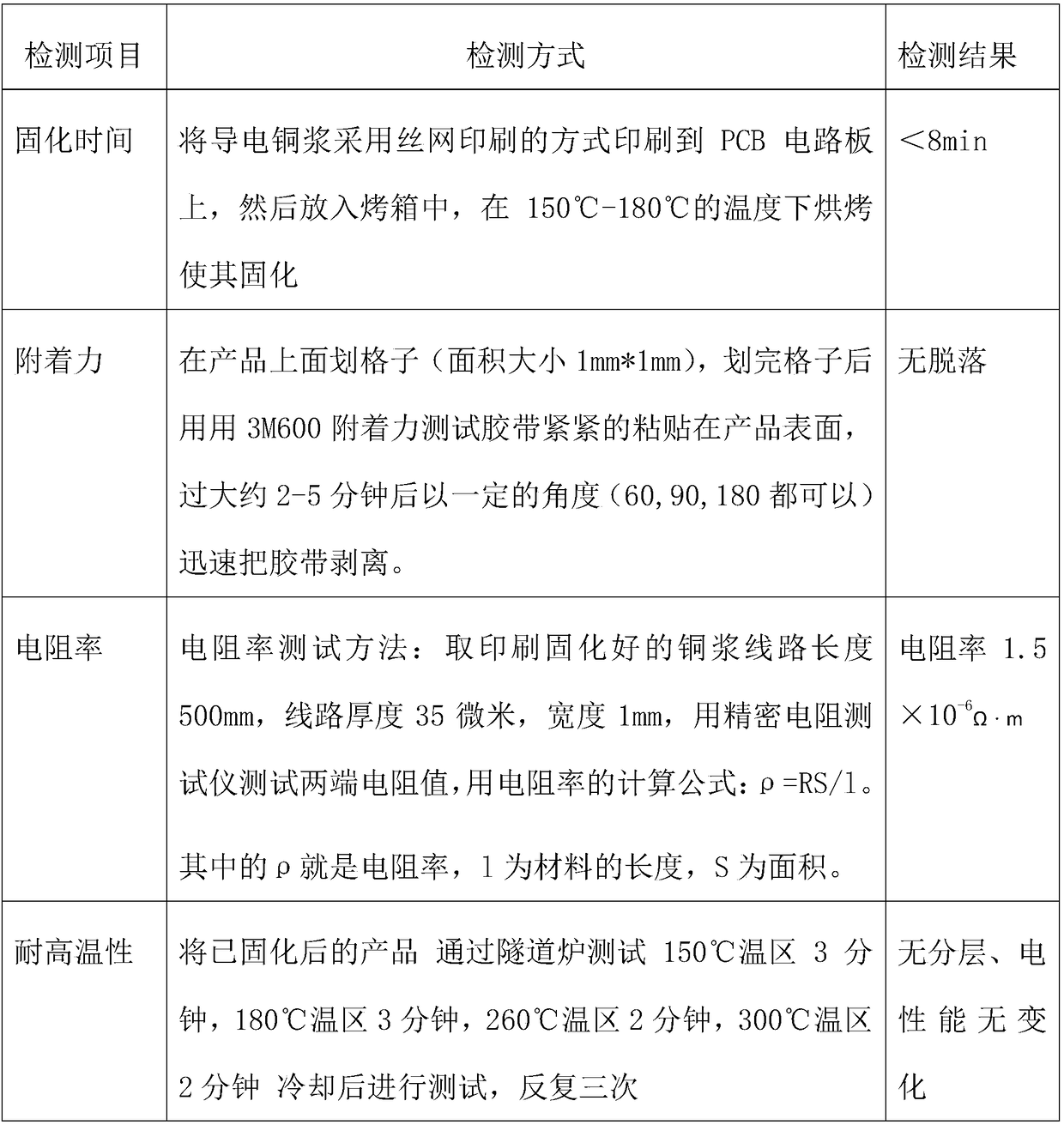

Examples

Embodiment 1

[0043] Embodiment 1 of the present invention provides a conductive copper paste, which is mainly made of the following components in proportion by weight: 14 parts of trimethylolpropane triacrylate, 26 parts of N-vinylpyrrolidone, and 10 parts of butyl acetate , 5 parts of secondary alcohol, 10 parts of dimethylformamide, 10 parts of divalent acid ester, 2 parts of azobisisobutylcyanide, 50 parts of epoxy acrylic resin, 3 parts of fatty alcohol polyoxyethylene ether, 3 parts of imidazole and 250 parts of silver-clad copper powder.

[0044] The preparation method of the conductive copper paste of the present embodiment is as follows:

[0045] Under normal temperature and normal pressure, first mix trimethylolpropane triacrylate and N-vinylpyrrolidone in the weight parts of the above ratio and stir together for about two minutes, so that they are fully mixed and uniform to obtain mixture A; Add butyl acetate to mixture A and stir for about two minutes to ensure that butyl aceta...

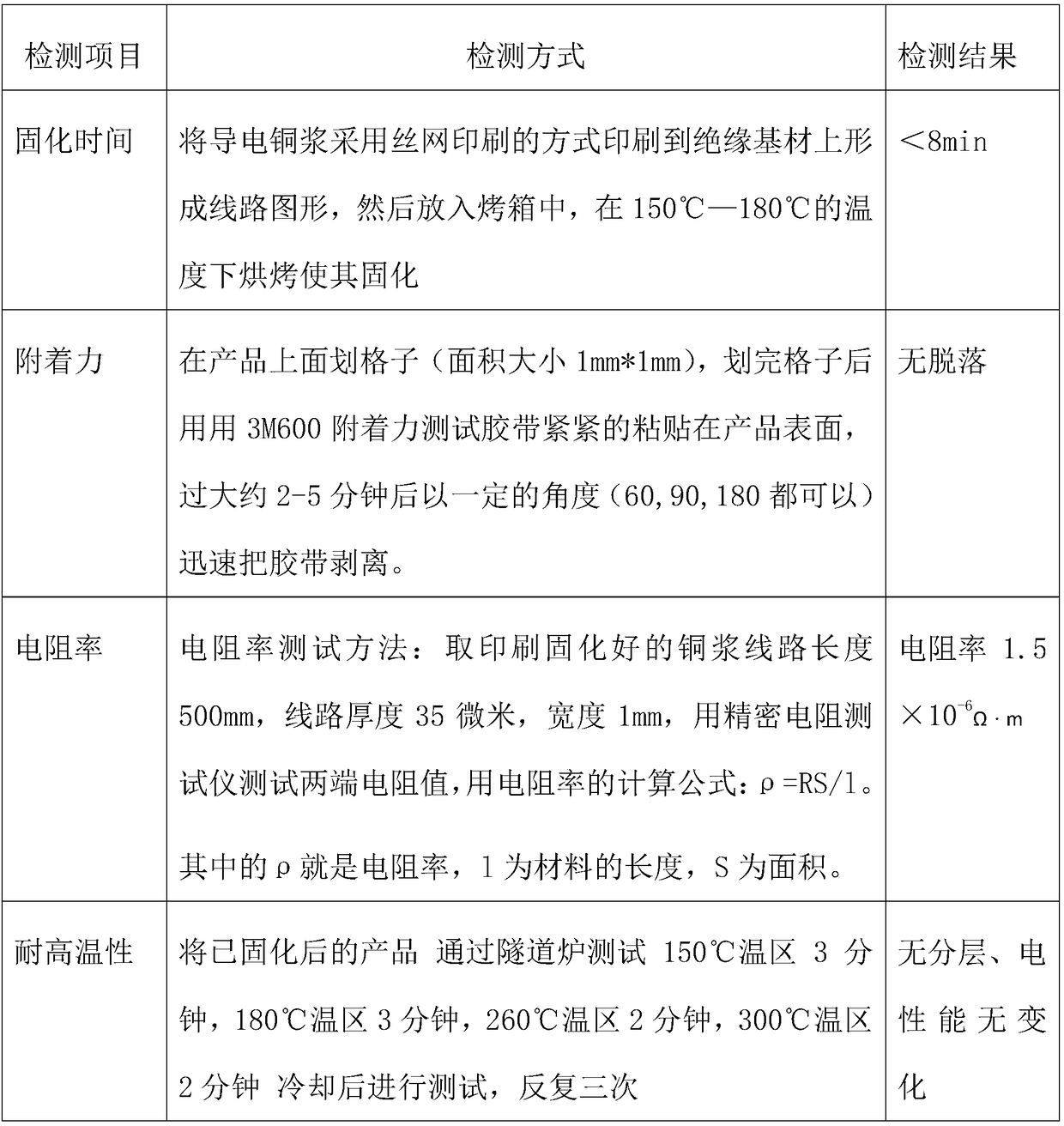

Embodiment 2

[0051] Embodiment 2 of the present invention provides a conductive copper paste, which is mainly made of the following components in proportion by weight: 12 parts of trimethylolpropane triacrylate, 25 parts of N-vinylpyrrolidone, and 8 parts of butyl acetate , 3 parts of secondary alcohol, 8 parts of dimethylformamide, 8 parts of divalent acid ester, 1 part of azobisisobutylcyanide, 45 parts of epoxy acrylic resin, 2 parts of fatty alcohol polyoxyethylene ether, 2 parts of imidazole and 260 parts of silver-clad copper powder.

[0052] The preparation method of the conductive copper paste of the present embodiment is as follows:

[0053]Under normal temperature and normal pressure, first mix trimethylolpropane triacrylate and N-vinylpyrrolidone in the weight parts of the above ratio and stir together for about two minutes, so that they are fully mixed and uniform to obtain mixture A; Add butyl acetate to mixture A and stir for about two minutes to ensure that butyl acetate an...

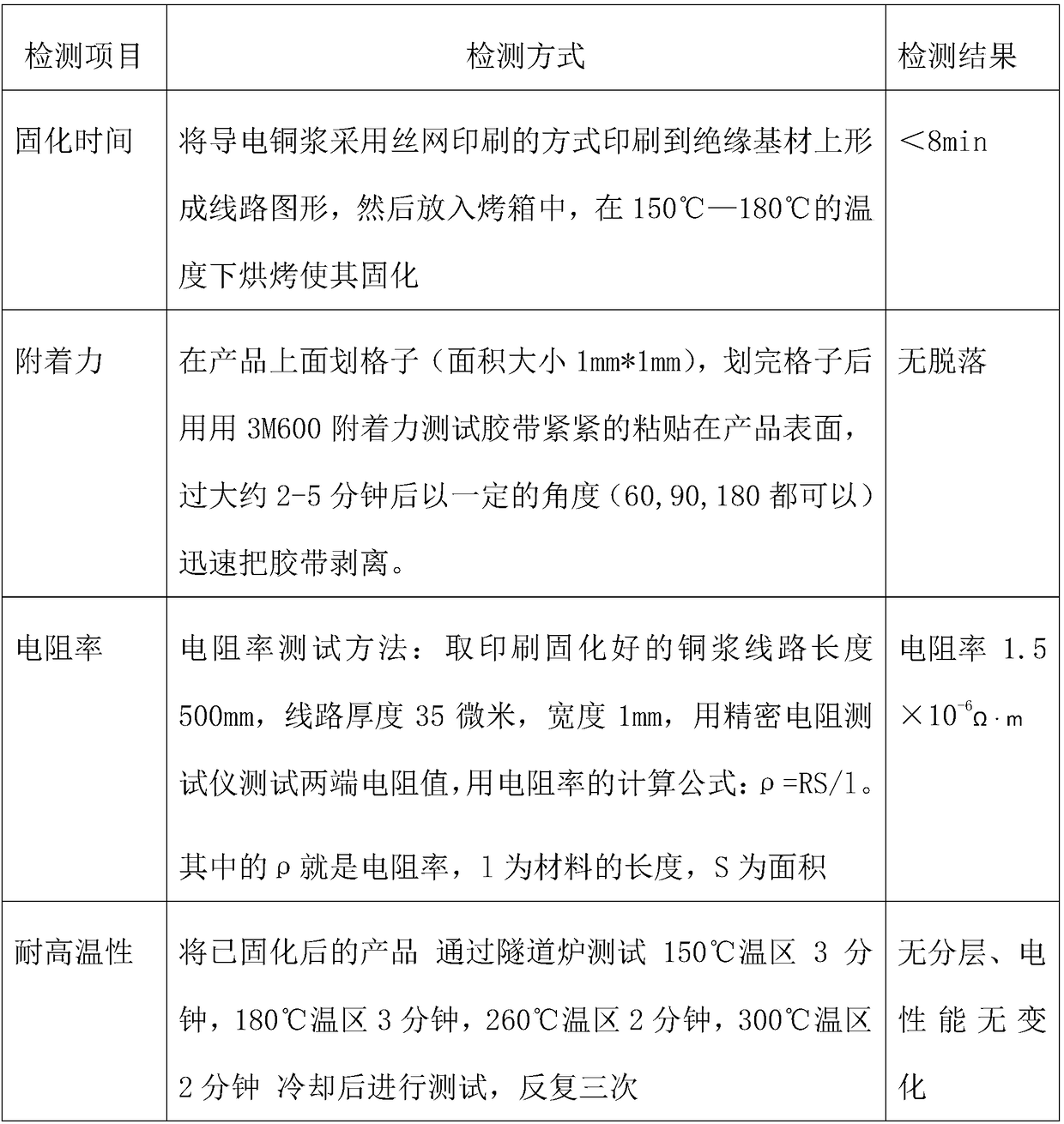

Embodiment 3

[0060] Embodiment 3 of the present invention provides a conductive copper paste, which is mainly made of the following components in proportion by weight: 16 parts of trimethylolpropane triacrylate, 28 parts of N-vinylpyrrolidone, and 12 parts of butyl acetate , 6 parts of secondary alcohol, 12 parts of dimethylformamide, 12 parts of divalent acid ester, 3 parts of azobisisobutylcyanide, 55 parts of epoxy acrylic resin, 5 parts of fatty alcohol polyoxyethylene ether, 5 parts of imidazole and 240 parts of silver-clad copper powder.

[0061] The preparation method of the conductive copper paste of the present embodiment is as follows:

[0062] Under normal temperature and normal pressure, first mix trimethylolpropane triacrylate and N-vinylpyrrolidone in the weight parts of the above ratio and stir together for about two minutes, so that they are fully mixed and uniform to obtain mixture A; Add butyl acetate to mixture A and stir for about two minutes to ensure that butyl aceta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com